1-10

Features

The Octopus 4000 incorporates several mecha-

nisms to protect your aquatic environment from

controller failure. For example, the controller is

engineered to overcome problems associated with

power fluctuations through the periodic re-sending of

control module commands to make sure that an X-

10 control is “latched” in the correct state.

Lighting System

The lighting system will support up to 16 indepen-

dent lighting times. Each channel has one ON and

OFF time per 24-hour period. With separate lighting

timers, there is a high degree of flexibility in setting

up your lighting system. See steps 4, 5, 17 and 22

for complete instruction.

System Hold

The H2O/S system hold software is a feature de-

signed to aid in the feeding of fish and invertebrates.

When the Octopus controller is put into feed mode,

all systems, except the Lighting and WaveMaker

systems, are shut down for a period of time selected

by the user. At the end of the specified time (user

selectable 0 to 60 minutes) all systems are turned

back on and will restart within 5 minutes. If desired,

the system hold option may be turned off by setting

the feed time to 0 minutes. The Octopus controller

will then no longer prompt you to enter the system

hold mode. See step 19 for complete instruction.

WaveMaker System

The H2O/S Dual Channel WaveMaker software

feature allows the Octopus 4000 to control two

independent wave or surge generation systems.

Each system supports two pumps which are driven

by Control Modules. The cycle time for each pump is

selected by the user, from 1-999 minutes (over 16

hours). See steps 4, 5, 18 and 22 for complete

instruction.

Alarm System

The H20/S alarm system software provides visual

and audible notification in the event that a monitored

parameter exceeds the user defined range. The

pager alarm system used in conjunction with a

modem provides remote alarm notification via a

digital pager. See steps 6 and 21 for complete

instruction.

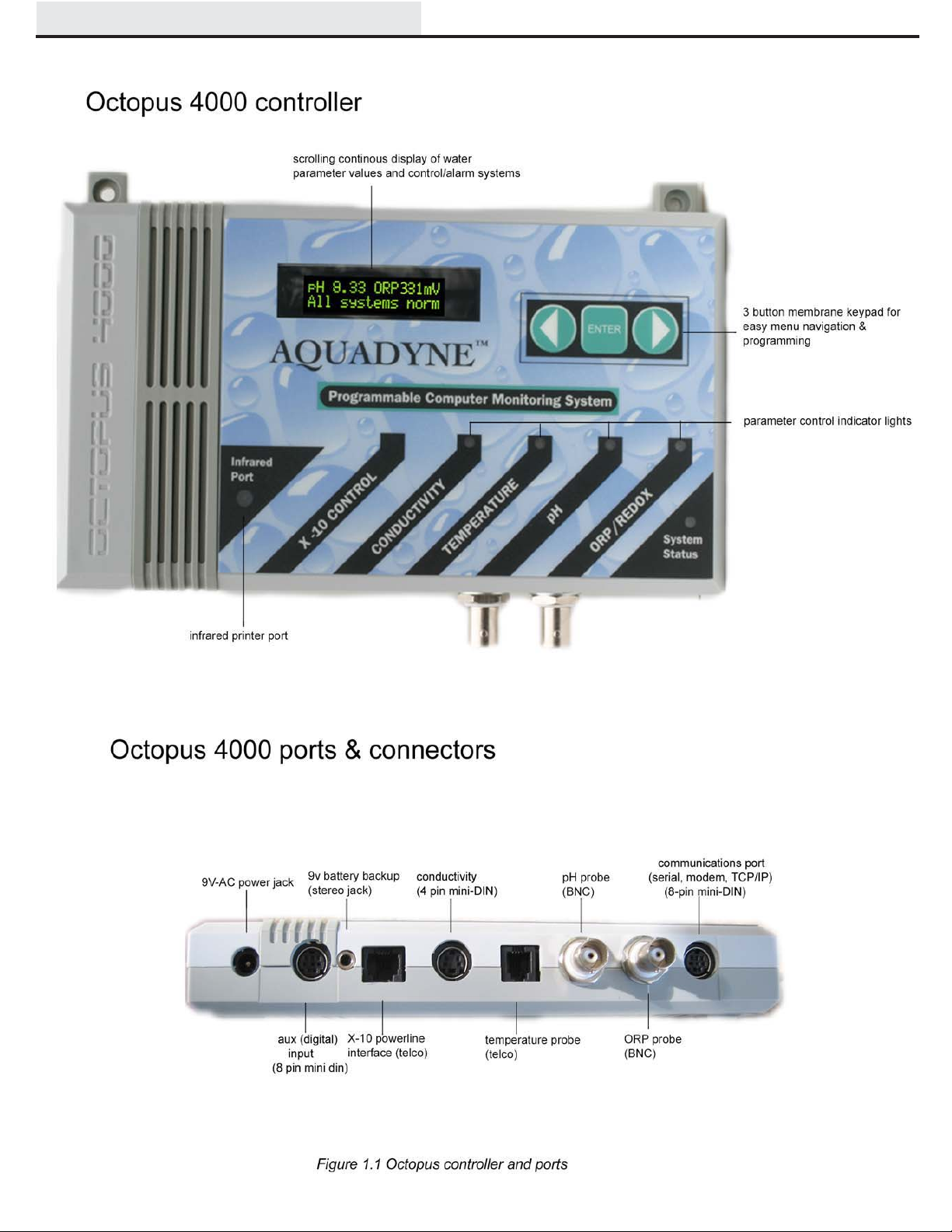

Infrared Printer Port

The infrared printer port located at the bottom left of

the face of the Octopus 4000 is standard. This port

provides access for the optional infrared datalog

reporting feature. Using the Infrared Printer data

collected by the Octopus 4000 can be printed out in

a variety of formats, including the current data, the

high and low points of data collected within the last

24 hours, 48 hours, or 1 week. Temperature, pH, and

ORP can be graphed. See #6 of the Operation And

Maintenance guide for additional information.