aquilar EcoLeak Eco-6 User manual

Eco-6

Six Zone Panel

EcoLeak

INSTALLATION

INSTRUCTIONS

ECO-6

100 to 240 Vac, 50-60 Hz,

POWER CONSUMPTION

5 watts

RELAYS

Number: Twa for leak relay and one for cable

break / power failure.

Type: SPDT

Rating: 3 A at 250Vac/24 Vdc

SENSING CABLE COMPATIBILITY

All EcoLeak and TraceTek sensing cable

(TT1000, 1100, 3000, 5000, series)

PROBE COMPATABILITY

All EcoLeak, Aquitron Probes

DETECTION PROBES

1 x EL-MPS-R or 4 x AT-PROBE per zone

INSTALLATION ITEMS

(NOT SUPPLIED)

• Wall fasteners for surface mounting (four

screws)

• Rubber or elastomeric washers to seal

at mounting points

TOOLS REQUIRED

• Drill or hole punch for electrical

conduit entries

• Phillips (cross-head) screwdriver

• Small at-head screwdriver

STORAGE

Keep the module in a dry place prior to

installation to avoid possible damage to

internal components.

MAXIMUM LENGTH OF SENSING

CABLE

30 metres per zone

MAXIMUM LENGTH OF LEADER

CABLE

300 metres per zone

NUMBER OF ZONES

6

SENSING CIRCUIT

2 and 4 wire sensing

CABLE ENTRY

20mm dia, 6 along the bottom, 8 on the back,

1 on right side. Appropriate stung glands

should be used.

DIMENSIONS AND WEIGHT

226 x 206 x 70, WxHxD. 1.85kg

WORKING TEMPERATURE RANGE

5°C to 40°C

Please read these

instructions carefully

and keep them in a

safe place (preferably

close to the module) for

future reference. These

instructions must be

followed carefully to ensure

proper operation.Wiring of

this alarm panel should be

carried out by a suitably

qualified technician in

accordance with the

applicable regulations and

standards in the relevant

industry/country. This

manual is intended as a

guide, and Aquilar Ltd

bears no responsibility

for damage or injury

arising from incorrect

installation of this and any

supplementary equipment.

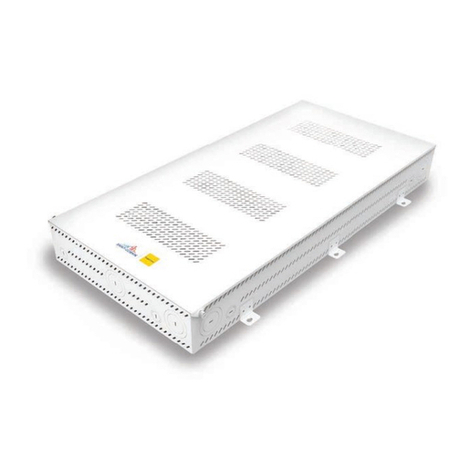

A. GENERAL INFORMATION

The Eco-6 alarm panel is designed for use with all AquiTron and TraceTek sensing cables and

sensors for detection of water, acid, hydrocarbon liquids (fuels) and refrigerant gas leaks.

Including built in battery back up as standard, while monitoring for both leak and cable break

on up to six separate zones. The Eco-6 is a truly versatile leak alarm panel.

B. PRODUCT INFORMATION

LEAK DETECTION SOLUTIONS

Eco

L

eak

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

1

Eco-6

Six Zone Panel

Eco-6

Six Zone Panel

LEAK DETECTION SOLUTIONS

Eco

L

eak

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

2

ENCLOSURE

Powder coated steel, colour RAL 9006 matt,

lockable, IP43 - Indoor use only

WORKING HUMIDITY RANGE

5% to 80% non-condensing

STATUS LED

Power Mains-Green, Leak-Red, Cable break-

Yellow

AUDIBLE ALARM

90dB at 10cm

BATTERY BACK-UP

24 hours, integral 6Vdc, 1850mA battery

APPROVALS

BS EN 61000-6-1 2007 Electromagnetic

compatibility (EMC). Generic standards.

Immunity for residential, commercial and

light-industrial environments.

BS EN 61000-6-3 Electromagnetic

compatibility (EMC) Generic standards.

Emission standard for residential,

commercial and light-industrial

environments.

2006/95/EC The Low Voltage Directive

2004/108/EC The Electromagnetic

Compatibility Directive

2011/65/EU The Restriction of Hazardous

Substances Directive

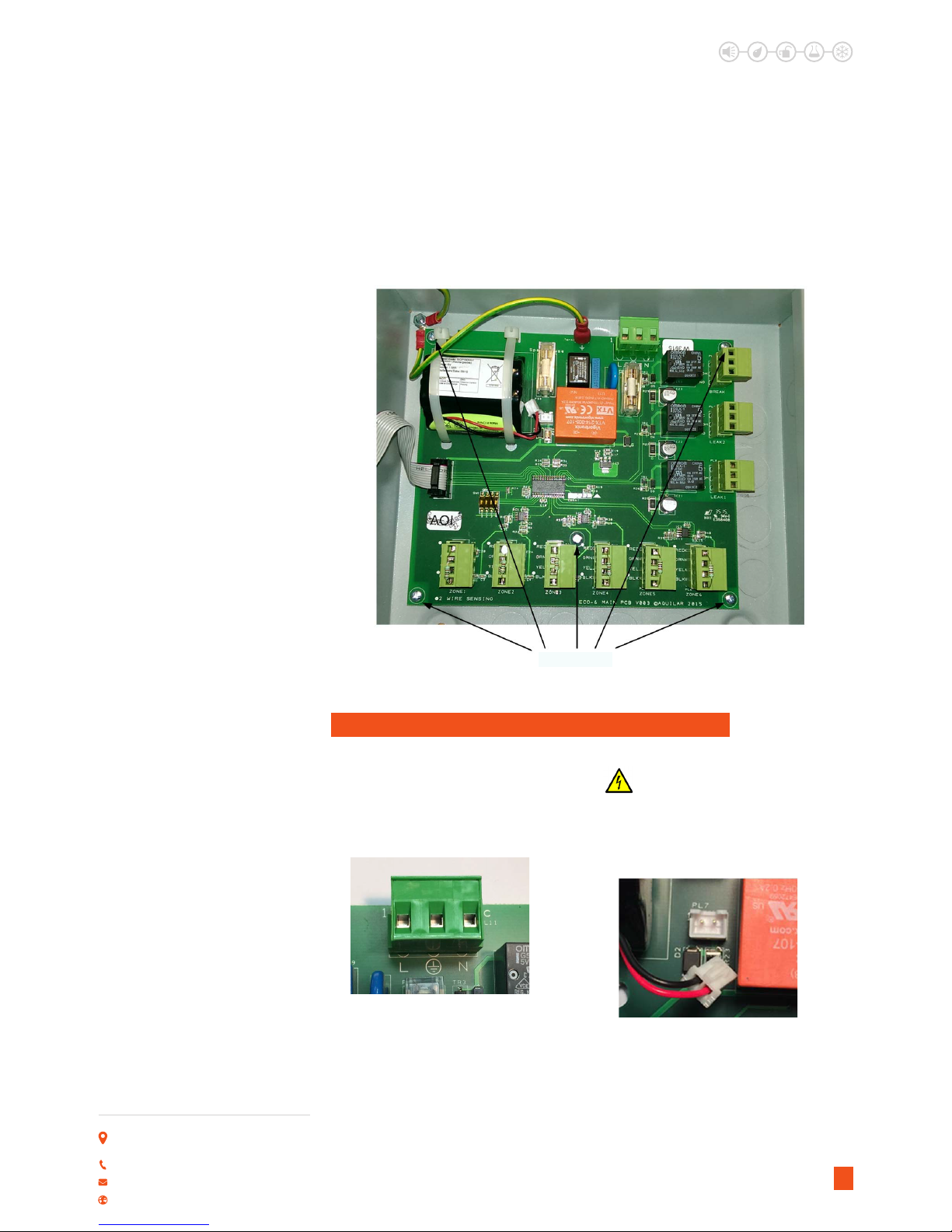

C. ALARM PANEL MOUNTING

The Eco-6 leak alarm panel should be mounted on an internal at surface away from direct

contact with water.3 x xing holes are provided along with several 20mm diameter knockouts.

To access the xing holes it is recommended the circuit board is removed prior to mounting

and any holes knocked out/drilled for conduit being tted. To remove the circuit board the

door board ribbon cable connector and earth bond lug should be carefully unplugged from the

circuit board rst.

LEAK DETECTION SOLUTIONS

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

3

Eco-6

Six Zone Panel

Eco

L

eak

Remove the ve xing screws retaining the board. Carefully remove the circuit board and

keep safe. Once the enclosure has been xed, ret circuit board taking care not to overtighten

screws. The earth lug and door board ribbon cable must also be retted for correct operation

of this device.

D. MAINS POWER AND BATTERY CONNECTION

It is recommended this alarm panel should

be connected to 230Vac mains power via an

un-switched 3A fused spur. The panel has the

capability to be connected to 110 – 240Vac.

Mains power must be isolated prior to any

connection being made or altered.

This alarm panel MUST be earthed.

Warning Shock Hazard. Exposed

Circuitry within! It is strongly

recommended the power is isolated before

opening the control panel lid and carrying out

any work within the unit.

Ensure the battery pack is plugged in. Allow

24 hours for full charge. While the panel is in

use this should be left connected at all times.

5 x Fixing Screws

Eco-6

Six Zone Panel

LEAK DETECTION SOLUTIONS

Eco

L

eak

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

4

E. IMPORTANT SENSOR

INFORMATION

TWO WIRE SENSING: ECOLEAK

SENSING CABLE, ECOLEAK PROBES

Two wire systems should be connected

using the red-black outer terminals only. As

indicated by the white dots. Use only Aquilar

EcoLeak cable or Aquilar probes for two wire

sensing. Use of other sensing devices could

cause the panel to malfunction.

EcoLeak sensing cable is not extendable. If

sensing is required in more than one area

on each zone, TT1000 should be used with

AT-MJC/AT-BJC jumper cable between the

sensing areas (up to a maximum of 30m total

sensing cable per zone).

FOUR WIRE SENSING: TT1000,

TT1100, TT5000, AT-PROBE ETC.

When using four wire system with Aquilar

AT-MLC leader cable or AT-BJC jumper cable

the red-green and yellow-black colour coding

on the zone sensor input terminals should be

observed.

NOTE: Do not connect more than one

sensing circuit into the Eco-6. Doing so

will cause malfunction in the cable break

checking system and may prevent the

panel from detecting cable faults and

leaks.

Any unused zones must be linked out at

the panel as shown, or an 82KΩ resistor

tted between the dotted terminals (red

and black). Failure to do this will cause the

panel to show a cable fault on that zone.

F. RELAY CONNECTIONS

Three volt free relays are available for

connection to external equipment. The

relays have common, normally open and

normally closed contacts. All relays are volt

free contacts. No power is available from

them. If using them to control equipment that

requires power, an external power source

must be supplied (by others) and the relay

used as a switch. Please see relay connection

addendum at the end of this manual for

further connection guidance. The relays

are rated for a maximum load of 5A 250V.

Exceeding this may cause irreparable damage

to the alarm panel.

Warning Shock Hazard! Caution 230V

mains voltage could be present at

these relays that may require isolation

elsewhere.

Leak 1 and Leak 2 relays both operate when

a leak is detected within any of the six zones

and the leak alarm is in operation.

The break relay operates when a cable break

is detected on any of the six zones or power

is lost to the panel. (Note: if the integral

battery pack is plugged in and charged the

system will continue to monitor for leaks and

cable break for a minimum 24hrs until the

backup battery discharges).

Eco-6

Six Zone Panel

LEAK DETECTION SOLUTIONS

Eco

L

eak

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

5

All relays will only reset when the leak/fault

has been rectied and the reset button is

operated. Mute has no eect on relay output.

IMPORTANT! Relay output terminals refer

to the panel in its ‘o’ state. The Break/Fault

relay is energized when the panel is mains

powered. Once power is applied to the panel

the normally open and closed terminals are

reversed.

G. NORMAL OPERATION

After connections are complete, supply

power to the unit. If the sensing circuit is

complete and free of leaks or other problems,

the panel will run a function test and then

the green mains power LED only will remain

illuminated.

After connections are complete, supply

power to the unit. If the sensing circuit is

complete and free of leaks or other problems,

the panel will run a function test and then

the green mains power LED only will remain

illuminated.

Testing the alarm panel after supplying

power and Routine maintenance

procedure:

• When power is supplied, the GREEN LED

illuminates for mains power.

• Place water or a mapping tool on the

probe or sensing cable and the Eco-1 panel

should report an alarm condition. For the

TraceTek TT5000 systems, simulate a leak

condition by tightly bending and holding

the sensorcable. Please refer to relevant

TraceTek datasheet.

• Verify that the RED alarm LED is illuminated.

• Conrm the Leak relay operates.

• The buzzer will sound and will only be

silenced when the mute button is pressed

or system is reset. Reset is onlypossible

once the probe or sensing cables are dried.

• To test the fault alarm operation disconnect

the probe or sensing cable from the leader/

jumper cable. The Eco-6 panel will report a

fault alarm.

• Verify the YELLOW alarm LED is illuminated

• Conrm fault relay operates.

• Buzzer mute and reset in same method as

for a leak alarm. Reset is only possible once

the fault has been repaired.

• Turn o mains power (after allowing

sucient time for battery charge). Green

power light will go out, Red battery

• LED will illuminate to indicate panel is

running on battery power. If battery LED

is ashing or does not illuminate battery

power is too low for proper operation and

will require further charging.

• While on battery power ensure leak and

fault functions operate correctly.

If the Eco-6 unit still does not appear to

operate properly contact your supplier for

assistance.

H. RESETTING THE UNIT

When the probe or sensing cables are dried

or repaired press the reset button. The unit is

designed so an alarm can be muted, but the

panel cannot be reset until the leak or fault

has been rectied. If auto reset is enabled the

system will still not reset until the leak/fault

has been rectied.

Eco-6

Six Zone Panel

LEAK DETECTION SOLUTIONS

Eco

L

eak

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

6

I. CLEANING THE UNIT

If it is necessary to clean the outside surface,

use a dry cloth or sponge. Do not use

solvents or abrasive cleaners. Do not open

the enclosure if it is wet (risk of electrical

shock).

J. FUSE REPLACEMENT

The panels mains input is protected by a

T500mA, 250-V fuse. Use no other type of

fuse or the Eco-6 panel could be damaged or

could fail to perform properly.

Warning Shock Hazard. Exposed

Circuitry within! It is strongly

recommended the power is isolated before

carrying out any work within the unit.

K. STORAGE AND HANDLING

OF SENSING CABLE

Despite their rugged construction, EcoLeak

and TraceTek sensing cables must be handled

in a manner appropriate for a sensing

device or they may be damaged and require

replacement.Therefore, you should follow

some basic rules for storing and handling all

sensing cables:

• Store spare cable in its original packaging

or container in a clean, dry place until ready

for installation.

• Schedule cable and probe/sensor

installation after all mechanical, plumbing,

and electrical work has been completed

• Clean the area where the cable is to be

installed, and remove any obvious debris or

other sources of contamination.

• Do not solder or weld near the cable

without providing protection from heat,

solder ux, or weld splatter.

• Do not drop tools or oor tiles on the cable;

sharp and heavy objects may damage the

cable.

• Avoid walking or stepping on the cable.

Provide shielding (for example, a half shell

• of plastic pipe or upturned cable tray) where

additional protection is necessary.

• Do not use insulation tape or similar to

secure sensing cable (some tapes and

adhesives absorb moisture) or use solvents

that could eventually cause an alarm.

• Do not drag sensing cable through

contaminants (such as pipe ux, PVC

cement, solvents, oil, water or dirt)

L. NOTE ON CABLE CLEANING

EcoLeak and TraceTek sensing cables use

a solid core polymer construction and can

usually be easily cleaned with tap water. In

extreme cases or when large amounts of

cable are contaminated, either cable can

be washed in a dishwasher. Try a water

only (no detergent) cycle rst and avoid the

heated dry cycle. When placing the cable in

the dishwasher be sure to keep water out of

the connectors (TraceTek cable ends can be

connected together for convenience).

The TraceTek TT5000 sensing cables cannot

be cleaned and must be replaced after

exposure to fuel or solvent.

K. FINAL COMMISSIONING

CHECK LIST

1. Complete a system inspection in the

presence of the owner.

2. Ensure a plan showing the location of the

zone and sensor is available.

3. Check that the following information

is clearly visible adjacent to the alarm

module:

• “In case of alarm” instruction.

• Location of the system “as tted

drawing” in case it is not installed adjacent

to the alarm module.

• Name and contact number of the person

responsible for operating the system

• Supplier’s contact name and address.

Or details of the installation/maintenance

company.

4. Hand over these Installation, Operating

and Maintenance Instructions.

Eco-6

Six Zone Panel

LEAK DETECTION SOLUTIONS

Eco

L

eak

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

7

5. Make the owner aware that it is strongly

recommended to perform a systems check

at regular intervals, as a minimum once

every 12 months.

M. ROUTINE MAINTENANCE

AND TESTING

Perform a functional check per the following

procedure as a minimum of 12-month

intervals. Repair or replace all damaged

wiring, probes and sensor cables. Such a

check will identify conditions that adversely

aect the capability of the system.

More frequent checks may be required if the

sensing cable is repeatedly exposed to leaks,

or if construction or repair work is done

where the sensing cable or probes may be

exposed. Apart from fuse replacement there

N. ROUTINE TEST

PROCEDURE:

• Should be carried out as initial setup

procedure as set out above.

• Important Note: This may cause external

equipment to shut down or go into alarm if

devices are connected to the leak and fault

relay contacts.

are no eld repair procedures for the Eco-6

panel. If the module fails to perform the

functional tests it must be returned to your

supplier for repair or replacement.

Contact your local EcoLeak representative

for further information on service and

maintenance support.

N. TROUBLESHOOTING

POWER

Problem:

Green mains power LED Does not illuminate

Possible Cause:

No power to alarm panel. Mains or internal

fuse blown.

Action:

Check 3A fuse within spur, replace if

necessary. Verify mains power present at

mains terminals of panel. Check internal

T500mA fuse, replace if necessary. If panel

remains inoperative please contact supplier.

Problem:

Red battery power LED does not illuminate,

or ashing when mains power removed.

Possible Cause:

Battery pack not plugged in. Battery not

charged

Action:

Plug battery pack into connector PL7 and

leave with mains power on for minimum

24hrs.

Problem:

Red battery power LED fails to illuminate or

continues to ash after 24hrs charging.

Possible Cause:

Faulty battery pack.

Action: Contact supplier for replacement.

RELAY OUTPUTS

Problem:

No power from the relay

Possible Cause:

Relays are volt free contacts. No power is

available from them.

Action:

Rewire to use relay as a switch from an

external power source. Please see relay

connection addendum.

Problem:

Solenoid valve opening when expected to

be closed (or vica versa), or other connected

equipment behaving in the opposite manner

to required. Paying particular attention to the

break/fault relay as it is energized when the

alarm is powered.

Possible Cause:

Cable is pinched (all cables).

Action:

Use other terminal. Please see relay

connection addendum.

Eco-6

Single Zone Panel

LEAK DETECTION SOLUTIONS

Eco

L

eak

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

WATER SENSING

Problem:

Leak Alarm, but no leak is found.

Possible Cause:

Sensing cable is dirty or contaminated.

Action:

Clean cable using water (no solvents, acetone,

white spirit or turps). Dry the cable and check

Eco-Leak front panel. Heavily contaminated

cable may require replacement. But if dirt is

accumulating, cleaning and/or replacement

will eventually be required.

Problem:

Leak Alarm, but no leak is found.

Possible Cause:

Sensing cable is exposed to occasional water

spraying.

Action:

It is best to keep the sensor cable at least

1 meter (3 feet) from the airow of any air

conditioning units, or areas where occasional

wetting of the sensor could be expected.

Problem:

Leak Alarm, but no leak is found.

Possible Cause:

Cable is in contact with sharp metal edges.

Action:

Check the sensor cable for possible points of

contact with sharp edges such as the edges of

drip trays or the pipe threads on adjustable

oor supports trunking and ducting.

Reposition the cable as necessary or insert a

small piece of insulating material to prevent

the cable from making contact with the metal

edge.

FUEL OIL SENSING

Problem:

Leak Alarm, but no leak is found.

Possible Cause:

Cable is pinched (TT5000 cable)

Action:

Check the sensor cable for possible pinch

points. TT5000 can indicate a leak if tightly

bent or compressed by a heavy object

8

Problem:

Leak Alarm.

Possible Cause:

Probe or sensing cable is contaminated

(TT5000 cable)

Action:

Locate the spill area, investigate the cause of

the spill and take necessary repair actions.

Clean up in the spill area and clean and dry

the probe, if necessary. Any TT5000 cable

contaminated with hydrocarbons (oil, fuel

etc.) will need to be replaced, it cannot be

cleaned and re-used. Leak LED will turn o

when cable/probe is replaced/dried and reset

button is pressed.

FAULT ALARM

Problem:

Fault output to BMS but no fault indicated on

zones (Battery LED illuminated).

Possible Cause:

Mains power lost to panel.

Action:

Check mains power is connected and

turned on. Check fuses. Test and replace as

necessary.

Problem:

Fault indicated, but no obvious fault found.

Possible Cause:

Loose connection on sensing circuit.

Action:

Check all connections are suciently

tightened within the alarm panel, connectors

are fully pressed home, and any modular

connectors are fully tightened. If using

TT1000 sensing cable or AT-PROBE-M ensure

the TT-MET-PC end termination is tted

properly on the end of line. If using AT-

PROBE-TS ensure the last probe has end of

line terminations (cable loops) tted.

Problem:

Fault indicated, but no obvious fault found.

Possible Cause:

Sensing cable or probe faulty or damaged.

Action:

Check sensors for damage, test and replace

as necessary.

Eco-6

Six Zone Panel

LEAK DETECTION SOLUTIONS

Eco

L

eak

Weights & Measures House, 20 Barttelot Road,

Horsham, West Sussex RH12 1DQ

+44 (0) 1403 216100

www.aquilar.co.uk

9

Problem:

Fault indicated, but no obvious fault found.

Possible Cause:

Short to earth on sensing circuit.

Action:

Check sensing cables or probes are not

earthed. Pins on probes should be positioned

not touching metal surfaces. Sensing cable

not positioned running over sharp metal

surfaces (drip tray edges, false oor support

pedestals etc.)

Important: All information, including illustrations, is believed to be reliable. Users, however,

should independently evaluate the suitability of each product for their application. Aquilar

Limited makes no warranty as to the accuracy or completeness of the information, and

disclaims any liability regarding its use. The only obligations of Aquilar Limited are those in

the Aquilar Standard Terms and Conditions of Sale for this product, and in no case will Aquilar

Limited be liable for any incidental, indirect, or consequential damages arising from the sale,

resale, use or misuse of the product. Specications are subject to change without notice. In

addition, Aquilar Limited reserves the right to make changes – without notication to Buyer

– to processing or materials that do not aect compliance with any applicable specication.

AquiTron, EcoLeak are trademarks of Aquilar Limited.

V1 05.2017

Table of contents

Popular Control Panel manuals by other brands

Biamp

Biamp TEC-X 1000 Installation & operation guide

auto maskin

auto maskin Marine Pro 200E Series Configuration manual

Junkers

Junkers TR 100 instruction manual

Haes

Haes ESG-2001 Installation, commissioning & operating manual

SAINT-GOBAIN

SAINT-GOBAIN SageGlas 300-1176-001 Product sheet

Ampac

Ampac ZoneSense Plus Operation & programming manual