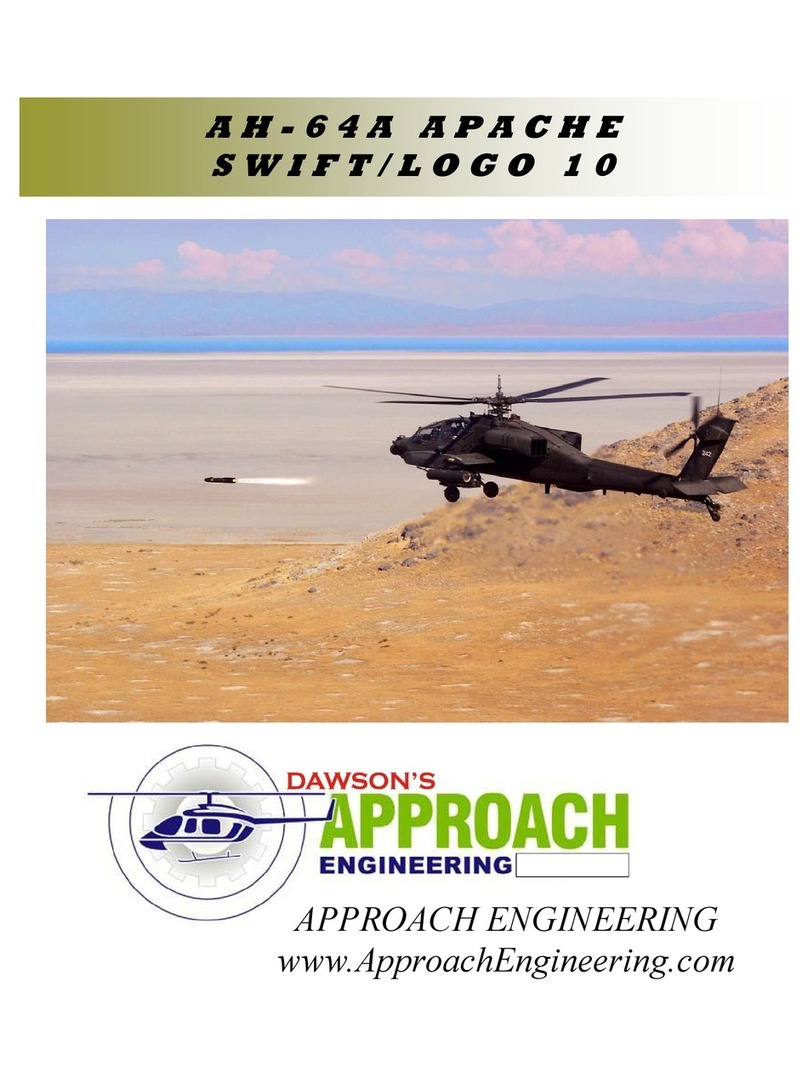

APACHE 50 PAGE # 2

Dawson’s APPROACH EGIEERIG

AH-64A 50 MECHAICS

1.0 Purpose

To establish a process that ensures control and standardization in the anufacturing of AH-64A Apache for use with 46 size

echanics. Part Nu ber AP-100.

2.0 Tools Require

Note: (A) denotes tools required for asse bly and

(T) denotes tools required for testing.

Basic Hand Tools (A, T)

Epoxy 30 Minute (A)

Cyanoacratulate (CA) (A)

3.0 Reference Documents

Exploded view drawing appendix AH-64A Apache part nu ber AP-100. (A, T)

4.0 Limitation of liability

Accessing and using this Product and any infor ation contained therein is at your own expense and risk. Under no circu stances

will Dawson’s Approach Engineering, or any of its affiliated co panies, nor any directors, e ployees and agents, nor any third party

which has supplied infor ation for this Product accept any liability for any costs incurred and/or da ages suffered (including direct,

indirect or consequential da age or da ages, as well as loss of inco e or profits.) by you as a result of your use of the Product or

any infor ation contained therein.

5.0 Intro uction

1. WARIG This aircraft is not a toy. It is capable of serious bodily har and property da age. Every precaution

ust be taken to properly build this kit and install all radio co ponents. It is your responsibility alone to ensure all

safety steps are taken outlined in the Acade y of Model Aeronautics safety codes. If this is your first ti e building a

aircraft kit it is highly reco ended that you find experienced help for the first flights. Consult your local hobby shop

or write to the AMA for further guidance.

Acade y of Model Aeronautics

5151E. Me orial Drive

Muncie, IN 47302 (800) 435-9262

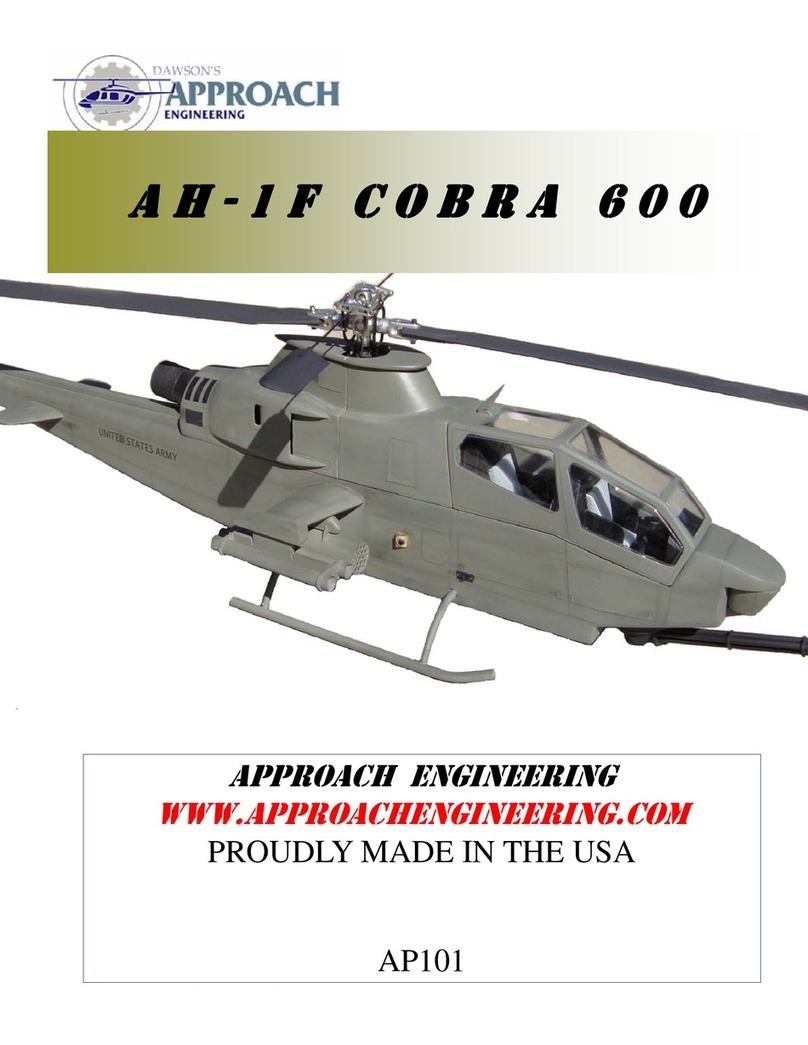

2. Please inspect all parts before building. If any parts are broken or issing please feel free to call or write for replace-

ent. The CD includes pictures of the full size aircraft to aid in finish sanding and detailing. If you have any ques-

tions, co ents, or i prove ents please call or write to:

Dawson’s Approach Engineering

220 W. Mariposa Ave.

Ridgecrest, CA. 93555

3. We as the kit anufacturer can provide you with assistance and a top quality kit and instruction anual. When built

light, straight, and true you will have a odel that flies as well as it looks on the ground. However the finished product

depends on the quality built into it. We can not guarantee the flight perfor ance. Take your ti e and read all instruc-

tions carefully before and during construction.

4. During the asse bly procedure the use of the ter CA refers to thin CA glue and CA+ refers to ediu viscosity glue.