Undermount Sink Cut Out

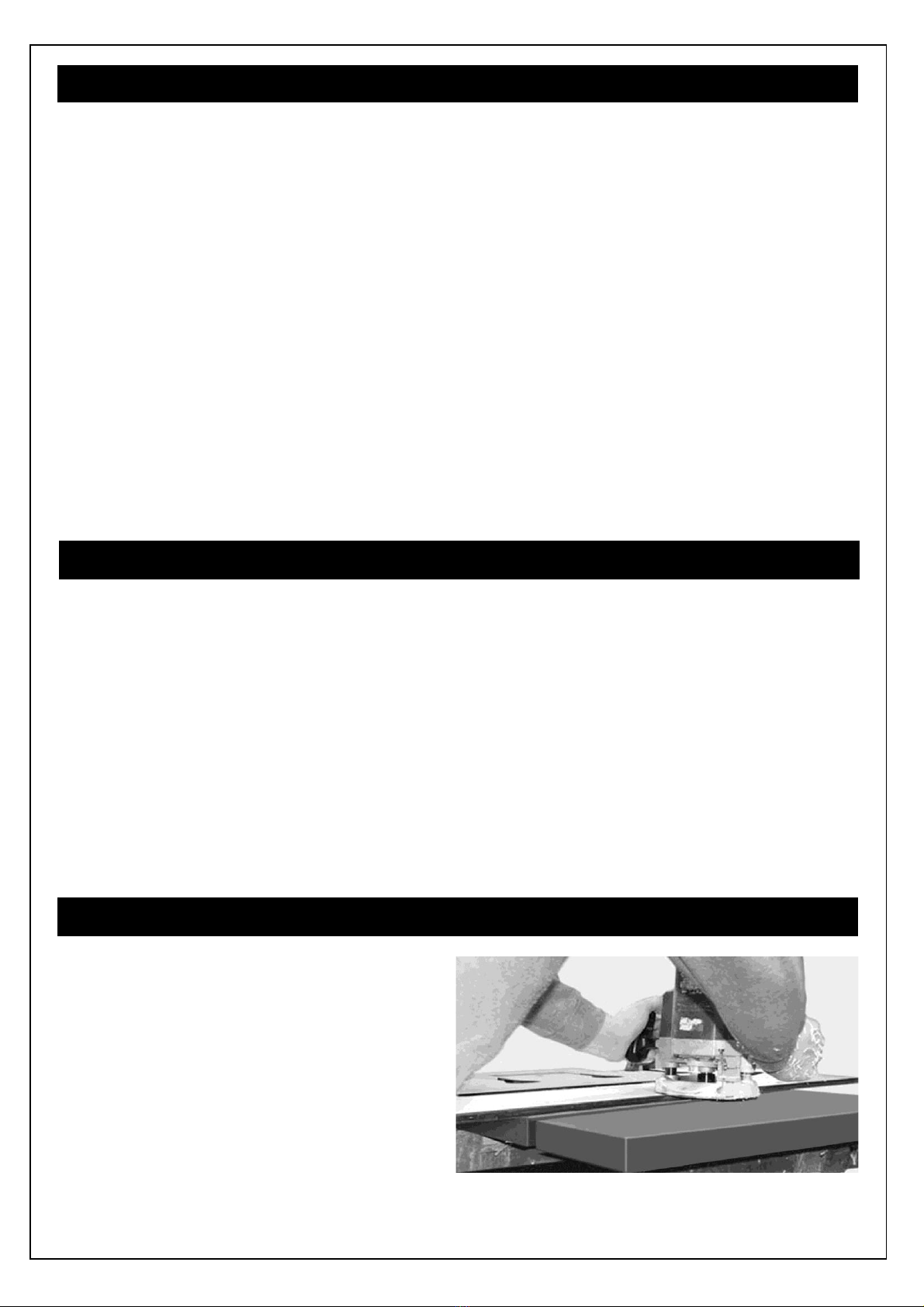

•Follow the instructions and the template supplied with the Hob or Sink or use them to make a Jig from the Template that will enable you

to make the Cut Out in the Magna® Solid Surface and the rebated Cut Out into it’s underside.

•. Clamp the hob or sink jig/template in correct position onto the worktop (Fig. 8). Check that corners have correct radius for the hob or

sink (some sink radii are rather large) before commencing. In all cases use a minimum radius of 6mm.

•All cut-outs must be machined using a router with a 12.7mm router cutter and a 30mm guide bush. When routing through the thickness

of the worktop, to ensure a clean cut and avoid “chatter marks”, make 3 to 5 passes along the cut increasing the depth of cut by 6/7mm

with each pass until the complete thickness is cut through.

•Remove the sharp top and bottom edges with fine sandpaper or profile the edges with a 2mm radius all round using a router.

Fitting Under mounted Sinks to a Cut Out:

Please Note: If Drainer Grooves are required, they should be made at this stage, please refer to the later section “Installing Drainer

Grooves” before continuing.

Using the instructions above, cut the opening in the top surface for the under mounted Sink using the Template supplied with the sink.

The underside of the sink cut out is made next, ensuring that the worktop is fully supported and that the working surface is dust and

debris free, turn it over to be face down to work on the underside.

•As before, accurately clamp the correct jig into position onto the underside of the worktop ensuring that the jig handing corresponds to

the Cut-out handing.

•Using a hand router carefully remove the excess chipboard from the back face in 2or 3 passes, the final pass should remove 0.5mm of

the underside of the solid surface material, leaving 5.5mm thickness of solid surface material around the sink Cut-out material to provide

a fresh clean and flat face to fit the sink flange into, this is needed for the silicon sealant to fully seal the sink to the worktop

•Confirm that the fit is correct by placing the inverted sink (s) in position without any sealant; adjust the machined “rebated” edges to suit.

•The edges of the exposed chipboard core of all cut-outs must be sealed well with PVA Adhesive to stop any possible water ingress.

•Before installing under mounted Sinks, ensure that the underside of the exposed solid surface face of the worktop around the cut out is

thoroughly clean and dust free then degrease using the alcohol wipes (provided in the Installation kit) and allow to dry.

•Apply a continuous bead of Rotobond 2000 or suitable High Modulus Silicon sealant to the flange of the sink and press into position,

ensure that the bead is squeezed out continuously all along the joint line along both the inner and outer edge to provide a watertight

seal. Following the sink instructions, fit (using 12mm screws) and tighten the sink clamps in the correct order and then remove excess

sealant and smooth the bead then leave without moving to allow the sealant to set.

•Apply a length of the Aluminium Reflective Tape along this front edge and in any position that is exposed to moisture (i.e. in front of a

dishwasher), This Tape must bridge the joint line between the bottom edge of the Downturn (front edge) and the bottom face of the white

coated Chipboard core material.

•Note: If a Wasted disposer is to be fitted to an Under mount Sink, the sink will need additional independent support such that the weight

of the Waste Disposer is not supported by the Under mount Sink. Additional extra support is also required such that the weight is not

supported by the worktop if a Ceramic Sink is fitted.

Hand Sanding the Drainer Grooves.

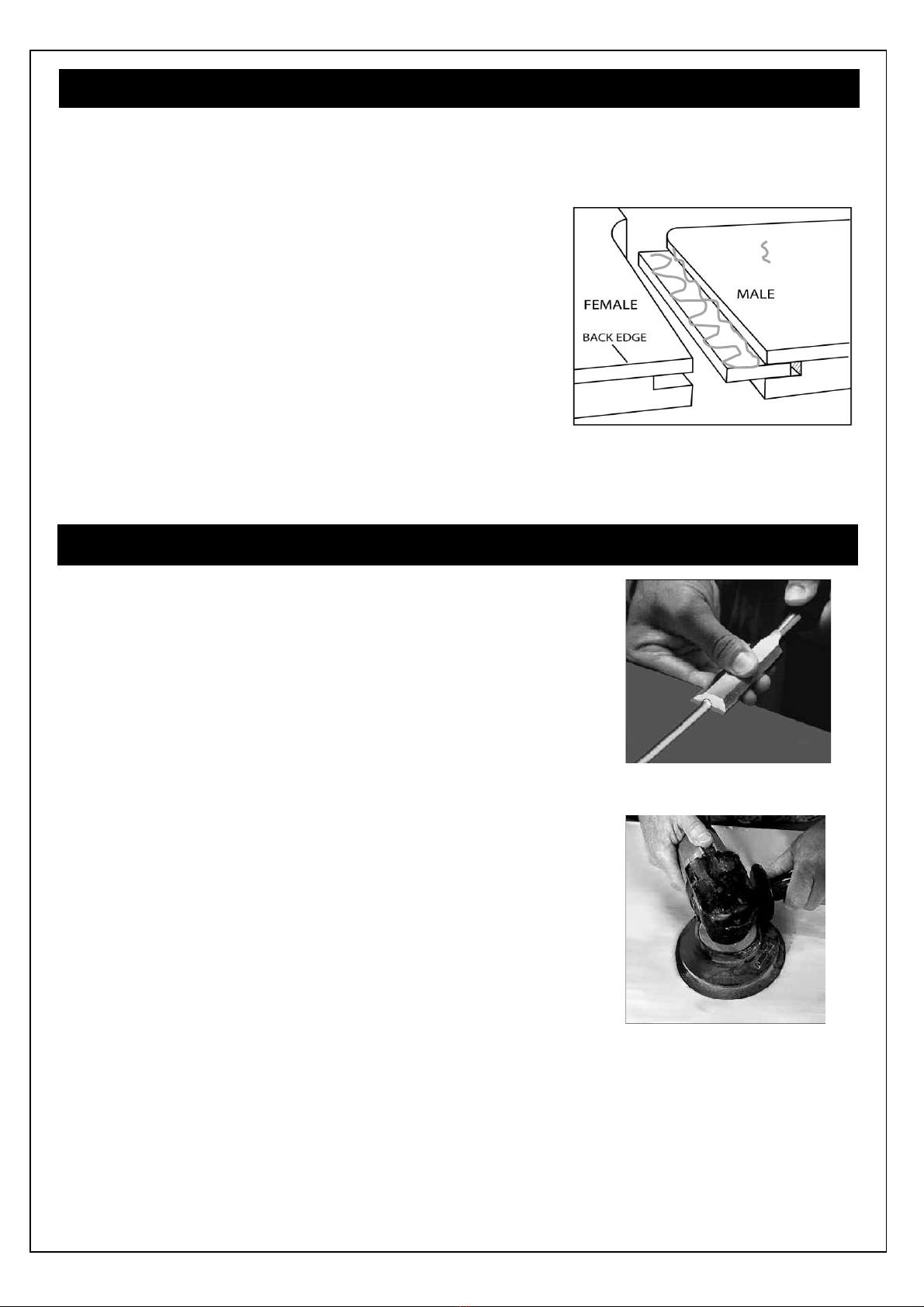

•Using the sandpaper pads supplied (wrapped in a loop around a spare

Hot Melt Glue cartridge) in the correct order of 100 grit, 150 grit and finally

220grit, sand along the grooves.

•Complete the finishing process using the supplied abrasive pads in the

correct order of Maroon, Grey and finally the white Abrasive Pad.

•The white abrasive pad should be used on a dust free surface that has

been wetted with the Stone guard cleaner spray.

Installing Drainer Grooves:

•A Jig is available for the cutting of Drainer Grooves. The jig is designed for up to 6 grooves but you can install the quantity required to

suit your sink , either using part of the jig for fewer grooves or using it in another position to add more grooves.

•Place the Jig in the position that suits your needs –it is 600mm deep (the same depth as your worktop) –if you line up the front and

back edges the grooves will be positioned central to the worktop. You can also vary the length of the grooves to extend them further

from the sink bowl by moving the Jig either closer or further away from the sink along the worktop.

•Clamp the Jig firmly in the desired position.

•Use a hand router fitted with a 30mm guide bush and a 25mm diameter “Water Channel” cutter, set the plunge depth to 2mm – do not

cut deeper than 2mm.

•Starting at the end away from the sink, plunge the router and machine smoothly along the Jig to create the drainer groove –do not

force the router and try to finish in one pass along each groove –this will provide a smooth finish that is much easier to sand and finish.

•Check the Jig position and clamps and repeat for all of the remaining grooves that you require.

•Follow the finishing instructions to hand sand and finish the grooves as described below.

Tap Holes

•Tap holes are drilled with a hole saw fitted with an appropriate sized cutter with fine teeth, then remove the sharp top and bottom and

hole edges with fine sand paper. The edges of the exposed chipboard core of the tap hole must be sealed well with PVA Adhesive to stop