GAS PRESSURE

The appliance and its individual shutoff valve must be disconnected from the gas supply piping system

during any pressure testingof that system at test pressuresin excess of ½ psi (3.45 kPa).

The appliance must be isolated from the gas supply piping system by closing its individual manual shut-off

valve during any pressure testing of the gas supply piping system at test pressures equal to or less than ½

psi (3.45 kPa).

Congratulations on your purchase of APW Wyott commercial cooking or refrigeration equipment. APW

Wyott takes pride in the design and quality of our products. When used as intended and with proper care

and maintenance, you will experience years of reliable operation from this equipment. To ensure best

results, it is important that you read and followthe instructions in thismanual carefully.

!

!

NOTICE:

Local codes regarding installation vary greatly from one area to another. The

National Fire Protection Association, Inc., states in its NFPA96 latest edition that local

codes are Authority Having Jurisdiction when it comes to requirement for installation of

equipment.Therefore, installation should complywith all local codes.

!

!NOTICE:

This product is intendedfor commercial use only. Not for householduse.

!

!NOTICE:

Instructions to be followed if anyonesmells gas should be posted in a prominent

place.Thesemay be obtained fromthe gassupplier.

!

WARNING:

Check the data plate on this unit before installation. Connectthe unit only to the voltage

andfrequencylisted on the dataplate.Connectonlyto 1or3 phaseas listedon the dataplate.

!

!

WARNING: IMPROPER GROUNDING COULD RESULT IN ELECTRICAL SHOCK.

This

appliance is equipped with a three-prong (grounded) plug for your protection against shock hazard

and should be plugged directly into a properly grounded three-prong receptacle. Do not cut or

removethegroundingprongfromthisplug.

!

!

!

WARNING:

Disconnect device from electrical power supply and place a Tag Out-Lockout on the

powerplug,indicatingthatyouare workingonthecircuit.

WARNING:

Install per the spacing requirements listed in the installation section of this manual. We

strongly recommend having a competent professional install the equipment.A licensed electrician

should make the electrical connections and connect power to the unit. Local codes should always

be used when connecting these units to electrical power. In the absence of local codes, use the

latestversionof theNationalElectricalCode.

!

!

!!

WARNING: -

SHOCKHAZARD

Donotopenanypanelsthat requirethe use of tools.

!

!

WARNING:

Improper installation, adjustment, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and maintenance instructions

thoroughlybeforeinstallingor servicingthisequipment.

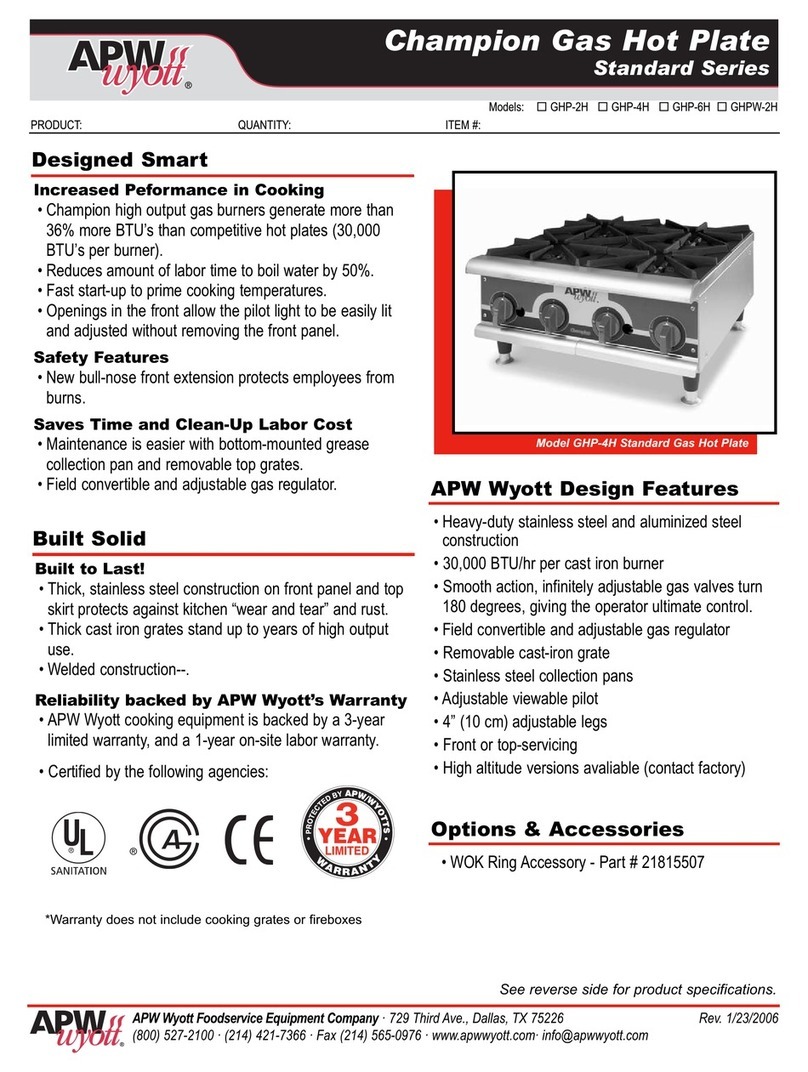

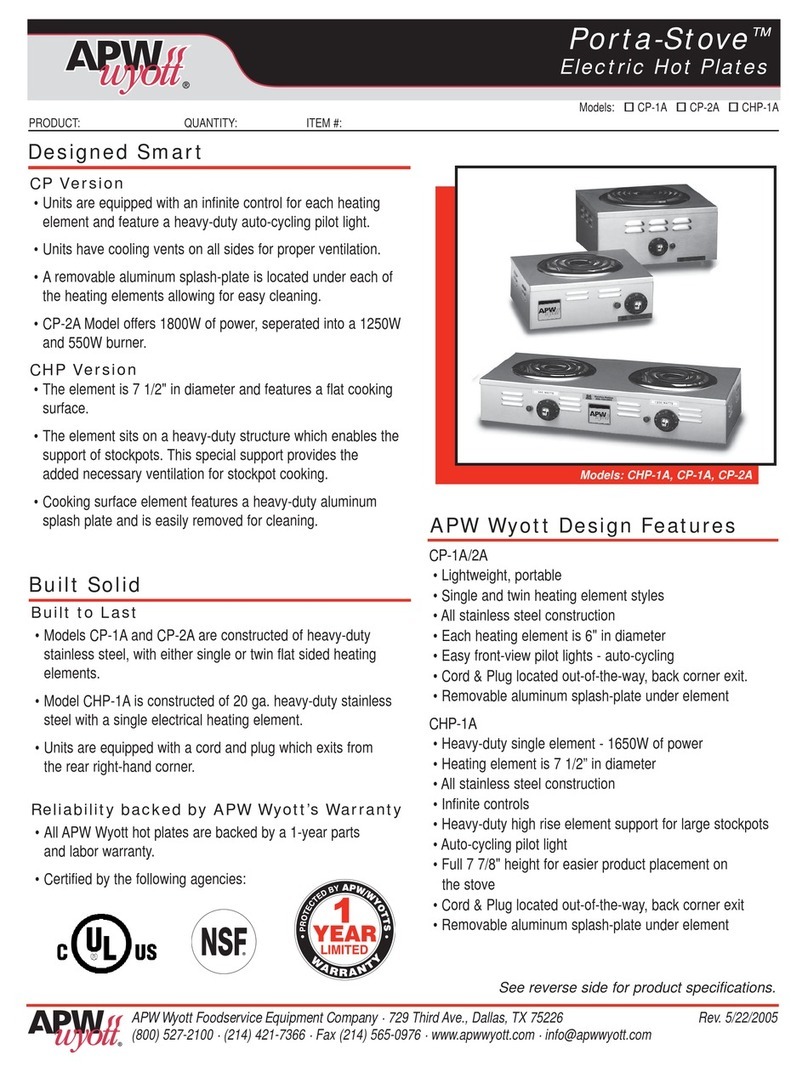

The countertop foodwarmer provides countertop warming capabilities. This unit incorporates a 4,000

BTU/Hr burner for efficient operation.The countertop hot plate,model GHP-W provides countertop heating

& cooking capabilities. This unit incorporates two 12,000 BTU/Hr burners for fast and even cooking &

heating.

Disconnect the powersupply to the appliance beforecleaning or servicingunit.

Do not use this unit in the event of an electricaloutage.

3