2 VCS – Viscosity Controller

Content

1Introduction.................................................................................................................................. 3

1.1 Liability disclaimer ...............................................................................................................................................................................3

1.2 Safety precautions...............................................................................................................................................................................3

1.3 Receiving and storage requirements...........................................................................................................................................4

2Application.................................................................................................................................... 4

2.1 Description of Viscosity Controller ...............................................................................................................................................4

3Controller installation / implementation................................................................................... 5

3.1 General.....................................................................................................................................................................................................5

3.1.1 Planning ............................................................................................................................................................................................6

3.1.2 Installation........................................................................................................................................................................................7

3.1.3 Electrical wiring ..............................................................................................................................................................................8

4Controller operation .................................................................................................................... 8

4.1 Putting into operation .......................................................................................................................................................................8

4.2 Display and operation level .............................................................................................................................................................9

4.3 Display operating status (VC622/722 only)...............................................................................................................................9

4.4 Parameter settings level.................................................................................................................................................................10

4.5 Configuration level...........................................................................................................................................................................11

4.6 Manual optimization ....................................................................................................................................................................... 14

5Maintenance and repair............................................................................................................. 15

5.1 Calibration ........................................................................................................................................................................................... 15

5.2 Service maintenance........................................................................................................................................................................ 15

5.3 Spare parts .......................................................................................................................................................................................... 16

6Troubleshooting ......................................................................................................................... 17

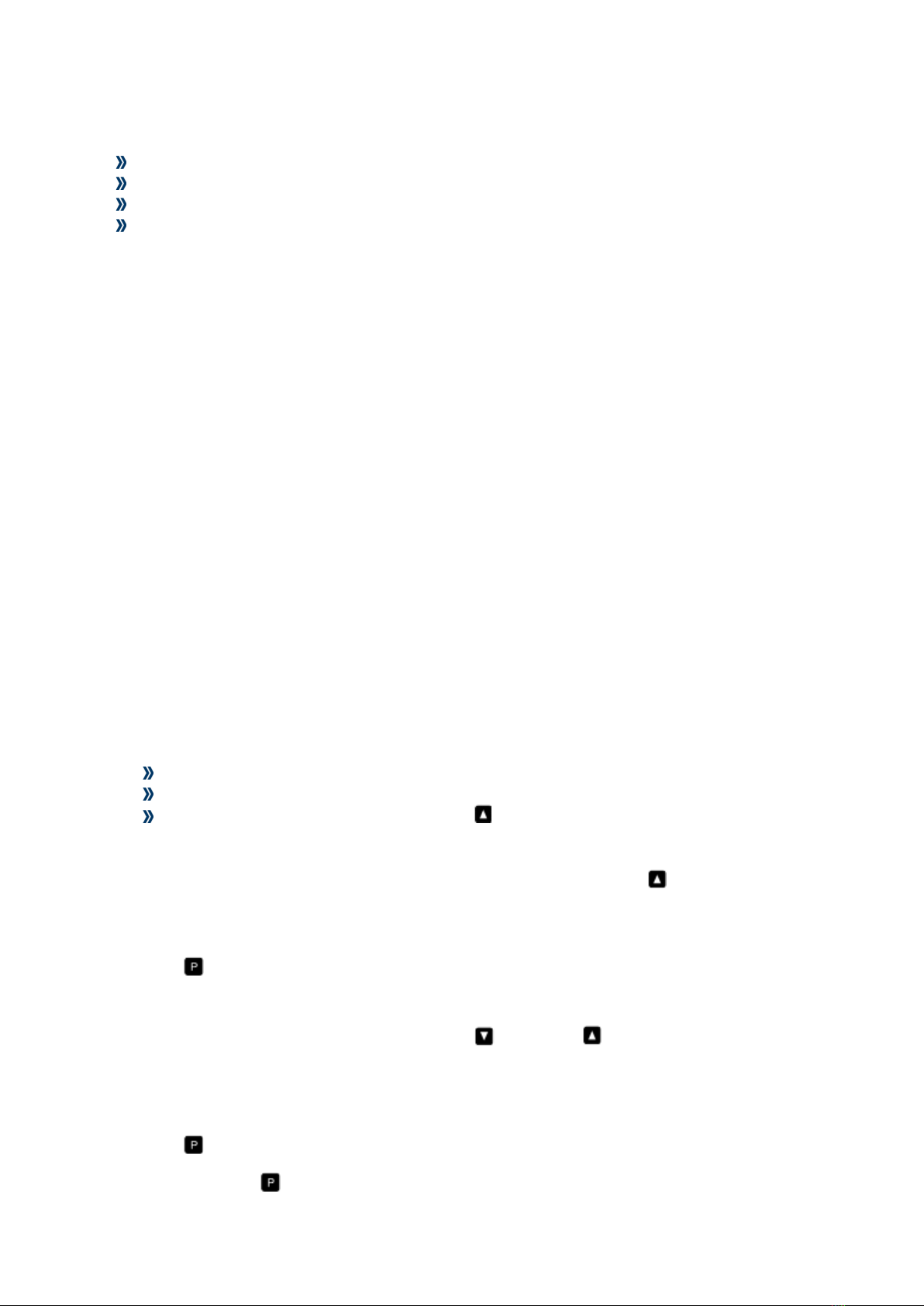

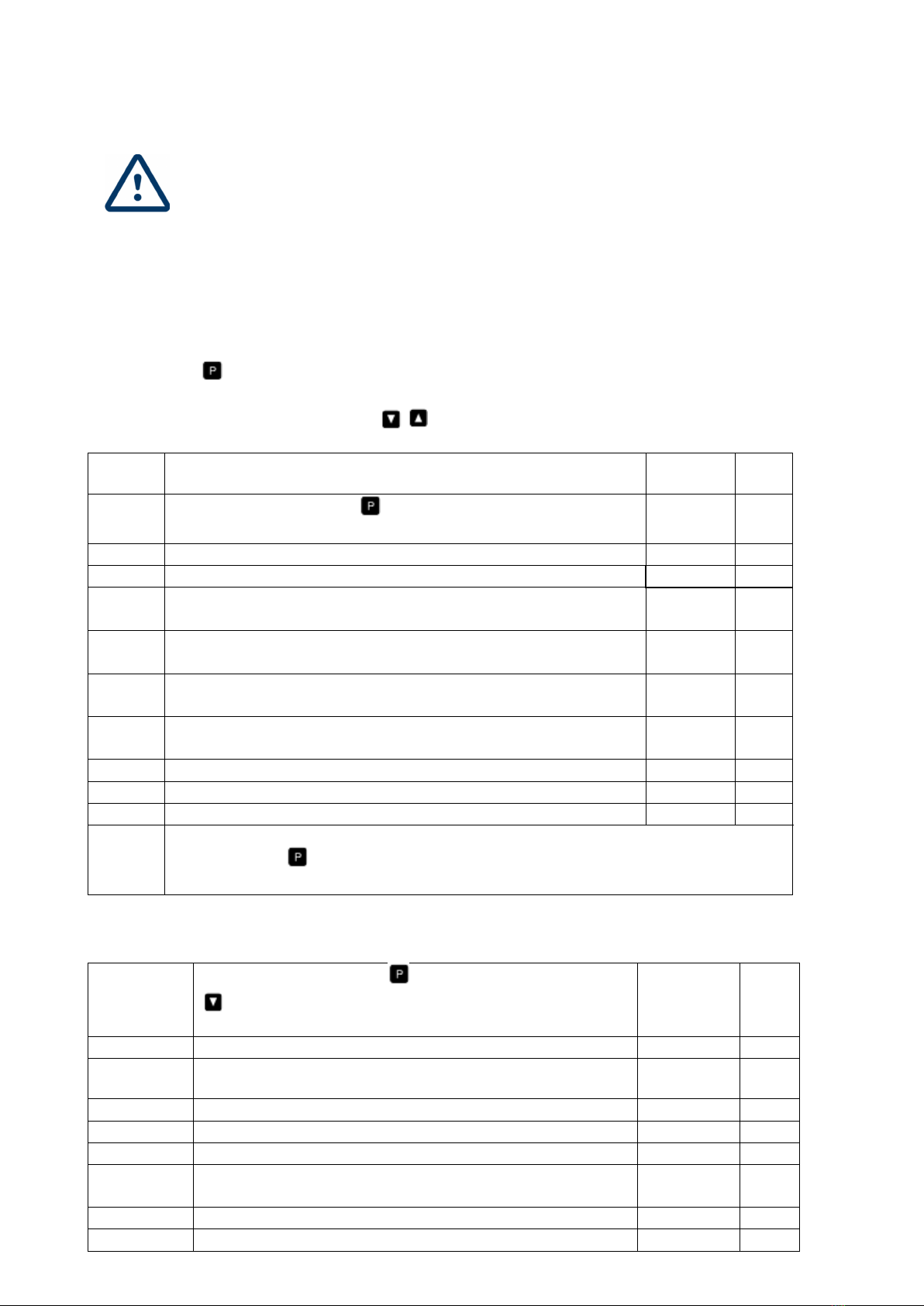

6.1 Controller problems and recommended actions................................................................................................................. 17

6.2 Process troubleshooting................................................................................................................................................................ 18

7Decommissioning, dismantling and disposal.......................................................................... 20

7.1 Decommissioning............................................................................................................................................................................. 20

7.2 Dismantling ......................................................................................................................................................................................... 20

7.3 Return of materials........................................................................................................................................................................... 20

7.4 Disposal ................................................................................................................................................................................................ 21

8Technical data............................................................................................................................. 21

8.1 Hardware characteristics................................................................................................................................................................21

8.2 Dimensional drawings .................................................................................................................................................................... 22

8.3 Electrical connection diagrams ................................................................................................................................................... 22

8.3.1 VC312 controller connection................................................................................................................................................. 22

8.3.2 VC622 (322/622/722) controller connection................................................................................................................... 27