Innovative purication solutions

www.aquablu.com

3

Health and safety instructions

YOUR HEALTH AND THE PURIFICATION SYSTEM

The system is processing future drinking water and therefore, good care and cleanliness is

required while installing and/or maintaining the system to prevent potential health risks. In

particular the introduction of any polluting or contaminating materials into the system during the

replacement of the membrane lter insert must be prevented.

Always wash your hands carefully when replacing lter inserts or lter

cartridges to avoid the introduction of undesired materials into the ltering

system.

SAFETY INSTRUCTIONS

• Please read the instructions carefully and keep them in a safe place.

• The operator must understand the instructions before operating the purication

system, and must follow all safety and operational guidelines.

• The system is intended for purication of fresh water from any source that is

considered potable.

• Only use the system for the intended purpose.

• In spite of the system complying to the applicable rules and safety regulations for

electrical machinery, there is always risk of injury when using electrical systems

improperly.

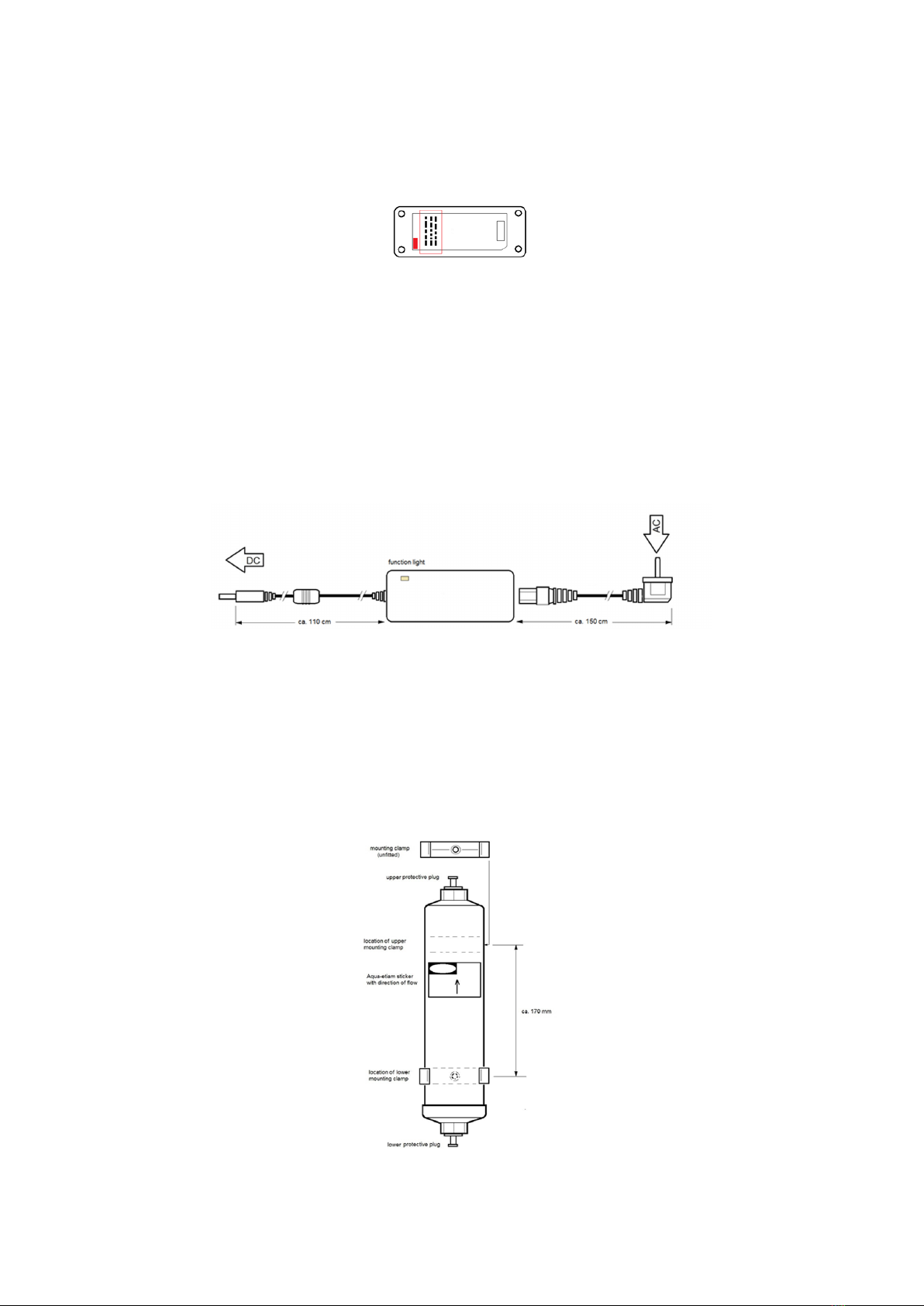

• The voltage of the power source must be the same as specied on the rating plate

of the power converter unit supplied with the machine.

• Make sure there is an earth leakage switch or automatic current dierential switch

in the power line to the ltering system. (e.g. 30 or 500mA).

• Do not pull the power cable over sharp edges, clamp it into place or allow it to

hang down. Keep the cable away from hot and damp areas and abrasive surfaces.

• Check the system at regular intervals for damaged or defective parts. The system

should not be used when it shows any visible damage, or has damage to components

or any other conditions that may aect its safe operation.

• Have any damaged or defective parts repaired or replaced by an authorized

Aquablu dealer. Improper repairs can cause considerable danger.

• Never attempt to remove or replace any parts other than those specied in this manual.

• Do not open/remove the plastic cover of the purication unit. Only authorized

Aquablu dealer may take system components apart, unauthorized opening of

system components makes any warranty void.

• Before performing any maintenance work on the ltering system, ensure that the

power supply is switched o and disconnected.

• Do not operate a purication system that has not been properly maintained or

equipped.

• Do not mount any purication system components on unsafe or unstable surfaces.

This Aquablu equipment does not have an ATEX certication and must NOT

be operated in hazardous or potentially explosive environments.