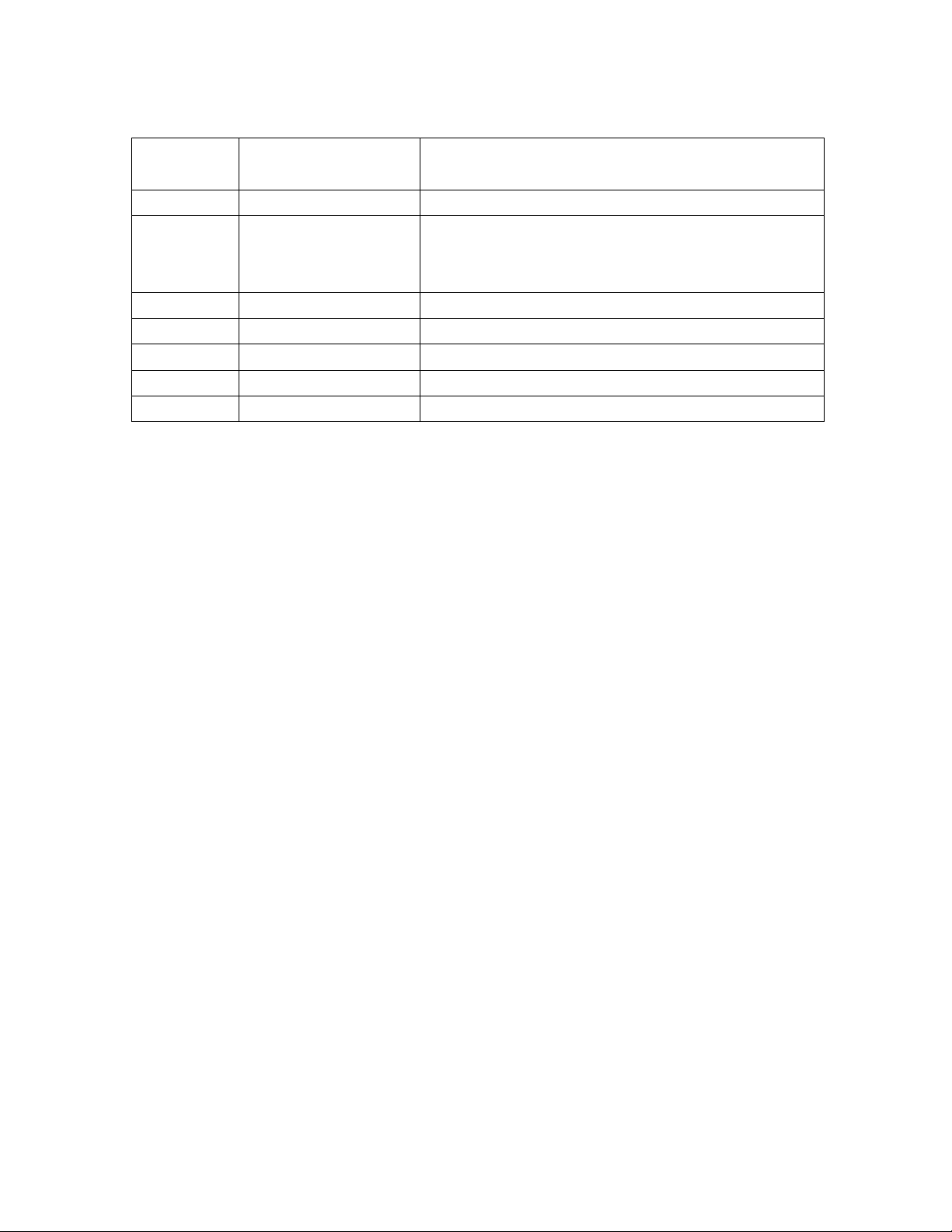

Shipping Carton Description / unit:

Contents Description

Distributor pipe installed

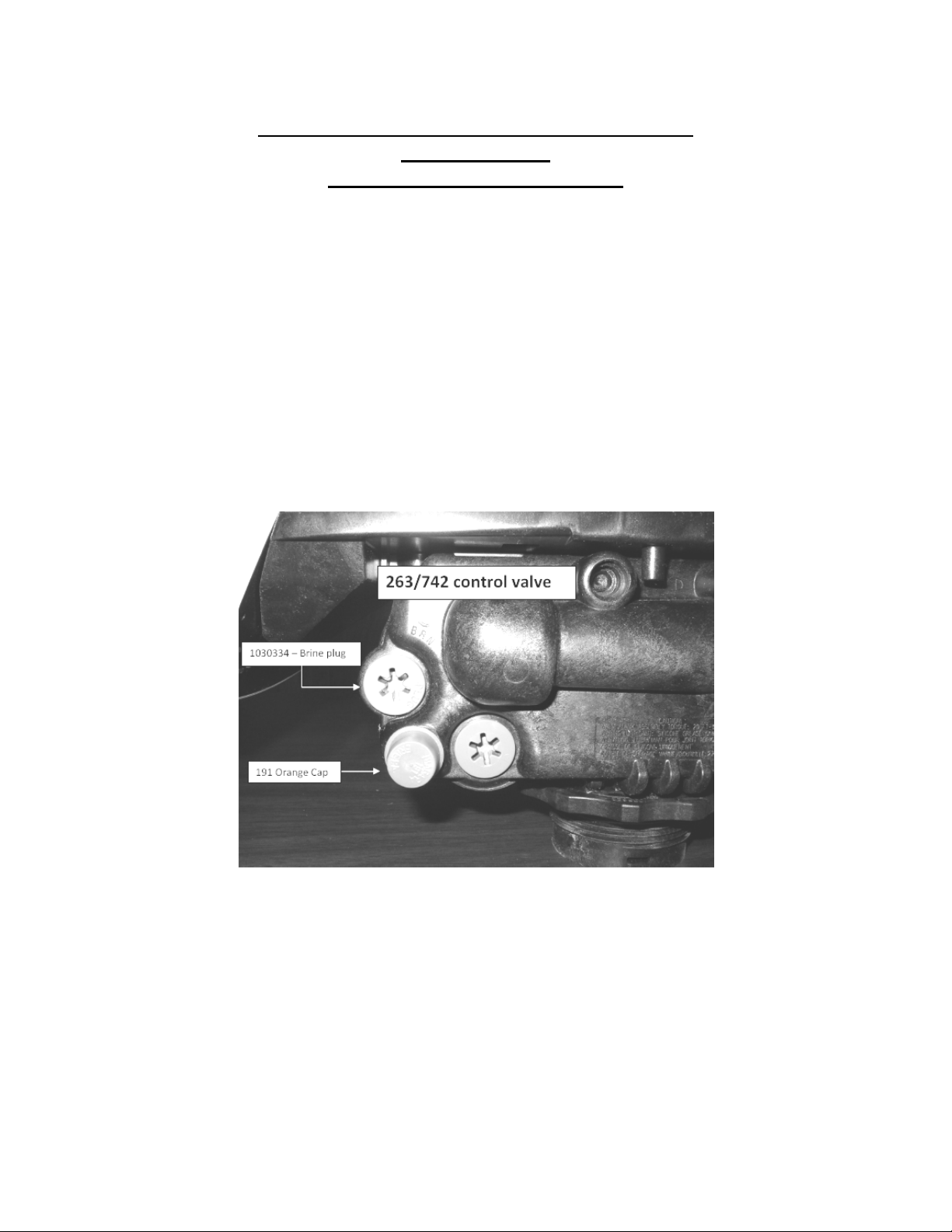

Logix control

263/742 timer and backwash flow

control and bypass with 1” copper or

Note: all units have a Vortech distributor and do not require

gravel.

System Description:

The multi media filter tank has a Logix top mounted automatic

control valve with an electronic time clock to initiate regeneration.

The Logix Valve is constructed of non-corrosive Norylmaterial and

is rated at a maximum working water pressure of 100 psi. It uses a

742 microprocessor based timer to actuate regeneration in the

following ways:

a.Manual regeneration button to start an emergency

regeneration

b.Regeneration day setting

NOTE: THIS FILTER IS NOT INTENDED TO BE USED FOR TREATING WATER THAT

IS MICROBIOLOGICALLY UNSAFE OR OF UNKNOWN QUALITY WITHOUT

ADEQUATE DISINFECTION WHETHER BEFORE OR AFTER THE SYSTEM.

Multi Media Filter Positioning:

1. Place Multi Media Filter in desired position, far enough from walls

and other obstructions to allow for servicing the unit.

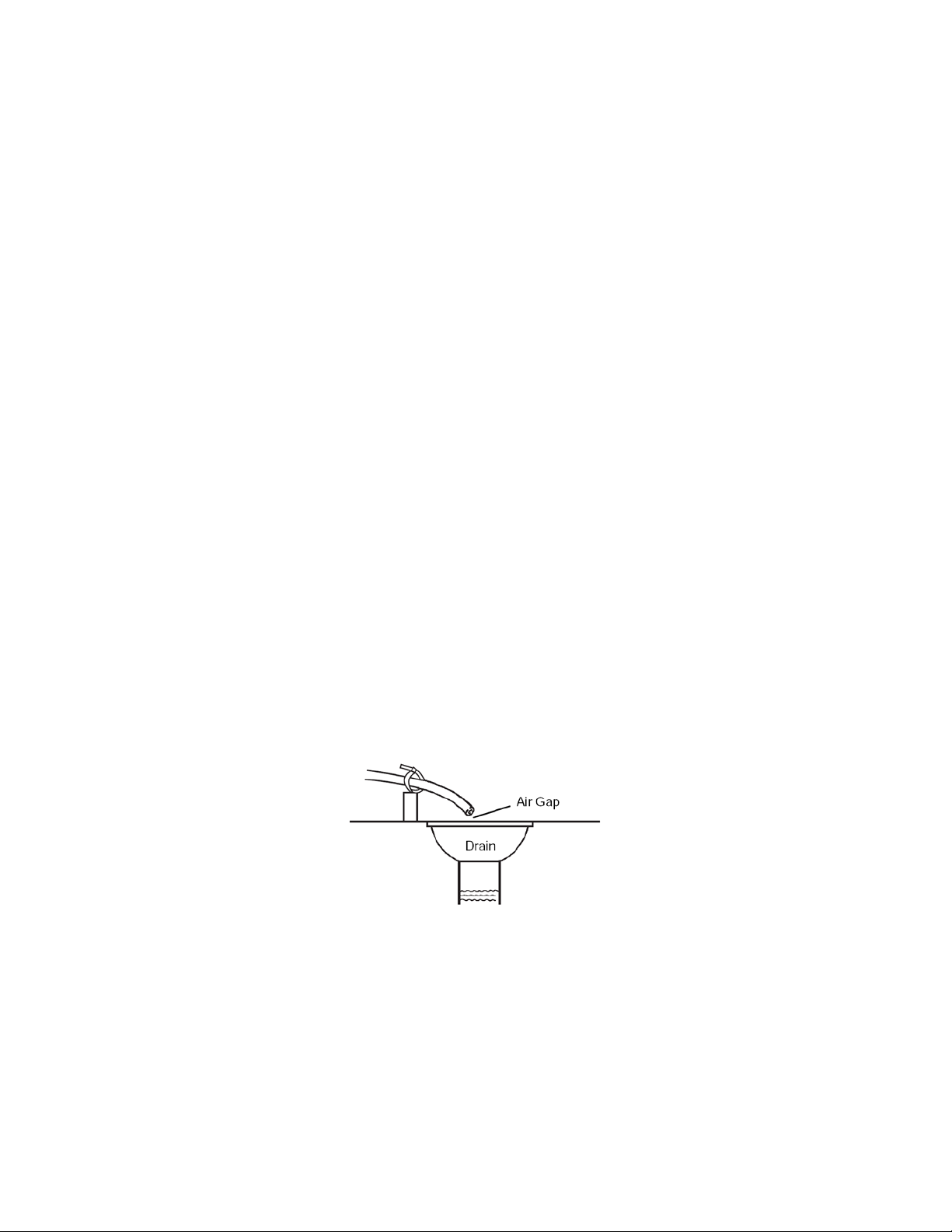

2. Place the Multi Media Filter within reasonable access to a

grounded 115V/60 HZ circuit and a legal drain line connection.