8

MAINTAINING YOUR POOL CLEANER

CLEANING AND CHANGING THE FILTER BAG

Thoroughly cleaning the Filter Bag (see step 4 below) after every use is the most important maintenance step you can take to ensure

optimum performance of your cleaner. The Filter Bag’s (Page 4, Fig. 3) holding capacity is large in comparison to all other brands of

independent pool cleaners, but far smaller than that of a pool’s main filter. Perhaps it is more important to know that your cleaner’s

Filter Bag can filter out particles down to 20 times smaller than what many main filters can. This means that the fine particles such as

algae and bacteria, invisible to the naked eye, which slip through the main filter and back into the pool to settle into the pores of the

pool’s surface, will be scrubbed loose and vacuumed up by your cleaner and retained in its Filter Bag. Therefore, although you may

see only a fine coating of dirt, the Filter Bag itself may be deeply saturated with ultra fine particulate matter from your pool’s large

surface area and the flow of water through it becomes restricted and suction is reduced. This will result in remaining dirt and debris

not being completely removed from the pool.

Also, strong water flow is required to force the cleaner against the wall when climbing. A dirty Filter Bag weighs the cleaner down,

making it hard for your cleaner to climb due to the added weight and reduced water flow. This lack of climbing may limit your cleaner’s

ability to cover the entire pool and pick up any more dirt. Therefore, it is important to clean the Filter Bag thoroughly (see step 4 below)

with every use so that the fine particles that get trapped within the fibers of the Filter Bag are removed.

To Clean The Filter Bag:

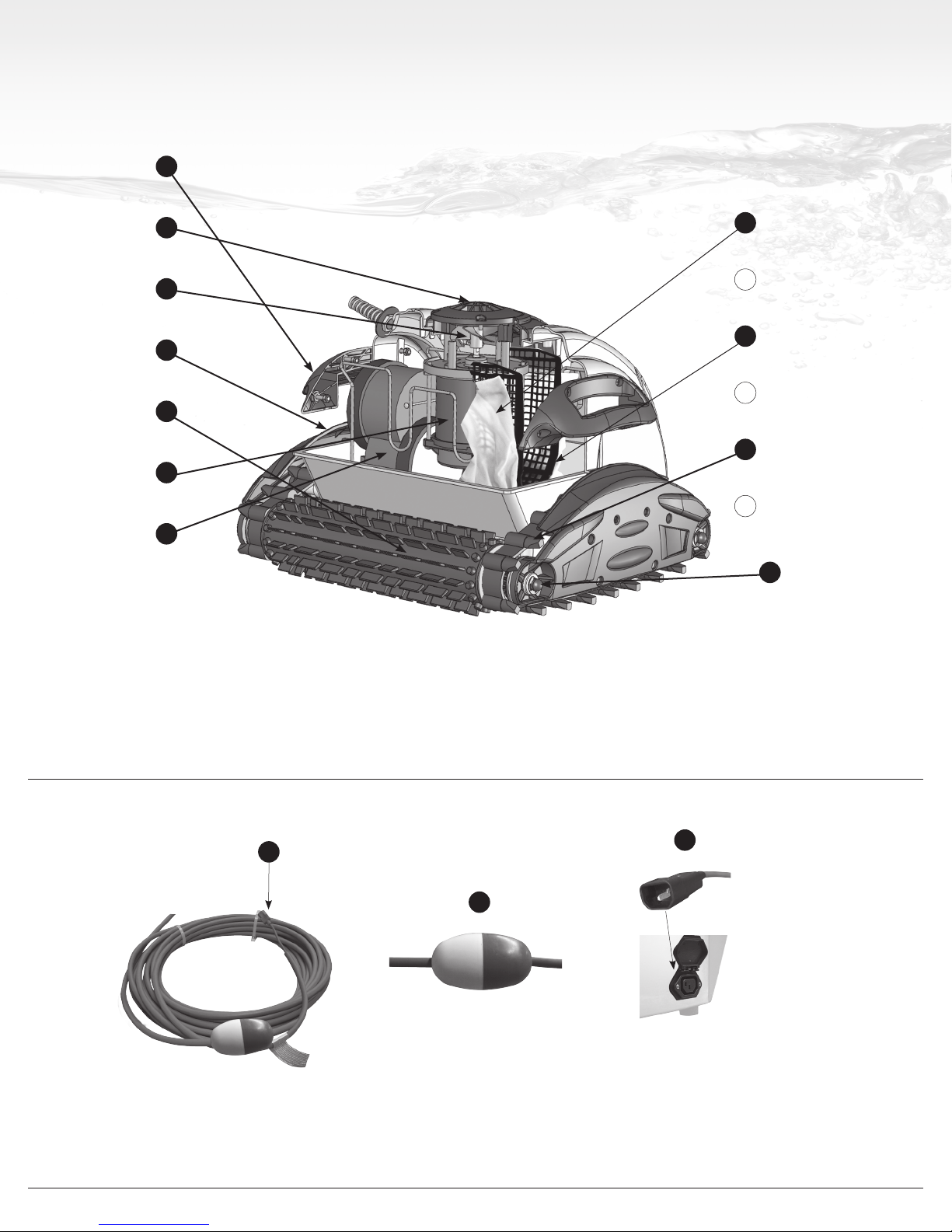

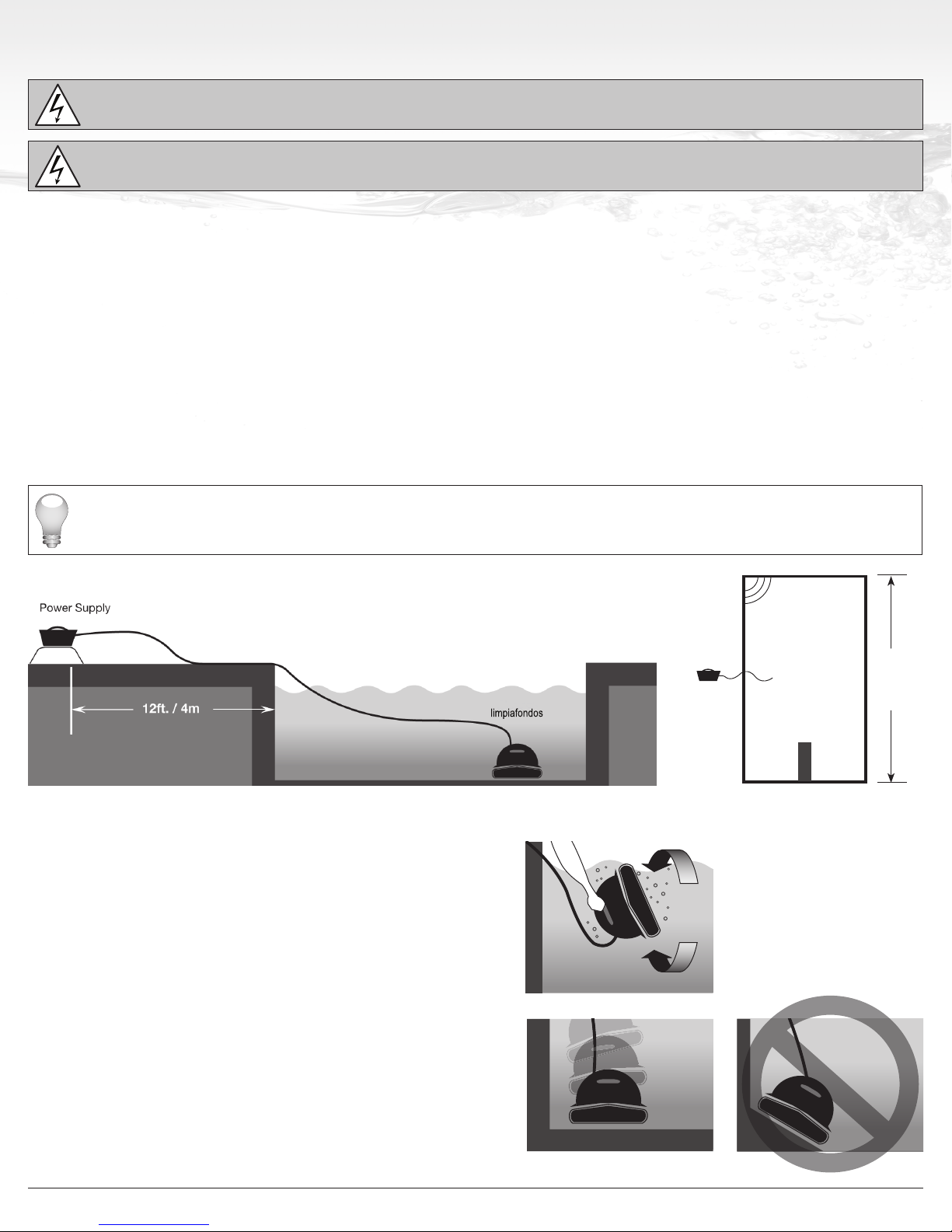

1. Unplug the Power Supply (Fig. 7a).

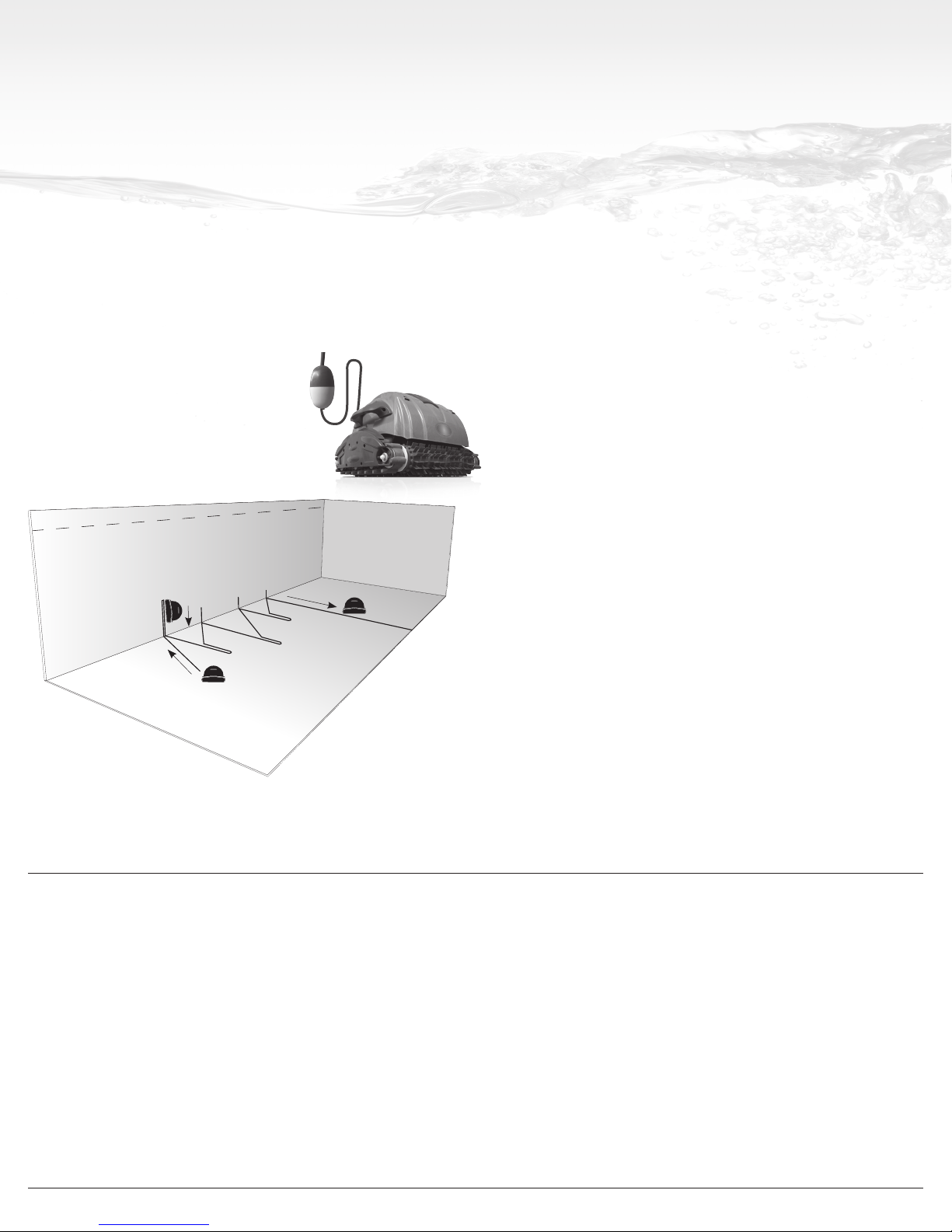

2. If your cleaner is in the pool, gently pull it toward you using

the Floating Cable (Fig. 7b) until the Handle is within reach.

Use the Handle (not the Floating Cable) to slowly pull your

cleaner out of the pool after allowing most of the water to

drain from your cleaner back into the pool.

IMPORTANT: Using the Floating Cable to lift the

cleaner out of the water will cause severe damage to

your cleaner and may result in costly repair!

Power Supply

GFCI / R.C.D.

outlet

Floating

Cable

Floating Cable Handle

3. Lay your cleaner on its back or side on a soft surface to avoid

scratching it. Individually pull each Lock Tab gently away

from your cleaner’s body to free the Bottom Lid (Fig. 8).

4. Remove the Filter Bag from the Wire Frame Bag Supports

(Fig. 9a), turn it inside out and with a high pressure garden

hose, wash off all the dirt from the inside out or dunk it in

a clean bucket of water and wring the Bag continuously

until the rinse water is clear. If necessary, you may machine

wash (Gentle Cycle / Cold Water only) the Bag with NO

DETERGENT. You may re-install the bag immediately or

allow it to air dry (never iron or machine dry the Filter Bag).

5. Re-install the Bag on the Wire Frames of the Bottom Lid

Assembly, making sure that the “felt” (soft) side of the Fine

Filter Bag is facing in. To ensure a proper fit of the Filter

Bag onto the Bottom Lid Assembly, locate the Small Label

near the Filter Bag’s elastic bottom. Position the Filter Bag

so that the Small Label is at the center of either long side of

the Bottom Lid (Fig. 9a). Then pull the elastic bottom over

each Wire (Fig. 9b) and slide the Filter Bag down along the

Wires until the Bag reaches the Bottom Lid. At that point

the Filter Bag’s elastic bottom should be stretched over the

plastic ridges located at the base of the Bottom Lid. This

holds the Filter Bag in place. Pull the Filter Bag corners to

the top corners of the Wire Frame and pull the extra Bag

material from each corner inwards along the top center of

the Wire Frames (Fig. 9b).

6. Re-install the Bottom Lid Assembly into the bottom of your

cleaner. Be sure that the Filter Bag’s fabric is not interfering

with the locking of the Lock Tabs and that you clearly hear

each Tab lock shut.

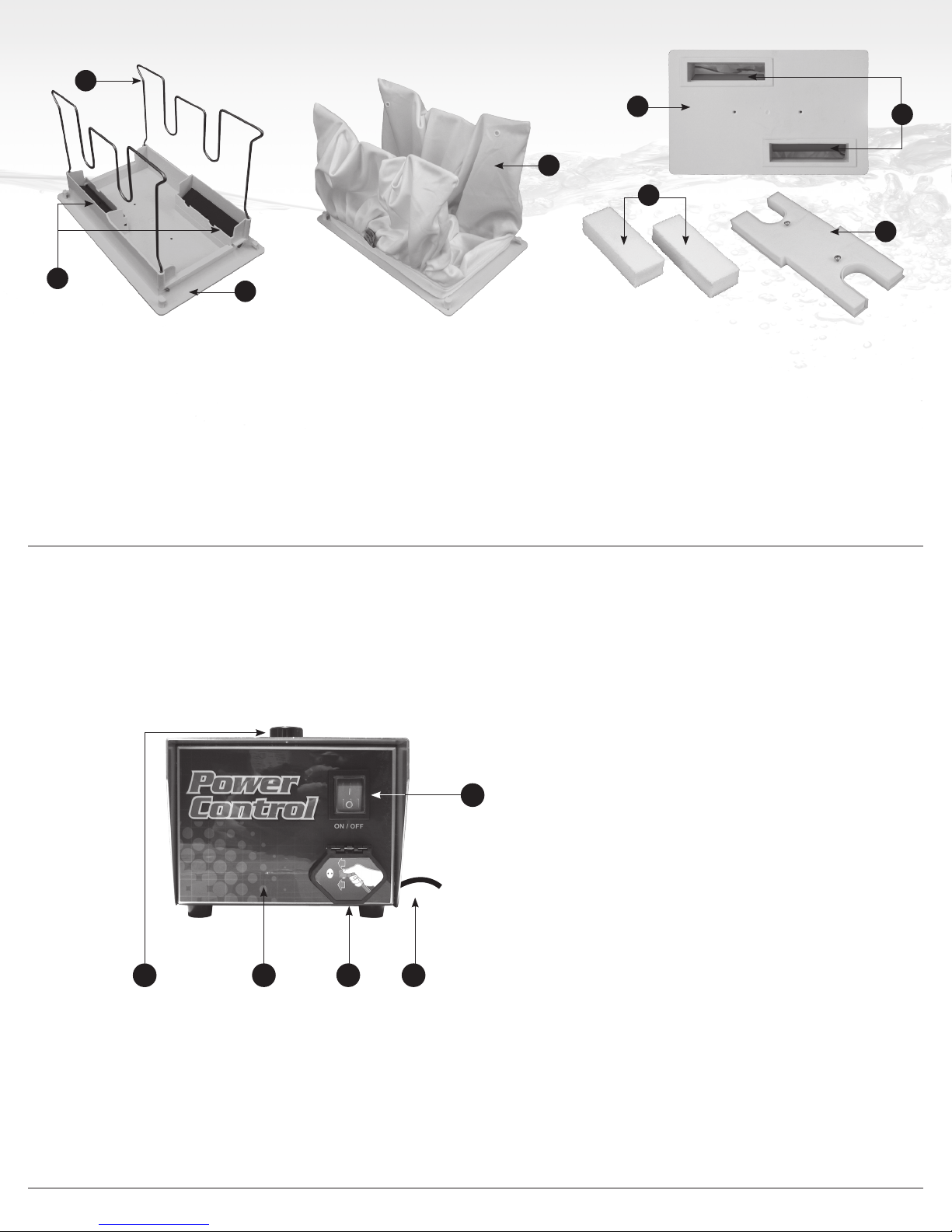

Figure 9bFigure 9a

Figure 8

Figure 7a

Figure 7b

Small Label

Wire Frame Bag

Support

Lock Tabs

Bottom Lid

Assembly

IMPORTANT: Although a Filter Bag may appear clean it is capable of microfiltering out particulates 20 times smaller

than what the naked eye can see! It is crucial to thoroughly clean the Bag with each use to ensure its ability to

properly cover and clean your pool!