5

SYSTEM LOCKOUT

& DIAGNOSTIC FEATURES

SYSTEM LOCKOUT FEATURES

When system lockout occurs,

1. Diagnostic LED will flash or glow continuously to indicate

system status.

2. Gas valve is de-energized.

3. Circulator blower is energized at heat speed, and, if

4. Flame is sensed, the inducer blower is energized.

(System lockout will never override the precautionary

features.)

To RESET the control after System Lockout

• Interrupt the call for Heat or Cool at the thermostat for at

least 1 second but less than 20 seconds.

(If flame is sensed with the gas valve de-energized,

interrupting the call for heat at the thermostat will not

reset the control.)

OR

• Interrupt the 24 VAC power at the control for at least 1

second. You may also need to reset the Flame Rollout

Sensor switch.

Serviceable Parts

50M56U-801has onlyone serviceablepart –anautomotive

type fuse, which protects the low voltage transformer from

damage if the output is short-circuited.

• If the fuse has opened up, remove whatever caused

the short circuit and replace the fuse with only a 3 Amp

automotive type fuse.

• If the fuse does not correct the condition, REPLACE

the entire 50M56U-801 control. There are no other user

serviceable parts.

DIAGNOSTIC FEATURES

The 50M56U-801 control continuously monitors its own

operation and the operation of the system.

• If a failure occurs, the LED will indicate a failure code as

shown on page 5 in flash – pause sequences.

• Flash will last approximately for 0.25 seconds, and each

pause will last approximately 2 seconds.

FAULT RECALL

Control must be in STANDBY mode (no call for heat or cool)

• Last 5 fault codes stored can be displayed on the

Diagnostic LED.

• Press the FAULT RECALL switch for approximately 2

seconds or until the LED turns off.

• Release the switch and the LED will remain off for 2

seconds.

• Fault codes will display beginning with the most recent

fault first with a 2 second pause between codes.

• After the stored fault codes have all displayed, the LED

will remain off for 2 seconds and then turn on to indicate

return to normal status.

(While displaying the stored fault codes, the control will

ignore any new call for heat, cool or fan.)

FAULT CODES RESET Automatically after 14

days. To manually reset see steps below.

Control must be in STANDBY switch mode (no call for

heat or cool)

Press the FAULT RECALL switch for approximately 5-10

seconds or until the LED begins to rapid flash.

• Release the switch and the LED will turn off for 2 seconds

indicating that the codes are erased.

• After 2 seconds, the LED will turn on to indicate return

to normal status.

• If the switch is held pressed for over 10 seconds, the rapid

flash will stop and the LED will turn on to indicate return

to normal status and the fault codes will not be erased.

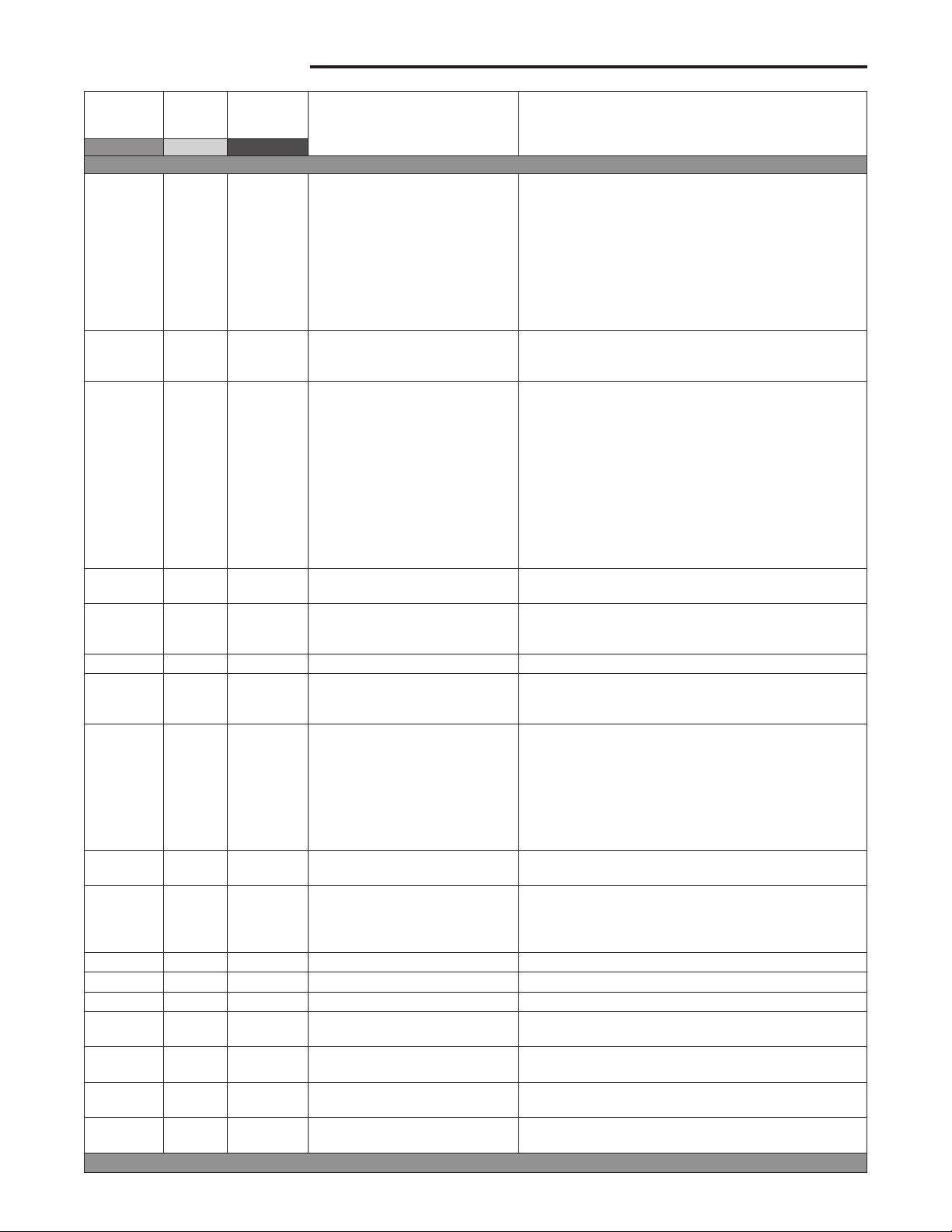

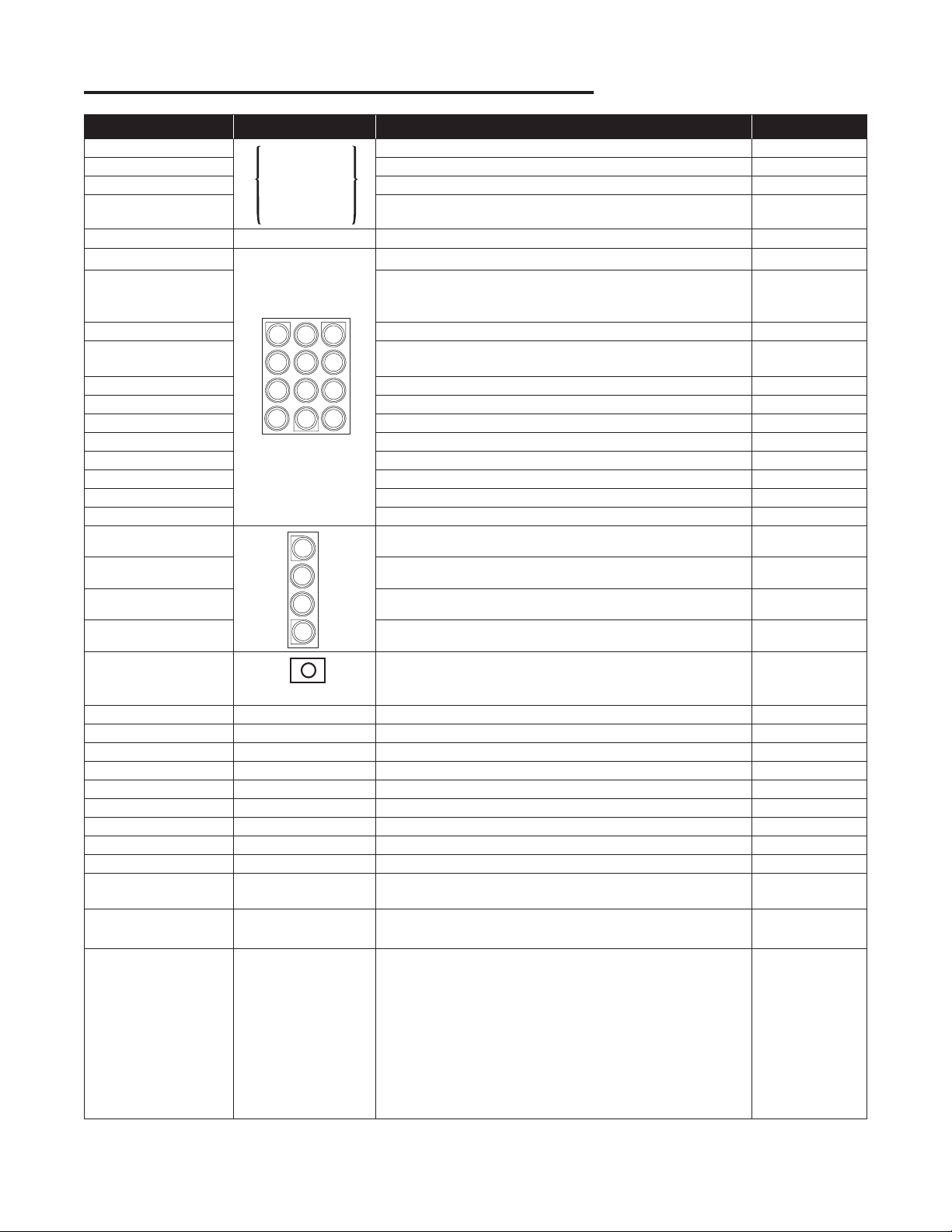

TROUBLESHOOTING

Green

LED

Flash

Amber

LED

Flash

Red

LED

Flash Error/Condition Comments/Troubleshooting

Below flash codes shall be stored if fault occurs

1 Flame Present Without Gas

Valve Energized - Verify the gas valve is operating and shutting down

properly.

- Flame in burner assembly should extinguish promptly

at the end of the cycle.

- Check orifices and gas pressure.

2 Pressure Switch Stuck Closed /

Inducer Error - Check switch function, verify inducer is turning off.

- Refer to wiring diagram, terminals PSI / PSO

3 Pressure Switch Stuck Open /

Inducer Error - Check pressure switch function and tubing.

- Verify inducer is turning on and pulling sufficient

vacuum to engage switch.

- Refer to wiring diagram, terminals PSI / PSO.

4 High Limit Switch Open - Verify continuity through limit switch circuit.

- Refer to wiring diagram terminals, HLI / HLO.