Contents

1Safety Information .............................. 5

1.1 Intended Use ............................... 5

1.2 Statutory Obligations...................... 5

1.3 Electrical Safety ........................... 5

1.4 Installation Safety ......................... 6

1.5 Post-Installation Safety ................... 6

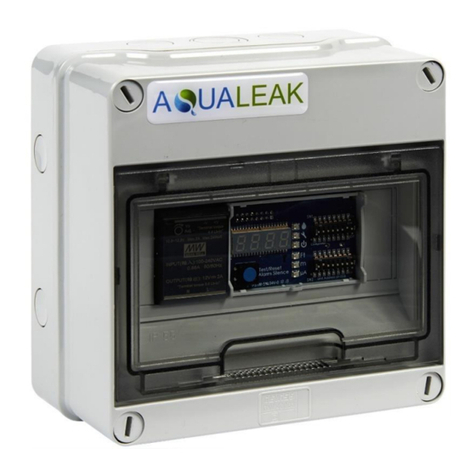

2Product Overview ............................... 7

2.1 Technical Specifications .................. 8

2.2 Input-Output Connections ................ 9

2.3 Multiple Zone Application Examples ...11

3Installation ......................................13

3.1 Master Panel Installation ................ 13

3.1.1 Mounting ................................ 13

3.1.2 Power Connection ..................... 13

3.2 Relays and Sensors .......................14

3.2.1 Relay Functions and Triggers ........ 14

3.2.2 Reboot Relay ........................... 14

3.2.3 Sensor Connections .................... 15

3.3 Ancillary Devices.......................... 19

3.3.1 Signalling to Ancillary Device ........ 19

3.3.2 12/24V Output to Ancillary Device .. 19

3.3.3 230V Output to Ancillary Device..... 20

3.4 Outstations ................................ 21

4Configuration ...................................22

4.1 USB Port....................................22

4.2 XML Configuration File ................... 23

4.2.1 Export to USB........................... 23

4.2.2 EMS Settings ............................ 24

4.2.3 User PIN Types and Numbers......... 25

4.2.4 Network Settings....................... 26

4.2.5 Modbus Settings........................ 27

4.2.6 Email Settings .......................... 30

4.2.7 Relay Settings .......................... 33

4.2.8 Interface Board and Outstation

Settings.................................. 36

4.2.9 Configuration File Installation ....... 37

4.3 Operating System Updates .............. 38

5Operation ........................................40

5.1 Master Panel LCD Touch Screen ........ 40

5.1.1 Summary Screen ....................... 40

5.2 User Menu ................................. 41

5.2.1 Date / Time ............................ 41

5.2.2 LCD Backlight .......................... 42

5.2.3 Live Zone Readings .................... 42

5.2.4 Alarm Log ............................... 43

5.3 Engineers Menu ........................... 44

5.3.1 Live Communications ................. 45

5.3.2 Relay Maintenance .................... 46

5.4 Alarms...................................... 47

5.4.1 Active Alarms .......................... 47

5.4.2 Mute Alarms ............................ 49

6Maintenance ....................................50

6.1 Cleaning.................................... 50

6.2 Relays ...................................... 50

6.3 Troubleshooting........................... 50

7Warranty.........................................51

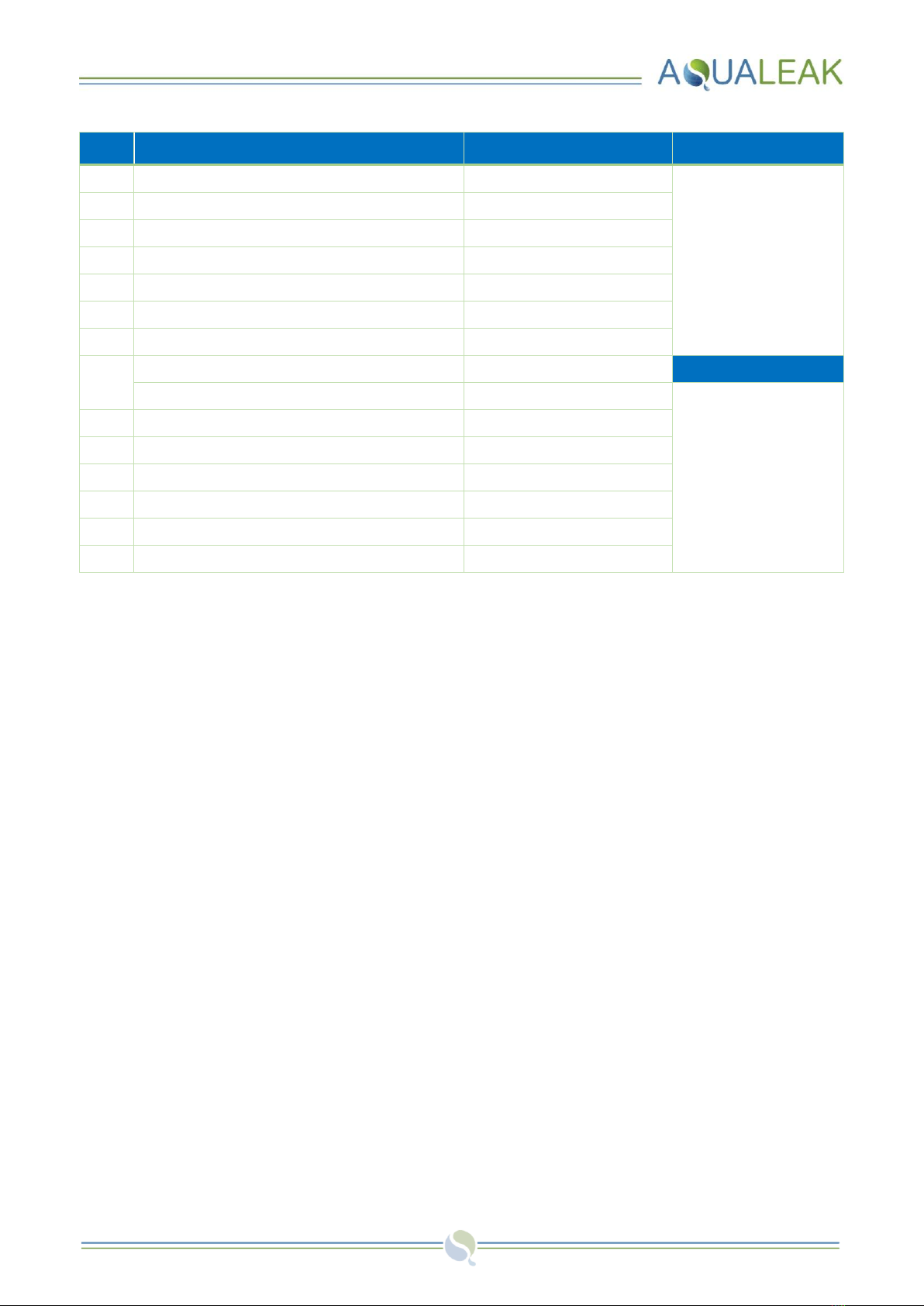

8Outstation Dip Switch Address Sheet.......52

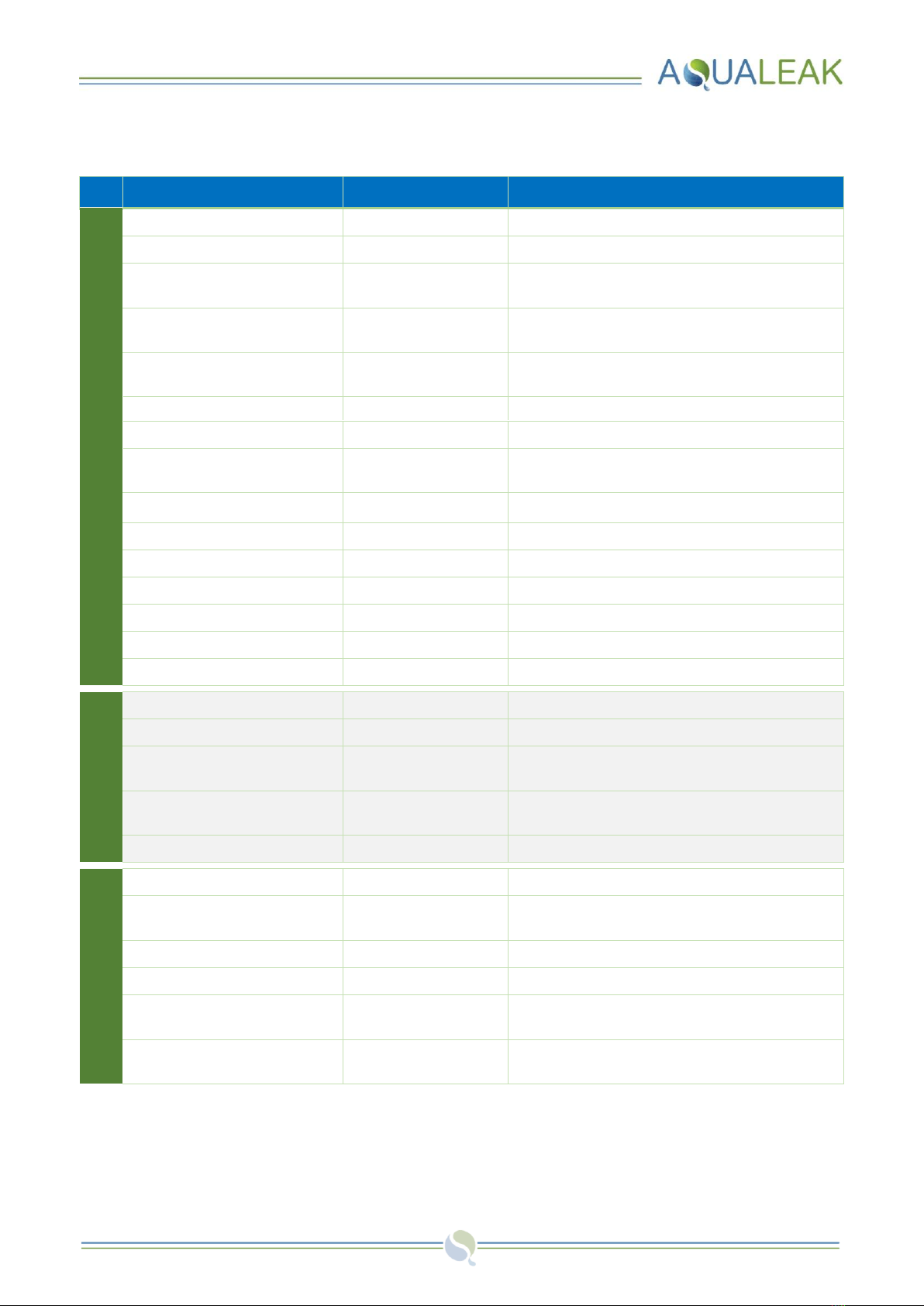

Tables

Table 1: EMS-5X, 10X and OS Technical

Specifications ........................... 8

Table 2: EMS-X / OS Input-Output Connections

........................................... 10

Table 3: Relay Functions and Notes / Triggers

........................................... 14

Table 4: EMS Configuration File Settings ..... 24

Table 5: User PIN Settings ...................... 25

Table 6: EMS Network Settings................. 26

Table 7: Register 0 Corresponding Replays and

Register 1 Corresponding Functions 27

Table 8: Modbus Ethernet/TCP Settings ...... 28

Table 9: Modbus Serial Link/RTU Settings.... 29

Table 10: Email Alert Settings ................... 30

Table 11: Email Summary Request Settings ... 32

Table 12: Relay 14 Settings ...................... 33

Table 13: Relay 1–10 Settings.................... 34

Table 14: Interface Board and Outstation

Settings ................................. 36

Table 15: Troubleshooting ....................... 50