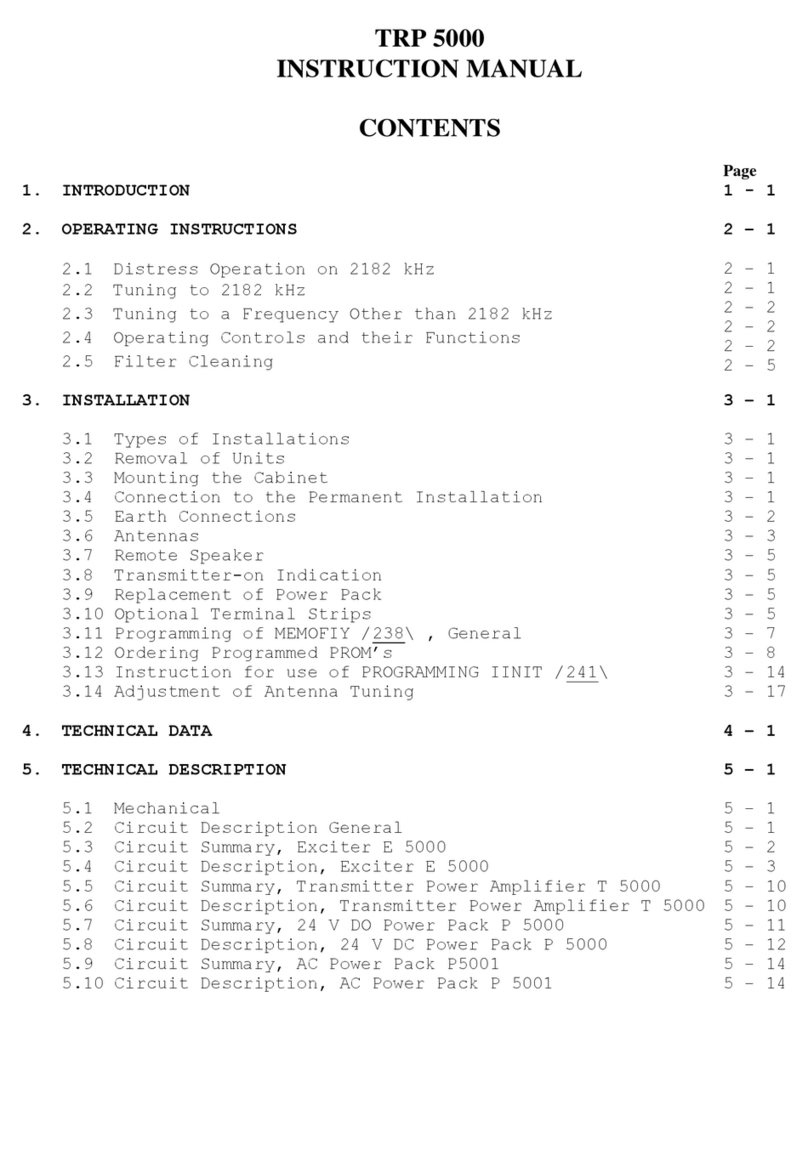

Table of Contents

Apollo SL40 Field Maintenance Manual i

TABLE OF CONTENTS

SECTION 1 - INTRODUCTION.................................................................................................1

ABOUT THIS MANUAL......................................................................................................................1

APOLLO SL40 DESCRIPTION.............................................................................................................1

FEATURES.........................................................................................................................................1

REGULATORY COMPLIANCE .............................................................................................................2

HANDLING CONSIDERATIONS ...........................................................................................................2

ESD PROTECTION..................................................................................................................................................... 2

COMPONENT HANDLING............................................................................................................................................ 3

SHIPPING CONSIDERATIONS....................................................................................................................................... 3

OTHER TOOLS AND EQUIPMENT .......................................................................................................3

TOOLS....................................................................................................................................................................... 3

TEST EQUIPMENT ...................................................................................................................................................... 3

SECTION 2 - TROUBLESHOOTING.......................................................................................5

OVERVIEW........................................................................................................................................5

ESD SAFE WORK AREA REQUIREMENTS .........................................................................................5

PRELIMINARY CHECKOUT.................................................................................................................5

SYSTEM FUNCTIONS .........................................................................................................................6

SOFTWARE VERSION DISPLAY................................................................................................................................... 6

SIGNAL STRENGTH DISPLAY...................................................................................................................................... 6

AUDIO NOISE LEVEL DISPLAY................................................................................................................................... 6

HEADPHONE LEVEL DISPLAY AND ADJUSTMENT ...................................................................................................... 7

INTERCOM SQUELCH THRESHOLD DISPLAY AND ADJUSTMENT................................................................................. 7

INTERCOM AUDIO LEVEL DISPLAY AND ADJUSTMENT.............................................................................................. 7

SIDETONE LEVEL DISPLAY AND ADJUSTMENT .......................................................................................................... 7

BASE STATION LOCKOUT MODE DISPLAY AND ADJUSTMENT................................................................................... 8

TEST MODE OPERATION...................................................................................................................9

TEST MODE ACCESS ................................................................................................................................................. 9

GENERAL OPERATION ............................................................................................................................................... 9

TEST MODE PAGE ..................................................................................................................................................... 9

DISPLAY TEST FUNCTION.......................................................................................................................................... 9

CONTROLS TEST FUNCTION .................................................................................................................................... 10

TEST SETUP ....................................................................................................................................10

EQUIPMENT TESTS..........................................................................................................................12

TRANSMITTER...........................................................................................................................13

TRANSMITTER PERFORMANCE ................................................................................................................................13

T

RANSMITTER FREQUENCY ERROR ......................................................................................................................... 13

TRANSMITTER POWER MEASUREMENT................................................................................................................... 14

TRANSMITTER MODULATION................................................................................................................................... 15

TRANSMITTER SNR (SIGNAL TO NOISE RATIO)........................................................................................................ 16

TRANSMITTER AUDIO DISTORTION........................................................................................................................... 17

RECEIVER....................................................................................................................................17

RECEIVER PERFORMANCE....................................................................................................................................... 18

SPEAKER AUDIO TEST...................................................................................................................................... 18

RECEIVER SENSITIVITY................................................................................................................................... 19

UNIT DISASSEMBLY /REASSEMBLY................................................................................................20

DISASSEMBLY ......................................................................................................................................................... 20

REASSEMBLY .......................................................................................................................................................... 21