Guarantee Certificate

1.

GENERAL TERMS

1.1. In accordance with these provisions, the seller guarantees that the product corresponding to this guarantee is in

perfect condition at the time of delivery.

1.2. The Guarantee Term for the Product is two (2) years from the time it is delivered to the purchaser.

1.3. In the event of any defect in the Product that is notified by the purchaser to the seller during the Guarantee

Term, the seller will be obliged to repair or replace the Product, at his own cost and wherever he deems suitable,

unless this is impossible or unreasonable.

1.4. If it is not possible to repair or replace the Product, the purchaser may ask for a proportional reduction in the

price or, if the defect is sufficiently significant, the termination of the sales contract.

1.5. The replaced or repaired parts under this guarantee, will not extend the guarantee period of the original Product,

but will have a separate guarantee.

1.6. In order for this guarantee to come into effect, the purchaser must provide proof of the date of purchase and

delivery of the Product.

1.7. If, after six months from the delivery of the Product to the purchaser, he notifies a defect in the Product, the

purchaser must provide proof of the origin and existence of the alleged defect.

1.8. This Guarantee Certificate is issued without prejudice to the rights corresponding to consumers under national

regulations.

2.

INDIVIDUAL TERMS

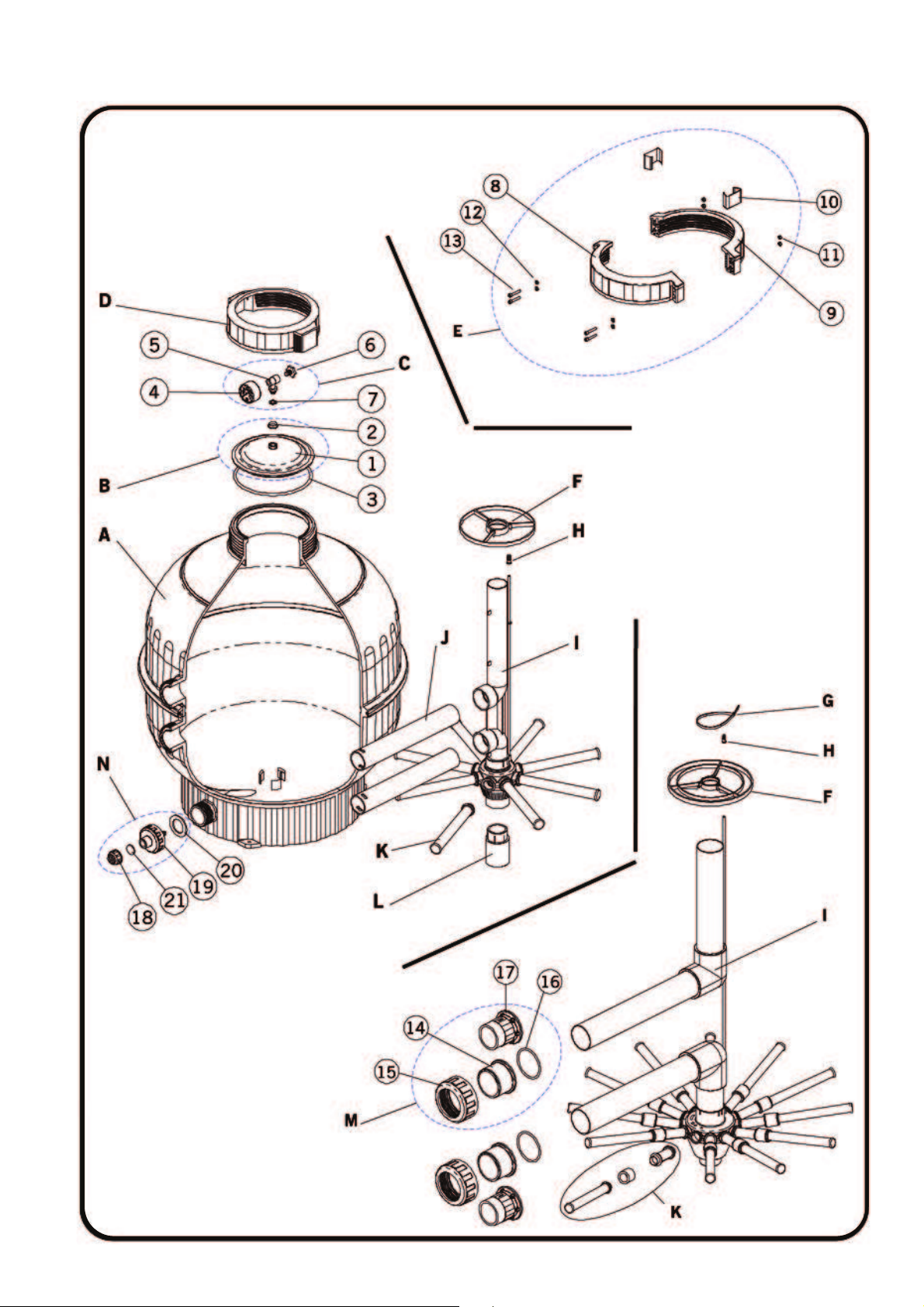

2.1. This guarantee covers the following products and ranges: CANTABRIC model filters.

2.2. For this guarantee to be effective, the purchaser must strictly follow the Manufacturer’s instructions included in

the documentation provided with the Product, in cases where it is applicable according to the range and model

of the Product.

2.3. When a time schedule is specified for the replacement, maintenance or cleaning of certain parts or components

of the Product, the guarantee will only be valid if this time schedule has been followed.

2.4. The manufacturer of the product offers the possibility of extending the guarantee of Cantabric filters from the

third year up to the fifth or tenth year depending on the model as indicated below. This Guarantee Extension is

governed by the following terms:

2.4.1. Coverage of the Guarantee Extension by the Manufacturer: In the event of any defect or non-

conformity in the container of the filter, the manufacturer will repair or replace the filter as he sees fit.

2.4.2. Replacement will construe that the purchaser accepts the payment of a variable charge depending on

the age of the product, as indicated in the following tables:

Time from the date of acquisition of

CANTABRIC model filters

Payable percentage of the price at the

time of the claim

from 2 to 4 years 30%

from 4 to 5 years 40%

from 5 to 6 years 50%

from 6 to 7 years 60%

from 7 to 8 years 70%

from 8 to 9 years 80%

from 9 to 10 years 90%

2.4.3. The manufacturer of the filter also offers the possibility of extending an additional guarantee during the

third year for internal and external components of the filter.

2.4.4. The filtering means is excluded from any guarantee extension.

2.4.5. Other terms during the guarantee extension from the third year are:

In the event of replacement, all transport charges or expenses to or from the factory, for moving or

reinstalling the product or installing a spare part, will be covered by the purchaser.

In the event of repair, expenses incurred by labour and transport will be covered by the purchaser.

The manufacturer is not held responsible for damages and expenses caused by downtime, nor the

time and material incurred by the replacement of products.

The manufacturer does not authorise third parties to extend any guarantee regarding its articles, nor

is it assumed that it is subject to any non-authorised guarantee made in connection with the seller of

its products.

2.4.6. The request for the manufacturer’s services during the guarantee extension period should be made

through the seller or fitter that supplied the product to the purchaser.