5

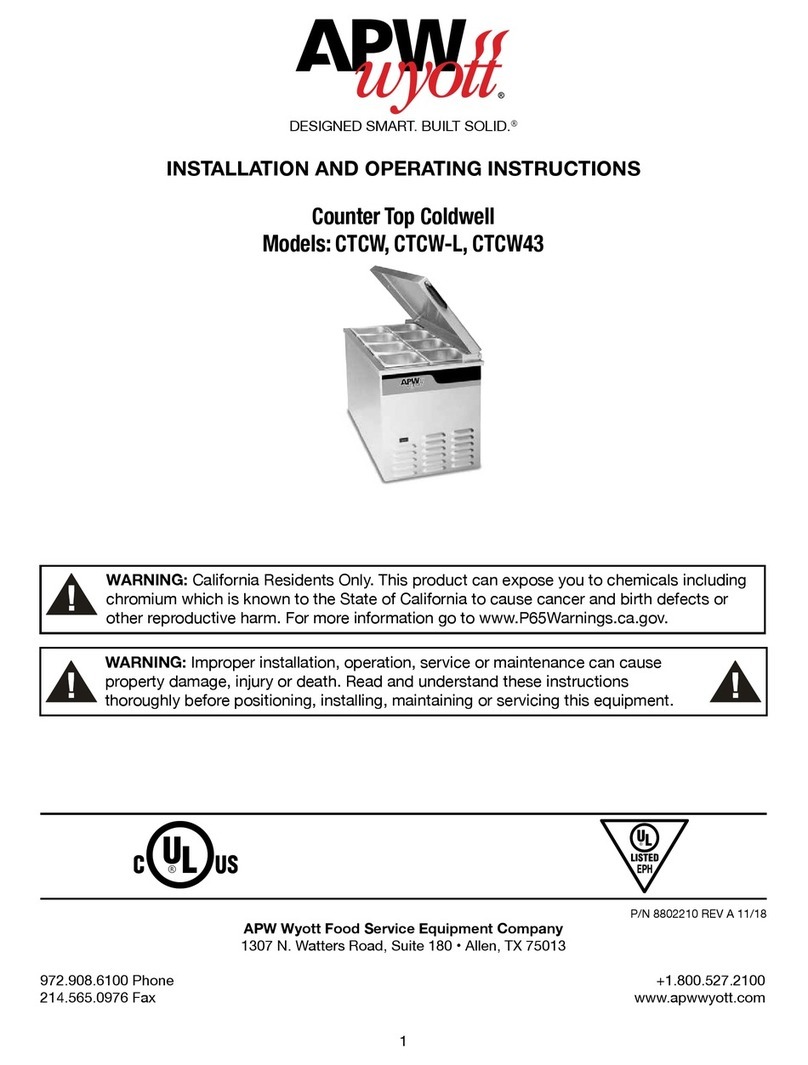

5. INSTALLATION

7. CLEANING

8. TROUBLESHOOTING

A. Alwaysclean equipment thoroughlybefore first use (See cleaninginstructions).

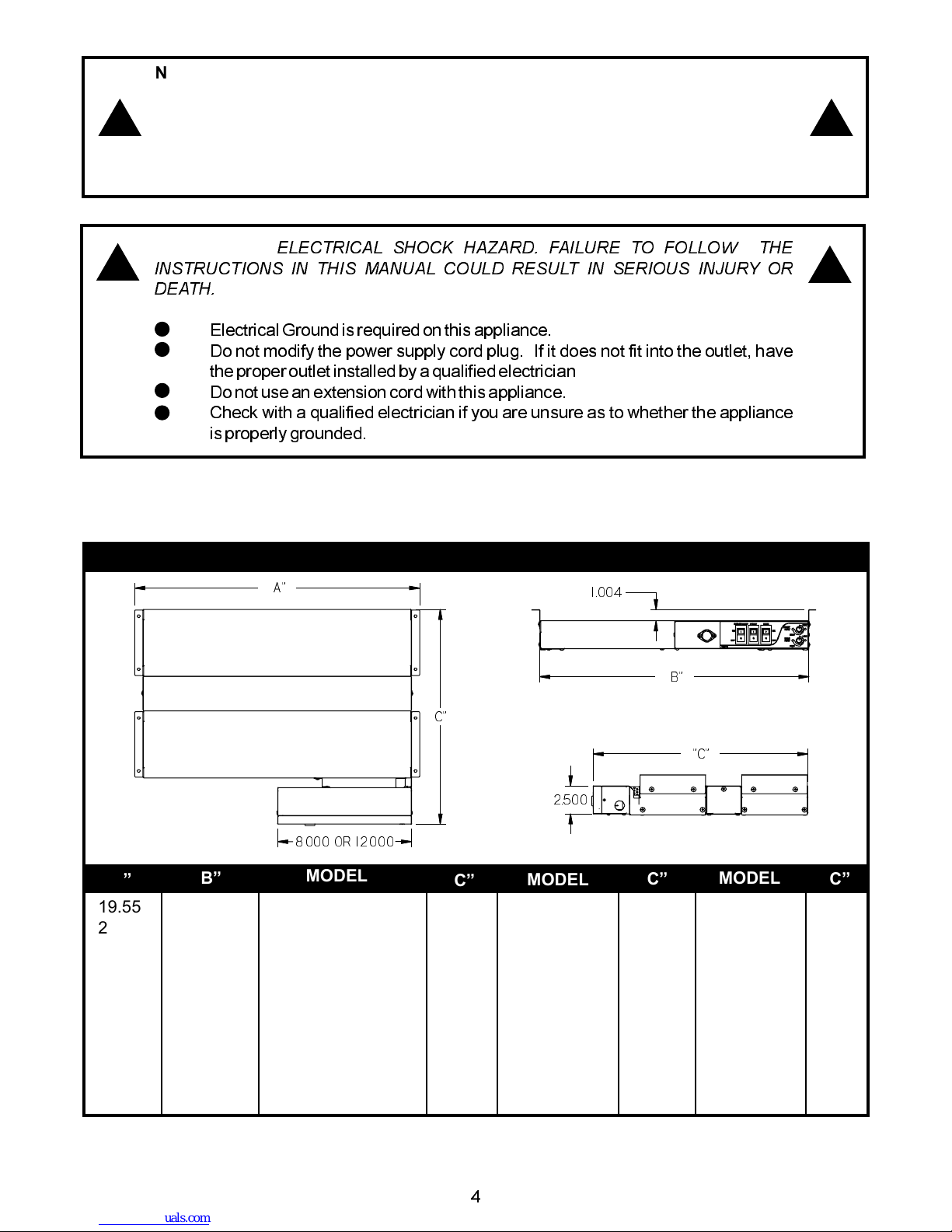

B. Providethe following clearancesaround foodwarmer:

1. Single model minimum distance to non-combustible surface below = 4 to 10. Dual model

minimum distance to non-combustible surface below = 8 to 14. For combustible surface,

install the singleand dual not closer than 13-1/2to surface below.

2. Minimum distance to side (end) walls = 2.

3. Minimum distance to back walls = 2.

4. Minimum distance to ceiling = 1.

C. Consult foodwarmer rating label for model designation and correct operating voltage and

amperage.

D. Ceiling mounting brackets are provided with each foodwarmer for chain or shelf mounting.

Remove brackets from packaging and screws from ends of foodwarmer to attach brackets.

Use four #10 screws or studs with locknuts for shelf mounting. For chain mounting, use #14 jack

chainand S hooks.

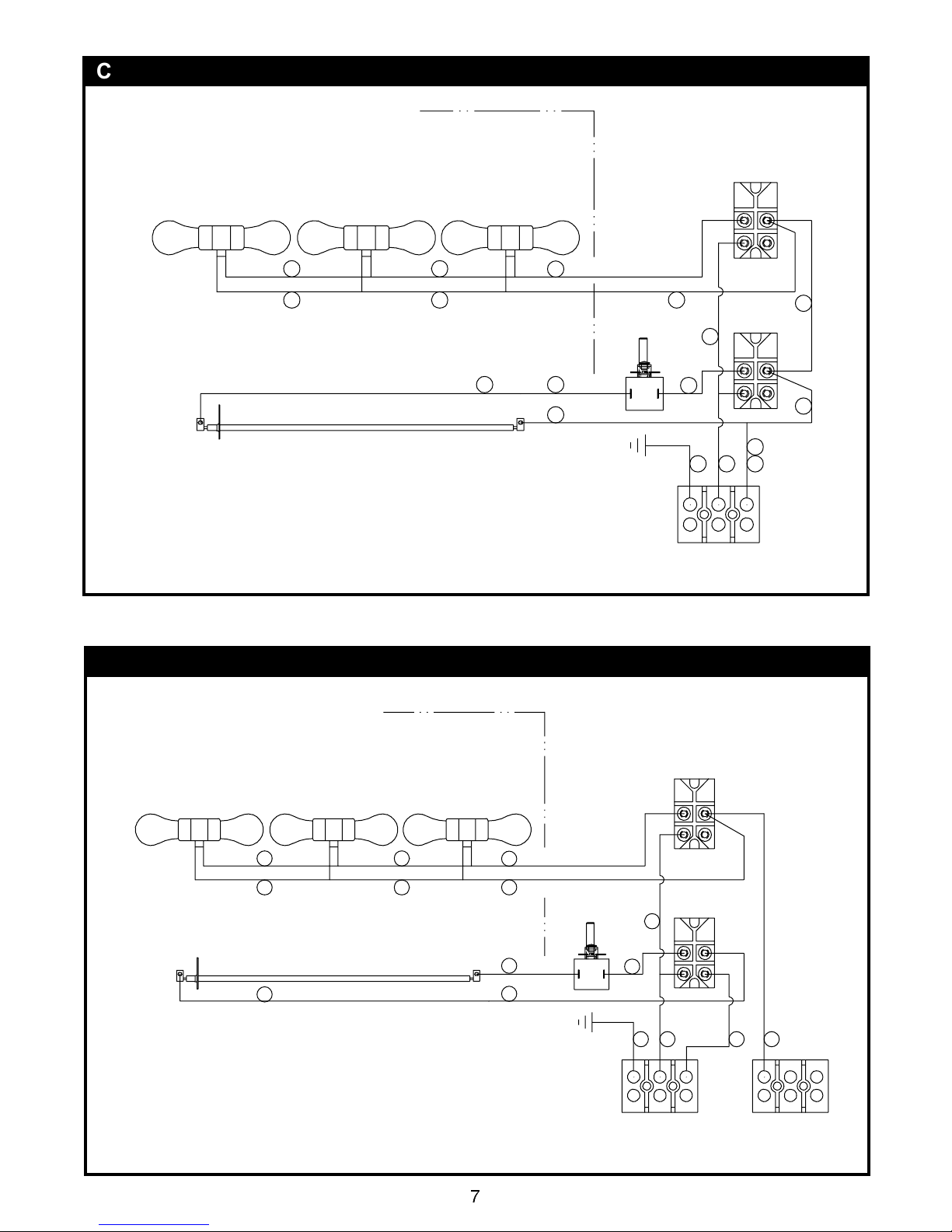

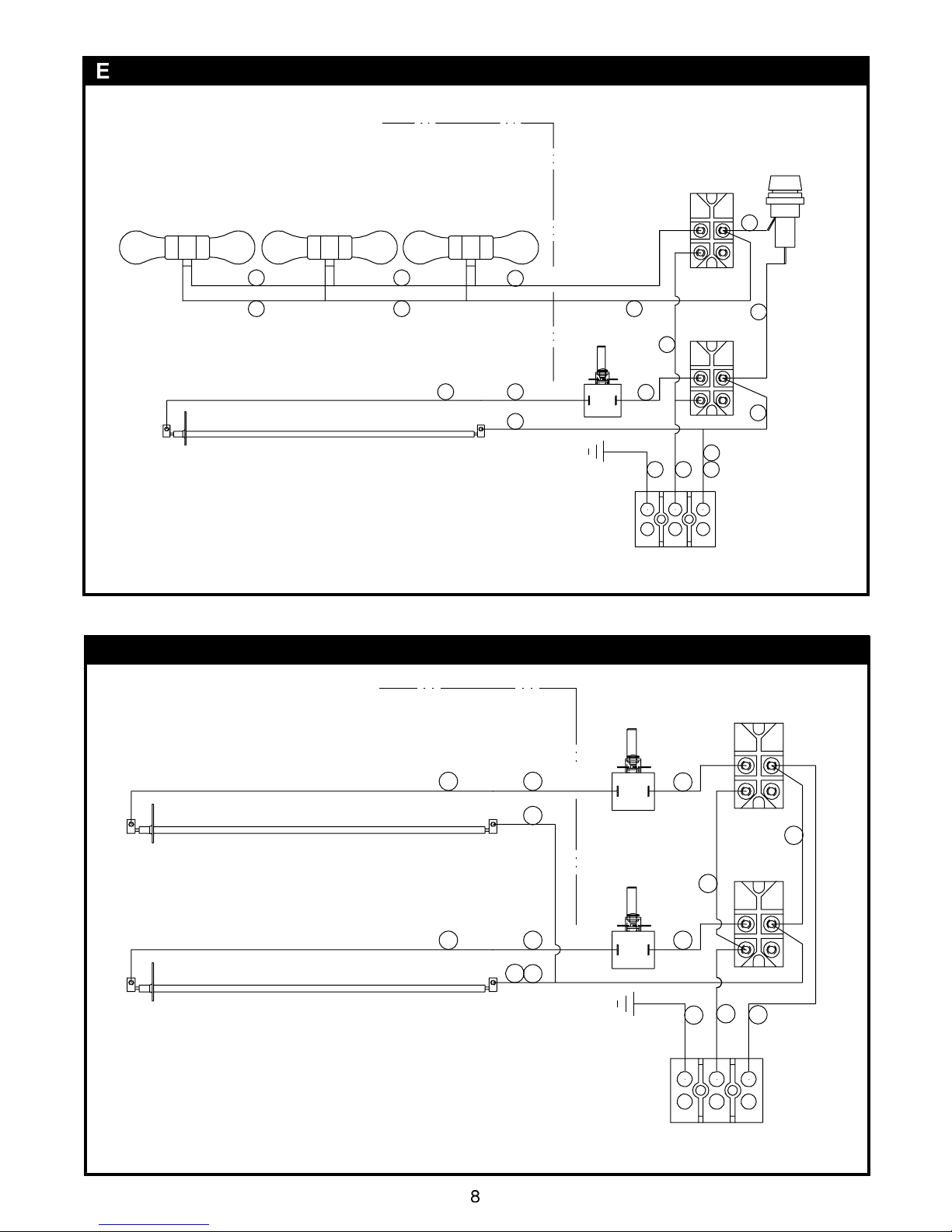

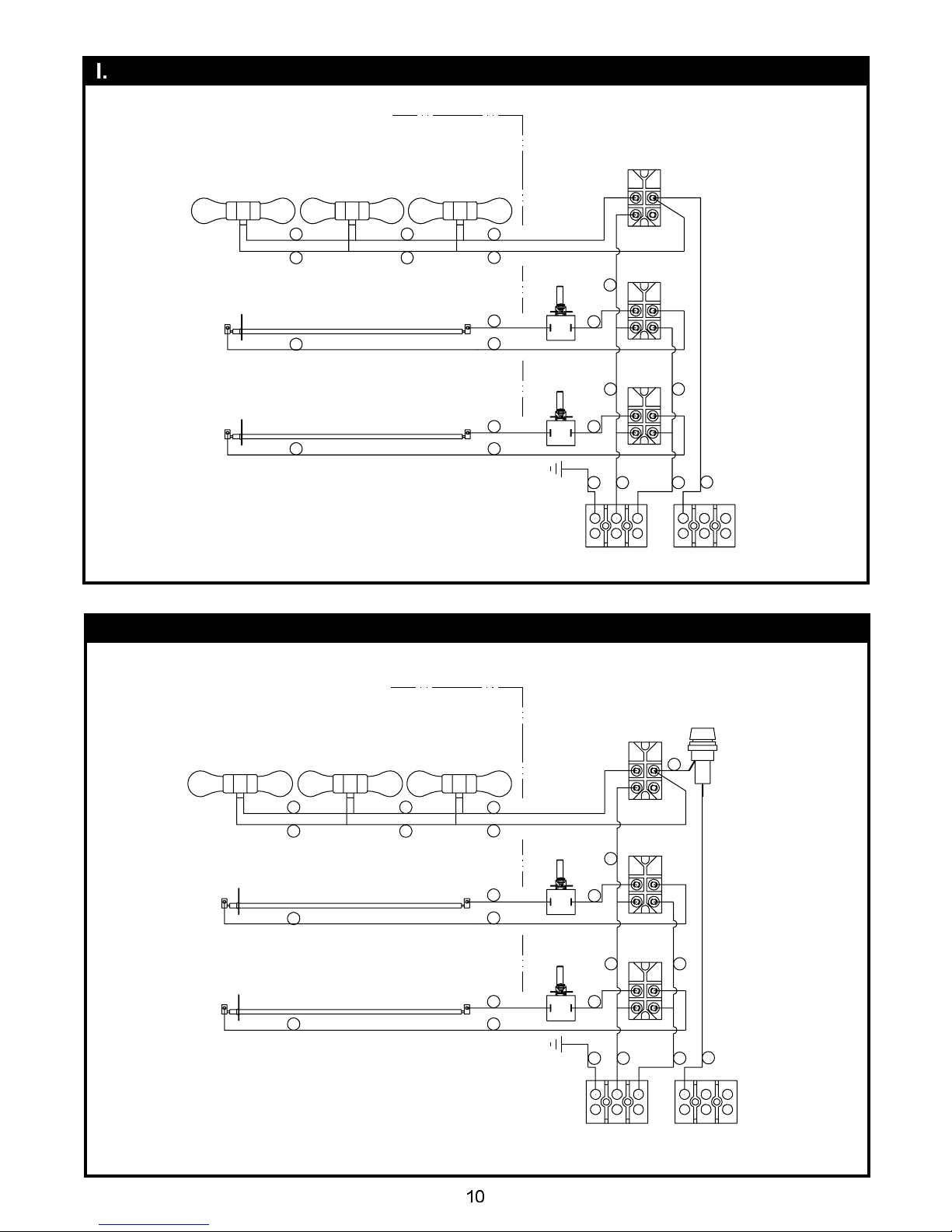

E.

Mount remote box to flat surface with two #10 screws or studs with locknuts. All

wiresmarked as shown on wiring diagram.

F. Optional tubular stands are available for permanently mounting foodwarmers to non-combustible

countertops.

G. Optionalportablelegs are available for foodwarmersfor use over non-combustiblecountertops.

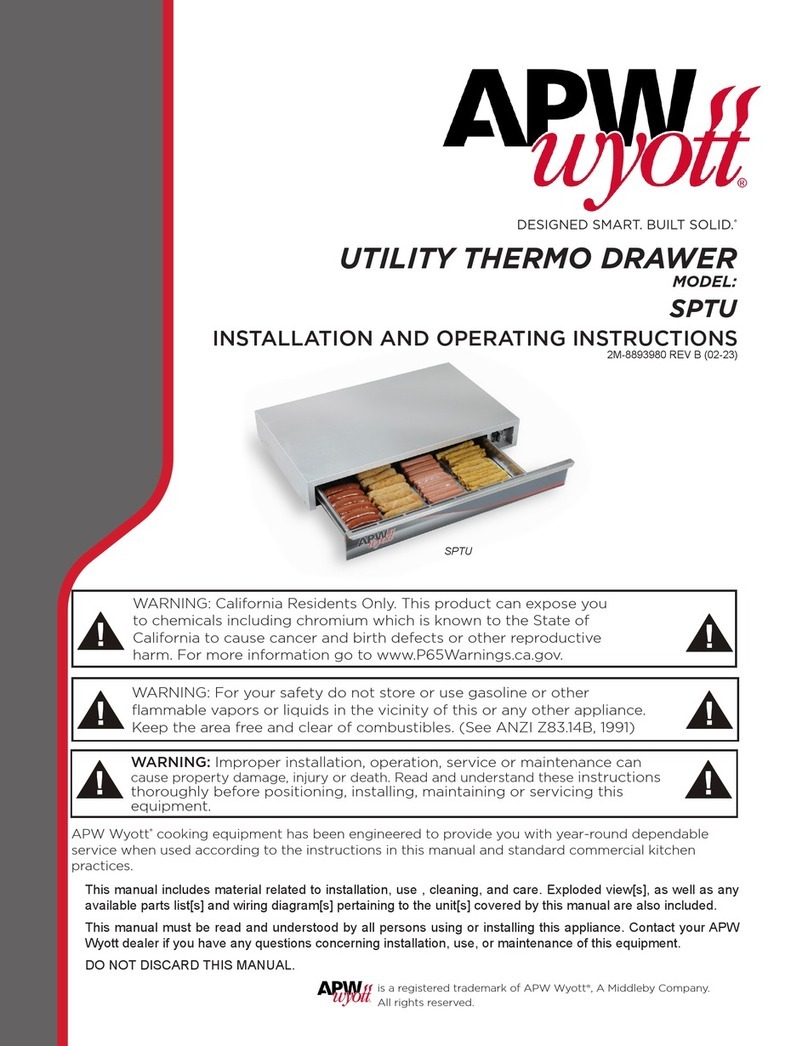

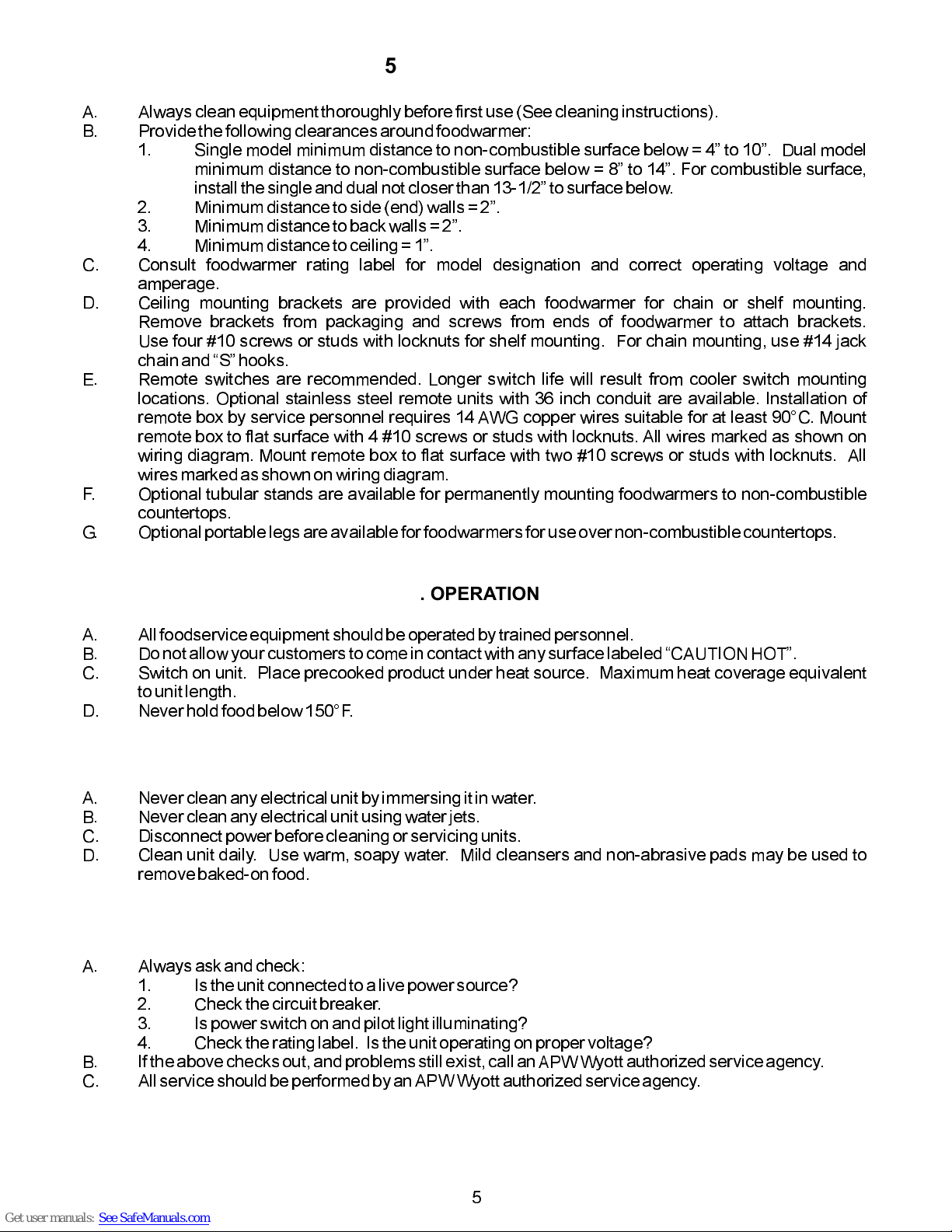

A. Allfoodserviceequipmentshouldbe operated by trained personnel.

B. Do not allow your customersto come in contact with any surface labeled CAUTIONHOT.

C. Switch on unit. Place precooked product under heat source. Maximum heat coverage equivalent

to unit length.

D. Neverhold food below 150°F.

A. Never clean any electricalunit by immersing it in water.

B. Neverclean any electrical unit usingwaterjets.

C. Disconnect power beforecleaning or servicing units.

D. Clean unit daily. Use warm, soapy water. Mild cleansers and non-abrasive pads may be used to

removebaked-on food.

A. Alwaysask and check:

1. Is the unit connected to a live powersource?

2. Checkthe circuit breaker.

3. Is power switch on and pilot lightilluminating?

4. Check the rating label. Is the unit operating on proper voltage?

B. If the above checks out,and problems still exist,call anAPW Wyott authorized service agency.

C. Allserviceshould be performed by anAPWWyott authorizedservice agency.

6. OPERATION

Remote switches are recommended. Longer switch life will result from cooler switch mounting

locations. Optional stainless steel remote units with 36 inch conduit are available. Installation of

remote box by service personnel requires 14 AWG copper wires suitable for at least 90°C. Mount

remote box to flat surface with 4 #10 screws or studs with locknuts. All wires marked as shown on

wiring diagram.

Get user manuals: See SafeManuals.com