Contents

1Safety Information ..................................................................................................... 5

1.1 Intended Use ...................................................................................................... 5

1.2 Statutory Obligations............................................................................................. 5

1.3 Electrical Safety .................................................................................................. 5

1.4 Installation Safety ................................................................................................ 6

1.5 Post-Installation Safety .......................................................................................... 6

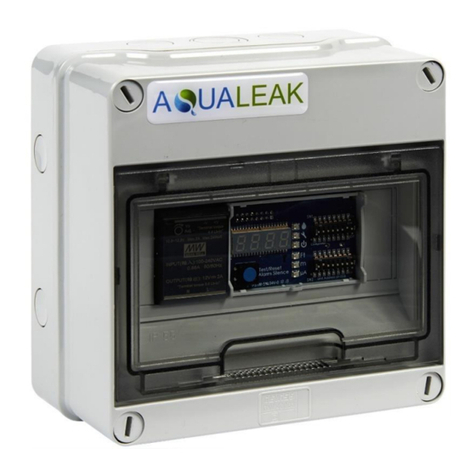

2Product Overview ...................................................................................................... 7

2.1 Technical Specifications ......................................................................................... 8

2.2 Input-Output Connections ....................................................................................... 9

2.3 Multiple Zone Application Example ........................................................................... 11

3Installation .............................................................................................................12

3.1 Master Panel Installation ....................................................................................... 12

3.1.1 Mounting ....................................................................................................... 12

3.1.2 Power Connection ............................................................................................ 12

3.2 Relays and Sensors .............................................................................................. 13

3.2.1 Relay Functions and Triggers ............................................................................... 13

3.2.2 Sensor Connections ........................................................................................... 14

3.3 Ancillary Devices................................................................................................. 18

3.3.1 Signalling to Ancillary Device ............................................................................... 18

3.3.2 12/24V Output to Ancillary Device ......................................................................... 18

3.3.3 230V Output to Ancillary Device............................................................................ 19

4Operation ...............................................................................................................20

4.1 Monitor Mode..................................................................................................... 21

4.2 Fault Mode........................................................................................................ 21

4.3 Alarm Mode....................................................................................................... 22

4.4 Override Mode ................................................................................................... 22

5Maintenance ...........................................................................................................23

5.1 Cleaning........................................................................................................... 23

5.2 Troubleshooting.................................................................................................. 23

6Warranty................................................................................................................24

Tables

Table 1: EMS-5 / 10 Technical Specifications ..................................................................... 8

Table 2: EMS-5 / 10 Input-Output Connections .................................................................. 10

Table 3: Relay Functions and Notes / Triggers .................................................................. 13

Table 4: Monitor Mode Button Inputs and Effects ............................................................... 20

Table 5: Monitor Mode Button Inputs and Effects ............................................................... 21

Table 6: Fault Mode Button Inputs and Effects .................................................................. 21

Table 7: Alarm Mode Button Inputs and Effects ................................................................. 22

Table 8: Override Mode Button Inputs and Effects.............................................................. 22

Table 9: Troubleshooting ........................................................................................... 23