7

Step4: Upon completion of timer setting, hold for 5 seconds or wait 15 seconds to save

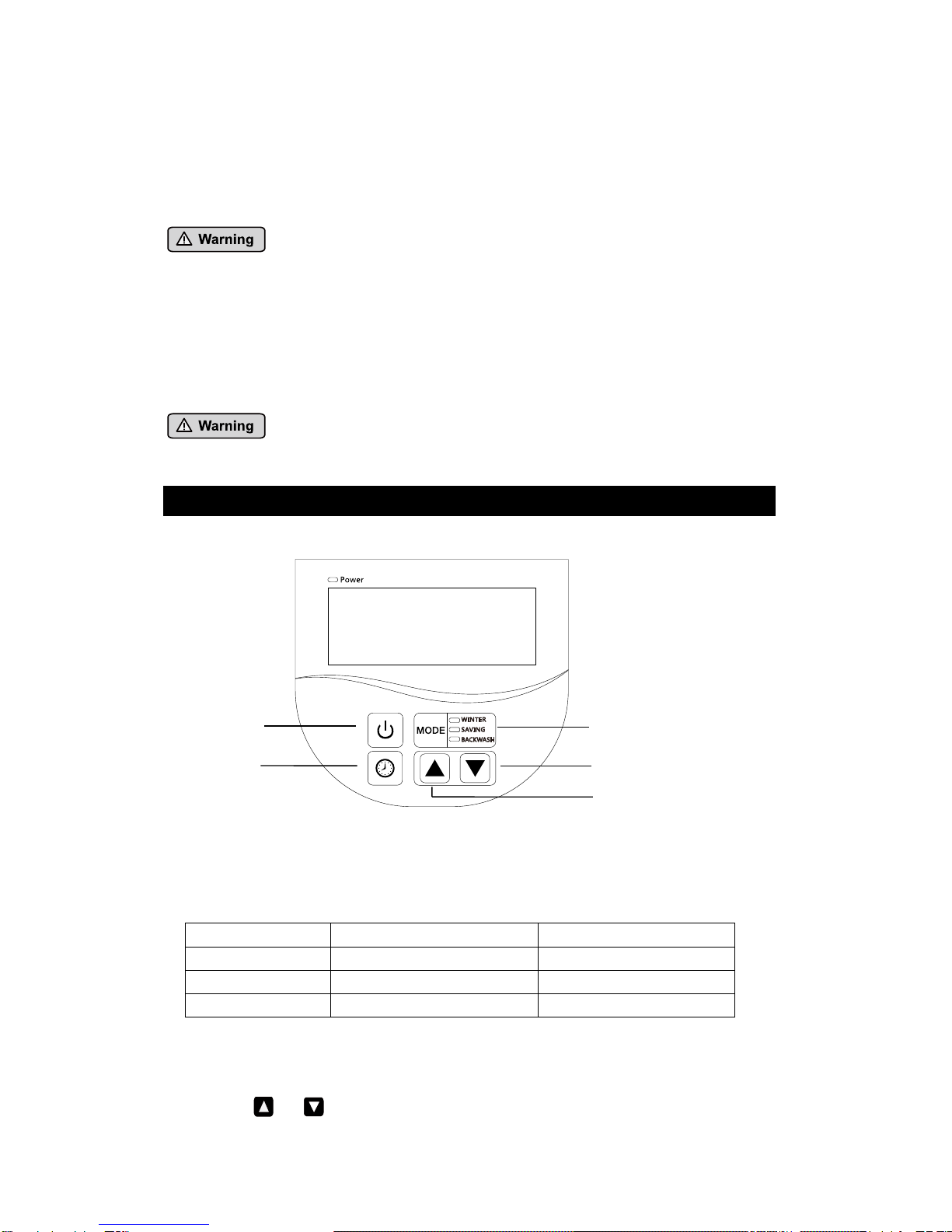

setting, device will operate accordingly based on setting. A flashing indicates

waiting for time to start, a flowing wave indicates a running status.

Step5: press or , to check 4 timers., make sure there is no invalid setting.

Please note:

a) Overlap setting of time will be considered as invalid, in case of invalid setting, the device

will only run based on previous valid setting.

b) During the process of timer setting, if you want to abandon timer setting, hold for 3

seconds.

c) In case of no further operation or setting after 1 minute, backlight will be off , to activate

backlight, press any button (including on/off button )

8.4 External on/off control

The on/off of frequency inverter can be controlled

from third party pool controls using potential

free contacts. See Fig.5 for connection. Fig 5

Under OFF mode, connect terminal 4 and 7 to enable external control, disconnect these two to

terminate external control.

Note: Even if it’s working via external control, Press on the frequency inverter can stop the

frequency inverter.

Do not apply voltage to these inputs.

8.5 Factory setting

Under OFF mode, hold for 5 seconds to retrieve factory setting .

Please note: The frequency inverter has power-off memory, it will resume operation /setting state

upon power restoration .

Note: When over heat occurs on ‘backwash’mode, a protection mechanism kicks in for auto self

protecttion, product will automatically switch from “backwash’mode to ‘saving’mode, when over

heat relieved, product will resume backwash mode.

9. PROTECION / ERROR CODE

When one of the following codes appears, frequency inverter will stop working, to resume