Smoke detectors and alarm system control panels have

specifications for allowable loop resistance. Consult the

control panel manufacturer’s specifications for the total

loop resistance allowed for the particular model control

panel being used before wiring the detector loop.

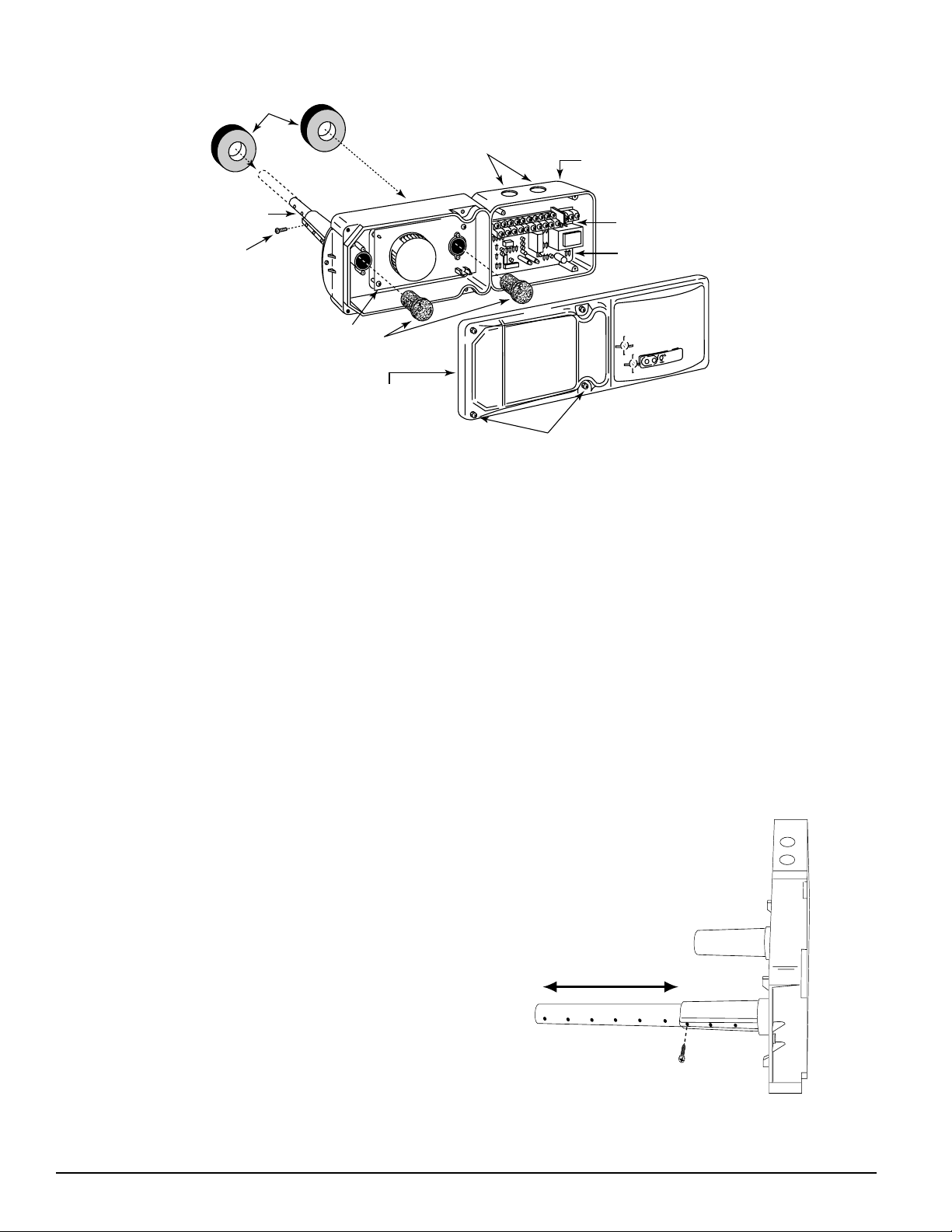

Wiring Instructions

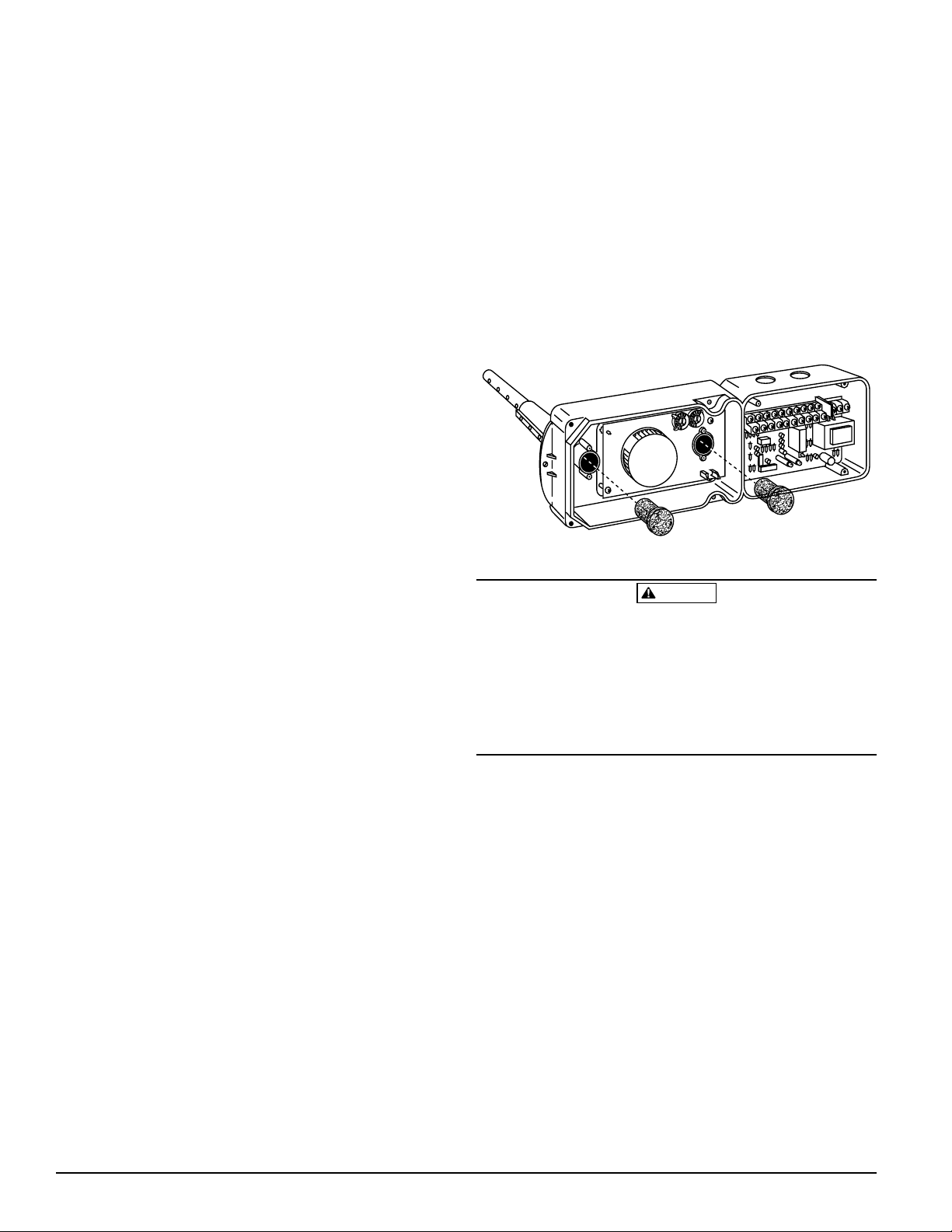

The DH100ACDC detectors are designed for easy wiring.

The housing provides a terminal strip with clamping

plates. Wiring connections are made by stripping about

3/8-inch of insulation from the end of the wire, sliding

the bare end under the plate, and tightening the clamp-

ing plate screw.

[5.7] Perform Detector Check

1. Perform STANDBY AND TROUBLE TEST per Section

[6.2.1].

2. Perform MAGNET TEST per Section [6.2.2.1]. The

RTS451 test of Section [6.2.2.2] may substitute for this

requirement.

3. Perform AIR FLOW TEST per Section [6.1.1].

4. Perform SMOKE RESPONSE TEST per Section [6.1.2].

5. Perform SENSITIVITY TEST per Section [6.2.3].

[5.8] Install The Cover

Install the cover using the four screws that are captured in

the housing cover. Be certain filters are installed as speci-

fied in Section [5.5]. Make sure that the cover fits into the

base groove and that all gaskets are in their proper posi-

tions. Tighten the four screws.

[6] Duct Smoke Detector Maintenance And Test

Procedures

Test and maintain duct smoke detectors as recommended

in NFPA 72. The tests contained in this manual were de-

vised to assist maintenance personnel in verification of

proper detector operation.

Before conducting these tests, notify the proper authorities

that the smoke detection system will be temporarily out of

service. Disable the zone or system under test to prevent

unwanted alarms.

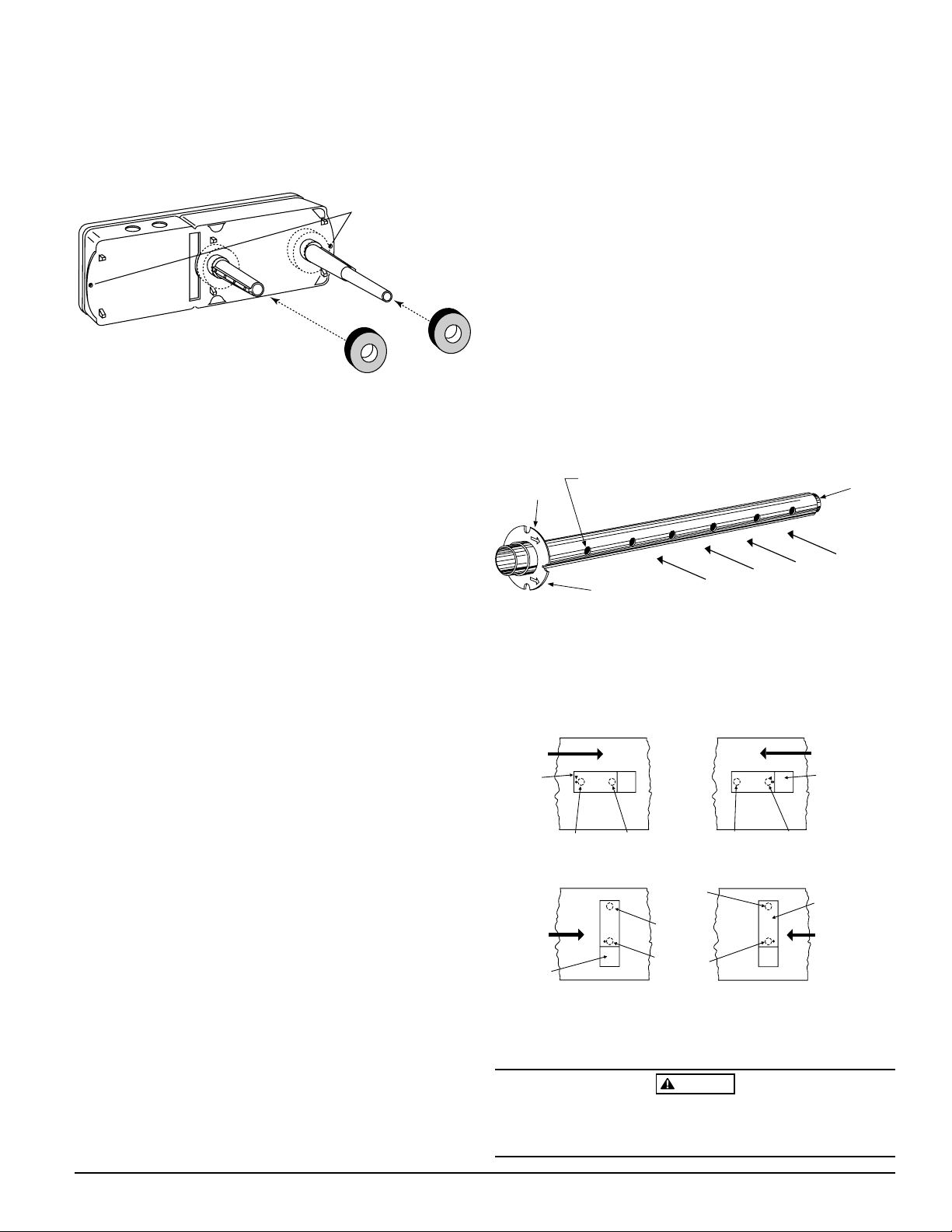

[6.1] Smoke Entry Tests

[6.1.1] Air Flow

To verify sufficient sampling of ducted air, use a manometer

to measure the differential pressure created from air flow

across the sampling tubes. The pressure should measure no

less than 0.03 inches of water and no greater than 1.4 inches

of water. The air handler must be operating for this test.

[6.1.2] Smoke Response

To determine if smoke is capable of entering the sensing

chamber, visually identify any obstructions. Plug the ex-

haust and inlet tube holes to prevent ducted air from carry-

ing smoke away from the detector head, then blow smoke

such as cigarette, cotton wick, or punk directly at the head

to cause an alarm. REMEMBER TO REMOVE THE PLUGS

AFTER THIS TEST, OR THE DETECTOR WILL NOT FUNC-

TION PROPERLY.

[6.1.3] Filter Replacement

The filters do not substantially affect smoke performance

even when up to 90% of the filter is clogged. Quarterly vi-

sual inspection usually suffices to determine whether the

filters should be replaced because only a high percentage of

contamination affects performance. If further testing is re-

quired, compare differential pressure readings with and

without the filters installed. If the difference exceeds 10%

replace the filters. In no case should the pressure differen-

tial fall below 0.03 inches of water.

[6.2] Standby, Alarm, And Sensitivity Tests

[6.2.1] Standby And Trouble

Standby — Look for the presence of the flashing green

LED through the transparent housing cover.

The LED should flash approximately every 10

seconds.

Trouble — If the detector LED does not flash, then the de-

tector lacks power (check wiring, panel, or

power supply), the detector board is missing

(replace), the cover has been missing or not se-

cured properly for more than 20 minutes (se

cure cover properly), or the unit is defective

(return for repair).

Test — The trouble condition can be caused intention

ally to verify correct operation of the system.

Remove the detector board to cause a trouble

condition locally and at the system control

panel.

Cover

Tamper — If the cover is removed or not properly secured

for a period longer than 20 minutes, a trouble

signal is generated to indicate the cover is missing.

[6.2.2] Alarm Tests

[6.2.2.1] M02-04-00 Magnet Test

1. Place the painted surface of the magnet onto the TEST

locator on the bottom of the housing (Figure 13).

2. The red alarm LED on the detector should latch on, as

should any accessories (i.e. RA400Z, RTS451). Verify

system control panel alarm status and control panel ex-

ecution of all intended auxiliary functions (i.e. fan shut-

down, damper control, etc.).

3. The detector must be reset by system control panel, front

cover reset button, or remote accessory.

D100-68-00 5 I56-1147-08

Technical Manuals Online! - http://www.tech-man.com