2Subject to changes without notice

Product information/unwrapping

Electrical installation

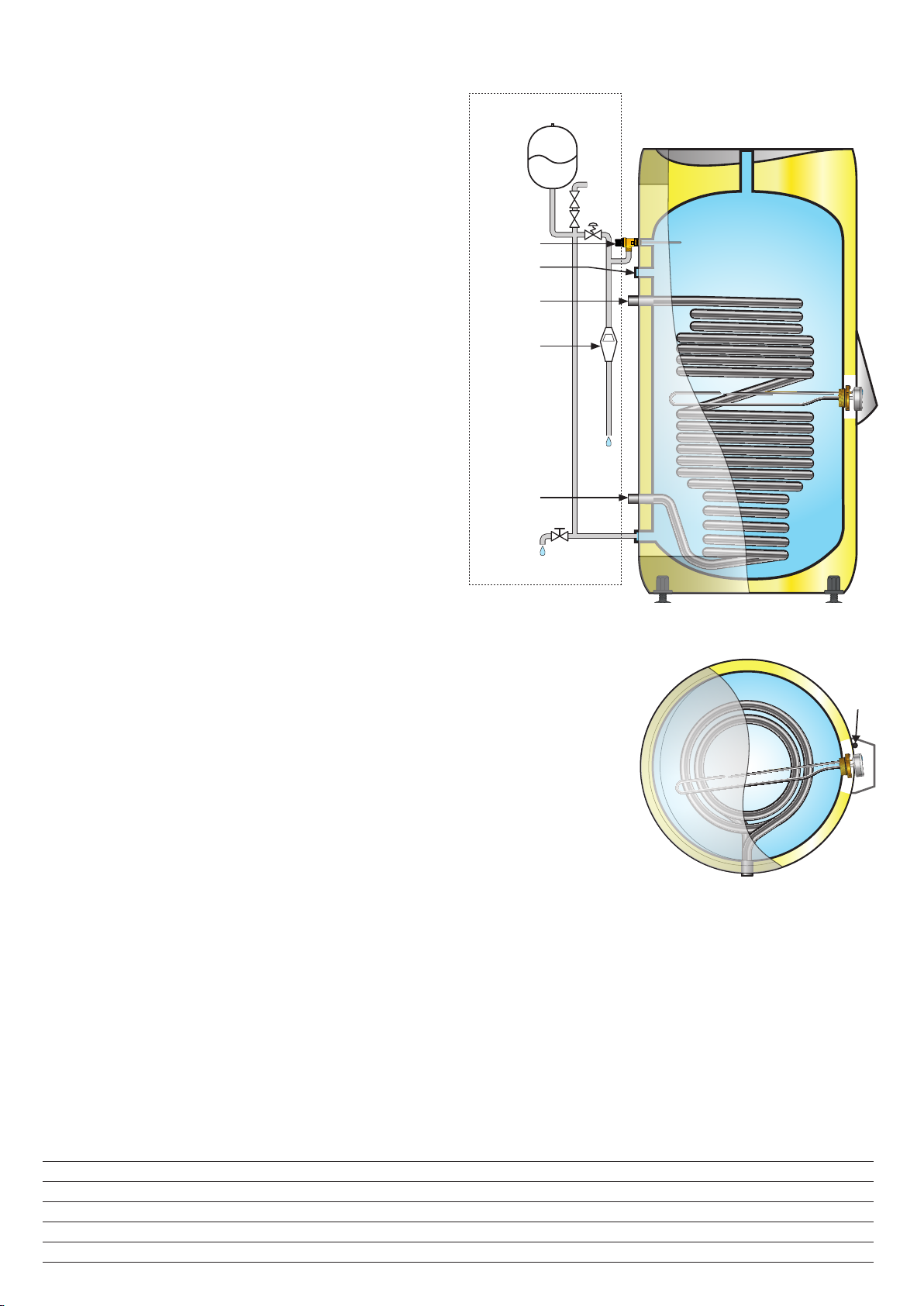

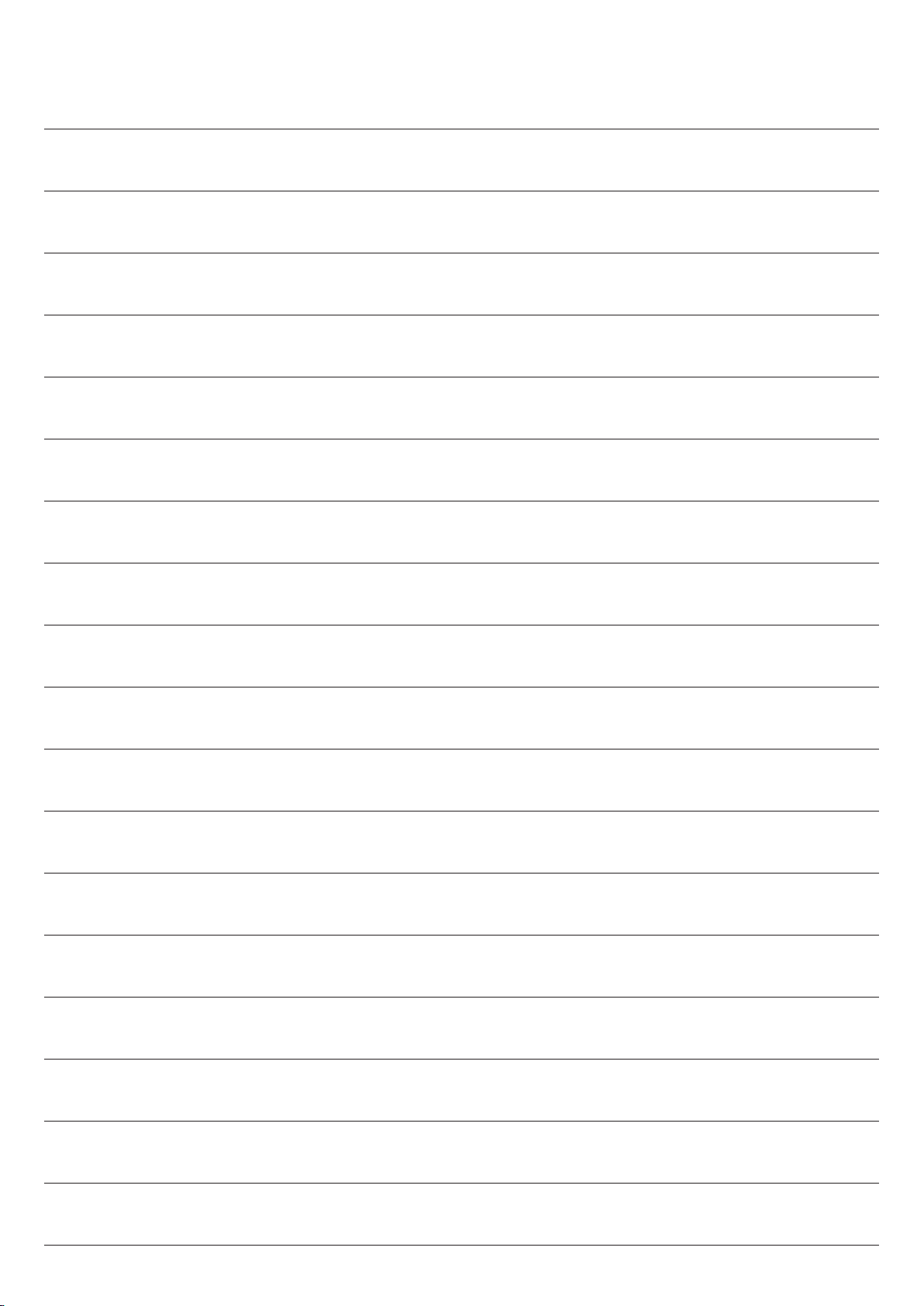

Aquarea Delta is a stainless steel indirect water heater.

The product is designed for heating domestic hot water

from an external heat source such as heat pump, solar

panel, gas boiler, biomass etc. Technical data, see table

below.

Unwrap the product carefully to avoid cosmetic damage.

Install the product on a flat, even surface designed to carry the

full weight of the product when filled with water. Adjust the

factory fitted adjustable feet as needed. The product must be

installed in an upright, level position. All piping and electrical

work must be performed by an authorized installer.

Before filling unit with water it is recommended to fit the

electric power cable, see ‘Electrical installation’ on next page.

Important: Fill unit with water before turning power on.

Failure to comply will terminate guarantee.

On tilted floors the appliance must be installed upright and

level by adjusting the built-in feet. Units 250 l. and larger must

be securely fastened to the wall.

The appliance can be positioned with minimal clearance from

walls, but it is recommended to leave at least 800 mm. service

space in front of the electric central and 300 mm. clearance

above unit top.

This appliance is intended to be permanently connected to

the main water supply.

All units are CE approved. Only safety valve approved to NBI

06870/387 is allowed for use with this product. All electrical

equipment is approved to LVD 2006/95EC (directive for low

voltage systems) and EMC 2004/108 EC (electromagnetic

compatibility).

Pipe fitting, see next page.

Guarantee, see page 6.

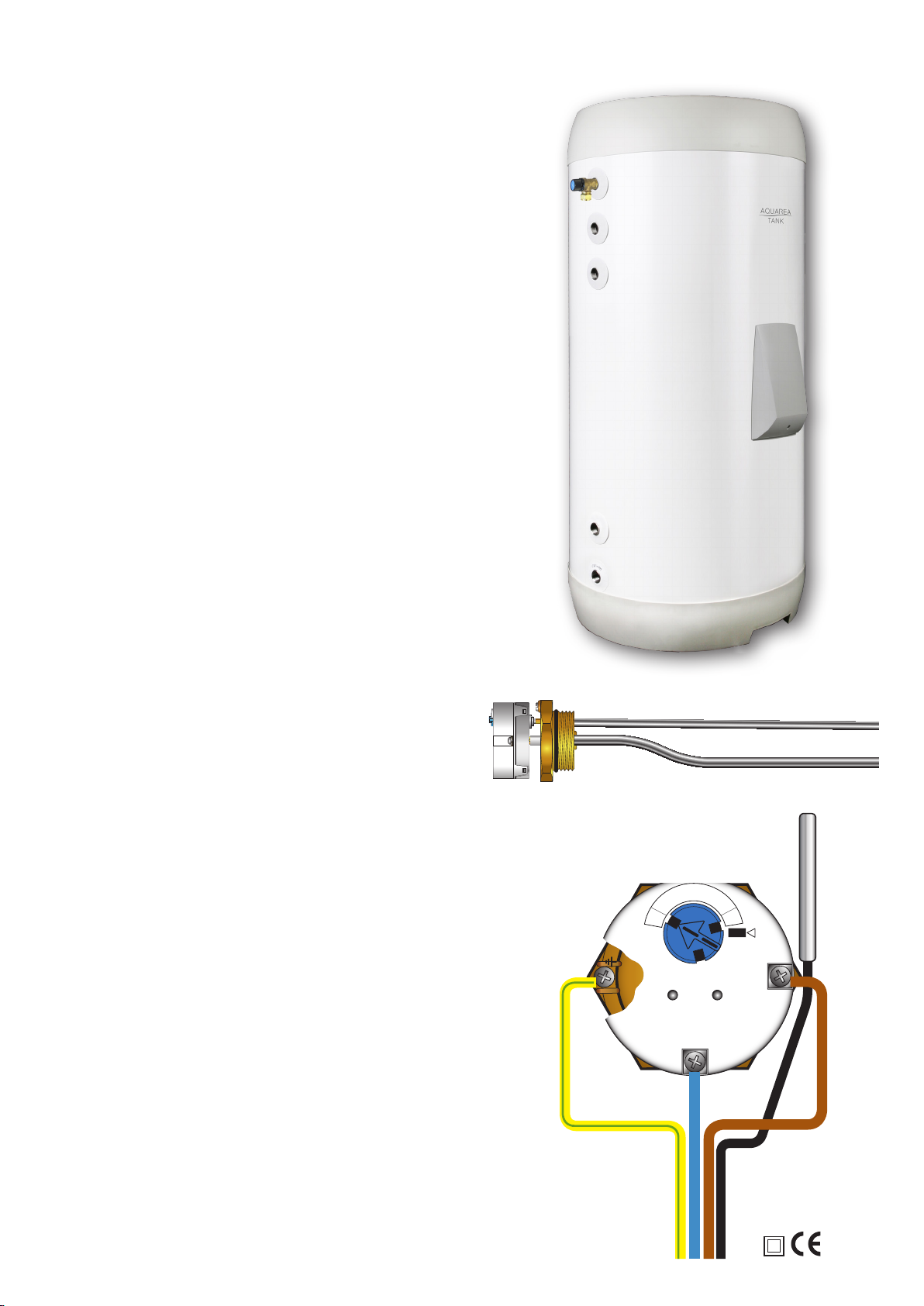

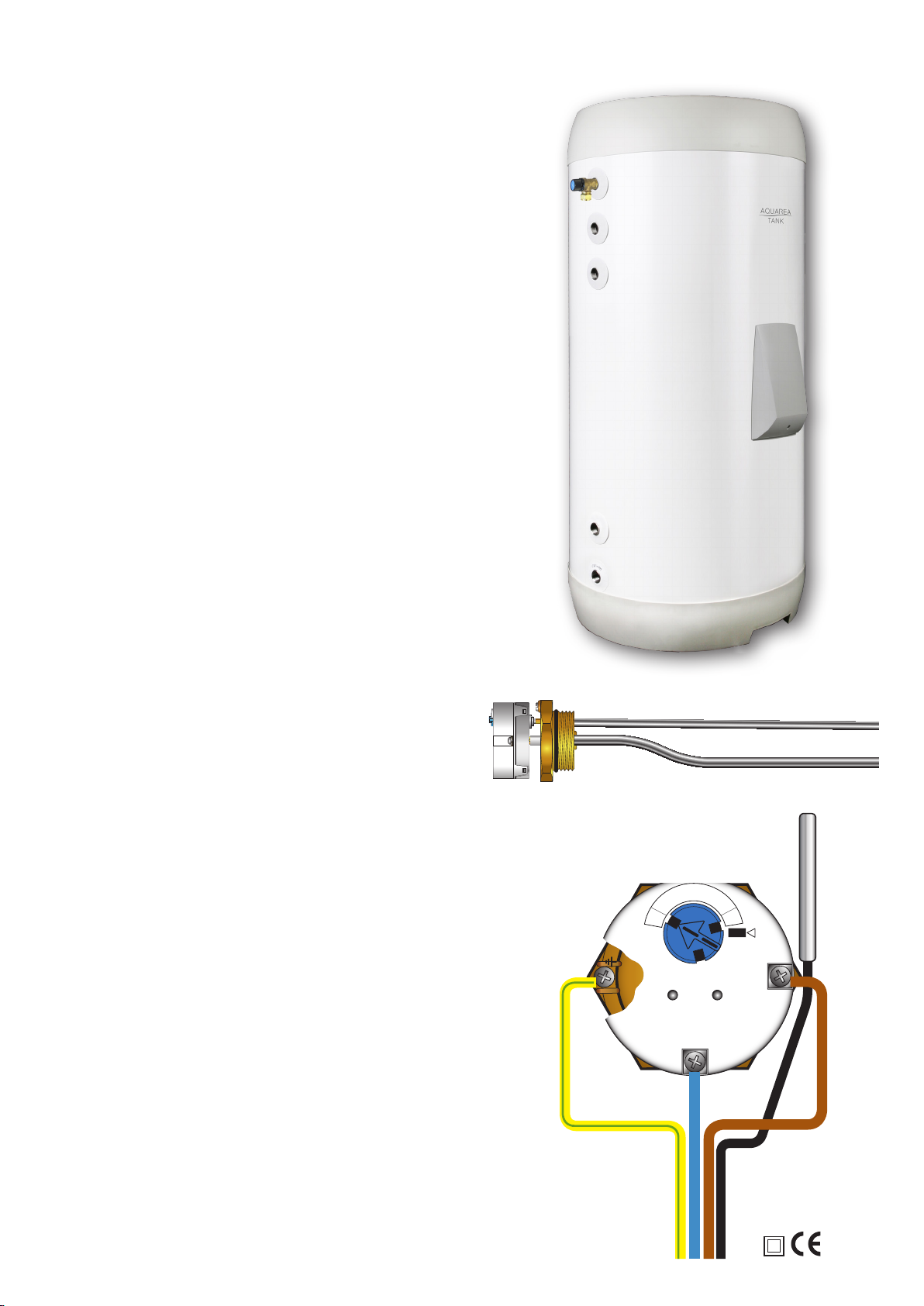

Ground wire

is connected

to the heating

element

Main power cable is

supplied by installer in

accordance with local

regulations.

Minimum cable type is

H05 VV-F. Aquarea

recommends H05 V2V2

or similar.

Thermostat Element

Sensor pocket

IP21

All electrical installation and service must be performed by

authorized electrician. Thermostat is connected as shown.

Ground wire connects directly onto heating element.

The power supply cable is led into the electric central from

below. The cable can be fitted in the desired cable slot in the

unit base by turning the water heater on its back before instal-

lation/filling.

DO NOT turn power on before unit is filled with water. Failure

to comply will terminate guarantee.

When heating the unit with an external heat source (gas boil-

er/heat pump/solar panels) the system must be secured with a

suitable thermostat to ensure the water heater thermal cut-off

does not operate.

Note: The power cable must be fitted with an appropriate

strain relief at the point where it is fed into the electric central.

The Delta series is approved to IP 21.

Disconnecting the appliance from the main power grid must

be done with electric fuse or an appropriate switch.

Replacing the thermostat/element:

Turn off power supply and remove electric central cover. Turn

off water supply and drain unit. Unscrew wires on thermostat

and element. If only the thermostat is being replaced the wire

on the element can be left on. The thermostat is removed by

pulling it straight out from its sockets on the element. The

element can then be removed/replaced by using an element

tool, see ‘Spare parts’. Ensure the o-ring seal on the element

is in place and undamaged before fitting the element. Fill unit

completely with water and make sure the element is not leak-

ing. Fit wire to element. Install thermostat by pressing firmly.

Fit the electric wires to thermostat. Tighten all wire connec-

tions thoroughly. Re-tighten after 3 months.

The electric central cover must be re-fitted and the unit must

be filled with water before power is turned on.

Temperature

sensor is

tted inside

the electric

central,

ensuring it

is in direct

contact with

the stainless

steel vessel.

324

5

a

t

e

n

t

e

d

T

1

1

5

1

6

A

2

5

0

V

A

B

Safety