Table of Contents

Section Page

Specifications .................................................................................................... 1

1.0 Overview ........................................................................................................... 2

1.1 Unpacking and Inspection of the Instrument and Accessories ............. 2

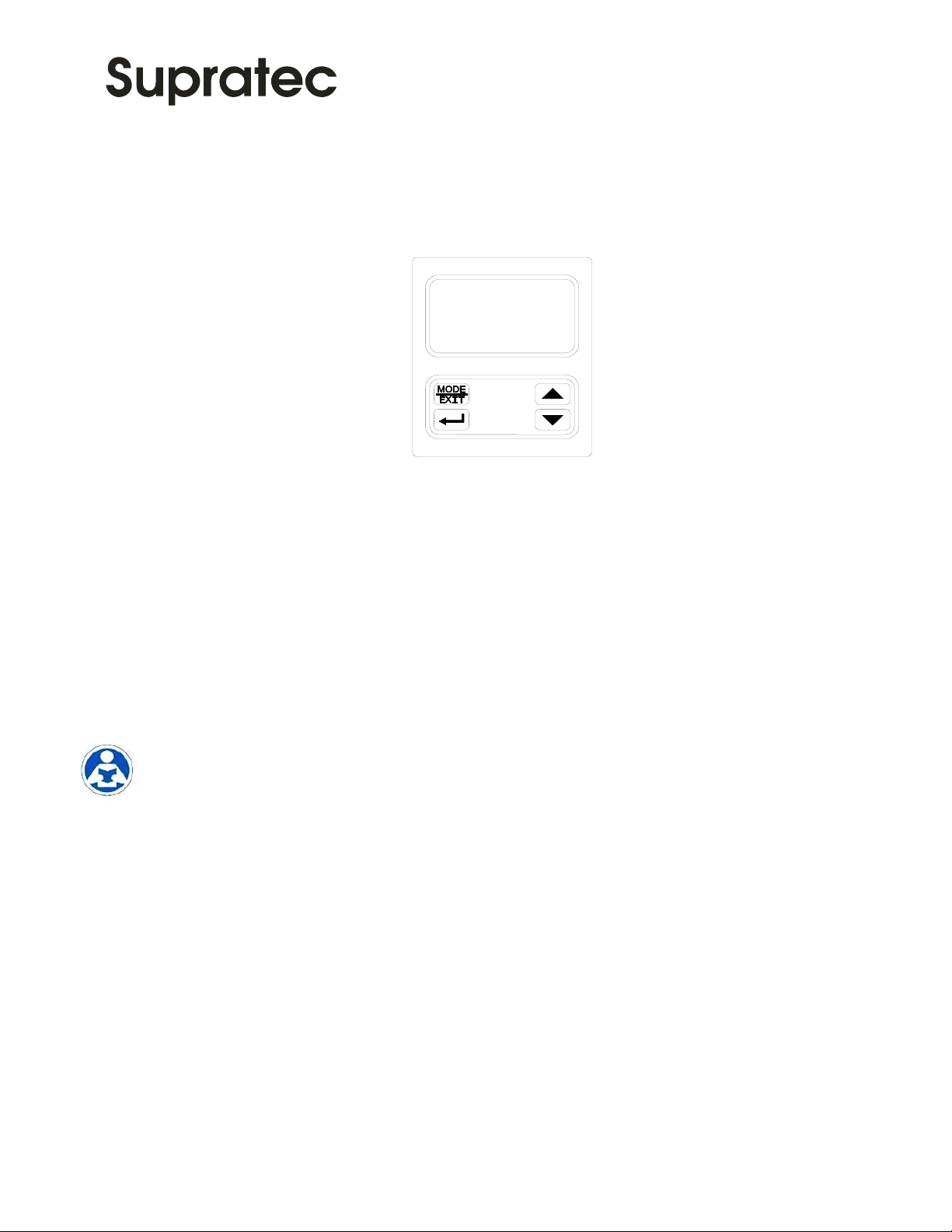

1.2 The Display .......................................................................................... 3

1.3 The Touch Pad ...................................................................................... 3

1.4 Vapor Purge........................................................................................... 3

2.0 Safety................................................................................................................. 3

2.1 Symbols Used in This Manual ............................................................. 4

3.0 Installation and Commissioning ....................................................................... 5

3.1 Mounting and Site Selection ................................................................. 5

3.2 Plumbing ............................................................................................. 6

3.2.1 Drain Vent ................................................................................. 7

3.2.2 Wetted Materials ....................................................................... 7

3.3 Electrical Connections .......................................................................... 7

3.3.1 Power ........................................................................................ 8

3.3.2 RS-485 ..................................................................................... 8

3.3.3 Relays ........................................................................................ 8

3.3.4 4-20 mA .................................................................................... 8

4.0 Operation .......................................................................................................... 9

4.1 Routine Measurement ........................................................................... 9

4.2 Security Access Feature ........................................................................ 9

5.0 Instrument Calibration .................................................................................... 10

5.1 Calibration Standards ......................................................................... 10

5.2 Calibration Procedures ....................................................................... 10

5.3 Calibration Error ................................................................................. 11

6.0 Instrument Offset ........................................................................................... 12

6.1 Indexing Calibration Cuvettes ............................................................ 13

6.2 Restoring Factory Settings .................................................................. 13

7.0 Instrument Configuration (CONFIG mode).................................................... 14

7.1 Selecting the Output (O/P) ................................................................. 14

7.2 Setting the 4-20 mA ............................................................................ 14

7.3 Configuring the Error Level ................................................................ 15

7.4 Configuring the RS-485 Port .............................................................. 15

7.5 Configuring the Alarms....................................................................... 16

7.5.1 Alarm 1.................................................................................... 16