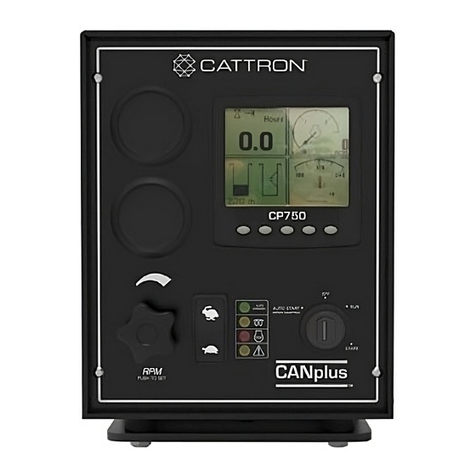

CANplusTM CP800

Control Panel Operation Manual

Revision E

Contents

1Important Safety and Emissions Information...........................................................................................................................6

1.1 Safety Notation ................................................................................................................................................ 6

1.2 Safety Instructions ........................................................................................................................................... 6

1.3 Auxiliary Engine Stop Disclaimer..................................................................................................................... 7

1.4 General Emissions Disclaimer......................................................................................................................... 8

1.5 Exhaust Emissions Compliance Disclaimer .................................................................................................... 8

2Overview .......................................................................................................................................................................................9

3Display.........................................................................................................................................................................................10

3.1 Adjusting Lighting .......................................................................................................................................... 10

3.2 Button Bar...................................................................................................................................................... 10

3.3 Analog Gauge Pages .................................................................................................................................... 11

3.4 Autostart Dashboard...................................................................................................................................... 12

3.5 Active Alarms................................................................................................................................................. 12

3.6 Alarm List....................................................................................................................................................... 13

3.7 Service Timers............................................................................................................................................... 13

3.8 Menus............................................................................................................................................................ 14

3.8.1 Menu Tree ......................................................................................................14

3.8.2 Access Levels.................................................................................................18

4Engine Setup..............................................................................................................................................................................19

4.1 Electronically Governed Engines................................................................................................................... 19

5CANplus Control ........................................................................................................................................................................20

Dynamic Throttling ................................................................................................................................................ 20

Pause at Run speed............................................................................................................................................... 20

Throttle by Maintain Point ........................................................................................................................................ 20

Controlled Off......................................................................................................................................................... 20

Linear Throttling....................................................................................................................................................... 21

Auto/Manual mode Toggle....................................................................................................................................... 21

Auto Ramp.............................................................................................................................................................. 21

Autostart .................................................................................................................................................................. 21

Autothrottle Maintain Point....................................................................................................................................... 21

6Manual Operation ......................................................................................................................................................................22