3

COVER SAFETY

Sources: Drowning Prevention Society; United States Consumer Product Safety Commission; Association

of Pool & Spa Professional’s Operation Water Watch; and the American Academy of Pediatrics.

Child Monitoring Devices: www.safetyturtles.com

You can find other safety tips at: www.firstgov.com input ‘pool safety’ in the search engine.

A swimming pool can provide your family with hours of entertainment and the opportunity for

healthy recreation. As a pool owner, be aware that you must secure your child’s safety. There is a risk

of a child drowning when around any body of water. There is no substitute for constant adult supervision.

Most drowning occurs during a five minute or less lapse in supervision. By providing barriers between

your child and the pool, you can avoid a tragic accident should your child momentarily slip out of sight.

Don’t rely on one system - laying safety precautions provides the strongest safeguard.

Never leave a child alone - not even for a second.

Maintain constant eye contact with your children when they are in and around the pool.

Do not consider young children water-safe because they have had swimming lessons.

Instruct baby-sitters about the potential hazards to young children in and around swimming pools and

the need for constant supervision.

Train all caretakers in life-saving, cardiopulmonary resuscitate and first aid. No exceptions.

Install a telephone pool side with emergency numbers posted.

Keep toys away from the pool when the pool is not in use. They can lure a child into the pool.

Use inflatable toys only under adult supervision. They may deflate or your child may slip off.

Post and enforce rules such as No Running, No Pushing, No Dunking, and Never Swim Alone.

Make sure you have a rescue devices accessible pool side.

Keep all doors and windows leading from the house to the pool area secure. Install self-closing

mechanisms on doors.

Enclose the pool with a barrier. In fact, fencing may be required in certain areas. Check with local

city or county building code for more information.

Install only child-proof, self-closing, self-latching gates around the pool.

Vertical bars on a pool fence should be no more than three-and three-fourths inches apart. Avoid

fences such as chain link that provide footholds for the little climber’s feet.

Place table and chairs well away from the pool fence to prevent children from climbing in the pool area.

Alert your pool maintenance people, utility personnel, and your neighbors to keep cover, gates doors

to pool closed and locked at all times.

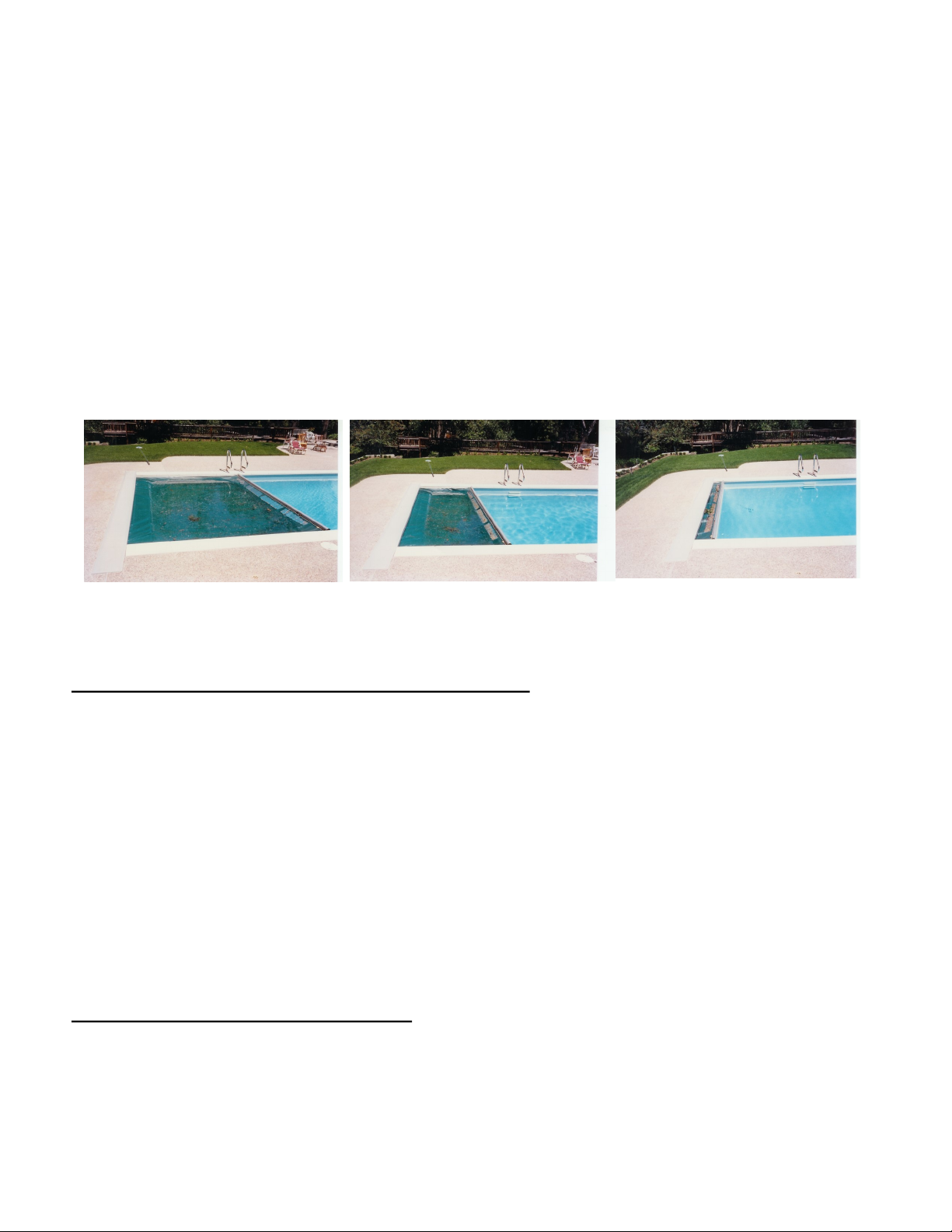

Check to ensure that spa and pool covers pass minimum safety requirements set by the American

Society of Testing Materials, ASTM F1346-91.

Never use a pool with its cover partially in place since children may become trapped under it.

Beware of a free-floating pool cover. A child can slip beneath one unnoticed.

Realize that a child can drown in as little as two inches of water. Remove any standing water off of

your spa or pool cover.

Investigate using a pool alarm and/or a monitoring system that can be worn by a child.

No objects should be in the pool area for a child to climb on and into the water.

Inspect safety and pool equipment regularly. Preventive devices are only effective if they are in proper

working order.