3

ATEX Operating Manual DO50-DO90

AquaDuna GmbH & Co. KG / Ferdinand-von-Steinbeis-Ring 31 / 75447 Sternenfels / Germany

Telephone: +49 (0) 7045 204980 / www.aquaduna.com

Subject to technical modifications.

© Copyright by AquaDuna GmbH & Co. KG (2019) All rights reserved. Contact: www.aquaduna.com

Contents

1General information......................................................................................................4

1.1 Function ..............................................................................................................................4

1.2 Proper use ........................................................................................................................... 4

1.2.1 ATEX zone.........................................................................................................................................5

1.2.2 Component marking.........................................................................................................................5

1.2.3 Operating conditions........................................................................................................................6

1.2.4 Hazards............................................................................................................................................. 7

2Technical data...............................................................................................................8

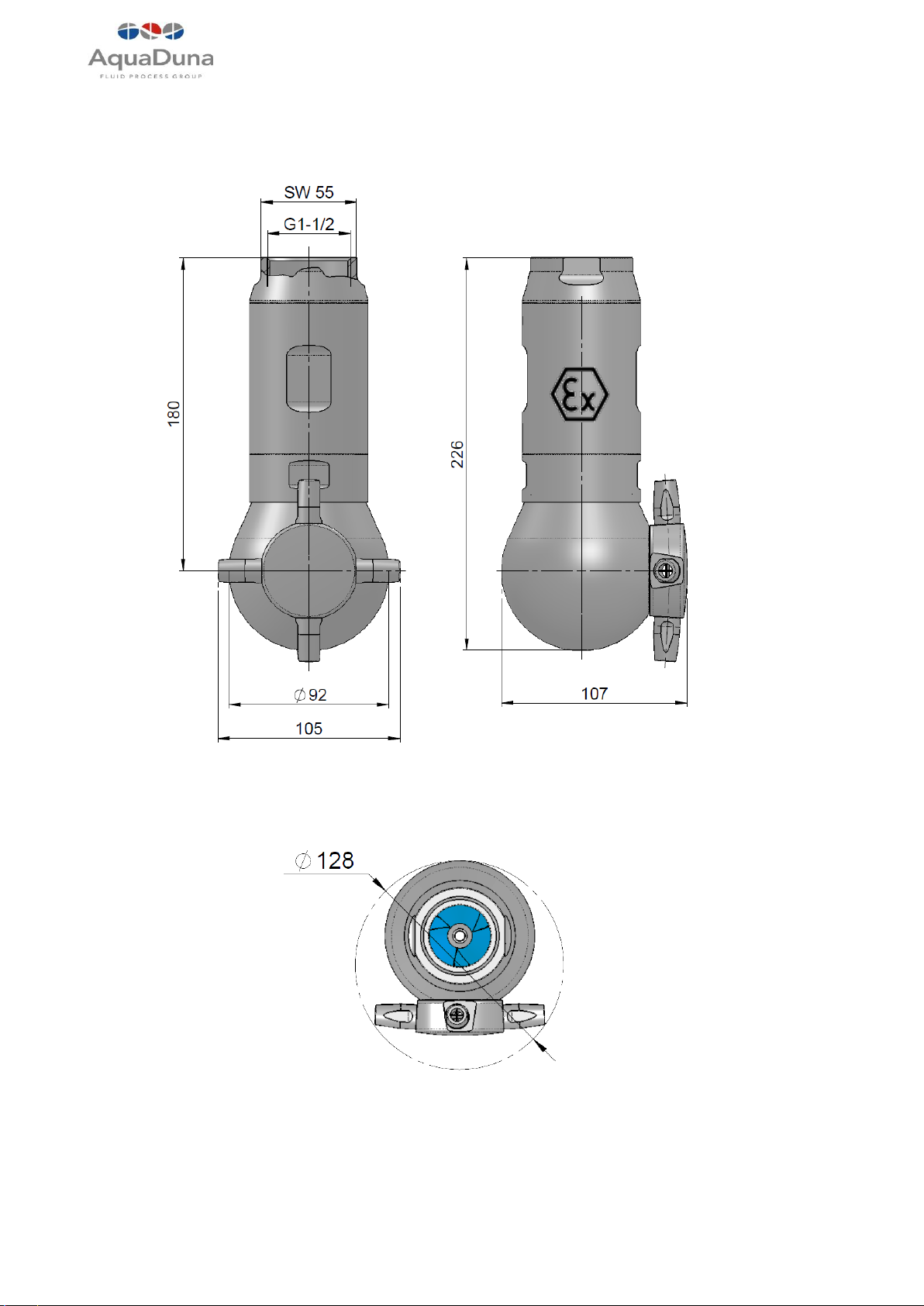

2.1 Measurements DO50 ........................................................................................................... 9

2.2 Measurements DO90 ......................................................................................................... 10

3Maintenance...............................................................................................................11

4Installation and commissioning ...................................................................................12

4.1 Installation of Ex target jet cleaners.................................................................................... 12

4.2 Assembly and operating personnel..................................................................................... 12

4.3 Commissioning................................................................................................................... 13

5Integration into a plant...............................................................................................14

5.1 Automatic control .............................................................................................................. 14

5.2 Manual control .................................................................................................................. 14

5.3 Emergency shutdown of the plant ...................................................................................... 14

6Transportation............................................................................................................15

6.1 Scope of delivery................................................................................................................ 15

6.2 Transportation and packaging ............................................................................................ 15

7Quality assurance .......................................................................................................15

8Disposal ......................................................................................................................16

9Annex .........................................................................................................................17

9.1 Symbols used..................................................................................................................... 17

9.2 Dunos O –Ex performance values....................................................................................... 18

10 EU Declaration of conformity ......................................................................................19

11 Masthead ...................................................................................................................20