auto maskin Marine Pro 200E Series Instruction sheet

Manual# 1006496

Configuration Manual

200E Series

DCU 210E/208E –Engine Panel

RP 210E/220E –Remote Panel

Configuration Manual - 200E Series

Page ii

Configuration Manual

for the

Marine Pro 200E Series

~~~

DCU 210E/208E Diesel Engine Control Unit

RP 210E/220E Remote Panel

Revision

1.3

Revised

January 23, 2017

Revision history:

Rev.

Date

Description

1.0

15.10.2015

Release

1.1

18.03.2016

Firmware update

1.2

25.11.2016

Added RP 220E

1.3

22.01.2017

Synched to firmware 3.5P2

Copyright © 2017 by Auto-Maskin AS.

All rights reserved. No part of this document may be reproduced or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of Auto-Maskin AS.

Configuration Manual - 200E Series

Page iii

Table of Content

DOCUMENT INFORMATION ................................ 1

ABOUT THIS MANUAL .............................................. 1

Responsibilities .............................................. 1

MATCHING FIRMWARE ............................................ 1

ORDERING INFORMATION......................................... 1

OVERVIEW OF THE 200 SERIES .................................. 2

DCU 210E Engine Panel ................................. 2

DCU 208E Engine Panel ................................. 2

Configuration................................................. 2

RP 210E/220E Remote Panel......................... 2

Ethernet Switch ............................................. 3

Expansion ...................................................... 3

FIRST POWER-ON................................................... 4

Preparations .................................................. 4

First Power-On Wizard .................................. 4

CONFIGURATION................................................. 5

CONFIGURATION-AND FIRMWARE FILES...................... 5

DCU Web Server Configuration Interface ...... 5

USB memory with Configuration file ............. 5

Connecting to the DCU .................................. 5

Further connection settings........................... 6

Logged in ....................................................... 7

DCU................................................................ 7

RIO................................................................. 8

SDU................................................................ 8

Upload Wallpaper ......................................... 8

Versions ......................................................... 8

Troubleshooting ............................................ 8

MAIN DCU WEB SERVER MENU................................. 9

Password ....................................................... 9

File ................................................................. 9

I/O CONFIGURATION ............................................ 10

Flexible I/O................................................... 10

Config Inputs ............................................... 10

Config Outputs............................................. 21

USER INTERFACE ................................................25

CONFIGURATION .................................................. 25

Header......................................................... 25

Instruments ................................................. 25

PAGES ................................................................ 25

Page details ................................................. 25

Apply a signal to a slot ................................ 26

Edit a signal ................................................. 26

Insert a new Page ........................................ 26

Choose a Template ...................................... 26

Delete a Page .............................................. 26

FLOW CHARTS...................................................... 26

RP HOME VIEW CONFIGURATION............................ 27

CONTROLS........................................................... 27

Gear............................................................. 27

SHORTCUTS ......................................................... 27

LANGUAGE .......................................................... 27

BUZZER............................................................... 28

START/STOP/ PRELUBE...................................... 29

PRELUBE ............................................................. 29

Prelube –Fixed Time.................................... 29

Prelube –Until Pressure .............................. 29

Oscillating.................................................... 29

DCU ENGINE START/STOP CONTROL ....................... 30

AUTOMATIC START ............................................... 30

STARTER 1........................................................... 30

STARTER 2........................................................... 30

AUTOMATIC STOP................................................. 31

START/STOP BUTTONS .......................................... 31

Latched buttons........................................... 31

Momentary buttons .................................... 31

E-Start.......................................................... 31

USER INTERFACE................................................... 32

Language..................................................... 32

Buzzer .......................................................... 32

ENGINE MODEL.................................................... 33

Engine Name ............................................... 33

SERVICE INTERVAL ................................................ 33

View Service Status...................................... 33

Configure ..................................................... 33

COMMUNICATION ................................................ 33

Network Communication............................. 34

Modbus RTU ................................................ 34

Configuration Manual - 200E Series

Page iv

Modbus TCP................................................. 34

J1939 Configuration .................................... 34

MISCELLANEOUS .................................................. 35

Alarm Configuration .................................... 35

Counters ...................................................... 35

Acknowledge Configuration ........................ 36

Event Log ..................................................... 36

Suppress DM1 faults.................................... 36

Engine Application Configuration................ 36

System Voltage............................................ 37

Factory Reset ............................................... 37

RP CONFIGURATION...........................................38

POWER-ON WIZARD............................................. 38

ADMINISTRATION MENU........................................ 39

DCU Connection / Connections.................... 39

DCU Alarms ................................................. 39

DCU Acknowledge ....................................... 39

IP Address .................................................... 40

Cameras....................................................... 40

Station Location........................................... 40

Functional Inputs......................................... 40

Change Password ........................................ 41

Station priority............................................. 42

Lock.............................................................. 42

System Voltage............................................ 42

Reset to Factory Default.............................. 43

Configuration Manual - 200E Series

Page 1

Document

Information

About this manual

This manual has been published

primarily for professionals and

qualified personnel.

The user of this material is assumed to

have basic knowledge in marine

systems, and must be able to carry out

related electrical work.

Warning!

Work on the low-voltage circuit should

only be carried out by qualified and

experienced personnel.

Installation or work on the shore

power equipment

must only

be carried

out by electricians authorized to work

with such installations.

Responsibilities

Warning!

It is the

sole responsibility of the

installer

to ensure that the installation

work is carried out in a satisfactorily

manner, that it is operationally in good

order, that the approved material and

accessories are used and that the

installation meet all applicable rules

and regulations.

Note! Auto-Maskin continuously

upgrades its products and reserves the

right to make changes and

improvements without prior notice.

All information in this manual is based

upon information at the time of

printing.

For updated information, please

contact your local distributor.

Matching firmware

This Configuration Manual is for the

200E Series of panels.

It has been updated to match the

following firmware releases.

Panel

Firmw.

Release

DCU 210E/ 208E

3.5 P2

January 2017

RP 210E/RP 220E

3.5 P2

January 2017

Ordering information

The Marine Pro covers a wide range of

compatible products within both the

200- and 400 Series. Please visit our

web site for more information.

http://auto-maskin.com/marine/

Configuration Manual - 200E Series

Page 2

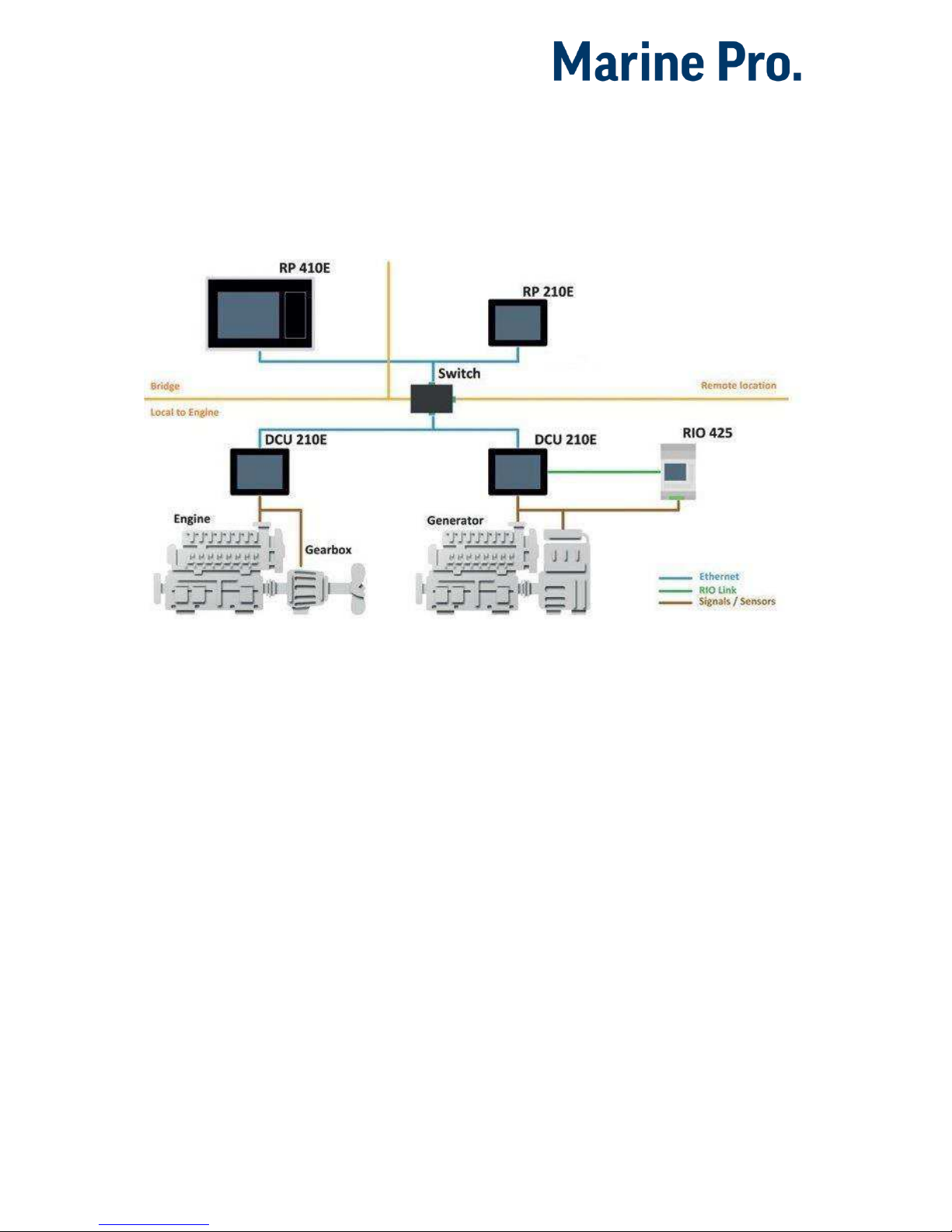

Overview of the 200

series

The drawing below shows a typical

layout.

DCU 210E Engine Panel

The DCU 210E engine panel is the

main building block in the 200 Series.

Engine sensor values are displayed on

the color touch screen, and commands

and other user interaction is also here.

DCU 208E Engine Panel

The DCU 208E is basically the same as

the DCU 210E, but without the color

touch screen.

It saves cost being used in smaller

engine rooms, where a remote panel is

all that is needed.

Configuration

An ordinary PC web-browser is used

to configure the DCU, using the inbuilt

web-server on the DCU.

RP 210E/220E Remote Panel

The optional RP remote panel brings

everything on the DCU to a remote

location, with the exact same user

interface. It does not need any

configuration, as it is reading the

configuration from the DCU.

As such, the RP can easily be

retrofitted.

The RP also supports one IP-camera to

be installed on the network.

Configuration Manual - 200E Series

Page 3

Ethernet Switch

The Ethernet switch is not necessary if

only one DCU 210E and one RP

210E/220E is in use. These can then

be wired with an Ethernet cable

directly.

It is recommended to make use of an

Ethernet switch though, as it simplifies

PC configuration connection and

future expansion to remote panels

and/or camera interface.

Expansion

The basic system can be expanded

with more input and output channels

using the versatile RIO units (Remote

I/O).

Currently, there are RIO units for

General I/O expansion, RIO 410

and RIO 210.

Exhaust temperature

monitoring, RIO 412

Generator monitoring, RIO 425

Load sharing, LSU 408

Configuration Manual - 200E Series

Page 4

First Power-On

Preparations

First, make sure to consult the Quick

Installation Guide (QIG) that came with

the panel.

Installation

Install the panel according to

guidelines in the Installation manual.

Connections

Connect power to the panel according

to guidelines in the Installation

manual.

First Power-On Wizard

The DCU (not DCU 208E) will display

the

first power-on wizard

at the first

power up after delivery, or after a

factory reset of the panel.

All wizard settings can be changed

later.

Configuration Manual - 200E Series

Page 5

Configuration

This section explains the configuration

of the DCU.

Configuration- and

Firmware files

The DCU may be configured either

using the built in web server, or by

inserting a USB memory stick with a

predefined configuration file.

DCU Web Server Configuration

Interface

The panel has a built in web server,

offering access to full configuration.

USB memory with Configuration

file

Insert a USB memory with the

configuration file(s) and follow the

guidelines appearing on the panel

screen.

Valid filename characters

a-z

A-Z

0-9

“_” (underscore)

“-“(hyphen)

If other characters are being used,

then the panel may not “see” it.

Rename the configuration file to solve

the issue.

When the USB memory is inserted, the

panel asks for the administration

password (4 digits).

The panel then lists the configuration

file(s) available on the USB memory.

Select file(s) then select COPY to copy

these files into the User Files area in

the panel. Note that this does not

activate the file; it is merely a copy of

the file into the panel.

Select a file, and then select USE to

copy and activate this configuration

file.

Note! The DCU 208E does not have a

screen interface and hence this

method does not work on that unit.

USB memory with Firmware

file

A USB memory stick can be used to

install a new firmware in the DCU.

Note! If the memory unit has firmware

for both the DCU and the RP, and the

intention is to upgrade both panels,

then make sure to upgrade the RP

firmware first!

Connecting to the DCU

It is possible to connect a laptop to the

DCU either directly or through a LAN

(Local Area Network).

Note! For use in an existing Ethernet

network, check the configuration of

the LAN with the LAN manager.

To connect to the DCU

Connect an Ethernet cable between the

laptop and the DCU port Ethernet port.

Configuration Manual - 200E Series

Page 6

In the DCU menu, select Help –

Version Information. Note the IP

address. From factory, the IP

address is 192.168.0.101.

In the internet browsers

address field area, type the IP

address, eg.

http://192.168.0.101.

Press Enter, and note the login

screen.

In the login screen, type

- Username: dcu

- Password: 1234 (from factory)

Logged In?

Proceed to the Web Server

Configuration section, page 7.

Not Logged In?

Continue with connection settings as

described below.

Further connection settings

Change the IP address of the

DCU

If necessary, the IP address of the DCU

can easily be changed.

Note! The last digit in the IP address

becomes the engine number.

The DCU has a fixed IP address that is

set during the first power-on set up.

The IP address may also be changed

later, in the DCU panel menu here:

Menu –Settings –

Administration –Network

Configuration

IP address convention

The factory default IP address of the

DCU is 192.168.0.101. The first three

groups must be the same for all

components in the LAN, for instance

192.168.0.x, where x is the other unit

in the LAN.

Note! The x-number must be unique

within the LAN. Also, the two last

digits in x will represent the engine

number.

Example: A DCU with the IP address

192.168.0.104 will be named “Engine

#4”.

Factory defaults for the DCU

Factory defaults are valid at initial

startup only.

IP address: 192.168.0.101

Subnet Mask: 255.255.255.0

Default Gateway: 192.168.0.1

The IP address configuration will not

be kept, if a Factory Reset operation is

performed.

DHCP IP addresses range: 101 –199

within the subnet defined by the DCUs

IP address.

Configuration Manual - 200E Series

Page 7

Connection troubles

Make sure that the PC and the DCU is

connected to the same subnet.

If still a problem with configuring the

IP address check the following:

Use the ‘Connect a PC’ feature

From the DCU select “Connect a PC”

icon in the Settings Menu and

mark/toggle the Enabled check box.

In addition and after enabling you may

have to disconnect and reconnect the

Ethernet cable.

Use Static IP connection

Change computer IP settings for LAN

to static IP settings.

Web Server Configuration

Note! This chapter is not applicable for

the RP 210E/220E.

Logged in

Once logged in, the DCU can be

configured.

When logged in, the browser displays

the Home screen.

The Home screen has the following

menu items.

Note! All changes to DCU, RIO and SDU

configuration is applied directly on

DCU, and not in the PC.

DCU

This is the top level menu for the DCU

configuration.

To access the DCU section, log in with

the following:

User Name: dcu

Password: 1234 (from factory)

Configuration Manual - 200E Series

Page 8

RIO

This is the menu top level for the

optional expansion I/O modules RIO

210, 410, 412 and 425.

SDU

This is the menu top level for the

optional Shutdown unit modules SDU

404 and SDU 410.

Upload Wallpaper

A personal wallpaper can be uploaded.

Versions

This top level menu item lists the

hardware and software version of the

DCU . If the DCU is connected to J1939

and the ECM data is transmitted, ECM

version will also be displayed.

Tip! If contacting Auto-Maskin for help

or questions regarding your product,

the data in the Versions page provide

vital data that might help speed up the

resolution to your enquiry.

Troubleshooting

The troubleshooting section makes it

possible to troubleshoot I/O and

communication on the DCU, and the

RIO units.

Configuration Manual - 200E Series

Page 9

Main DCU web server

menu

The menu is found here:

Home DCU.

This is the main menu for the DCU

configuration. The following is an

overview of the menu items.

Password

The DCU configuration is password

protected with a pin code.

Select this option to change the

password. First, type in the old

password and then the new password

twice.

Default password is “1234”.

File

File handling.

Load any file

To change the configuration of the

DCU, load a different configuration

file.

Note! Panel will restart with the new

configuration file.

Factory Default

Select a file to activate a predefined

factory configuration file.

User Uploaded

This lists the files that are previously

user uploaded to this DCU.

Select a file to activate a new

configuration for the DCU.

Delete configuration file

The possibility to delete a user

uploaded configuration file.

Configuration Printout

This prints the current configuration

to screen.

To print to paper, use the browsers

print menu.

Save file as…

This saves the current configuration of

the DCU into a file on the PC. The

default file extension is .cfg.

Upload to DCU

Firmware

The firmware can be updated

whenever there is a new version

available.

Wallpaper

A personal wallpaper can be uploaded.

Make sure the file is in PNG format.

Configuration

A new configuration file can be loaded

into the DCU. Note that this menu

loads the file only. To activate the file,

choose the User Uploaded section as

described under File.

Configuration Manual - 200E Series

Page 10

I/O Configuration

The I/O section is found under:

Home DCU I/O Configuration.

It has menu items for flexible I/O,

input and output signals. These are

separated into three sections.

Note! Always remember to press the

Submit button after each change on

the configuration pages. No changes

are saved until this button is pressed!

Flexible I/O

This is where the Flexible I/O channels

are defined. Each channel can be used

for a variety of input and output

functions, such as:

24VDC Supply

0VDC

Switch Input

Configurable Output

4-20mA sensor

Voltage sensor

5V (#6)

J1939#2 (#20 and #21)

Note! Making changes to the flexible

I/O configuration may result in

damage to sensors connected to the

panel. It is recommended to

disconnect all sensors from the panel

before making changes.

After a flexible I/O channel has been

defined it will appear in the respective

menu as enabled.

Eg. Connector C1P1 has been defined

as a “4-20mA” channel in the Flexible

I/O section. It will now be available in

DCU Config Inputs 4-20mA.

Config Inputs

This is where the I/O input channels

are configured, such as 4-20mA,

PT100 and switch inputs.

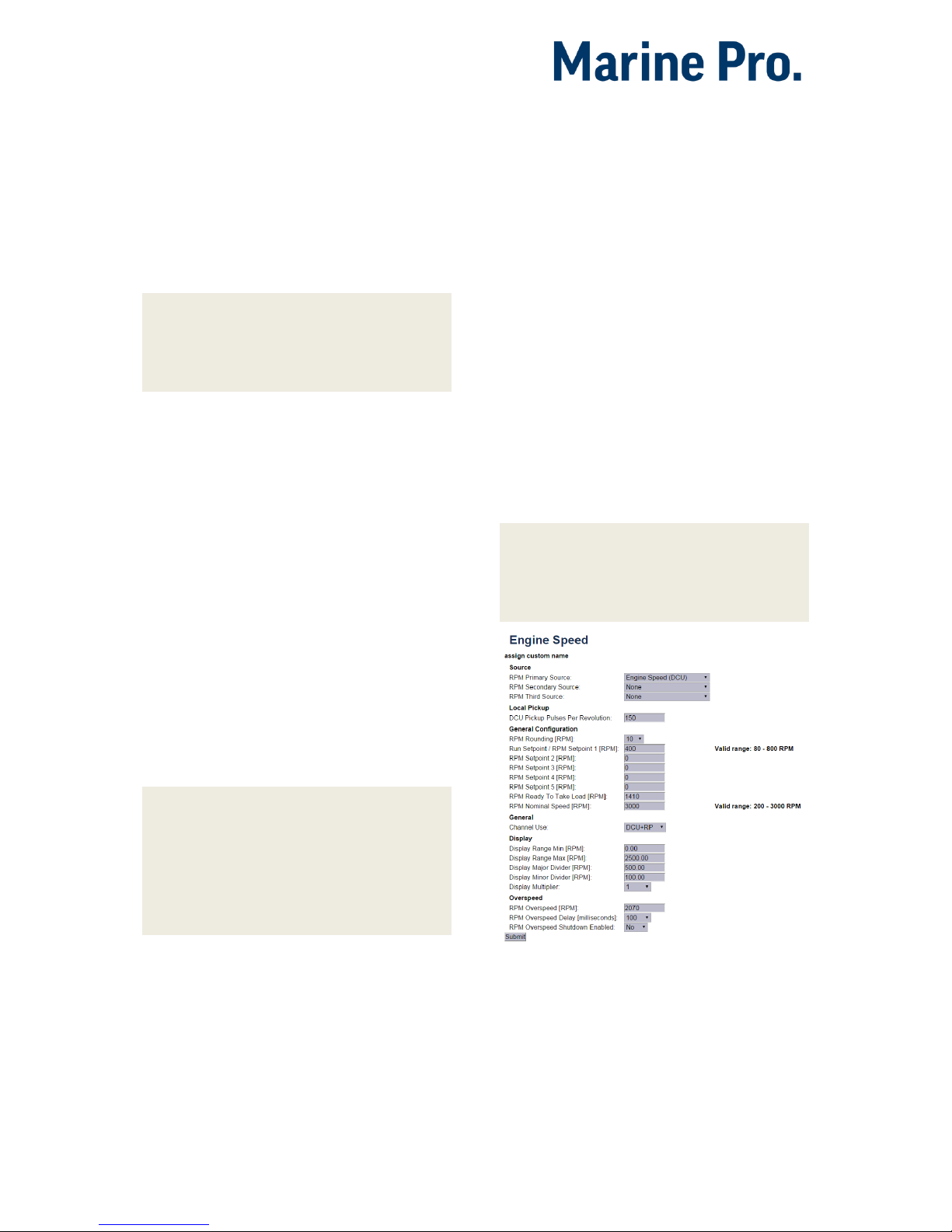

Engine Speed

This is where engine speed sensors

are configured, and the overspeed

setpoint is set. The majority of the

configuration is synchronized with

SDU.

Note! This section is central to any

installation. It provides the DCU with

data required to form an exact and

reliable reading of the engine speed.

HomeDCUI/O ConfigurationEngine Speed

Configuration Manual - 200E Series

Page 11

Source

The Engine Speed is constructed by

reading data from up to three sources

simultaneously. These three sources

are prioritized by the DCU. As long as

the RPM Primary Source is functional,

it is used to form the actual Engine

Speed. Should the RPM Primary Source

fail, the DCU uses the RPM Secondary

Source if available. Finally, the RPM

Third Source is used only when both

Primary and Secondary fails.

Each of the RPM Sources can be

configured to receive data from a

number of possible sensors.

Source

Comment

J1939

J1939 CANbus connected to

terminals C1P7-8.

J1939#2

J1939 CANbus #2 connected

to Flexible I/O #20-#21.

DCU

Magnetic pickup locally

connected to DCU,

terminals C4P1 and Flexible

I/O#18.

SDU

410

One of the two pickups

connected to the SDU safety

unit.

The SDU has a scheme for

selecting from its two

connected pickups.

SDU

404

Magnetic pickup locally

connected to SDU.

Local Pickup

If there is a pickup connected to the

DCU, or “DCU” is selected among the

sources above, then set the pulses per

revolution here.

General Configuration

RPM Rounding rounds off the

displayed value to nearest 1, 5 or 10

RPM.

RPM Setpoint is the RPM at which the

DCU indicates the engine is running,

and disconnects the cranker.

RPM Setpoint 2-5 are optional

setpoints that can be used in

conjunction with other sensors.

RPM Ready to take Load is a signal

that can be configured to an output. It

activates when that RPM is reached. It

deactivates when a stop command is

given, OR the speed drops below the

threshold, minus 15%.

RPM Nominal Speed is the engines

nominal speed, and is used to lower

the RPM Overspeed on the Overspeed

test to 95 % of the nominal speed.

General

Channel Use is the selection for where

the signal shall be displayed.

Select DCU+RP to display the

instrument in the DCU and in the RP.

Select DCU to display in DCU only, and

not in any connected RP.

Select RP to display in any connected

RP only, and not in the DCU.

Display

These values define how the

instrument widget is presented.

Display Range Min is the minimum

value displayed, normally 0 (zero).

Configuration Manual - 200E Series

Page 12

Display Range Max is the maximum

value displayed. For an engine running

at 1500 rpm nominally, a typical

maximum setting would be 1800 RPM.

Display Major Divider is where the

instrument widget writes an RPM

value, normally every 500 RPM.

Display Minor Divider is the tickmarks

between the major divider marks,

normally every 100 RPM.

Display Multiplier is the multiplier

value. The value is printed in the RPM

meter.

Overspeed

RPM Overspeed is the setpoint where

the DCU indicates overspeed.

RPM Overspeed Delay is the delay –in

milliseconds –before alarm or

shutdown. Typical setpoint is 100ms.

RPM Overspeed Shutdown Enabled is

where the overspeed behavior is

selected. Select Yes for the DCU to

shut down the engine. Select No to

disable overspeed shutdown.

Individual Speed Sensors

Note that

any

speed signal can be

connected here, and that this is

treated separately from the Engine

Speed signal configured above.

By configuring these sensors it is

possible to view the current RPM from

a individual speed sensor as opposed

the standard Engine Speed sensor that

acts on many inputs at once.

All Individual Speed sensors are

configured the same way.

Channel Use

This selects the panel the instrument

widget is displayed on. It is possible to

display the instrument on

The DCU engine panel, and

The RP remote panel, or

A combination of the two.

Sensor Unit

There is no choice; select RPM.

Sensor Range Min/Max

These values are fixed

Display Unit

There is no choice; select RPM.

Display Range Min

Select the low end of the scale.

Display Range Max

Select the high end of the scale.

Display Major Divider

Select the major tickmarks. These are

labeled with RPM values.

Display Minor Divider

Select the number of minor tickmarks

between the major tickmarks.

Display Multiplier

Select a value multiplier of 1, 10, 100

or 1000.

Event

Select type of event for this channel.

Configuration Manual - 200E Series

Page 13

Engine Load

First, configure either a 4-20mA, 0-5V

input or the J1939 PGN 0Xf003, SPN

92. Select then the engine load source

from the dropdown menu. Engine load

can now be used as an additional

setting when configuring alarms.

Transmission

The transmission menu are used for

Gear control, to Indicate current Gear

or as start interlock.

Gear control is enabled under

Home DCU User Interface.

When enabled the “Backlight” button

will be replaced with “Gear” in

instrument view. Selecting “Gear” will

open a new page on the DCU with

functions for Gear control as described

below.

Gear

The gear source is used as start

interlock when a gear is engaged

and/or to display the current gear.

Select the gear feedback source used.

To display current gear go to:

Home DCU User Interface

and enable “Show Gear Indicator

Instead Of All Ok”. To get the Gear

indicator as an half height vertical bar

graph go to: HomeDCUInterface

designPages. Choose witch page and

slot the gear indicator shall be shown.

Shaft Lock

If the DCU gear control is used, the

shaft lock input will prevent gear

changes when active. Select a Shaft

Lock source from the pull down menu.

Note! The shaft lock source must be a

switch input.

RPM Interlock

If the DCU gear control is used, the

RPM Interlock input will prevent gear

changes when active. Select a RPM

Interlock source from the pull down

menu.

Note! The RPM Interlock source must

be a switch input.

Shaft Speed

If the DCU gear control is used, the

Shaft Speed can be displayed wherever

the user wants. To choose its

placement go to:

HomeDCUInterfacedesignPages

It is possible to enable “Mirrored view”

which will put the zero value on top of

the gauge.

Switch

There are 21 configurable channels

available as switch inputs. Each

channel can be configured as an

(ordinary) engine switch input channel,

or it can be configured to perform a

function, like Automatic Start.

Configuration Manual - 200E Series

Page 14

HomeDCUI/O ConfigurationSwitch

First, select any of the enabled switch

channels. Then, for each channel, set

the following parameters.

Available functions for Switch inputs

The following functions are available

for the switch inputs.

The highlighted functions are the most

typically being used.

Function Name

Description

None

The channel is being used as

an (ordinary) engine sensor

switch input

Local Mode

Sets the panel to local mode,

meaning all external

commands are blocked.

Remote Mode

Sets the panel to remote mode,

meaning all local commands

are blocked.

Backlight 100%

Force backlight to 100%

Prelube override

The configured prelube

sequence is aborted

Prelube

complete

Signal shall come from the

prelube system, notifying the

panel that the prelube

sequence is completed. The

panel will commence start.

Start disabled

Start is disabled

Function Name

Description

Automatic mode

The panel accepts automatic

start/stop signals

Automatic start

Panel will commence the start

sequence. Requires Automatic

mode.

Automatic stop

Panel will commence the stop

sequence. Requires Automatic

mode.

Remote start

Same as the local start button.

Disabled if panel in local mode.

Remote stop

Same as the local stop button.

Disabled if panel in local mode.

Local Start

Local Start button

Local Stop

Local Stop button

Local

Acknowledge

Used to acknowledge all events

in the alarm list

Local/Remote

Acknowledge

Used to acknowledge all events

in the alarm list

Remote

Acknowledge

Used to acknowledge all events

in the alarm list

Shutdown

override

Makes all the configured

shutdown channels into alarm

channels, so engine will not

shut down automatically.

Engine overspeed shutdown is

however always enabled.

In gear

From gearbox on prop.

Engines. Disables start

attempts.

In Gear (Ahead)

From gearbox on prop.

Engines to indicate Ahead

gear.

In Gear (Astern)

From gearbox on prop.

Engines to indicate Astern

gear.

Toggle Crank

mode

Toggle between crank modes.

Power On

Toggle Sleep mode.

Function Use as

Select None if the channel is to be

used as an ordinary engine switch

input.

Configuration Manual - 200E Series

Page 15

Select any of the other functions

described above to assign that

function to the input channel.

Channel Use

This describes how the channel is

used.

Select Not in use if the channel shall

be disabled.

Select Event if the channel shall make

any form of event. An event can be a

warning, an alarm or an engine

shutdown.

Select Silent

Event for an active

channel, but no panel alarms. The

event will be available on

communication only.

Event

If any type of event was selected under

Channel Use, then select the type of

event here. It can be a Warning, Load

Reduction, Alarm or a Shutdown.

If None is selected, then the channel is

active but no events are created.

Input State

Normally Open means the contact

must close to make the event, whereas

Normally Closed means the contact

must open to make the event.

Delay Before Event

Choose the desired persistence time

before the channel activates the event.

This field is only available if the Event

field is selected.

1An engine speed source can be either the magnetic

pickup or the SAE J1939 CANbus signal connected

to the DCU.

Requires Running Engine

Typically, this shall be set to Yes for

pressure sensors, and to No for all

other sensors.

Select any of the other setpoints to

activate the channel at other rpm

values.

Requires in gear

If gear is required to monitor event

Must be in gear (Switch)

Requires Engine Load

Initial Delay

If the requires above is set Yes, set the

persistence time after the engine is

running until the channel is enabled.

This field is only available if all

requires that is selected are fulfilled.

Use as Additional Run

If the DCU has one pickup source only,

we recommend adding an engine oil

pressure switch as an engine running

indication.

Note! Do not use any other pressure

sensors –or any other signals –as

engine running

indication!

If two engine speed (pickup)

sources1are in use, then we

recommend leaving this off for

all switches, i.e. set to No.

Configuration Manual - 200E Series

Page 16

If one engine speed source only

is in use, then locate the engine

low oil pressure switch and use

this as the Additional Run

signal. Set to Yes.

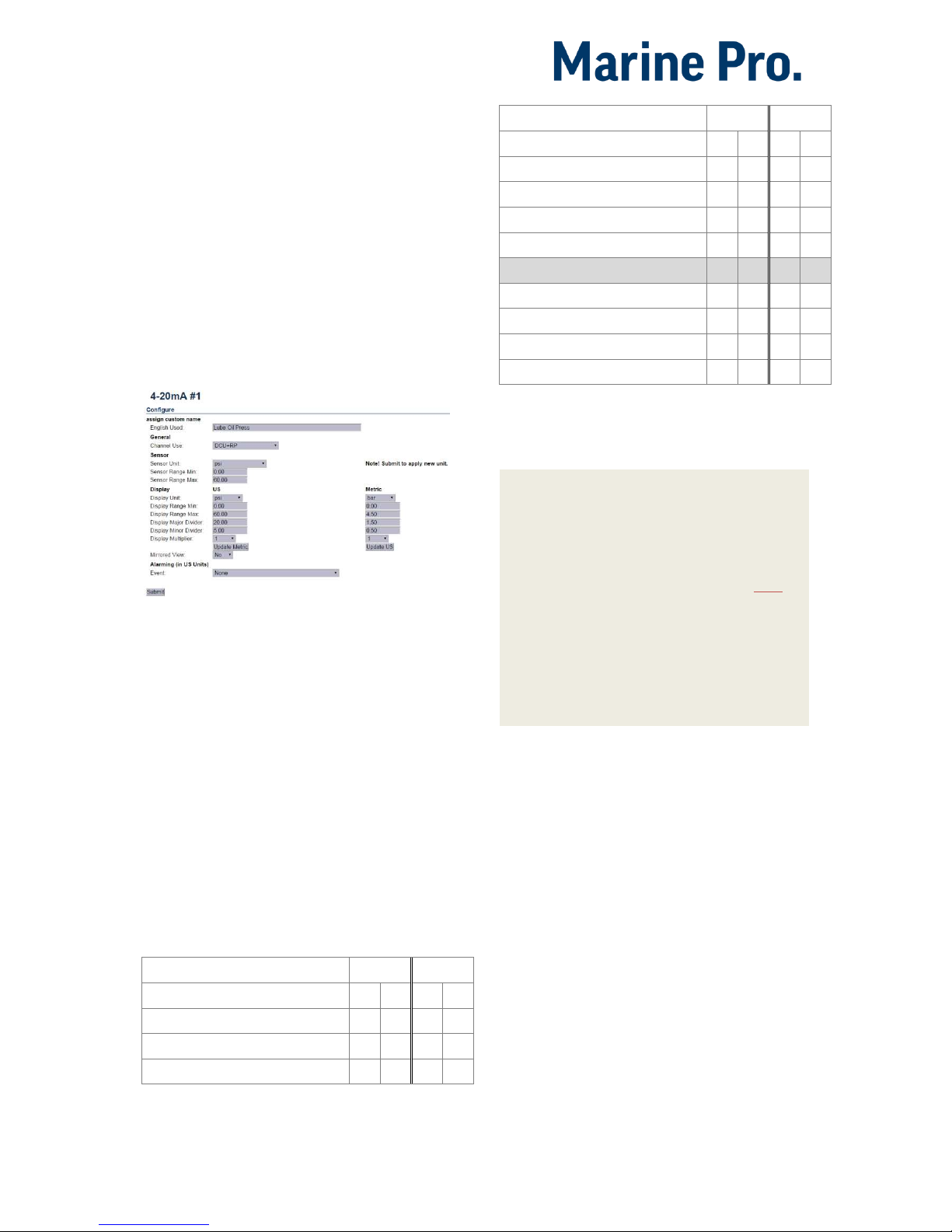

4-20mA

First, select one of the enabled 4-

20mA channels. Then, for each

selected channel, set the following.

HomeDCUI/O Configuration4-20mA

Channel Use

This selects the panel the instrument

widget is displayed on. It is possible to

display the instrument on

The DCU engine panel, and

The RP remote panel, or

A combination of the two.

It is also possible to suppress the

alarm events, as can be seen in the

following table overview.

Type of use

DCU

RP

D

E

D

E

Not in use

Event

x

x

DCU

x

Type of use

DCU

RP

D

E

D

E

DCU + Event

x

x

x

RP

x

RP + Event

x

x

DCU + RP

x

x

DCU + RP + Event

x

x

x

x

Silent Event

DCU + Silent Event

x

RP + Silent Event

x

DCU + RP + Silent Event

x

x

D = Displayed on panel

E = Event

Event = warning, alarm or shutdown

Silent Event = no local event; on communication only

Note! Normally - and in most cases -

the selection should be “DCU + RP +

Event”, as bolded and outlined in the

table above. This makes sure the

channel is displayed in the DCU and in

the RP, if and when an RP is installed.

If for example a signal is necessary in

the DCU engine panel only, and not in

the RP remote panel, then select DCU

+ Event from the selection.

Sensor

Sensor Unit

Select the unit, as printed on the

sensor. An oil pressure sensor might

for instance be in

Bar

or

psi

.

Sensor Range Min/Max

Select the sensor range values for min

and max, as printed on the sensor.

Other manuals for Marine Pro 200E Series

1

This manual suits for next models

4

Table of contents

Other auto maskin Control Panel manuals

Popular Control Panel manuals by other brands

Beckhoff

Beckhoff CP78 Series Installation and operating instructions

Truma

Truma CP plus VarioHeat operating instructions

Nordmann Engineering

Nordmann Engineering SPA Display Installation and operation manual

Firegear

Firegear PAVER CONTROL PANEL-TPSI Installation and operating instructions

Mitsubishi Electric

Mitsubishi Electric E1070 installation manual

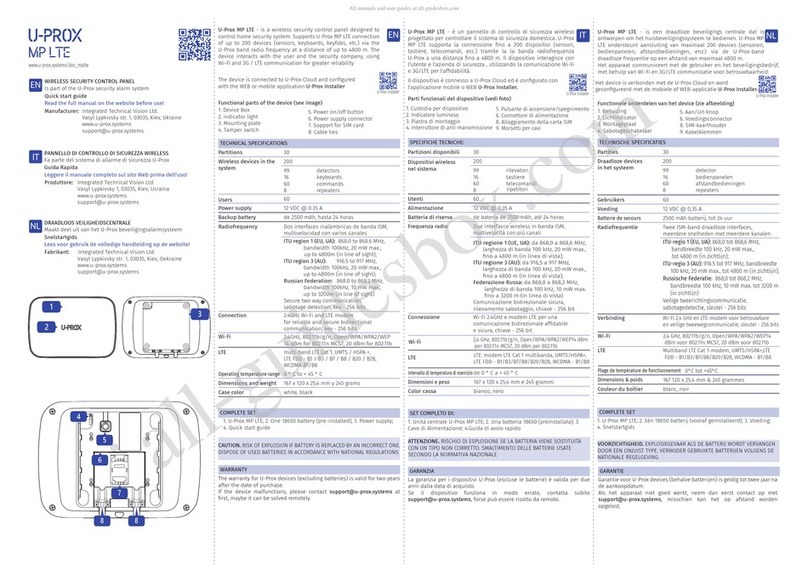

U-Prox

U-Prox MP LTE quick start guide