Aqualisa ilux User manual

ilux Digital Bath with diverter installation instructions Page 1

ilux

Digital

Bat wit diverter

Installation guide

TM

ilux Digital Bath with diverter installation instructions Page 2

ilux Digital Bath with diverter

ilux Digital Bath with diverter

ilux Digital Bath with diverter installation instructions Page 3

Components (H /Combi)

iterature not shown.

Components (Gravity umped)

ilux Digital Bath with diverter installation instructions Page 4

Important information

Safety information

This product must be installed by a competent person in accordance with all relevant current Water Supply Regulations.

A PRODUCTS REQUIRING AN E ECTRICA CONNECTI0N MUST BE INSTA ED BY A QUA IFIED PERSON

FO OWING THE ATEST REVISION OF BS 7671 (WIRING REGU ATIONS) AND CERTIFIED TO CURRENT BUI DING

REGU ATIONS.

This system should be installed so that other taps or appliances operated elsewhere within the premises do not

significantly affect the flow.

The Digital bath must not be used with a hot water supply temperature of over 65ºC.

The processor is supplied factory pre-set at maximum temperature of 45ºC. The maximum temperature is fully

adjustable to suit site conditions. If adjusted, we recommend the outlet temperature is set to a MAXIMUM of 46ºC.

THE DIGITA PROCESSOR AND DIVERTER MUST BE INSTA ED IN AN ACCESSIB E OCATION FOR SERVICING AND

MAINTENANCE.

The Digital processor and diverter must not be installed in situations where either the ambient temperature is likely

to exceed 40ºC or where freezing may occur.

The control must not be installed in situations where the ambient temperature is likely to fall below 5ºC or rise above

40ºC.

We do not recommend the use of ilux Digital in steam therapy facilities.

This appliance must be earthed.

Cables which are chased into the wall must be protected by a suitably sized conduit or sheathing to allow for

removal in the event of service and maintenance purposes. Ensure that the conduit is run to avoid the controller

fixing holes.

Surface mounted cables must also be protected by a suitable approved conduit, even in a loft, where there may be

a risk of damage from vermin.

The power lead must only be replaced by the manufacturer or his accredited agent.

The user control is supplied from a safety low voltage source.

This product is suitable for domestic use only.

ilux Digital is supplied complete with a 5 year guarantee.

This product is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities or lack of experience and knowledge, unless they have been given initial supervision or instruction

concerning the use of the product by a person responsible for their safety.

Children should be supervised to ensure they do not play with the product.

Installation of Digital pumped processor (for gravity stored systems)

The ilux Digital pumped bath system is designed to operate up to a maximum static pressure of 100kPa

((1 bar)(10 metres head)(14.5psi)).

Under no circumstances must the pumped processor be connected directly to the water main or in line with another

booster pump.

The minimum actual capacity of the cold water storage cistern should be not less than 225 litres (50 gallons).

The capacity of the hot water cylinder must be capable of meeting anticipated demand.

ilux Digital Bath with diverter installation instructions Page 5

Installation of Digital standard processor (for balanced ig pressure and

unvented systems, combination boiler systems and separately pumped

gravity systems)

Pressures: The ilux Digital standard bath system is designed to operate up to a maximum static pressure of 700kPa

((7 bar)(100psi)). Where pressures are likely to exceed 700kPa ((7 bar)(100psi)), a pressure reducing valve must be

fitted to the incoming mains supply. A setting of 400kPa ((4 bar)(60psi)) is recommended. It should be noted that

daytime pressures approaching 600kPa ((6 bar)(80psi)) can rise above the stated maximum overnight.

Special notes for combination boiler systems

The appliance must have a minimum domestic hot water rating of 24kW (80,000BTU) and be of the type fitted with a

fully modulating gas valve. If in any doubt, please contact the appliance manufacturer before installation commences.

P EASE NOTE: DUE TO PERFORMANCE CHARACTERISTICS OF COMBINATION BOI ERS, SEASONA IN ET TEMPERATURE

CHANGE WI AFFECT THE PROCESSOR OUT ET F OW RATE RESU TING IN VARYING BATH F OW RATES AND F OWCONTRO

RANGE. THIS WI AFFECT PRE-SET DEPTH EVE S. IN ET TEMPERATURE CHANGE MAY A SO CAUSE THE TEMPERATURE ED’S

TO F ASH; THIS IS NOT NECESSARI Y CHANGING THE OUT ET TEMPERATURE.

Special notes for separately pumped gravity systems

We recommend a twin ended pump with a MINIMUM pump rating of 1.5 bar. For optimum performance a twin

ended 2.5 bar pump should be used.

The minimum actual capacity of the cold water storage cistern should be not less than 225 litres (50 gallons). The

capacity of the hot water cylinder must be capable of meeting the anticipated demand.

THIS PRODUCT IS NOT SUITAB E FOR USE WITH A SING E ENDED PUMP.

Connections

This product incorporates ‘push fit’ type connections. Tube should be cut using a rotary type cutter and lubricated

using a silicone-based lubricant or petroleum jelly (Vaseline or similar) prior to insertion into the fitting.

If plastic pipe is used, the tube insert must not increase the tube diameter or extend the cut-off length by more than

2mm.

TO MAXIMISE F OW RATES WE RECOMMEND USING COPPER PIPE WITH THE MINIMUM AMOUNT OF E BOWS. THESE

FITTINGS ARE NOT SUITAB E FOR STAIN ESS STEE TUBE.

Pipe sizing

ong pipe runs, on both inlet and outlet, will reduce the flow rate at the bath outlet or shower head. If long pipe runs

are unavoidable, use copper pipe rather than plastic. If plastic pipe is used, minimise the number of elbows as the

pipe inserts are very restrictive, consideration should be given to using 22mm plastic or copper pipe.

Flushing

Some modern fluxes can be extremely corrosive and, if left in contact, will attack the working parts of this unit. All

soldering must be completed and the pipe work thoroughly flushed out in accordance with current Water Supply

Regulations prior to connection of the product.

After installation

Familiarise the end user with the ilux Digital operation and hand them this guide. Complete and post the guarantee

card or register online at www.aqualisa.co.uk

ilux Digital Bath with diverter installation instructions Page 6

Installation instructions

70mm

90mm

445mm

270mm

350mm

265mm

To ensure safe operation and installation of this product, the processor and the Digital di-

verter MUST be installed in one of the orientations shown.

1

This product must be installed by a competent person in accordance with the relevant

current Water Supply Regulations.

In addition to the guide below it is essential that the written instructions overleaf are

read and understood and that you have all the necessary components (shown

overleaf) before commencing installation.

!

The ilux Digital Bath system is supplied with universal fixings intended to secure it to

a suitable wall.

!

!

Please note the orientations match the processor orientations and are shown on the

Digital diverter valve label.

!

197 mm

240 mm

70 mm

ilux Digital Bath with diverter installation instructions Page 7

Processor connected to diverter with

additional pipe

Processor connected to diverter with

additional pipe

Processor connected directly

to diverter valve

Processor connected directly to

diverter valve

H /Combi processor

IMAGES SHOWN ARE AERIA VIEWS AND ARE FOR I USTRATIVE PURPOSES ON Y.

!

Gravity umped processor

Isolation valves are supplied with the Digital

processor and diverter valve and must be fitted on

both inlets and the blended water outlets. All

pipe work should be run in 15mm pipe. All pipe

work should be supported. For externally pumped

gravity fed installations, 22mm pipe work should

be run as close to the processor as possible before

reducing down to 15mm.

2

The inlet supply centres are 48mm. The inlet supply centres deviate from EN1111

and EN1287, but are deemed to be a special case.

Please note arrow on isolation valve to indicate direction of flow.

Compression fittings should not be used on the inlet and outlet spigots and may

affect the warranty if fitted.

!

ilux Digital Bath with diverter installation instructions Page 8

Choose the position for the Digital processor as close to the Digital diverter as

possible, within range of the 2m connecting data cable provided. The Digital

processor and diverter assembly must be sited as close to the bath controller as

possible, within range of the 10m data cable provided for connecting the processor to

the controller. The processor and diverter may be sited in the roof space above the

proposed bath site, in the airing cupboard or behind a screwed bath panel if more

convenient. If siting in the roof space, ensure that freezing cannot occur and that no in-

sulation material is placed under or over the processor and diverter.

Please refer to the system layout diagrams overleaf.

3

!THE PROCESSOR AND DIVERTER MUST BE SITED IN A POSITION THAT IS SAFE Y AC-

CESSIB E FOR SERVICING AND COMMISSIONING PURPOSES. WHEN FITTED IN THE

OFT SPACE, THE ROUTE TO AND THE AREA AROUND THE PROCESSOR MUST BE

BOARDED TO ENSURE A SAFE WORKING ENVIRONMENT.

The optimum position for the Digital processor and diverter is in the roof space above

the bath site to take full advantage of the ease and speed of installation - please refer

to the note above.

The distance between the Digital processor and bath control must be within range of the

10m data cable supplied.

The Digital diverter valve inlet has been designed to enable connection directly inline

with the HP/Combi Digital processor outlet isolation valve connection or off the Gravity

Pumped Digital processor outlet using the cranked elbow connection fitting.

The distance between the Digital diverter valve and processor must be within the

2m range of the patch lead data cable connection provided.

ilux Digital Bath with diverter installation instructions Page 9

Place the Digital processor and diverter valve on a solid

mounting surface, and place the fixing feet into suitable

positions. Mark then drill and prepare suitable fixings be-

fore securing the processor and diverter to the mounting

surface using the screws provided, if suitable.

4

Flush through both hot and cold supply pipes.

5

The maximum hot water inlet temperature must be no more than 65˚C.

!

Attach the supply pipes to the Digital processor,

ensuring that the cold and hot feeds are fitted into

the appropriately marked inlets.

6

DO NOT SO DER NEAR TO P ASTIC COMPONENTS.

!

Prepare and run a pipe from the mixed water outlet on the Digital processor through to the

Digital diverter inlet. (The Digital diverter can be fitted directly onto the processor outlet if

required on the HP/Combi system installation. A cranked elbow is supplied for the Gravity Pumped

system for ease of installation. Refer to aerial view images in instruction 1).

7

ilux Digital Bath with diverter installation instructions Page 10

Depress the fixing clip at the end of the controller assembly and

carefully pull the controller away from the mounting plate.

10

Connect the mixed water outlet pipe from the Digital processor to the

inlet pipe on the Digital diverter ensuring the isolation valves are

connected to the diverter valve outlet, with the arrows correctly aligned

according to the direction of flow. Using pipe clips as appropriate,

ensure that all pipe work is perpendicular to the Digital

processor and Digital diverter, i.e. not putting any strain on the

fittings.

8

TO ENSURE OPTIMUM PERFORMANCE USE THE MINIMUM AMOUNT OF E BOWS ON A PIPES

EADING TO AND FROM THE DIGITA PROCESSOR AND DIGITA DIVERTER.

TO MAXIMISE F OW RATES WE RECOMMEND USING COPPER PIPE WITH THE MINIMUM AMOUNT

OF E BOWS ON A PIPES EADING TO AND FROM THE DIGITA PROCESSOR AND DIGITA

DIVERTER.

!

Prepare and run the pipes to the proposed siting for the bath outlet and shower hose connection,

depending on the accessories purchased. Ensure the pipe work connections have been flushed

through.

9

If fitting a bath outlet, a suitable non restrictive double check valve (not supplied) MUST be fitted to

the blended outlet pipe in line with current Water Supply Regulations.

!

Place the bath control mounting plate onto the finished wall surface

in the desired location and mark the fixing and data cable entry points.

11

!

ilux Digital Bath with diverter installation instructions Page 10

Drill and prepare suitable wall fixings for the two mounting plate screws. Drill a 16mm hole at the

appropriate position as previously marked within the lozenge for the data cable, ensuring there is

sufficient room for the data cable and connector.

12

13

Hook the left side of the controller into position, then carefully click

the controller into place.

15

Connect the data cable to the rear of the controller.

14

To remove the controller from the mounting plate,

depress the fixing clip on the right hand rear edge

of the controller and carefully remove the controller assembly away from the mounting plate

and set aside.

!

Apply a thin bead of mastic to the mastic groove at the rear of the

mounting plate. Secure the mounting plate to the wall using the

screws provided, if suitable.

ilux Digital Bath with diverter installation instructions Page 11

Installation instructions – Bath with diverter

Unscrew the single fixing on top of the

processor and Digital diverter box and carefully

tilt the lids up and off the location lugs and pull

the lids clear.

16

17 Connect the 10m low voltage data cable into

the socket adjacent to the temperature adjuster

as indicated on the label. Feed the cable out of

the processor box ensuring it is correctly routed

within the data cable channel.

The processor secondary socket MUST be used to connect the processor to the

diverter valve. This is located next to the processor main socket and is accessed

by carefully snapping and removing the entry pillar.

!

BEFORE ANY E ECTRICA ADJUSTMENT IS ATTEMPTED, THE E ECTRICITY

SUPP Y MUST BE TURNED OFF AT THE MAINS SWITCH.

E ECTRICA INSTA ATION MAY ON Y BE CARRIED OUT BY A QUA IFIED

PERSON.

!

ilux Digital Bath with diverter installation instructions Page 12

A secondary remote

control is supplied.

This connects wirelessly

to the main controller.

!

Connect the 2m low voltage patch lead to

both the diverter valve and secondary socket

on the processor box. Feed the cable out of the

processor and diverter ensuring it is correctly

routed within the data cable channel.

18

2m patch

lead data

cable

Bath divert

controller

with 10m

data cable

ilux Digital Bath with diverter installation instructions Page 13

Connect the processor power lead to a double

pole 3 amp fuse switched spur incorporated in

the fixed wiring circuit, in accordance with

current wiring rules. Ensure that this is located in

an accessible, dry location and not in the

bathroom.

19

THIS APP IANCE MUST BE EARTHED

We recommend protecting surface mounted cables in suitable approved

conduit to avoid the risk of damage from vermin.

The data cable and power lead should also be clipped in place with ‘P’ clips

or similar to avoid accidents.

!

The Digital processors are supplied factory set

with the flow rate at either ‘NORMA HP’ or

‘NORMA GRAVITY’ mode depending on which

bath system has been ordered.

STANDARD ROCESSORS ON BALANCED

H SYSTEMS:

Standard processors fitted to balanced high

pressure systems may be set to ‘NORMA HP’ or for water economy ‘ECO’ modes.

N.B. As ‘ECO’ mode can be achieved by the ilux Digital controller,

we recommend the processor is set to ‘NORMA HP’ mode.

STANDARD ROCESSORS ON COMBINATION BOILER SYSTEMS:

For Standard Digital processors installed on combi boiler systems, for optimum

performance we recommend setting the flow rate to the ‘COMBI’ mode.

20

N.B. The ‘ECO’ flow rate mode should not be selected for bath systems

fitted to combination boilers.

UM ED ROCESSORS:

Pumped processors fitted to gravity systems may be set to ‘NORMA

GRAVITY’ or for water economy ‘ECO’ flow rate modes.

N.B. As ‘ECO’ mode can be achieved by the ilux Digital controller,

we recommend the processor is set to ‘NORMA GRAVITY’ mode.

WHEN MAKING ANY ADJUSTMENT TO THE PROCESSOR SETTINGS

THE POWER MUST BE ISO ATED.

!

!

!

!

ilux Digital Bath with diverter installation instructions Page 14

Re-instate the electricity supply to the processor and press the ‘Start/Stop’

button on the controller to turn the bath on.

21

Run the bath at maximum temperature

(factory pre set to 45

0

C). If required, maximum

temperature adjustment can be made with a

flat bladed screwdriver using the ‘MAX TEMP

ADJUSTMENT’ control as indicated. When the

temperature has been set to the desired

position, carefully replace the Digital processor

lid and secure the fixing hand tight only.

22

Site conditions can affect temperature settings, installer to adjust as required.

A COPPER PIPE WORK MUST BE CROSS-BONDED AND CONNECTED TO A

RE IAB E EARTHING POINT.

!

Please refer to the separate ilux range user guide for full product operating

instructions.

!

Aqualisa Products imited

The Flyer’s Way

Westerham Kent TN16 1DE

Customer helpline: 01959 560010

Brochure Hotline: 0800 652 3669

Website: www.aqualisa.co.uk

Email: [email protected]

Republic of Ireland

Sales enquiries: 01-864-3363

Service enquiries: 01-844-3212

Part No:700539 Issue 01 Nov 12

Please note that calls may be recorded for training and quality purposes

The company reserves the right to alter, change or modify the product specifications without prior warning

® Registered Trademark Aqualisa Products imited

T e Waste Electrical and Electronic Equipment (Producer Responsibility) Regulation 2004

This product is outside the scope of the European Waste Electrical and Electronic Equipment Directive as interpreted within the UK.

In the UK this product can therefore be disposed of through commercial non-WEEE waste facilities.

The original manufacturer does not accept any liability under the WEEE directive.

Other manuals for ilux

1

Table of contents

Popular Home Automation manuals by other brands

LIVICOM

LIVICOM Livi Smart Hub manual

Inovelli

Inovelli Show Home ZW37 manual

NEROXDOMO

NEROXDOMO PULSE 45 installation manual

Cooper Lighting

Cooper Lighting Greengate NeoSwitch ONW-D-1001-MV-W installation instructions

Intesis Software

Intesis Software IntesisHome TO-RC-WIFI-1 installation guide

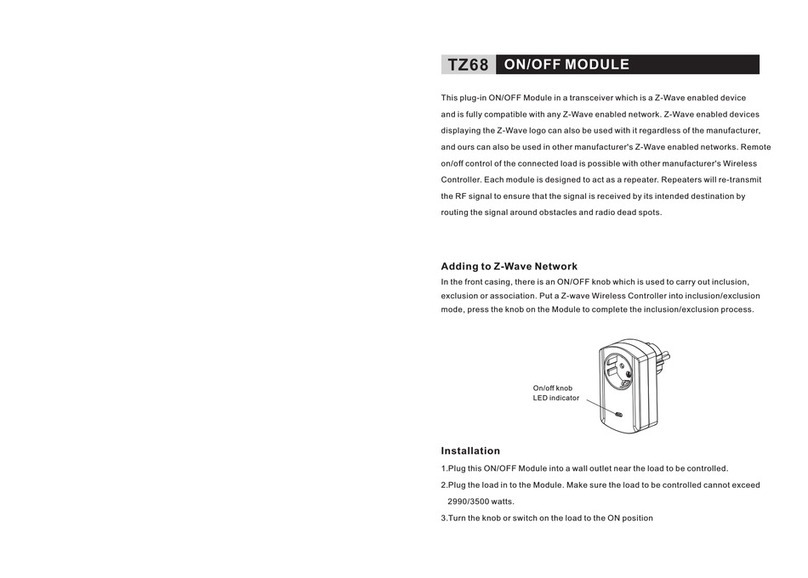

TKB Home

TKB Home TZ68 manual