2

STAC5 Hardware manual

920-0026 Rev. B

4/22/2011

Contents

Introduction................................................................................................................................................................................................ 3

Features ..................................................................................................................................................................................................... 3

List of STAC5 Model Numbers................................................................................................................................................................... 3

Block Diagram (-S Models)........................................................................................................................................................................ 4

Block Diagram (-Q and -IP Models)........................................................................................................................................................... 5

Getting Started ........................................................................................................................................................................................... 6

Connecting the Drive to Your PC using Ethernet........................................................................................................................................ 7

Addresses, Subnets, and Ports............................................................................................................................................................. 7

Option 1: Connect a Drive to Your Local Area Network........................................................................................................................ 8

Option 2: Connect a Drive Directly to Your PC.................................................................................................................................. 10

Option 3: Use Two Network Interface Cards (NICs) ........................................................................................................................... 11

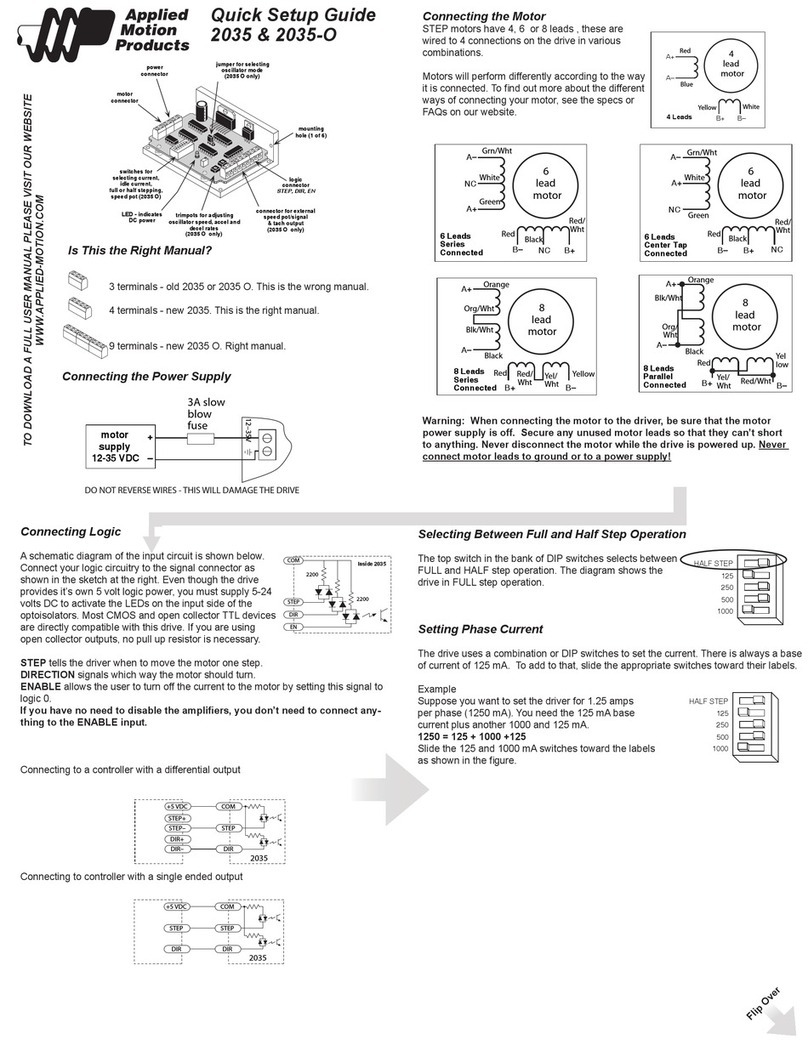

Connecting AC Power.............................................................................................................................................................................. 12

Fusing................................................................................................................................................................................................ 12

Line Filter........................................................................................................................................................................................... 12

Connecting the Motor .............................................................................................................................................................................. 13

Connecting Other Motors......................................................................................................................................................................... 13

Connecting an Encoder (Requires the Encoder Feedback option) ............................................................................................................ 15

IO Functions (-S model)........................................................................................................................................................................... 16

IO Functions (-Q and -IP models)............................................................................................................................................................ 17

Connecting Input Signals......................................................................................................................................................................... 18

Connector Pin Diagrams ........................................................................................................................................................................

High Speed Digital Inputs .................................................................................................................................................................. 19

Lower Speed, Differential Digital Inputs ............................................................................................................................................. 20

Single Ended Digital Inputs................................................................................................................................................................ 22

What is COM? .................................................................................................................................................................................. 22

Analog Input............................................................................................................................................................................................. 23

Connecting a Potentiometer to the Analog Input ................................................................................................................................ 23

Programmable Outputs ............................................................................................................................................................................ 24

Sinking Output Using OUT1, OUT2 or OUT3...................................................................................................................................... 24

Sinking Output Using Y1, Y2 or OUT4 ............................................................................................................................................... 24

Sourcing Output Using OUT1, OUT2 or OUT3 ................................................................................................................................... 25

Sourcing Output Using Y1, Y2 or OUT4............................................................................................................................................. 25

Driving a Relay OUT1, OUT2 or OUT3................................................................................................................................................ 25

Driving a Relay Using Y1, Y2, or OUT4.............................................................................................................................................. 25

Recommended Motors (120V Models) .................................................................................................................................................... 26

Recommended Motors (220V Models) .................................................................................................................................................... 26

Torque-Speed Curves............................................................................................................................................................................... 27

Motor Heating.......................................................................................................................................................................................... 29

Drive Heating ........................................................................................................................................................................................... 30

Mounting the Drive .................................................................................................................................................................................. 31

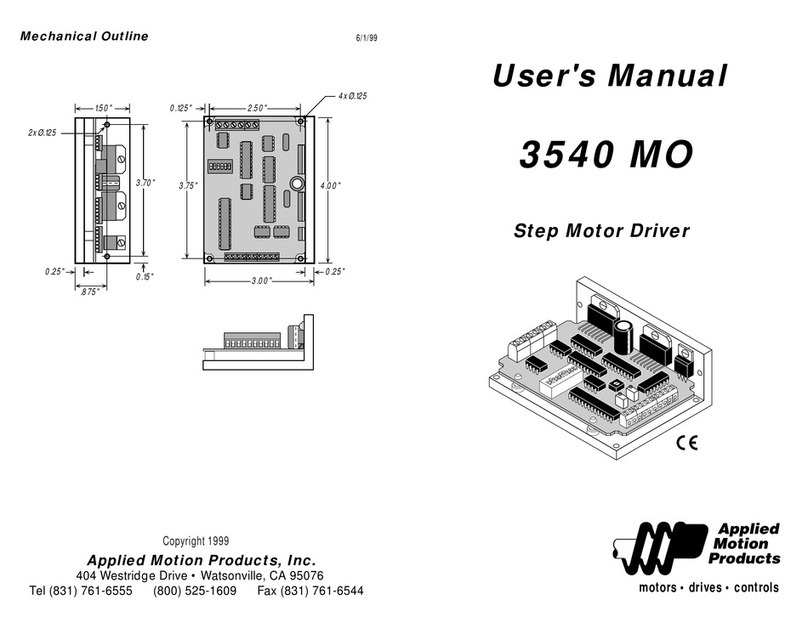

Mechanical Outline .................................................................................................................................................................................. 31

Technical Specifications........................................................................................................................................................................... 32

Mating Connectors and Accessories........................................................................................................................................................ 33

Alarm Codes ............................................................................................................................................................................................ 34

Connector Diagrams ................................................................................................................................................................................ 34