May 2007 5

clip just as much as needed to keep the upper and lower parts of the Separator together. There

must be no space between the Cyclone and the Wire-ring, see Figure 3.

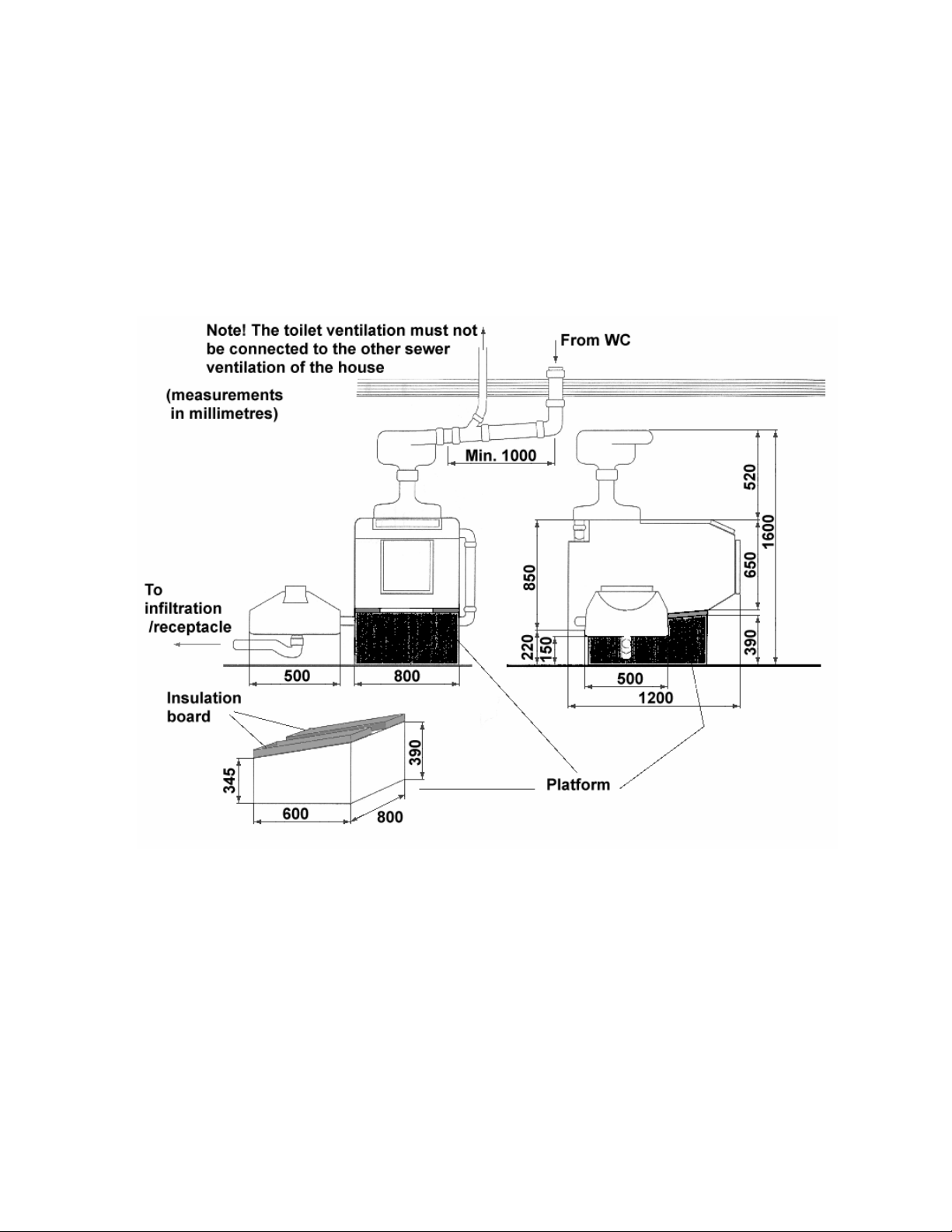

4.2.2 Place the Separator on the Bio Chamber. Turn it so that the fluid outlet located in the bottom part

faces towards the rear side of the Bio Chamber. Turn the upper part of the Separator towards the

pipe coming from the WC. Tighten the hose clip.

4.2.3 The Separator must be installed in a vertical position, see Figure 3.

4.3 Installing the UV unit

4.3.1 The UV unit should be positioned in such a way that the waste water from the Separator and from

the Bio Chamber can flow freely into the UV unit. It is recommended that the UV unit is placed on

consoles fixed on to the wall, see Figure 4. Make certain that the aluminium lid is positioned in such

a way that it can be easily removed for accessing the UV fixture when replacing burned-out UV light

tubes, for inspection, cleaning the interior of the UV Unit etc.

4.3.2 The UV unit must have its bottom surface horizontally installed.

4.3.3 The 2” Waterseal should be installed underneath the UV unit, see Figure 1, 2 and 4.

4.3.4 The UV unit should be connected to a 230 V grounded outlet.

4.3.5 Germicidal UV-C light tubes are made by:

- PHILIPS, type TUV 15

- OSRAM, type HNS

4.4 Waterseal alternative

If the Aquatron system was ordered without a UV unit, a waterseal must be installed between the branching

pipe outlet and the Grey Water outlet. The waterseal is needed to prevent bad smell from the Grey Water

outlet to enter the toilet system (Bio Chamber). Suggestion for waterseal, see Figure 5.

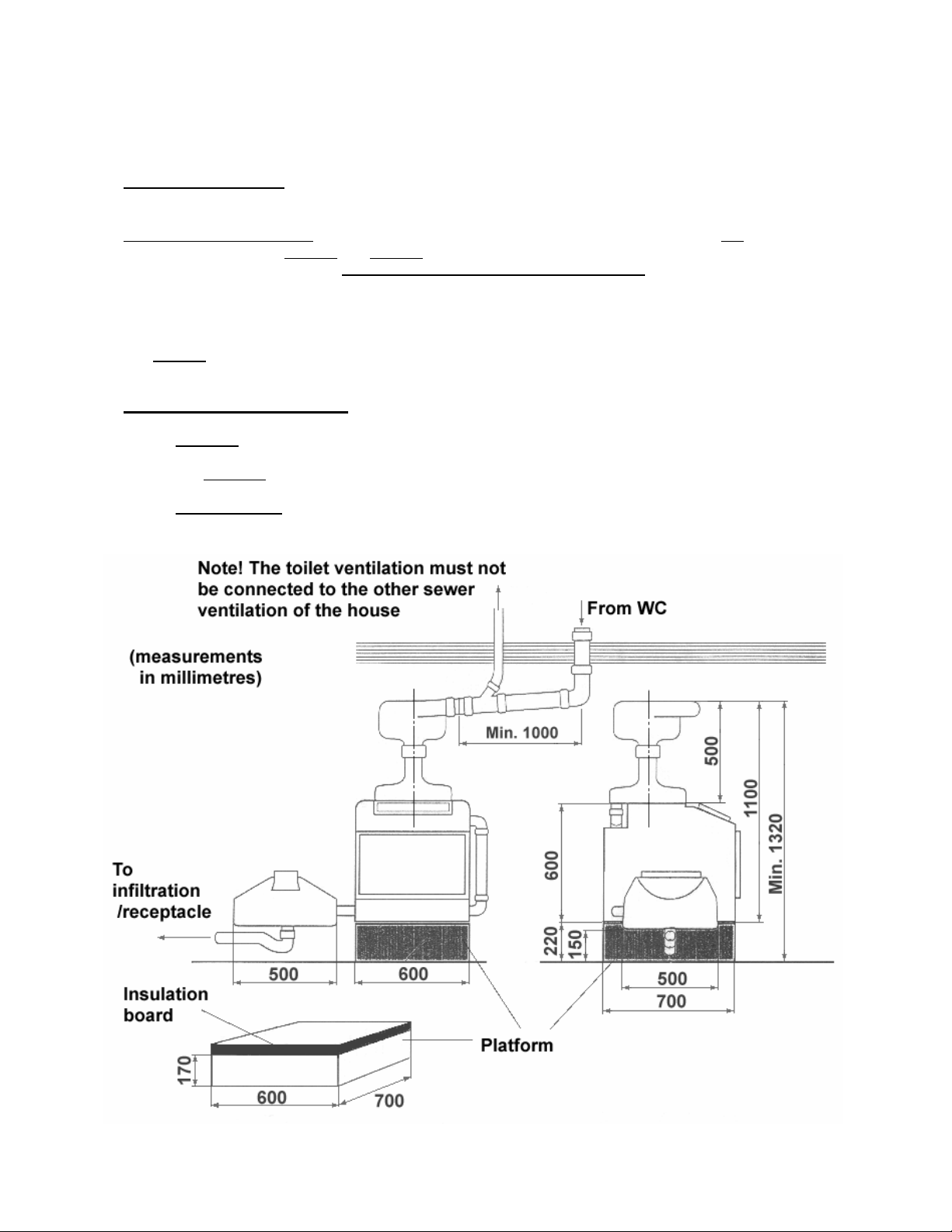

4.5 Pipe installation

4.5.1 Use 4” pipes between WC and Separator. For ventilation use 3-4” pipes.

4.5.2 The Separator should be connected to a 4” double socket.

NOTE: The Separator must be horizontal and its vertical line (Figure 3) perpendicular to the Bio

Chamber. The inlet pipe must be fully inserted into the socket. See Figure 6.

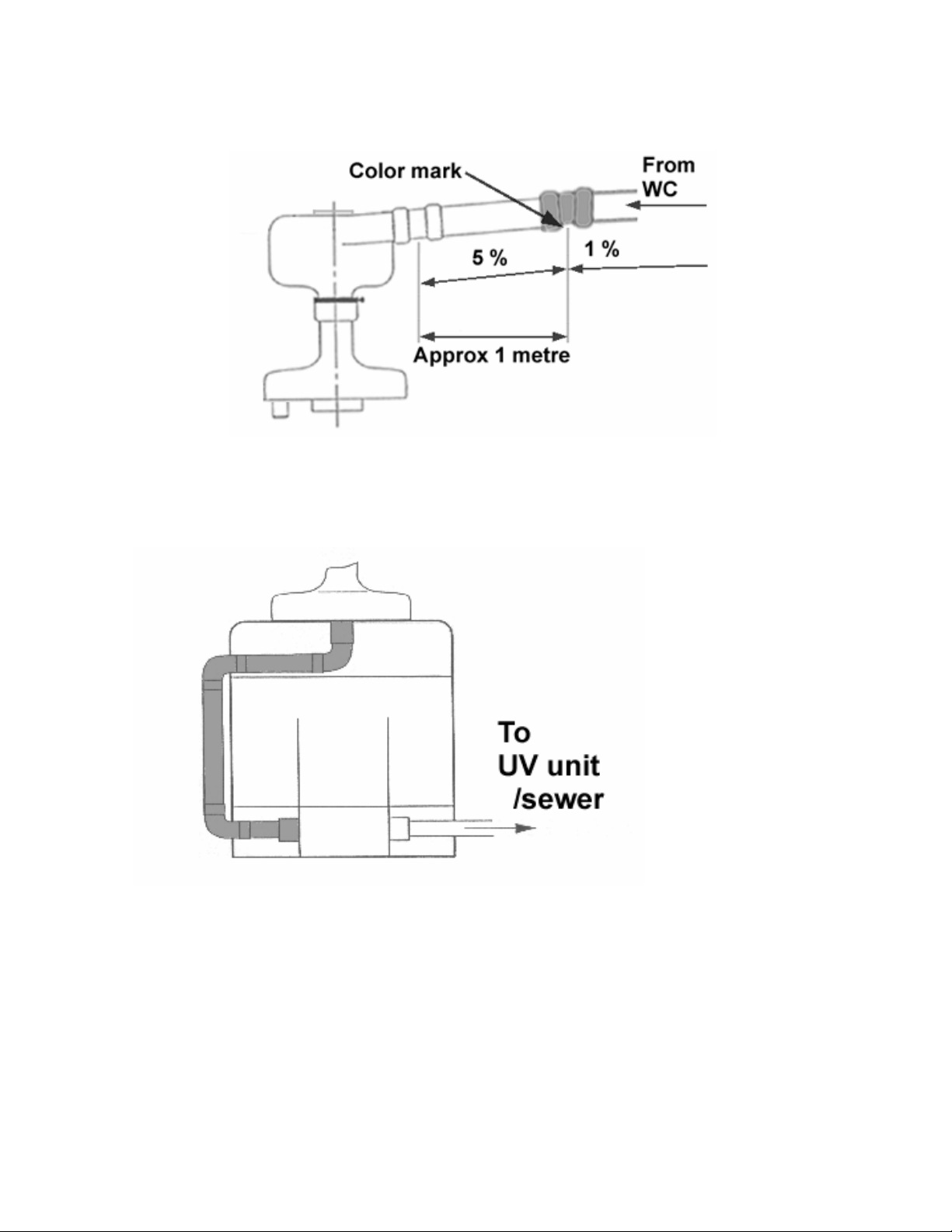

4.5.3 The horizontal distance between the WC and the Separator must be minimum 1 metre and that last

metre (closest to Separator) should be pitched at 5% (5 cm), see Figure 7. At further distances the

earlier part of the pipe should have a 1% horizontal slope, or as national standards. If needed,

use the special angled coupler double socket in order to achieve the pitch transition, see Figure 8.

NOTE: Turn the color mark of the angled coupler double socket downwards. Furthermore, check

that the inclination of the inlet pipe is smooth and that there are no depressions where fluid waste

may gather.

4.5.4 The ventilation should be installed between the WC and the Separator. The ventilation pipe should

extend above the roof.

4.5.5 If there is a large level difference between the WC-outlet and the Separator, then first install the

horizontal pipe pitched at the specified angle and then make the necessary level adjustment with the

vertical pipe, see Figure 1 or 2.

4.5.6 The pipe installation from Separator to Bio Chamber and further on to the UV-unit/sewer is shown in

Figure 9. If the UV unit is to be postitioned to the left of the Bio Chamber (as seen from the rear

side in Figure 3), the piping can be reversed. For Aquatron 90, please see text in Figure 9.

4.5.7 If horizontal bends are needed on the Separator inlet pipe, see Figure 10.

4.6 Flushing test

Ask someone to flush the WC with water only and check how much water is entering into the Bio Chamber.

If correctly installed, when flushing with water only, a maximum of 0.5 decilitres should go that way. If too

much water enters into the Bio Chamber there are two explanations:

WARNING! Do not expose your eyes or

skin to direct UV light.

NOTE! Only WC should be connected to the inlet of the Aquatron Separator.

Separate pipes should be used for sewage from bath, kitchen, laundry etc. If

these pipes are to be connected, it should be done after the Aquatron system.

NOTE! Do not use a vacuum-valve. The toilet ventilation must have a separate

vent pipe extending over the roof and must not be connected to the other sewer

ventilation of the house, as this may cause problems with odour and flies.