Benchmark 1282-004 User manual

WEAR CSA APPROVED

EYE PROTECTION

WEAR EAR

PROTECTION

WEAR A

FACE MASK

2IN1 AIR FLOORNAILER

5 Year Limited Warranty

PRODUCT SPECIFICATIONS

2IN1 AIR FLOOR NAILER

Magazine capacity

L Cleats: 100pcs, Staples:90pcs

L-Cleats

16 gauge 1-1/2 inch to 2 inch

Staples

15.5 Gauge 1-1/2inch to 2 inch Long

Maximum pressure

115 psi

Working pressure

70 psi – 115 psi

Air consumption

4.6 CFM@90PSI

Air inlet

1/4-inch NPT

Minimum hose size

1/4 inch

Weight

9.6 lbs. 4.4kg

NEED ASSISTANCE?

Call

Note these instructions pertain to the tool only. Please refer to your compressors

operator manual and follow the manufacturers instructions.

us on our toll-free customer support line:

1-866-349-8665 (Monday through Friday 9am – 5pm Eastern Standard Time)

•

Technical questions

•

Replacement parts

•

Parts missing from package.

1

•Please note (where the ¼” NPT connecter is not already installed on the tool)

your tool may be shipped with a black plastic cap installed in the air inlet.

Pry the cap out prior to installing the ¼” NPT connector.

1282-004

2IN1 AIR FLOOR NAILER

TABLE OF CONTENTS

Product Specifications ........................................................................... 1

Table of Contents ................................................................................... 2

Safety Guidelines ................................................................................ 3-6

Symbols ................................................................................................7

Tool specific Warnings…………………………………………………………………………..8

Know your Floor nailer ............................................................................9

Assembly and Operating............................................................................10-15

Maintenance and troubleshooting ......................................................16-18

Exploded View ..................................................................................... 19

Parts List .........................................................................................20-21

Warranty............................................................................................. 22

2

SAFETY GUIDELINES

WARNING:

This manual contains information thatrelates to PROTECTING PERSONAL SAFETY and

PREVENTING EQUIPMENT PROBLEMS. It is very important to read this manual carefully

andunderstand it thoroughly before using the product. The symbols listed below are

used to indicate this information.

DANGER!

Potential hazard that will result in serious injury or loss of life.

WARNING!

Potential hazard that could result in serious injury or loss of

life.

CAUTION!

Potential hazard that may result in moderate injury or damage

to equipment.

Note

- The word " Note " is used to inform the reader of something he / she needs to

know about the tool.

PERSONAL SAFETY

These precautions are intended for the personal safety of the user and others working

with the user. Please take time to readand understand them.

3

1282-004

2IN1 AIR FLOOR NAILER

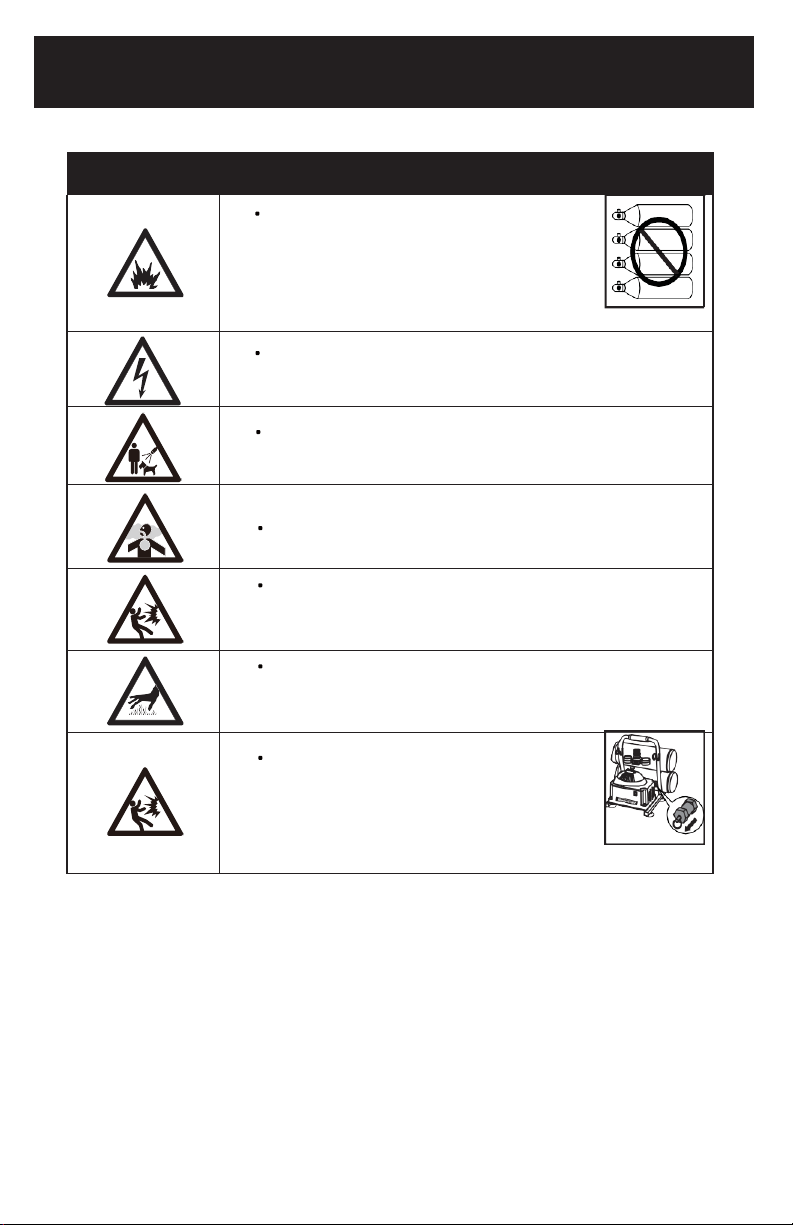

Oxygen

SYMBOL

MEANING

Do not use oxygen or any other combustible or bottled gas

to power air-powered tools. Failure to observe this warning

can cause explosion and serious personal injury or death.

Use only the compressed air to power the air-powered

Hydrogen

tools. Use a minimum of 25’ (7.6 m) of hose to connect

Explosive

the tool to the compressor. Failure to comply will result

in serious injury or loss of life.

Combustible

Risk of electric shock:

Do not expose a compressor to rain. Store it indoors.

Disconnect the compressor from power source before servicing. Compressor

must be grounded. Do not use grounding adaptors.

Risk of personal injury:

Do not direct compressed air from the air hose towards

the user or other personnel.

Risk of inhalation:

Never directly inhale the air produced by the compressor.

Risk of bursting

: Do not adjust the pressure switch or safety valve for any reason.

They have been preset at the factory for this compressor’s maximum pressure

Tampering with the pressure switch or the safety valve may cause personal injury

or property damage.

Risk of burns.

The pump and the manifold generate high temperatures. In order

to avoid burns or other injuries, do not touch the pump, the manifold, or the

transfer tube while the compressor is running. Allow the parts to cool down before

handling or servicing. Keep children away from the compressor at all times.

Risk of bursting

: Make sure the regulator is adjusted so that the

compressor outlet pressure is set lower than the maximum

operating pressure of the tool. Before starting the compressor,

pull the ring on the safety valve to make sure the valve moves

freely. Drain water from tank after each use. Do not weld or

repair tank. Relieve all pressure in the hose before removing

or attaching accessories.

4

DANGER!

Keep children away

from the work area. Do not allow children to handle power

tools.

Do not use this tool in the presence of flammable liquids or gases

.

Sparks that are created during use may ignite gases.

Keep air hose away

from heat, oil, and sharp edges. Check air hose for wear

before each use and ensure that all connections are proper.

Always ensure that the workpiece is firmly secured

leaving both hands free to

control the tool.

Always ensure that the tool has stopped before putting it down after use, for

safety purposes and to prevent possible damage to the tool/user.

Keep proper footing at all times in order to ensure correct balance.

Always assume that the tool contains fasteners.

Do not point the tool toward yourself or anyone else.

WARNING!

Do not allow unskilled or untrained individuals to operate

the air tool

.

Do not use the tool for any task other than that it is designed

to perform.

Locate the compressor in a well-ventilated area

for cooling, and a minimum of

12” (31 cm) away from the nearest wall.

Protect the air hose and the power cord from damage and puncture. Inspect them

for weak or worn spots every week

and replace them if necessary.

Always wear hearing protection

when using the air compressor. Failure to do so

mayresult in hearing loss.

Do not carry the compressor while it is running.

Do not operate the compressor if it is not in a stable position.

Do not operate the compressor on a rooftop or an elevated position

that could

allow the unit to fall or be tipped over.

Always replace a damaged gauge

before operating the unit again.

Do not connect the

tool to a compressed air source with a pressure output that is

higher than 115psi.

CAUTION!

Always ensure that the tool has stopped before disconnecting the air supply.

Do not wear watches, rings, bracelets, or loose clothing

when using any air-

powered tool.

Do not overload the tool

. Allow the tool to operate at its optimum speed for

maximum efficiency.

Do not use a tool that is leaking air, that has missing or damaged parts, or that

requires repairs.

Verify that all screws are securely tightened

.

For optimal safety and tool performance,

inspect the tool before every usage,

in order to ensure free movement of the trigger, safety mechanisms, and springs.

Always keepyour air tool clean and lubricated

. Daily lubrication is essential to

avoid internal corrosion and possible failures.

Ensure the floor is not slippery

and wear non-slip shoes. Floors should be kept

clean and clear.

Always follow all workshop safety rules, regulations, and conditions

when using

the tool and keep the work area clean.

Carry the tool by the handle only

, keeping fingers away from the trigger. Do not

carry the tool by the hose, magazine, or any other parts.

Do not use the tool near or below freezing point

, as doing so may cause tool failure.

Do not store the tool in a freezing environment

to prevent ice formation on the

tools operating valves, as doing so may cause tool failure.

Handling and storage of oil

: Use with adequate ventilation. Avoid contact of oil

with eyes, skin, and clothing. Avoid breathing spray or mist. Store in a tightly

closed container in a cool, dry, well-ventilated area free from Incompatible

substances.

Tripping hazard.

The air hose may become a tripping hazard

when it is placed in the work area. Use care when walking in the

work area.

5

1282-004

2IN1 AIR FLOOR NAILER

CAUTION!

Disconnect tool from the air supply and turn off the compressor

before performing any maintenance or changing accessories,

when clearing a jammed fastener, when the tool is not in use,

when it is being handed to another person, and when it is left

unattended. Failure to comply may result in moderate injury or

damage to equipment.

Use safety goggles and ear protection

: Wear safety glasses with

side shields when operating the tool/compressor and verify that

others in the work area are also wearing safety glasses. Safety

glasses must conform to American National Standards Institute

(ANSI Z87. 1) requirements and must provide protection from

flying particles from the front and the sides.

Air-powered tools are loud, and the sound can cause hearing

damage. Always wear ear protection to prevent hearing damage

and

loss. Failure to comply may result in moderate injury.

Note:

Recycle unwanted materials rather than disposing of them as waste. Sort the tools,

hoses, andpackaging in specific categories and take to the local recycling centre or dispose

of in an environmentally safe way.

6

SYMBOLS

WARNING:

Some of the following symbols may appear on the tool. Study these

symbols and learn their meaning. Proper interpretation of these symbols will allow for

more efficient and safer operation of this tool.

SYMBOLS

Read operator’s manual: To reduce the risk of injury,

user must read and understand operator’s manual

before using this product.

Risk to hearing

using this tool.

hearing loss.

Always wearear protection when

Failure to do so may result in

7

Eye protection: Always wear safety goggles, safety

glasses with side shields, or a full-face shield when

operating this product.

1282-004

2IN1 AIR FLOOR NAILER

TOOL SPECIFIC WARNINGS

DANGER Potential hazard that willresult in serious injury or death.

• Do not keep the tool pressed while loading fasteners.

• Do not disconnect or reconnect the air hose with the tool pressed or with a

fastener in the guide. The tool may fire when it is reconnected to the air supply.

WARNING Potential hazard that could result in serious injury or death.

•Keep hands and other parts of the body away from the nail guide during use. Keep hands

and feet and all other parts of the body at least 8” (20cm) away from the firing head.

• Objects in the workpiece can cause serious injury if they cause the fasteners to be deflected

or to be driven away from the point of entry.

• Do not drive fasteners on top of a fastener.The fastener may ricochet, causing serious

personal injury.

• Do not drive fasteners on scaffoldings, ladders, or such similar construction.

• Use only fasteners of the proper size and gauge, as specified in this manual.

• Do not drive fasteners close to the edge of the workpiece. The workpiece may split which

could allow the fastener to fly free or ricochet and cause serious personal injury.

8

KNOW YOUR FLOOR NAILER

7

4

5

6

1

2

3

8 9 10 11

FUNCTION

1. Magazine

2. Shoe

3. Shoe plate 3/4”

4. Hammer cap

5.

Air inlet plug

6. Magazine latch

7.

8.

9.

10.

11.

Dust shield

Shoe plate

(for floor boards 5/8" & 9/16" thick)

Mallet

Hex wrench

Lubrication oil

9

1282-004

2IN1 AIR FLOOR NAILER

WARNING: Risk of serious personal injury: Never place hands

or any other body parts in the fastener discharge

area of the nailer, the tool might eject a fastener,

and could result in death or seriouspersonal injury.

ASSEMBLY AND OPERATING

This 2 in 1 air floor nailer drives both 15.5-guage crown staples 1-1/2" - 2" long (38-50mm)

with 1/2" (12.7mm) crown, crown staples and 16-gauge "L" shaped cleats from 1-1/2"-2" in

length (38mm- 50mm) in length. It includes a die-cast aluminum housing that delivers a

strongandlightweightdesign, even during extended use. The ergonomically designed long

handle allows for easy operation. It has two interchangeable base plates to support a variety

of flooring thicknesses. It also features a hardeneddrive blade for longerlife, and economic

air consumption with low noise. This 2 in 1 air floornailer is specifically designed for

installing hardwood flooring.

COMPATIBLE COMPRESSORS

GUIDELINES FOR PROPER USE AND OPERATION

Be sure to use a proper air compressor with air-powered tools. The compressor should be

able to supply a minimal air delivery of 4.56 CFM @ 90 PSI to ensurethe compressor can run

continuously with the 2 in 1 air floor nailer.

Air Compressor

Size and Power

1 1/2-2 HP

2 1/2 HP

3+ HP

4-5 Gallons

Light-duty and

Intermittent use

Light-duty and

Intermittent use

Light-duty and

Intermittent use

6-11 Gallons

Light-duty and

Intermittent use

Medium-duty and

Intermittent use

Medium-duty and

Intermittent use

15+ GallonsMedium-duty and

Intermittent use

Heavy-duty and

Continuous use

Heavy-duty and

Continuous use

10

2

5

7

3

3

8

1

9

4

6

AIR SYSTEM

Always use clean, dry, regulated, compressed air at 4.8 to 7.93 bar (70 to 115 PSI)

Do not exceed the maximum or minimum pressures. Operating the tool at the wrongpressure

(too low or too high ) will cause excessive noise or rapid wear of tool.

No.

Description

No.

Description

1

2 in 1 air floor nailer

6

Regulator 0-123 PSI (0-8.5 bar)

2

Quick connector

7

Filter

3

Quick coupler

8

Cut-off valve

4

Air hose

9

Air compressor

5

Lubricator

This 2 in 1 air floor nailer accepts the following size and type of fasteners.

ACCEPTABLE FASTENERS

Staples (15.5 gauge)

Crown: 1/2” (12.7mm)

Length: 1 1/2-2” (38-50mm)

L-Shaped cleats/nails (16 gauge)

Length: 1 1/2-2” (38-50mm)

11

1282-004

2IN1 AIR FLOOR NAILER

NAIL TYPE ICONS

These icons are used to select the propernails for this specific nailer.

WARNING The use of any other types of fasteners will cause the tool to jam. Failure

to comply could lead to serious injury or loss of life.

It is recommended that a filter-regulator-lubricator is used and located as close to the tool as

possible.

If a filter-regulator-lubricator is not installed, place up to 3-5 drops of pneumatic tool oil into the

NPT inlet plug beforeeach use.

If a filter-regulator-lubricator is installed, keep the air filter clean. A dirty filter will reduce the

air pressure to the tool, which will cause reduction in power, efficiency, and general

performance.

For optimal performance, install a quick coupler in the hose, if applicable.

Verify that all the connections in the air supply system are sealed in order to prevent air

from leaking.

Air tools

Read this Instruction Manual carefully before using the tool.

Read and follow all the safety instructions at the beginning of this manual. Inspect the air-

powered tool prior to each use to:

-Ensure that the properpower source is being used.

-Verify that the tool is in proper working order.

-Verify that the air pressure level (s) are properly set on the air compressor.Do

not use the tool if it is not in proper working order.

Do not use oxygen, CO2(carbon dioxide) or any other combustible, or bottled gas to powerthis

tool.

Do not use this tool in the presence of any flammable liquids or gases.

Keephandsand otherparts of the body away from the firing head during use.

Do notpoint the tool towards the operator or otherpeople.

Never attempt to clear a jammed fastener while the air hose is connected.

Do not drive a fastener on top of an existing fastener. Failure to comply could lead to serious

injury or death.

12

Loading fasteners

WARNING Disconnect the tool from the compressed air source before loading fasteners.

Do notpoint the tool towards the operator or otherpeople while changing fasteners.

Do nothold the tool with the triggerdepressed while changing the fasteners.

Failure to comply will lead to serious injury or loss of life.

1.

Disconnect the tool (1) from the air supply (2) (fig. A).

2.

Take hold of the 2 in 1 air floor nailer firmly with one hand.

Use the other hand to press the latch (1) and pull the

magazine cover backward. Make sure you have the right

nails for your tool (see page11). Insert a strip of fasteners (2)

into the magazine. Ensure that the points of the fasteners are

facing down (Fig. B).

3.

Push the magazine cover forward,until it locks into position

(Fig. C).

Operating the tool

DANGER Do not operate the tool if the fasteners are not loaded-doing so may damage

the tool.

Do not fire fasteners into the air - doing so may cause injury to the operator

or othersand damage the tool.

Load the correct type of fasteners only. Do not load different sized fasteners

into the magazine-doing so may cause fasteners to jam. Failure to comply

will lead to serious injury or loss of life.

The nailer releases one fastener with each hit, so hitting the whack cap twice

will project a second fastener onto the first one which could cause a potential

ricochet hazard.

Ensure that the hammer exerts enough force on the nailer. If the force is too

low, the fastener willnot be inserted completely onto the flooring.For nails that

are not completely inserted, use a hammer to pull out the nailsor knock the

nails in with a nail setter. Do not attempt to drive a fastener into the same

location twice.

13

1

2

Fig. A

1

2

Fig. B

Fig. C

1282-004

2IN1 AIR FLOOR NAILER

1.

Plug in compressor, turn it on, set the pressureregulator

to 90 PSI, and attach one end of the air hose to the

compressor and the otherend of the air hose (1) to the

tool (2). Use plumber’s tape to avoid air leaks (Fig. D).

2.

Hold the handle securely and press the base plate against

the work surface, making sure the plate is over the fastener

targetposition. Press down hard so that the base plate is

firmly contacting the work surface. Swing the mallet and

strike the top end of the hammer cap (Fig. E).

Changing the base plate

The tool is equipped with a pre-installed base plate for

3/4” boardsandanadditionaluninstalled base plate for

5/8" & 9/16" thick boards. To change the base plate:

1.

Disconnect the tool from the air supply.

2.

Empty the magazine completely.

3.

Using the hex key (J), set the tool on its side to expose

the four screws and remove them by turning counter -

clockwise.

4.

Attach the desired plate (see Fig. F). Ensure the screw

holes on the base plate line up with the holes at the nailer

shoe(C).

5.

Secure the base plate to the tool using the three screws.

Insertion Methods

14

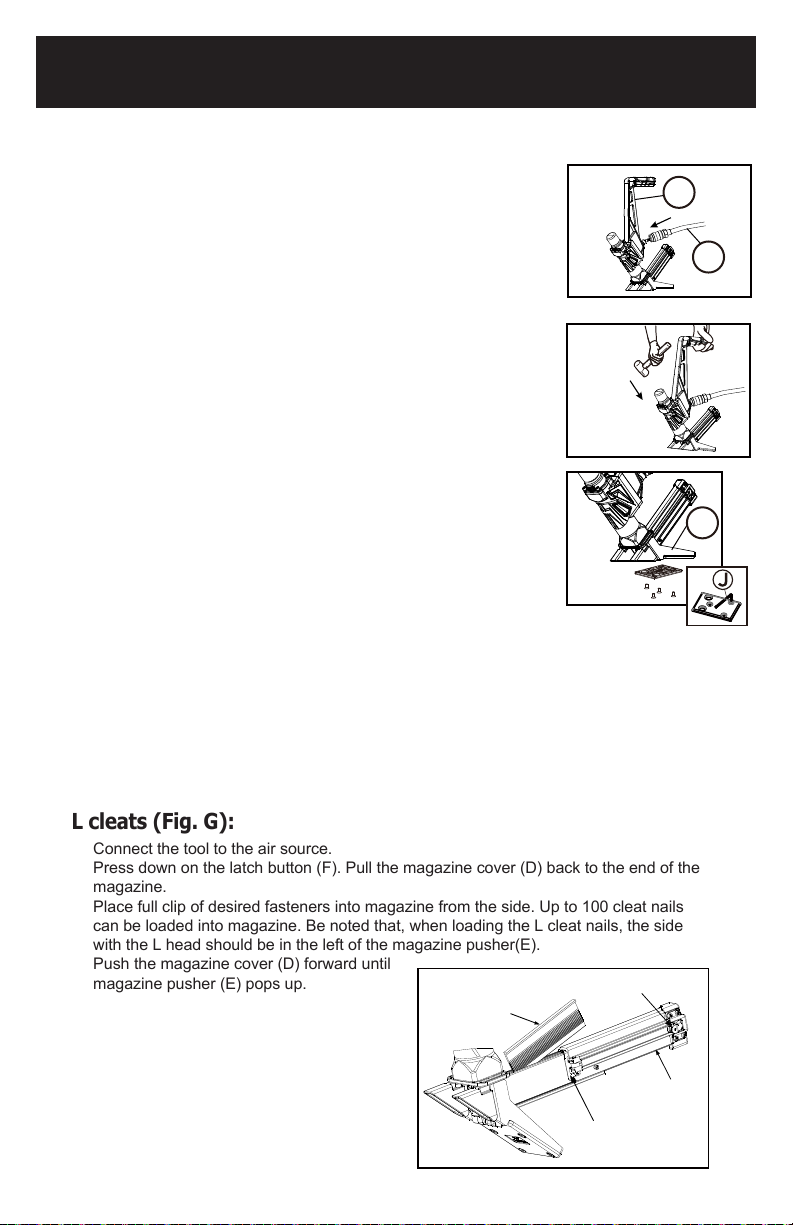

L cleats (Fig. G):

Connect the tool to the air source.

Press down on the latch button (F). Pull the magazine cover (D) back to the end of the

magazine.

Place full clip of desired fasteners into magazine from the side. Up to 100 cleat nails

can be loaded into magazine. Be noted that, when loading the L cleat nails, the side

with the L head should be in the left of the magazine pusher(E).

Push the magazine cover (D) forward until

magazine pusher (E) pops up.

1.

2.

3.

4.

Magazine

pusher

(E)

Magazine

cover

(D)

Latch button(F)

L Cleat head

direction

2

1

Fig. D

Fig. E

C

Fig. F

Fig. G

To clear a jammedfastener

Storage

If it is necessary to store the tool for an extendedperiod of time, apply a generous amount of

lubrication before storing. The tool should be allowed to run for approximately 30 seconds after

lubricating, in order to ensure that the lubrication is uniformly distributed throughout the tool.

15

Occasionally, fasteners may become jammed in the firing mechanism of the tool, making the tool

inoperable. To remove a jammed fastener, follow the steps below:

Staples (Fig. H):

1.

2.

3.

4.

Connect the tool to the air supply.

Press down the latch button ( F ), the pull the

magazine cover ( D ) back to the end of the

magazine.

Place a full clip of 1 / 2 in. Crown staples in the

magazine from the top. Up to 90 staples can be

loaded into magazine.

Push the magazine cover ( D ) forward until the

magazine pusher ( E ) pops up.

1. Disconnect the tool from air source.

2. Empty the magazine. Make sure all fasteners are removed.

3. Try to fire the tool into a piece of scrap wood or flooring to make

sure that it's incapable of firing any fasteners.

4. Set the tool on its side to expose the nose bolts ( J ).

5. Remove nose bolts ( J ) and driver guide ( K ) to expose the

jammed fastener.

6. Remove jammed fastener, using plier or a screwdriver if required.

7. Replace the driver guide ( K ) and nose bolts ( J ).

8. Reconnect tool to the air source, then reload the tool with fasteners.

9. Press the drive guide ( K ) against a piece of wood, and test fire the fasteners several times to

check for proper operation. If the tool is properly firing, you may continue using the tool. If the

tool fails to perform properly, immediately discontinue use and have the tool repaired by a

qualified service technician.

CAUTION Make sure there is no fastener in the magazine before clearing a jam.

D

Fig. I

river Guide (K)

Hex. Bolts (J)

Load staples

from the top

Magazine cover

(D)

Latch button (F)

Magazine

pusher

(E)

Fig. H

1282-004

2IN1 AIR FLOOR NAILER

Maintenance

Note:

Do not store the toolanywhere temperatures will fall below freezing.

DANGER Disconnect the tool fromthe air compressor before maintenance/service,

adjusting, cleaning jams, reloading, and when it is not in use. Repairs must be

performed by a qualified service technician only. Failure to comply will lead to

serious injury or loss of life.

MAINTENANCE

REQUIRED

DESCRIPTION

TOOLS OR

MATERIALS

REQUIRED

MAXIMUM SERVICE INTERVAL

Each use or

every 2 hrs

Monthly

As needed

In-depth inspection Worn or broken

parts

X X

Replace worn or

broken parts

X

Lubrication

See below

Pneumatic tool

oil X

Lubrication: If the 2 in 1 air floor nailer and the compressor are

notequipped with an in-line lubrication system, fill2to3drops

of pneumatic tool oil into the air inlet beforeeach use or after

every 2 hours of continuous use, depending on the

characteristics of the workpiece and type of fasteners used.

Air-operated tools must be inspected periodically, and worn or

broken parts must be replaced to ensure that the tools are

operating safely and efficiently.

Inspect andreplace worn or damaged O-rings, seals, etc. Tighten

all screws and caps frequently in order to help preventpersonal injury.

Keep the magazine of the tool clean and free of any dirt or abrasive particles.

16

Troubleshooting

DANGER If any of the following symptoms appear while the tool is in use, turn it off and

disconnect it from the air supply immediately. Failure to comply will lead to

serious injury or loss of life.

Disconnect the tool from the air supply before making anyadjustments.

Repairs must be performed by a qualified service technician only.

The following chart lists common operating system issues and solutions.

Please read it carefullyand follow all instructions carefully.

-

Disconnect the tool from the air supply before making anyadjustments.

-

Repairs andreplacement must be performed only by a qualified service technician or in an

authorized service centre.

Problem

Possible causes

Solutions

Air leakage near the

bottom of the tool.

1.

Screws are loose.

2.

The O-rings or the

bumper is/are

damaged.

Contact a qualified service technician:

1.

To tighten the screws.

2.

To inspect and replace the O-rings

or seals.

Air leakage between

the body and the

cylinder cap.

1.

Screws are loose.

2.

The O-rings or the

seals are worn or

damaged.

1.

Tighten the screws.

2.

Inspect and replace the O-rings or

the seals.

Have the tool serviced by a qualified

service technician.

The fasteners are

being driven too

deep.

1.

The bumper is

worn.

2.

The air pressure is

too high.

1. Replace the bumper.

2.

Adjust the air pressure.

The tool does not

operate properly.

- it does not drive

the fasteners or

operates sluggishly.

1.

The air supply is

inadequate.

2. Lubrication is

inadequate.

3.

The O-rings or

seals are worn or

damaged.

4.

The exhaust port

in the cylinder

head is blocked.

1.

Verify that the air supply is

adequate.

2.

Pour up to 6 drops of oil into the air

inlet.

3.

Inspect and replace O-rings or seals.

Have the tool serviced by a qualified

service technician.

4.

Replace the damaged internal parts.

Have the tool serviced by a qualified

service technician.

17

1282-004

2IN1 AIR FLOOR NAILER

Problem

Possible causes

Solutions

The tool skips

fasteners.

1.

The bumper is

worn, or the

spring isdamaged.

2.

There is dirt in the

front plate.

3.

Fasteners cannot

move freely in the

magazine because

of dirt or damage.

4.

The O-ring on the

piston is worn or

dry or there is not

enough lubrication.

5.

The cylinder cover

seal is leaking.

1.

Replace the bumper or pusher

spring. Have the tool serviced by a

qualified service technician.

2.

Clean the drive channel inside the

front plate.

3.

Clean the magazine.

4.

Replace the O-ring.

Have the tool serviced by a qualified

service technician.

5.

Replace the sealing washer.

Have the tool serviced by a qualified

service technician.

The tool jams.

1.

Fasteners are

incorrect or

damaged.

2.

The driver guide

is damaged or

worn.

3.

The magazine

screw is loose.

4.

There is dirt in the

magazine.

(See section “Cleaning a jammed

fastener”).

1.

Use the proper fasteners.

2.

Inspect and replace the driver.

3.

Tighten the magazine.

4.

Clean the magazine.

18

EXPLODED VIEW

*

*

*

*

*

*

*

*

**

19

Table of contents

Other Benchmark Nail Gun manuals