sageglass.com/resources

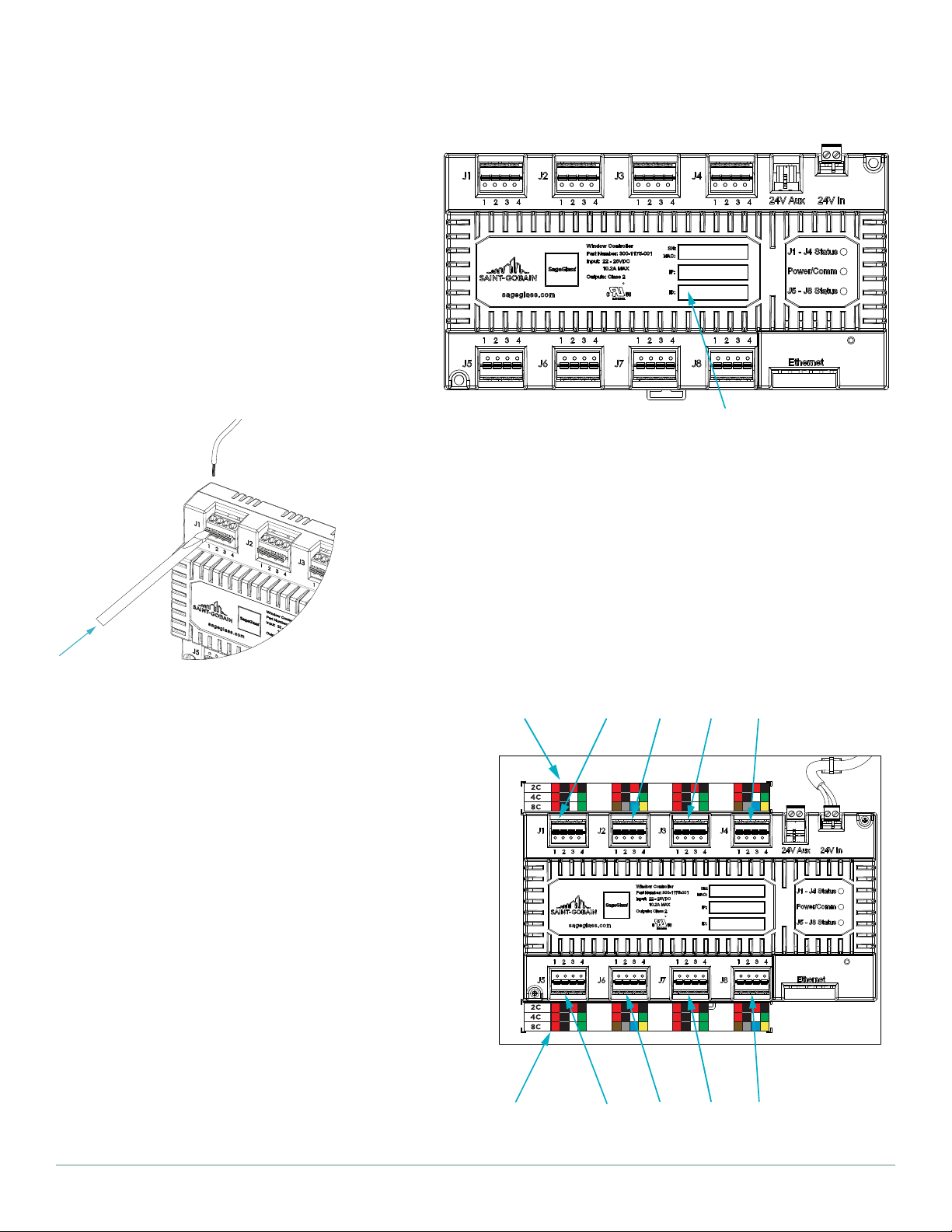

STEP 3:

Populate wire terminals (1) with 2-Wire Frame Cables,

4-Wire Frame Cables, and/or 8-Conductor Cables

according to the project specific Wiring Diagram and

the wire color code guide that is on sticker (2) below

each terminal’s row. The wire color code guide

between the controllers shall be used for top and

bottom controllers.

Refer to appropriate row of the wire color code

guide depending on cables the system is equipped

with and follow the color code.

If it is a 2-Wire Frame Cable, 2C row of wiring guide is

used. One set will be black and red. Each terminal block

can hold two sets.

If it is 8-Conductor Cable, 8C row of wiring guide is

used. It will have two of each set and mount to the

adjacent terminal blocks (i.e. J1 and J2).

If it is 4-Wire Frame Cable, 4C row of wiring guide is

used. One set will be red, black, white and green. Each

terminal block will hold one set.

If system is equipped with mixed cable types,

8-Conductor Cables must go to adjacent terminal

blocks (i.e. J1 and J2), 4-Wire Frame Cables should be

connected to one terminal block and 2-Wire Frame

Cables should be connected to one terminal block

according to the color code.

2C

8C

2C

4C

8C

2C

4C

8C

FIGURE 11: CONTROLLER CONNECTION

1

1

2

2

1

1

1

1

1

1

2C

4C

8C

FIGURE 12: 2-WIRES

2C

4C

8C

FIGURE 13: 4-WIRES

2C

4C

8C

FIGURE 14: 8-CONDUCTOR CABLES

2C

4C

8C

FIGURE 15: MIXED WIRES