IGM Professional Odyssey BAYLOAMS20 User manual

SSAAFFEETTYY WWAARRNNIINNGG

Only qualified personnel should install and service the equipment The installation, starting up, and servicing of heating, ventilating, and air-conditioning

equipment can be hazardous and requires specific knowledge and training Improperly installed, adjusted or altered equipment by an unqualified person

could result in death or serious injury When working on the equipment, observe all precautions in the literature and on the tags, stickers, and labels that

are attached to the equipment

August 2021 AACCCC--SSVVNN119900BB--EENN

Installation Guide

Head Pressure Control Kit

Odyssey™ Split System with Symbio™

Controls, 13 to 25 Tons

BBAAYYLLOOAAMMSS2200::

TTA156/180/201/240/251/300

TWA156/180/201/240

MOTOR

ON/OFF

N.O.

OK

LINE

120-600VAC

P/N ICM334-LF

MADE IN THE USA

C

Y1

Y2

REV. VALVE

P1&P2 BLK

HEAT

PUMP

N.C.

T AMBIENT

SETPOINT

155

35

psig 75 115

275

235

195

435

465 395

355

315

P1&P2 RED

P2 B.W.G.

P1 B.W.G.

1

Trane P/N

X13651682

LOAD

1

LINE

2

LOAD

2

LINE

3

LOAD

3

©2021 ACC-SVN190B-EN

Introduction

Read this manual thoroughly before operating or

servicing this unit

Warnings, Cautions, and Notices

Safety advisories appear throughout this manual as

required Your personal safety and the proper

operation of this machine depend upon the strict

observance of these precautions

The three types of advisories are defined as follows:

WARNING

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

serious injury.

CAU

TION

Indicates a potentially hazardous situation

which, if not avoided, could result in minor or

moderate injury. It could also be used to alert

against unsafe practices.

NOTICE

Indicates a situation that could result in

equipment or property-damage only

accidents.

Important Environmental Concerns

Scientific research has shown that certain man-made

chemicals can affect the earth’s naturally occurring

stratospheric ozone layer when released to the

atmosphere In particular, several of the identified

chemicals that may affect the ozone layer are

refrigerants that contain Chlorine, Fluorine and Carbon

(CFCs) and those containing Hydrogen, Chlorine,

Fluorine and Carbon (HCFCs) Not all refrigerants

containing these compounds have the same potential

impact to the environment Trane advocates the

responsible handling of all refrigerants-including

industry replacements for CFCs and HCFCs such as

saturated or unsaturated HFCs and HCFCs

Important Responsible Refrigerant

Practices

Trane believes that responsible refrigerant practices

are important to the environment, our customers, and

the air conditioning industry All technicians who

handle refrigerants must be certified according to local

rules For the USA, the Federal Clean Air Act (Section

608) sets forth the requirements for handling,

reclaiming, recovering and recycling of certain

refrigerants and the equipment that is used in these

service procedures In addition, some states or

municipalities may have additional requirements that

must also be adhered to for responsible management

of refrigerants Know the applicable laws and follow

them

WWAARRNNIINNGG

PPrrooppeerr FFiieelldd WWiirriinngg aanndd GGrroouunnddiinngg

RReeqquuiirreedd!!

FFaaiilluurree ttoo ffoollllooww ccooddee ccoouulldd rreessuulltt iinn ddeeaatthh oorr

sseerriioouuss iinnjjuurryy

AAllll ffiieelldd wwiirriinngg MMUUSSTT bbee ppeerrffoorrmmeedd bbyy qquuaalliiffiieedd

ppeerrssoonnnneell IImmpprrooppeerrllyy iinnssttaalllleedd aanndd ggrroouunnddeedd

ffiieelldd wwiirriinngg ppoosseess FFIIRREE aanndd EELLEECCTTRROOCCUUTTIIOONN

hhaazzaarrddss TToo aavvooiidd tthheessee hhaazzaarrddss,, yyoouu MMUUSSTT ffoollllooww

rreeqquuiirreemmeennttss ffoorr ffiieelldd wwiirriinngg iinnssttaallllaattiioonn aanndd

ggrroouunnddiinngg aass ddeessccrriibbeedd iinn NNEECC aanndd yyoouurr llooccaall//

ssttaattee//nnaattiioonnaall eelleeccttrriiccaall ccooddeess

WWAARRNNIINNGG

PPeerrssoonnaall PPrrootteeccttiivvee EEqquuiippmmeenntt ((PPPPEE))

RReeqquuiirreedd!!

FFaaiilluurree ttoo wweeaarr pprrooppeerr PPPPEE ffoorr tthhee jjoobb bbeeiinngg

uunnddeerrttaakkeenn ccoouulldd rreessuulltt iinn ddeeaatthh oorr sseerriioouuss iinnjjuurryy

TTeecchhnniicciiaannss,, iinn oorrddeerr ttoo pprrootteecctt tthheemmsseellvveess ffrroomm

ppootteennttiiaall eelleeccttrriiccaall,, mmeecchhaanniiccaall,, aanndd cchheemmiiccaall

hhaazzaarrddss,, MMUUSSTT ffoollllooww pprreeccaauuttiioonnss iinn tthhiiss mmaannuuaall

aanndd oonn tthhee ttaaggss,, ssttiicckkeerrss,, aanndd llaabbeellss,, aass wweellll aass tthhee

iinnssttrruuccttiioonnss bbeellooww::

•• BBeeffoorree iinnssttaalllliinngg//sseerrvviicciinngg tthhiiss uunniitt,,

tteecchhnniicciiaannss MMUUSSTT ppuutt oonn aallll PPPPEE rreeqquuiirreedd ffoorr

tthhee wwoorrkk bbeeiinngg uunnddeerrttaakkeenn ((EExxaammpplleess;; ccuutt

rreessiissttaanntt gglloovveess//sslleeeevveess,, bbuuttyyll gglloovveess,, ssaaffeettyy

ggllaasssseess,, hhaarrdd hhaatt//bbuummpp ccaapp,, ffaallll pprrootteeccttiioonn,,

eelleeccttrriiccaall PPPPEE aanndd aarrcc ffllaasshh ccllootthhiinngg))

AALLWWAAYYSS rreeffeerr ttoo aapppprroopprriiaattee SSaaffeettyy DDaattaa

SShheeeettss ((SSDDSS)) aanndd OOSSHHAA gguuiiddeelliinneess ffoorr

pprrooppeerr PPPPEE

•• WWhheenn wwoorrkkiinngg wwiitthh oorr aarroouunndd hhaazzaarrddoouuss

cchheemmiiccaallss,, AALLWWAAYYSS rreeffeerr ttoo tthhee aapppprroopprriiaattee

SSDDSS aanndd OOSSHHAA//GGHHSS ((GGlloobbaall HHaarrmmoonniizzeedd

SSyysstteemm ooff CCllaassssiiffiiccaattiioonn aanndd LLaabbeelllliinngg ooff

CChheemmiiccaallss)) gguuiiddeelliinneess ffoorr iinnffoorrmmaattiioonn oonn

aalllloowwaabbllee ppeerrssoonnaall eexxppoossuurree lleevveellss,, pprrooppeerr

rreessppiirraattoorryy pprrootteeccttiioonn aanndd hhaannddlliinngg

iinnssttrruuccttiioonnss

•• IIff tthheerree iiss aa rriisskk ooff eenneerrggiizzeedd eelleeccttrriiccaall

ccoonnttaacctt,, aarrcc,, oorr ffllaasshh,, tteecchhnniicciiaannss MMUUSSTT ppuutt

oonn aallll PPPPEE iinn aaccccoorrddaannccee wwiitthh OOSSHHAA,, NNFFPPAA

7700EE,, oorr ootthheerr ccoouunnttrryy--ssppeecciiffiicc rreeqquuiirreemmeennttss

ffoorr aarrcc ffllaasshh pprrootteeccttiioonn,, PPRRIIOORR ttoo sseerrvviicciinngg

tthhee uunniitt NNEEVVEERR PPEERRFFOORRMM AANNYY SSWWIITTCCHHIINNGG,,

DDIISSCCOONNNNEECCTTIINNGG,, OORR VVOOLLTTAAGGEE TTEESSTTIINNGG

WWIITTHHOOUUTT PPRROOPPEERR EELLEECCTTRRIICCAALL PPPPEE AANNDD

AARRCC FFLLAASSHH CCLLOOTTHHIINNGG EENNSSUURREE

EELLEECCTTRRIICCAALL MMEETTEERRSS AANNDD EEQQUUIIPPMMEENNTT AARREE

PPRROOPPEERRLLYY RRAATTEEDD FFOORR IINNTTEENNDDEEDD

VVOOLLTTAAGGEE

ACC-SVN190B-EN 3

WWAARRNNIINNGG

FFoollllooww EEHHSS PPoolliicciieess!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss bbeellooww ccoouulldd rreessuulltt iinn

ddeeaatthh oorr sseerriioouuss iinnjjuurryy

•• AAllll TTrraannee ppeerrssoonnnneell mmuusstt ffoollllooww tthhee

ccoommppaannyy’’ss EEnnvviirroonnmmeennttaall,, HHeeaalltthh aanndd SSaaffeettyy

((EEHHSS)) ppoolliicciieess wwhheenn ppeerrffoorrmmiinngg wwoorrkk ssuucchh aass

hhoott wwoorrkk,, eelleeccttrriiccaall,, ffaallll pprrootteeccttiioonn,, lloocckkoouutt//

ttaaggoouutt,, rreeffrriiggeerraanntt hhaannddlliinngg,, eettcc WWhheerree llooccaall

rreegguullaattiioonnss aarree mmoorree ssttrriinnggeenntt tthhaann tthheessee

ppoolliicciieess,, tthhoossee rreegguullaattiioonnss ssuuppeerrsseeddee tthheessee

ppoolliicciieess

•• NNoonn--TTrraannee ppeerrssoonnnneell sshhoouulldd aallwwaayyss ffoollllooww

llooccaall rreegguullaattiioonnss

Copyright

This document and the information in it are the

property of Trane, and may not be used or reproduced

in whole or in part without written permission Trane

reserves the right to revise this publication at any time,

and to make changes to its content without obligation

to notify any person of such revision or change

Trademar s

All trademarks referenced in this document are the

trademarks of their respective owners

Revision History

Jumper images updated for TTA and TWA models

IInnttrroodduuccttiioonn

ACC-SVN190B-EN 5

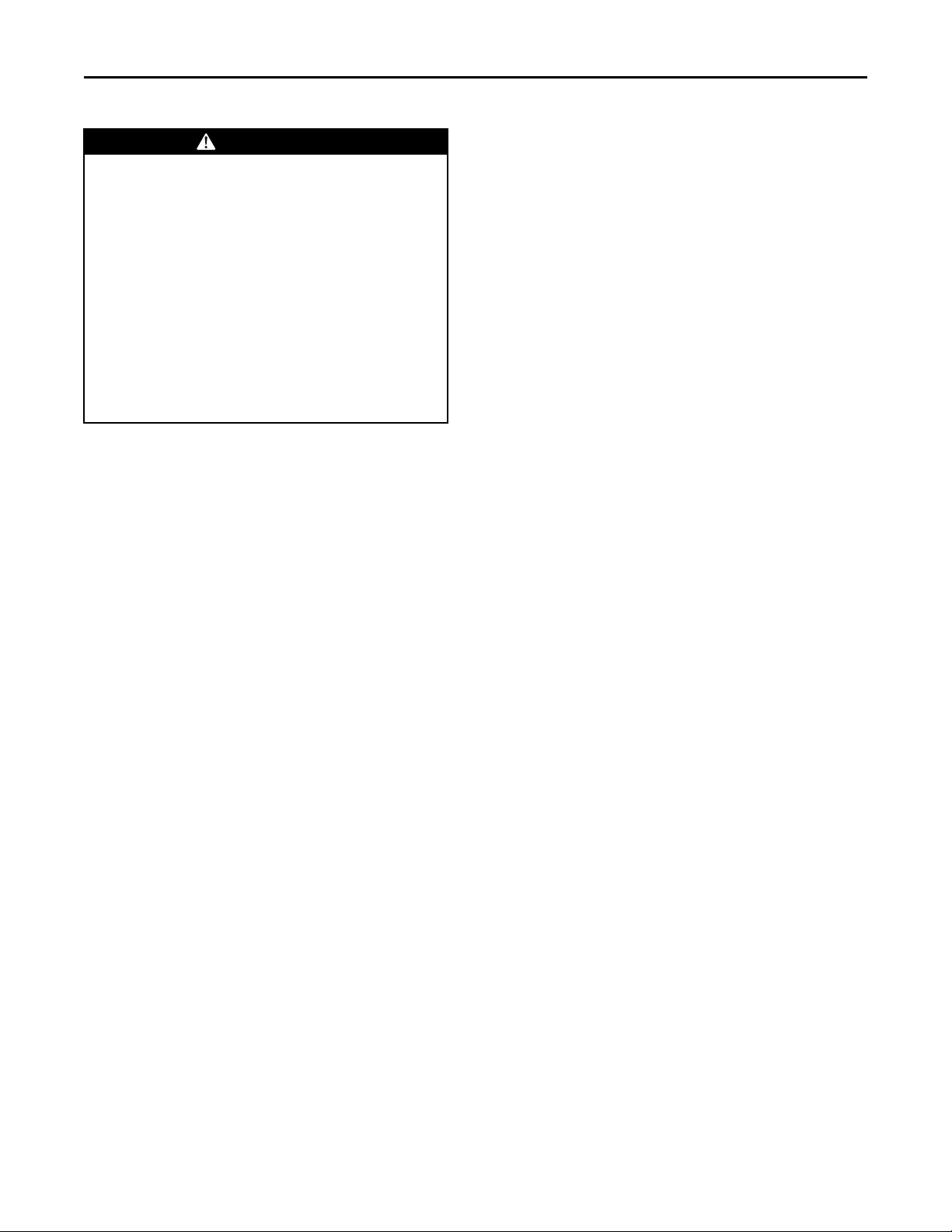

Pre-Installation

Parts List

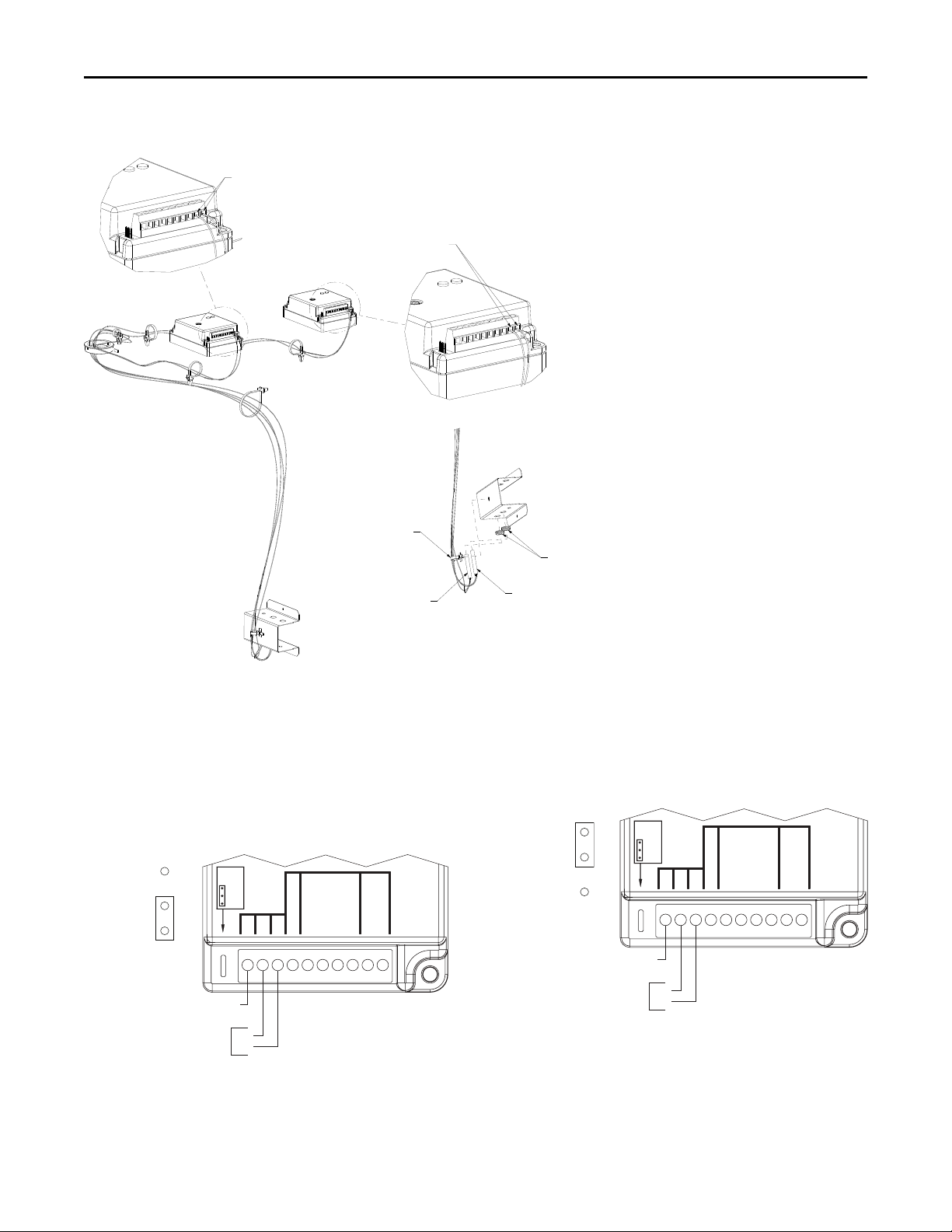

Figure 1. Parts list

3

11

1

2

4

5

6

7

8

9

10

12

13

14

15

16

17

18

Item

Number Quantity Description

1 1 Pop-in Wire Tie

2 2 Grommet

3 2 Sensor; Thermistor Probe

4 4 Edge Protector

5 4 Screw; # 8-32 X 1.25 Pan Head

6 4 Screw; # 10-16 X .50 Hex Head

7 1 Label; Information BAYLOAMS20

8 2 Tee; Pressure Tap

9 2 Bracket; Support

10 2 Harness; Low Ambient Kit - SOV

Item

Number Quantity Description

11 1 Harness; 2 Kits Jumper

12 1 Harness; 24V UC Board to Loam

13 2 Harness; Power

14 2 Transducer

15 2 Controller; Low Ambient

16 1 Supplemental Wiring Diagram

17 1 Installation Guide

18 12 Wire Tie

6ACC-SVN190B-EN

General Information

Table 1. Low ambient controller specifications

Volts, AC 208, 240, 380, 415, 480, 600

Control Voltage 18-30 Vac

Frequency 50-60 Hz

Operating Temperature -40ºF to 140ºF (-40ºC to

60ºC)

Full Load Amps 10 Amps

Transducer Pressure Control

Range

0-500 psi

Disable Evaporator Defrost Control

IImmppoorrttaanntt:: For proper operation of the low ambient

head pressure control accessory in an

Odyssey condenser, the Evaporator Defrost

Control (EDC) function M ST be disabled.

To disable the EDC, navigate to the "Utilities" menu on

the Symbio™700 user interface and change the

configuration parameter "Evaporator Defrost Control"

to "Disabled" The Symbio Service and Installation

mobile application can also be used to edit this

parameter

PPrree--IInnssttaallllaattiioonn

ACC-SVN190B-EN 7

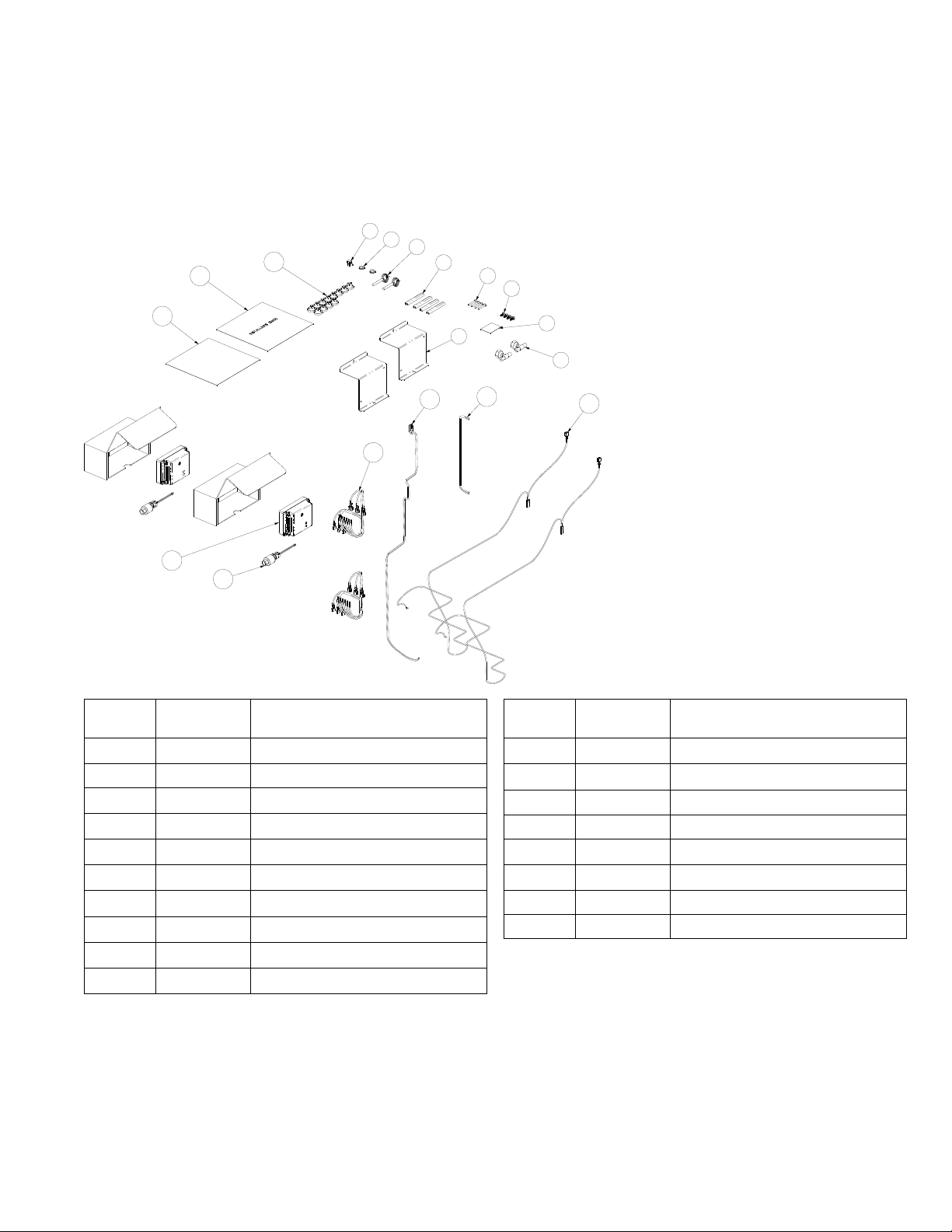

Installation

Controller

WWAARRNNIINNGG

HHaazzaarrddoouuss VVoollttaaggee ww//CCaappaacciittoorrss!!

FFaaiilluurree ttoo ddiissccoonnnneecctt ppoowweerr aanndd ddiisscchhaarrggee

ccaappaacciittoorrss bbeeffoorree sseerrvviicciinngg ccoouulldd rreessuulltt iinn ddeeaatthh oorr

sseerriioouuss iinnjjuurryy

DDiissccoonnnneecctt aallll eelleeccttrriicc ppoowweerr,, iinncclluuddiinngg rreemmoottee

ddiissccoonnnneeccttss aanndd ddiisscchhaarrggee aallll mmoottoorr ssttaarrtt//rruunn

ccaappaacciittoorrss bbeeffoorree sseerrvviicciinngg FFoollllooww pprrooppeerr

lloocckkoouutt//ttaaggoouutt pprroocceedduurreess ttoo eennssuurree tthhee ppoowweerr

ccaannnnoott bbee iinnaaddvveerrtteennttllyy eenneerrggiizzeedd FFoorr vvaarriiaabbllee

ffrreeqquueennccyy ddrriivveess oorr ootthheerr eenneerrggyy ssttoorriinngg

ccoommppoonneennttss pprroovviiddeedd bbyy TTrraannee oorr ootthheerrss,, rreeffeerr ttoo

tthhee aapppprroopprriiaattee mmaannuuffaaccttuurreerr’’ss lliitteerraattuurree ffoorr

aalllloowwaabbllee wwaaiittiinngg ppeerriiooddss ffoorr ddiisscchhaarrggee ooff

ccaappaacciittoorrss VVeerriiffyy wwiitthh aa CCAATT IIIIII oorr IIVV vvoollttmmeetteerr

rraatteedd ppeerr NNFFPPAA 7700EE tthhaatt aallll ccaappaacciittoorrss hhaavvee

ddiisscchhaarrggeedd

WWAARRNNIINNGG

PPrrooppeerr FFiieelldd WWiirriinngg aanndd GGrroouunnddiinngg

RReeqquuiirreedd!!

FFaaiilluurree ttoo ffoollllooww ccooddee ccoouulldd rreessuulltt iinn ddeeaatthh oorr

sseerriioouuss iinnjjuurryy

AAllll ffiieelldd wwiirriinngg MMUUSSTT bbee ppeerrffoorrmmeedd bbyy qquuaalliiffiieedd

ppeerrssoonnnneell IImmpprrooppeerrllyy iinnssttaalllleedd aanndd ggrroouunnddeedd

ffiieelldd wwiirriinngg ppoosseess FFIIRREE aanndd EELLEECCTTRROOCCUUTTIIOONN

hhaazzaarrddss TToo aavvooiidd tthheessee hhaazzaarrddss,, yyoouu MMUUSSTT ffoollllooww

rreeqquuiirreemmeennttss ffoorr ffiieelldd wwiirriinngg iinnssttaallllaattiioonn aanndd

ggrroouunnddiinngg aass ddeessccrriibbeedd iinn NNEECC aanndd yyoouurr llooccaall//

ssttaattee//nnaattiioonnaall eelleeccttrriiccaall ccooddeess

1 Prepare the unit for installation

a Disconnect and lock out all power from the unit

b Remove the compressor and control box access

panel(s), see Figure 2, p 7

2 Remove the Plug screws and install the two

brackets with edge protection as shown in Figure

3, p 8 and Figure 5, p 8

3 Mount one controller on each bracket using two 8-

32 x 1 25 screws provided Refer to Figure 4, p 8

Figure 2. Removing the compressor and control box access panel

Compressor

access panel

High voltage

control box cover

Low voltage

control box cover

Top cover

control box

Low ambient control

wiring diagram placement

Expansion control

wiring diagram placement

ACC-SVN190B-EN 9

Transducer and Tee

WWAARRNNIINNGG

RR--441100AA RReeffrriiggeerraanntt uunnddeerr HHiigghheerr

PPrreessssuurree tthhaann RR--2222!!

FFaaiilluurree ttoo uussee pprrooppeerr eeqquuiippmmeenntt oorr ccoommppoonneennttss aass

ddeessccrriibbeedd bbeellooww,, ccoouulldd rreessuulltt iinn eeqquuiippmmeenntt ffaaiilliinngg

aanndd ppoossssiibbllyy eexxppllooddiinngg,, wwhhiicchh ccoouulldd rreessuulltt iinn

ddeeaatthh,, sseerriioouuss iinnjjuurryy,, oorr eeqquuiippmmeenntt ddaammaaggee

TThhee uunniittss ddeessccrriibbeedd iinn tthhiiss mmaannuuaall uussee RR--441100AA

rreeffrriiggeerraanntt wwhhiicchh ooppeerraatteess aatt hhiigghheerr pprreessssuurreess

tthhaann RR--2222 UUssee OONNLLYY RR--441100AA rraatteedd sseerrvviiccee

eeqquuiippmmeenntt oorr ccoommppoonneennttss wwiitthh tthheessee uunniittss FFoorr

ssppeecciiffiicc hhaannddlliinngg ccoonncceerrnnss wwiitthh RR--441100AA,, pplleeaassee

ccoonnttaacctt yyoouurr llooccaall TTrraannee rreepprreesseennttaattiivvee

NNOOTTIICCEE

WWiirree DDaammaaggee!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss bbeellooww ccoouulldd rreessuulltt iinn

ddaammaaggeedd wwiirreess

UUssee pprroovviiddeedd wwiirree ttiieess ttoo mmaakkee ssuurree wwiirree aarree

sseeccuurreedd aanndd pprrootteecctteedd ffrroomm sshhaarrpp eeddggeess aanndd hhoott

ssuurrffaacceess

Install a tee and pressure transducer on the discharge

line service port at each compressor using the

following instructions:

1 Remove cap nut from the unit's high pressure

service port on the discharge line that runs from the

compressor

Figure 6. High pressure service port

High pressure

service port

2 Install the transducer onto the Tee port without the

valve core

Figure 7. Transducer to tee

3 Place the Tee flare nut with valve core depressor on

the unit high pressure tap, where the cap nut was

located

NNoottee:: If the high pressure service port is on another

Tee, refer to Figure 8, p. 9 for connection.

Figure 8. Tee and transducer installed on high

pressure service port

4 Tighten flare nut securely to the high pressure

service port and check for leaks

Wiring

NNOOTTIICCEE

WWiirree DDaammaaggee!!

FFaaiilluurree ttoo ffoollllooww iinnssttrruuccttiioonnss bbeellooww ccoouulldd rreessuulltt iinn

ddaammaaggeedd wwiirreess

UUssee pprroovviiddeedd wwiirree ttiieess ttoo mmaakkee ssuurree wwiirree aarree

sseeccuurreedd aanndd pprrootteecctteedd ffrroomm sshhaarrpp eeddggeess aanndd hhoott

ssuurrffaacceess

Control Box Wiring

WWAARRNNIINNGG

HHaazzaarrddoouuss VVoollttaaggee ww//CCaappaacciittoorrss!!

FFaaiilluurree ttoo ddiissccoonnnneecctt ppoowweerr aanndd ddiisscchhaarrggee

ccaappaacciittoorrss bbeeffoorree sseerrvviicciinngg ccoouulldd rreessuulltt iinn ddeeaatthh oorr

sseerriioouuss iinnjjuurryy

DDiissccoonnnneecctt aallll eelleeccttrriicc ppoowweerr,, iinncclluuddiinngg rreemmoottee

ddiissccoonnnneeccttss aanndd ddiisscchhaarrggee aallll mmoottoorr ssttaarrtt//rruunn

ccaappaacciittoorrss bbeeffoorree sseerrvviicciinngg FFoollllooww pprrooppeerr

lloocckkoouutt//ttaaggoouutt pprroocceedduurreess ttoo eennssuurree tthhee ppoowweerr

ccaannnnoott bbee iinnaaddvveerrtteennttllyy eenneerrggiizzeedd FFoorr vvaarriiaabbllee

ffrreeqquueennccyy ddrriivveess oorr ootthheerr eenneerrggyy ssttoorriinngg

ccoommppoonneennttss pprroovviiddeedd bbyy TTrraannee oorr ootthheerrss,, rreeffeerr ttoo

tthhee aapppprroopprriiaattee mmaannuuffaaccttuurreerr’’ss lliitteerraattuurree ffoorr

aalllloowwaabbllee wwaaiittiinngg ppeerriiooddss ffoorr ddiisscchhaarrggee ooff

ccaappaacciittoorrss VVeerriiffyy wwiitthh aa CCAATT IIIIII oorr IIVV vvoollttmmeetteerr

rraatteedd ppeerr NNFFPPAA 7700EE tthhaatt aallll ccaappaacciittoorrss hhaavvee

ddiisscchhaarrggeedd

IInnssttaallllaattiioonn

10 ACC-SVN190B-EN

WWAARRNNIINNGG

PPrrooppeerr FFiieelldd WWiirriinngg aanndd GGrroouunnddiinngg

RReeqquuiirreedd!!

FFaaiilluurree ttoo ffoollllooww ccooddee ccoouulldd rreessuulltt iinn ddeeaatthh oorr

sseerriioouuss iinnjjuurryy

AAllll ffiieelldd wwiirriinngg MMUUSSTT bbee ppeerrffoorrmmeedd bbyy qquuaalliiffiieedd

ppeerrssoonnnneell IImmpprrooppeerrllyy iinnssttaalllleedd aanndd ggrroouunnddeedd

ffiieelldd wwiirriinngg ppoosseess FFIIRREE aanndd EELLEECCTTRROOCCUUTTIIOONN

hhaazzaarrddss TToo aavvooiidd tthheessee hhaazzaarrddss,, yyoouu MMUUSSTT ffoollllooww

rreeqquuiirreemmeennttss ffoorr ffiieelldd wwiirriinngg iinnssttaallllaattiioonn aanndd

ggrroouunnddiinngg aass ddeessccrriibbeedd iinn NNEECC aanndd yyoouurr llooccaall//

ssttaattee//nnaattiioonnaall eelleeccttrriiccaall ccooddeess

1 Ensure Unit power has been disconnected and

locked out

2 Disconnect both fan motor harnesses from

contactors, install 14 gauge wire harnesses

(supplied in kit) between the controller, fan

contactors and outdoor fan motor harnesses for

both refrigeration circuits See Figure 9, p 11

3 FOR HEAT PUMP UNITS ONLY, connect Switchover

valve 1 (SOV1) harness (supplied in kit) using the

following steps:

a Disconnect black wire from SOV1 See Figure

10, p 12

b Reconnect black wire to black wire in kit harness

by making an in-line connection Securely

attach this in-line connection to adjacent wiring

with wire ties See Figure 11, p 12

c Connect terminal with black and orange wires to

the open tab on SOV1 See Figure 11, p 12

d Connect orange wire with stripped end to Rev

valve terminal on low amb controller 1 See

Figure 11, p 12

4 FOR HEAT PUMP UNITS ONLY, connect Switchover

valve 2 (SOV2) harness (supplied in kit) using the

following steps:

a Disconnect blue wire from SOV2 See Figure

10, p 12

b Reconnect blue wire to black wire in kit harness

by making an in-line connection Securely

attach this in-line connection to adjacent wiring

with wire ties See Figure 11, p 12

c Connect terminal with black and orange wires to

the open tab on SOV2 See Figure 11, p 12

d Connect orange wire with strip end to Rev valve

terminal on low amb controller 2 See Figure

11, p 12

5 Install jumper harness (supplied in kit) between the

two controllers See diagram for reference See

Figure 12, p 13

6 Install 24VAC harness (supplied in kit) between unit

controller (UC-P5) and the Low Ambient

Controller1 See Figure 13, p 13

7 For each refrigeration circuit install transducer

wires to controller as per kit diagram See Figure

14, p 14

8 For each refrigeration circuit install the thermistors

on the outdoor air sensor bracket and connect on

controller as per kit diagram See Figure 15, p 15

9 Finish wiring installation

a Using wire ties, bundle and dress any excess

wires away from sharp edges, moving parts, or

hot tubes

b Apply the diagram (supplied in kit) to an open

area on the low voltage access panel See

Figure 2, p 7 for proper replacement

c After the settings have been properly adjusted

(see ““Controller Settings,” p 15), reinstall the

compressor and control box access panels and

secure with screws that were removed

IInnssttaallllaattiioonn

ACC-SVN190B-EN 15

Figure 15. Thermistor wires

Thermistor #2

Low Ambient

Controller

Pop-in Wire Tie

Thermistor #1

Low Ambient

Controller

Grommets

To Thermistor #1

To Thermistor #2

Controller Settings

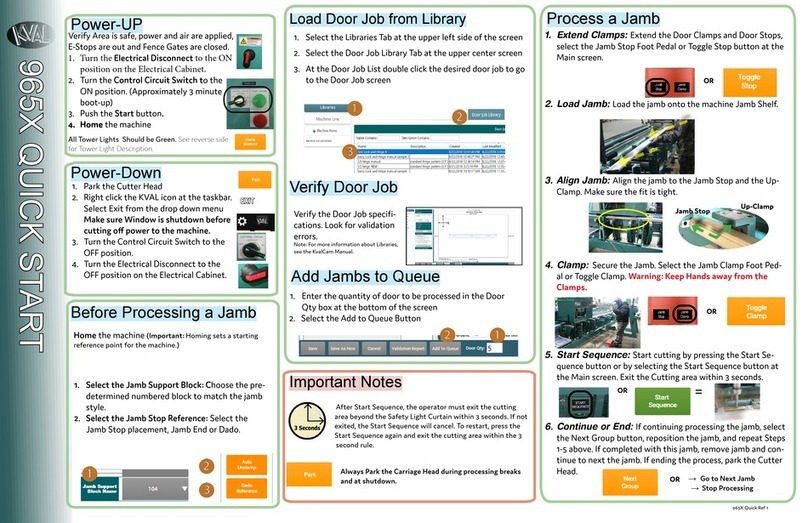

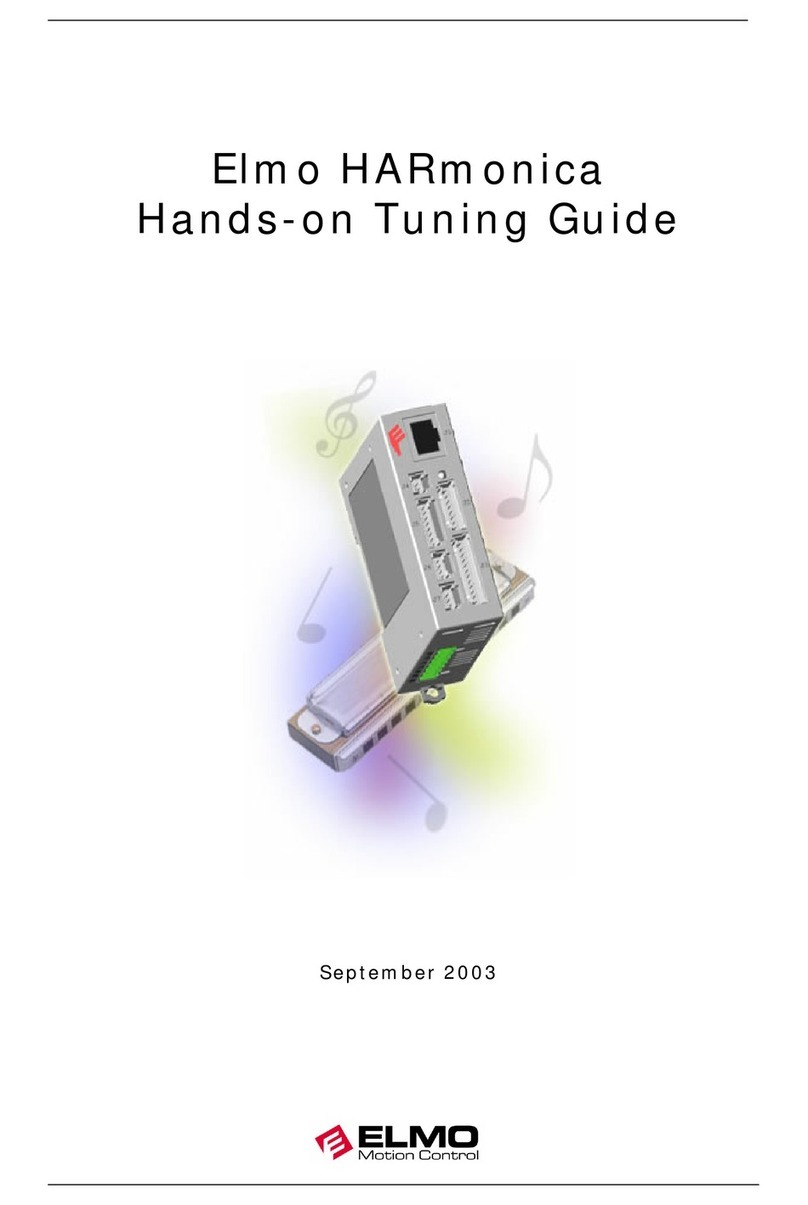

Jumper Position for TTA Models (Cooling

Only)

For non-heat pump applications, the heat pump select

jumper must be in the Default (N O ) position, and the

HP terminals must be left unconnected Refer to Figure

16, p 15

Figure 16. Jumper position for TTA

N.C.

C

Y1

REV. VALVE

P1&P2 BLK

HEAT

PUMP

N.O.

T AMBIENT

P1&P2 RED

P2 B.W.G.

P1 B.W.G.

Y1

Y2

T’STAT

24 VAC

COMMON

Y2

N.O.

Jumper Position for TWA Models (Heat

Pump)

For heat pump applications, the heat pump select

jumper must be in the (N C ) position, see Figure 17, p

15

Figure 17. Jumper position for TWA

N.C.

C

Y1

REV. VALVE

P1&P2 BLK

HEAT

PUMP

N.O.

T AMBIENT

P1&P2 RED

P2 B.W.G.

P1 B.W.G.

Y1

Y2

T’STAT

24 VAC

COMMON

Y2

N.C.

Operation

The low ambient controller is used to maintain head

pressure within an acceptable range when ambient

temperature falls below 50 °F It reads discharge

pressure from the refrigeration circuit and “cycles” the

outdoor fan motor on and off to maintain the desired

IInnssttaallllaattiioonn

16 ACC-SVN190B-EN

discharge pressure at the selected setpoint anytime the

compressor is operating

Set Pressure Setpoint

The pressure setpoint should be adjusted to 250 psig

initially When the ambient temperature is above 50°F

(10°C), the outdoor fan motor will be energized

continuously When the ambient temperature is below

50°F, the pressure sensor reading is used to switch the

motor on or off When the pressure is 15psi below the

set pressure the motor will be turned off When the

pressure is 15psi above the set pressure, the motor will

be turned on

After completion of installation and pressure setting

adjustment), reinstall the compressor and control box

access panels and secure with screws that were

removed

Reconnect all power to the unit Refer to

troubleshooting guide, if needed

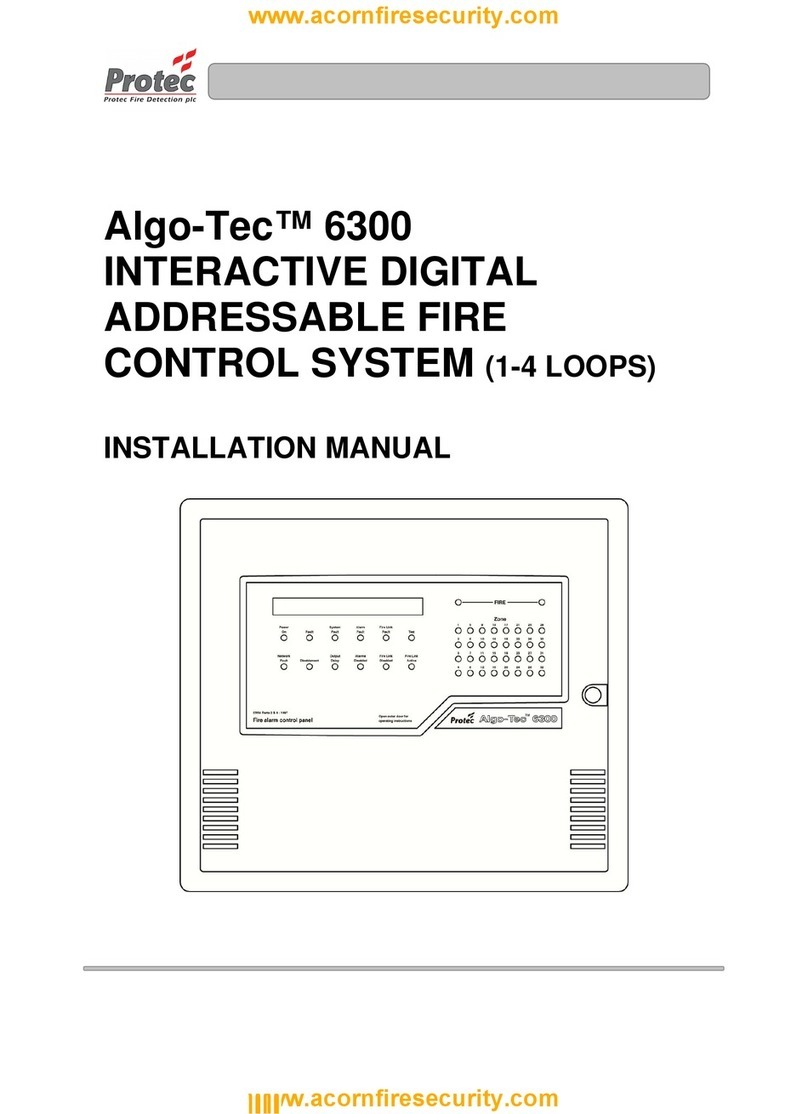

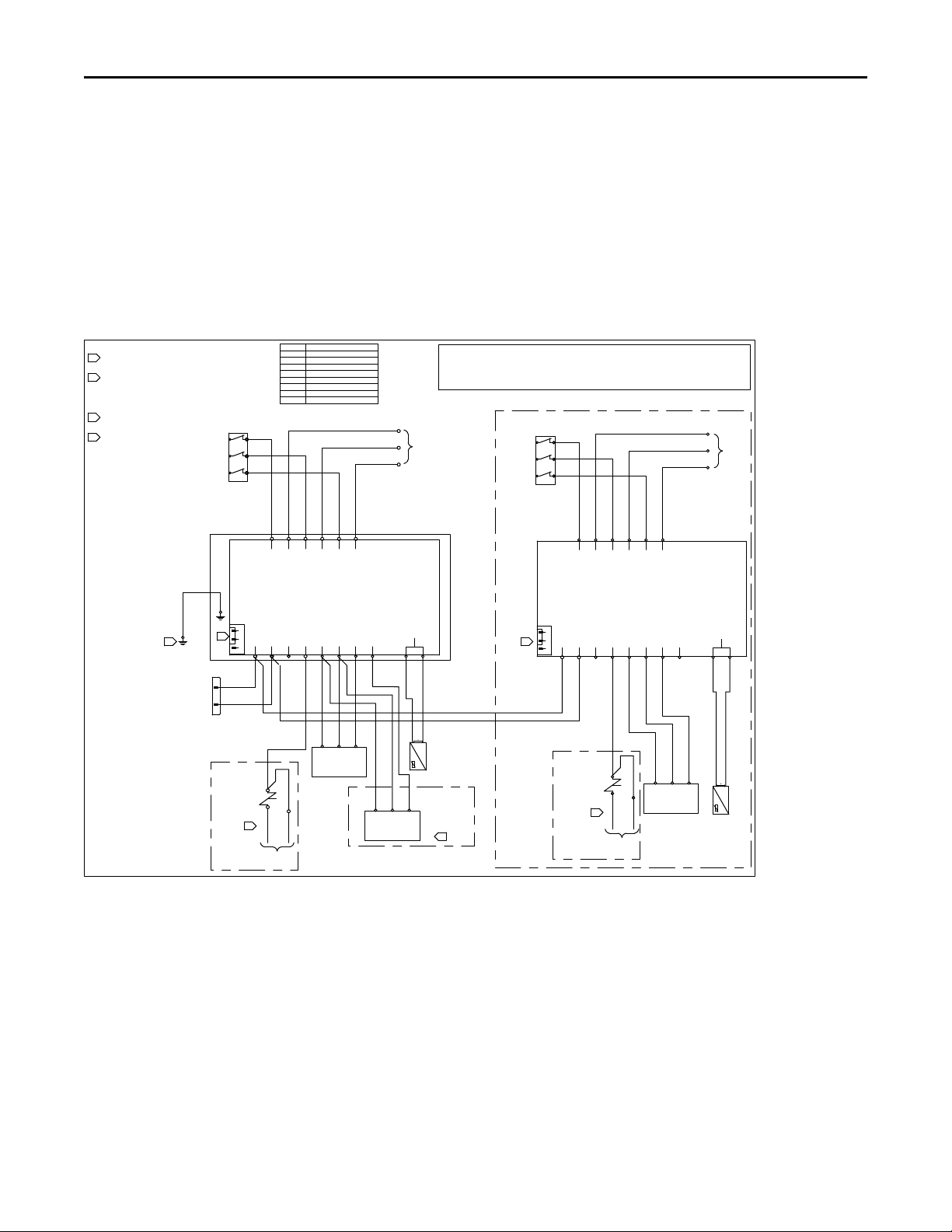

Figure 18. Supplemental wiring diagram

DEV DES DESCRIPTION

LAT1 AMBIENT TEMPERATURE 1

LAT2 AMBIENT TEMPERATURE 2

LOAM 1 LOW AMBIENT MODULE 1

LOAM 2 LOW AMBIENT MODULE 2

OFC1 OUTDOOR FAN CONTACTOR 1

OFC2 OUTDOOR FAN CONTACTOR 2

XDCR1 PRESSURE TRANSDUCER #1

XDCR2 PRESSURE TRANSDUCER #2

WHITEWHITE

RED

RED

BLACKBLACK

BROWN

BROWN

BROWN

BROWN

YELLOW

YELLOW

BROWN

BROWN

ORANGE

ORANGE

BROWN

BROWN

ORANGE

ORANGE

YELLOW

YELLOW

WHITE

WHITE

RED

RED

BLACK

BLACK

ORANGE ORANGE

BLACK

RED

BLACK

ORANGE

BLUE

BROWN

BROWN

BROWN

BROWN

WHITE

WHITE

RED

RED

BLACK

BLACK

YELLOW

YELLOW

BROWN

BROWN

ORANGE

ORANGE

BROWN

BROWN

ORANGE

ORANGE

YELLOW

YELLOW

RED

RED

BLACK, BLACK

BLACK

ORANGE

ORANGE

BLACK

RED

RED

BLACK

BLACK

GREEN

USE COPPER CONDUCTORS ONLY!

UNIT TERMINALS ARE NOT DESIGNED TO ACCEPT

OTHER TYPES OF CONDUCTORS.

FAILURE TO DO SO MAY CAUSE DAMAGE TO THE

EQUIPMENT.

CAUTION

¡UTILICE ÚNICAMENTE CONDUCTORES DE COBRE!

LAS TERMINALES DE LA UNIDAD NO ESTÁN DISEÑADAS

PARA ACEPTAR OTROS TIPOS DE CONDUCTORES.

SI NO LO HACE, PUEDE OCASIONAR DAÑO AL EQUIPO.

N'UTILISER QUE DES CONDUCTEURS EN CUIVRE!

LES BORNES DE L'UNITÉ NE SONT PAS CONÇUES

POUR RECEVOIR D'AUTRES TYPES DE CONDUCTEURS.

L'UTILISATION DE TOUT AUTRE CONDUCTEUR PEUT

ENDOMMAGER L'ÉQUIPEMENT.

PRECAUCIÓNATTENTION

LOW AMBIENT KIT FOR 2ND CIRCUIT

12133356-B

TO

OUTDOOR

FAN MOTOR

1 HARNESS

TO

OUTDOOR

FAN MOTOR

2 HARNESS

FACTORY SETTINGS:

CUT OUT SPEED - MIN

HARD START - MIN

SETPOINT - 250 PSIG

HEAT PUMP

ONLY

HEAT PUMP

ONLY

FACTORY

WIRES

FACTORY

WIRES

CONNECTIONS FOR

DUAL TRANSDUCERS

ON SINGLE MODULE

NOTES:

JUMPER DEFAULT POSITION IS ON N.O. FOR COOLING

ONLY UNITS, MOVE JUMPER TO N.C. POSITION FOR

HEAT PUMP UNITS

REMOVE BLACK FACTORY WIRE FROM SOV1, AND

BLUE FACTORY WIRE FROM SOV2. CONNECT THE

ORANGE WIRE/S FROM THE REV VALVE TERMINAL/S

TO SOV1 AND SOV2. CONNECT THE BLACK FACTORY

WIRE TO THE BLACK SUPPLIED WIRE IN LOAM1, AND THE

BLUE FACTORY WIRE TO THE BLACK SUPPLIED WIRE IN

LOAM2.

WHEN LOW AMBIENT KIT IS INSTALLED IN A SEPARATE

ENCLOSURE THEN TERMINATE THE GREEN WIRE IN THE

ENCLOSURE AND THE MAIN CONTROL BOX

CONNECTIONS FOR DUAL CIRCUIT ON ONE

MODULE WITH SINGLE FAN ONLY.

LAT1

L3 T3

L2 T2

L1 T1

OFC1

OUT

GND

IN

XDCR1

LAT2

L3 T3

L2 T2

L1 T1

OFC2

OUT

GND

IN

XDCR2

SOV1

SOV2

3

3

1

UC-P5

1

2

LOAM 1

T AMBIENT

C

Y1

Y2

REV VALVE

P1 & P2 BLK

P1 & P2 RED

P1 B.W.G.

P2 B.W.G.

LINE 1

LOAD 1

LINE 2

LOAD 2

LINE 3

LOAD 3

N.O.

HEAT

PUMP

N.C.

LOAM 2

T AMBIENT

C

Y1

Y2

REV VALVE

P1 & P2 BLK

P1 & P2 RED

P1 B.W.G.

P2 B.W.G.

LINE 1

LOAD 1

LINE 2

LOAD 2

LINE 3

LOAD 3

N.O.

HEAT

PUMP

N.C.

OUT

GND

IN

XDCR2

1

1

2

2

2

4

4

IInnssttaallllaattiioonn

ACC-SVN190B-EN 17

Operation and Troubleshooting

Chec out Procedure

WWAARRNNIINNGG

HHaazzaarrddoouuss SSeerrvviiccee PPrroocceedduurreess!!

FFaaiilluurree ttoo ffoollllooww aallll pprreeccaauuttiioonnss iinn tthhiiss mmaannuuaall aanndd

oonn tthhee ttaaggss,, ssttiicckkeerrss,, aanndd llaabbeellss ccoouulldd rreessuulltt iinn

ddeeaatthh oorr sseerriioouuss iinnjjuurryy

TTeecchhnniicciiaannss,, iinn oorrddeerr ttoo pprrootteecctt tthheemmsseellvveess ffrroomm

ppootteennttiiaall eelleeccttrriiccaall,, mmeecchhaanniiccaall,, aanndd cchheemmiiccaall

hhaazzaarrddss,, MMUUSSTT ffoollllooww pprreeccaauuttiioonnss iinn tthhiiss mmaannuuaall

aanndd oonn tthhee ttaaggss,, ssttiicckkeerrss,, aanndd llaabbeellss,, aass wweellll aass tthhee

ffoolllloowwiinngg iinnssttrruuccttiioonnss:: UUnnlleessss ssppeecciiffiieedd ootthheerrwwiissee,,

ddiissccoonnnneecctt aallll eelleeccttrriiccaall ppoowweerr iinncclluuddiinngg rreemmoottee

ddiissccoonnnneecctt aanndd ddiisscchhaarrggee aallll eenneerrggyy ssttoorriinngg

ddeevviicceess ssuucchh aass ccaappaacciittoorrss bbeeffoorree sseerrvviicciinngg

FFoollllooww pprrooppeerr lloocckkoouutt//ttaaggoouutt pprroocceedduurreess ttoo

eennssuurree tthhee ppoowweerr ccaann nnoott bbee iinnaaddvveerrtteennttllyy

eenneerrggiizzeedd WWhheenn nneecceessssaarryy ttoo wwoorrkk wwiitthh lliivvee

eelleeccttrriiccaall ccoommppoonneennttss,, hhaavvee aa qquuaalliiffiieedd lliicceennsseedd

eelleeccttrriicciiaann oorr ootthheerr iinnddiivviidduuaall wwhhoo hhaass bbeeeenn

ttrraaiinneedd iinn hhaannddlliinngg lliivvee eelleeccttrriiccaall ccoommppoonneennttss

ppeerrffoorrmm tthheessee ttaasskkss

Before leaving the installation, observe for correct

operation through the desired pressure range (see

Table 3, p 18)

Table 2. Troubleshooting guide

Problem Possible Cause Possible Solution

No fan operation

No 24 volt control voltage Check for 24 Vac between Y1 or Y2 and C terminals - it should read 24 volts.

No line voltage Check voltage across brown, orange, and yellow motor leads. If no voltage is

present verify all wiring is correct.

Bad fan motor or controller If fan does not start, motor is bad and should be replaced. If motor does start,

check controller settings. If motor still fails to start, replace controller.

Improper fan operation

Heat pump jumper not

configured correctly Verify the heat pump jumper is configured correctly.

Control is not wired correctly See wiring diagrams. Ensure that the 24 Vac power supply is connected.

No fan modulation

No need to modulate the fan If pressure is equal to or greater than the head pressure control setpoint, the fan

will be operating at full speed.

No input pressure to control Check for proper transducer and Tee installation. Schrader valve depressor must

depress Schrader valve enough to allow refrigerant into pressure transducer.

Heat pump inputs wired

incorrectly into the controller Check diagram and verify heat pump inputs are properly wired into the controller.

Miswired Check that the 24 Vac signal and the transducer are wired up correctly into the

controller.

Erratic fan operation

Control is not wired correctly See wiring diagrams.

Pressure transducer problem Check for proper transducer and Tee installation. Schrader valve depressor must

depress Schrader valve enough to allow refrigerant into pressure transducer.

Dirty or blocked condenser

coil Clean condenser coil.

The high pressure

switch trips off

Improper head pressure

setpoint setting

See unit fails to start above.

Check the setpoint and reduce it if needed.

Reduced cooling

capacity at low Ambient

Evaporative Defrost Control

is active Disable EDC function in Symbio™700

ACC-SVN190B-EN 19

NNootteess

Trane and American Standard create comfortable, energy efficient indoor environments for

commercial and residential applications For more information, please visit trane com or

americanstandardair com

Trane and American Standard have a policy of continuous product and product data improvement and reserve the right to change design and

specifications without notice We are committed to using environmentally conscious print practices

ACC-SVN190B-EN 20 Aug 2021

Supersedes ACC-SVN190A-EN (March 2020) ©2021

This manual suits for next models

10

Table of contents