Aquion Energy S Series User manual

Aquion Energy, Inc.

32 39th Street

Pittsburgh, PA 15201

+1 412.904.6400

www.aquionenergy.com AQ-OP-00016_C

S-Line and M-Line

Installation & Operation Manual

Battery Stack Model S30-0080

Battery Module Models M110-LS83, M110-L083

AQ-OP-00016_C

© 2016 Aquion Energy, Inc.

The information in this document is subject to periodic updates and changes. Upon any updates or

changes to the above-described material, Aquion Energy will provide new drawings and/or associated

documentation that will supersede those contained in this document. Contents are subject to change

without notice.

For the latest product documentation, visit http://info.aquionenergy.com/customer-portal or email

us at info@aquion-energy.com.

Warnings in This Document

WARNING WARNING indicates a hazardous situation that, if not avoided, could result in

death, injury, or damage.

i AQ-OP-00016_C

Table of Contents

1Introduction____________________________________________________________________ 1

1.1 About This Manual 1

1.2 Contact Information 1

2Product Information _____________________________________________________________ 1

2.1 Product Overview 1

2.2 Product Specification 1

2.3 UL Recognition 2

2.4 Cradle to Cradle Certification 2

2.5 M110-LS83 Electromagnetic Compatibility 2

2.5.1 FCC 2

2.5.2 CE 2

3Safety Information ______________________________________________________________ 3

3.1 Electrical Hazards 3

3.2 Electrical Safety 3

3.3 Chemical Hazards 3

3.4 Gas Emissions 3

3.5 Weight Hazards 4

3.6 Ingress Protection 4

3.7 Decommissioning Hazards 4

4Transportation and Receipt of Product _____________________________________________ 5

4.1 Shipping 5

4.1.1 Shipping Hazards 5

4.1.2 Shipping Requirements 5

4.2 Disassembly Hazards 5

4.3 Packaging 5

4.4 Delivery Inspection 5

5Installation _____________________________________________________________________ 7

5.1 Unpacking 7

5.2 Site Requirements 7

5.2.1 Exposure and Enclosure 7

5.2.2 Size and Weight 7

5.2.3 Ventilation 7

5.2.4 Humidity 8

5.2.5 Ambient Temperature 8

5.3 Moving 8

5.4 Placement 9

5.5 Battery Module Fuse Connection 9

ii AQ-OP-00016_C

6Electrical Integration____________________________________________________________ 11

6.1 Electrical Interfaces and Connections 11

6.1.1 Stack Connectors 11

6.1.2 Stack Accessories 11

6.1.3 Module Connectors 12

6.1.4 Module Accessories 15

6.1.5 Module Contactor Control 15

6.2 Product Wiring Diagrams 15

6.3 Racking/Scaling Systems 18

6.4 Cabling Requirements 18

6.5 Parallel Wiring 18

6.5.1 Monitoring 19

6.5.2 Overcurrent Protection 20

6.5.3 Grounding 20

7Commissioning ________________________________________________________________ 21

7.1 Initial Charge 21

7.2 Voltage Matching 21

7.3 Configuring Inverters and Charge Controllers 21

8Operation_____________________________________________________________________ 22

8.1 Operational Limits 22

8.1.1 Current 22

8.1.2 Voltage 22

8.1.3 Ambient Temperature 22

8.1.4 Configuration 22

8.2 Charge Profiles 22

8.2.1 Recommended Charge Profile 22

8.2.2 Boost Charge Profile 23

8.2.3 Three-Stage Charge Profile 24

8.3 State of Charge 24

8.3.1 Partial State of Charge 24

8.3.2 Determining State of Charge 24

8.4 Discharging 25

8.5 Self-Discharge 25

8.6 Long-Term Storage 25

8.7 Recycling and Disposal 25

8.8 Record Keeping 25

9Warranty _____________________________________________________________________ 26

10Technical Support______________________________________________________________ 26

1 AQ-OP-00016_C

1Introduction

1.1 About This Manual

This manual is intended to provide technical information and safe practices regarding receiving,

installing, and operating the Aquion Energy S30-0080 Battery Stack and the Aquion Energy

M110-LS83 and M110-L083 Battery Modules. For complete safety information, refer to the Safety

Data Sheet (SDS) included with your product shipment.

WARNING: Failure to follow the instructions in this document could result in fire, electric

shock, and/or other injury or damage.

1.2 Contact Information

Mail: Aquion Energy

32 39th Street

Pittsburgh, PA 15201

Telephone: +1 412.904.6400

Web:

www.aquionenergy.com

2Product Information

2.1 Product Overview

Aqueous Hybrid Ion (AHITM) batteries use non-toxic, non-corrosive materials to make the world’s only

clean and sustainable electrochemical storage solution. Aquion S-Line Battery Stacks and M-Line

Battery Modules provide long-duration, stationary storage for residential solar, off-grid, microgrid, and

energy management applications.

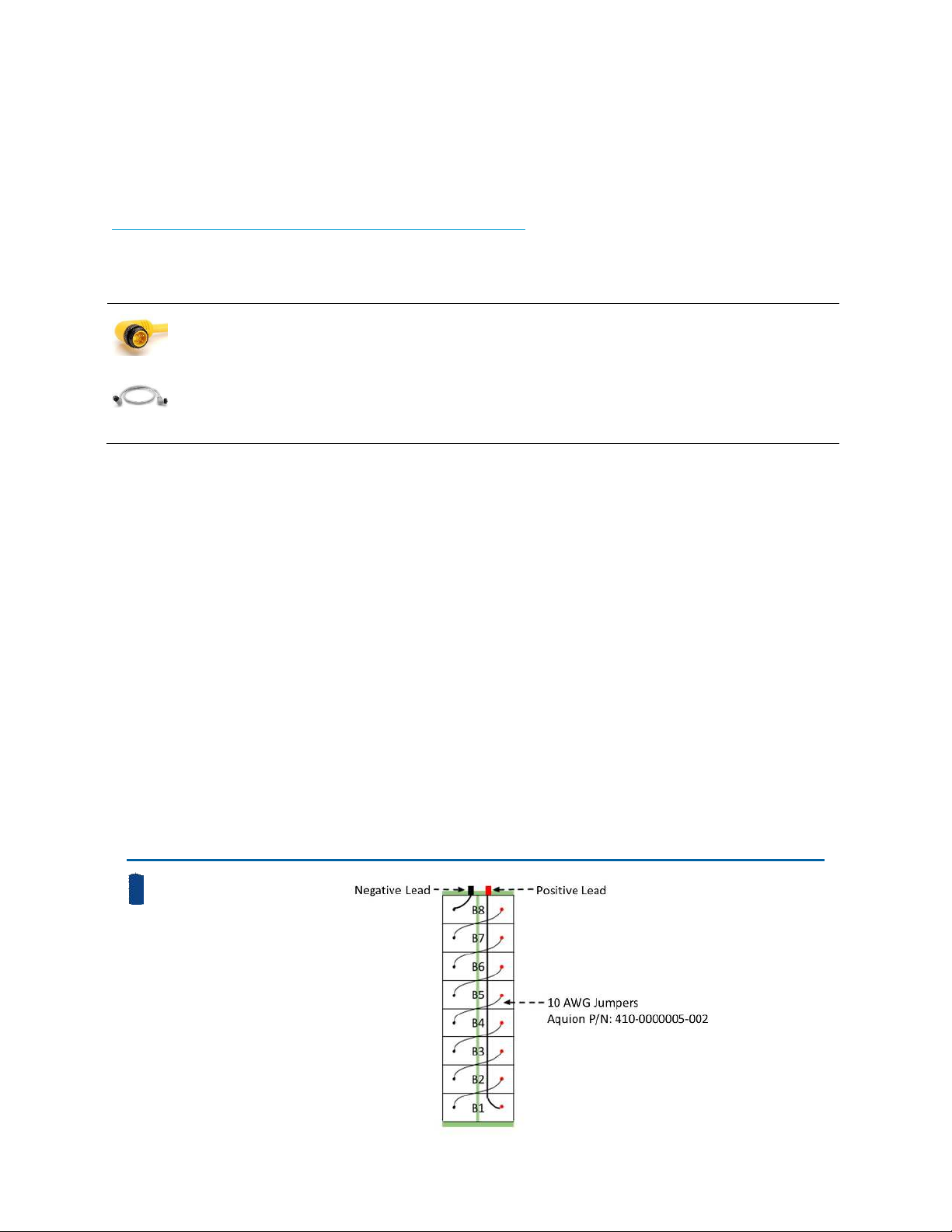

S-Line Battery Stack

The S-Line Battery Stack is the base component of Aquion Energy’s scalable energy solutions.

The S-Line battery stack connects eight Aquion batteries in series for a 48 V product. Aquion

offers one, unfused S-Line Battery Stack model: the S30-0080.

M-Line Battery Module

The M-Line Battery Module is a palletized energy storage module that serves as a stand-alone

system or as a building block for larger systems. The battery module connects twelve S30-0080

Battery Stacks in parallel. Aquion offers two M-Line Battery Module models:

Battery Module Model On-Board Sensing

M110-LS83 Voltage, current, temperature (VIS board)

M110-L083 None

2.2 Product Specification

Voltage curves, operational efficiency, capacity by charge and discharge currents, and more are on

the Product Specification Sheets: http://info.aquion-energy.com/customer-portal.

2 AQ-OP-00016_C

2.3 UL Recognition

The S-Line Battery Stack is UL recognized. The following UL certification tests have been completed:

+UL 1973-13 Overcharge

+UL 1973-14 Short Circuit

+UL 1973-15 Overdischarge Protection

+UL 1973-16 Temp and Ops

+UL 1973-17 Imbalanced Charging

+UL 1973-23 Vibration

+UL 1973-24 Shock

+UL 1973-25 Crush

+UL 1973-26 Static Force

+UL 1973-27 Impact

+UL 1973-30 Mold Stress

+UL 1973-31 Pressure Release

+UL 1973-32 Start-To-Discharge

+UL 1973-34 Resistance to Moisture

+UL 1973-35 Salt Fog

+UL 1973-36 External Fire Exposure

2.4 Cradle to Cradle Certification

The AHI S30-0080 Battery Stack is a Cradle to Cradle CertifiedTM Bronze1product. The Cradle to

Cradle Products Innovation Institute independently assesses and certifies products for material

health, material reutilization, renewable energy use and carbon management, water stewardship, and

social fairness. M110-LS83 and M110-L083 battery modules contain 12 of the S30-0080 stacks.

2.5 M110-LS83 Electromagnetic Compatibility

2.5.1 FCC

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference, in which case

the user will be required to correct the interference at his own expense.

2.5.2 CE

This product may cause interference if used in residential areas. Such use must be avoided unless the

user takes special measures to reduce electromagnetic emissions to prevent interference to the

reception of radio and television broadcasts.

1Cradle to Cradle CertifiedTM is a certification mark licensed by the Cradle to Cradle Products Innovation Institute.

3 AQ-OP-00016_C

3Safety Information

Only qualified individuals are to install and service battery systems.

3.1 Electrical Hazards

Never place foreign objects or tools in or on the unit. The metal parts of the battery terminals are

always live. Electrical hazards exist in the voltage and current ranges that are found in battery systems

and associated electronics.

S-Line Battery Stack

WARNING: Connecting battery stacks in series can lead to dangerously high voltages.

Any series configurations must be reviewed by Aquion prior to installation. When

connecting the unfused, S30-0080 stacks in parallel, Aquion recommends placing overcurrent

protection devices as close as possible to the DC bus.

3.2 Electrical Safety

S-Line Battery Stack

The maximum charge/discharge current of the S30-0080 is 17 A. The stacks must be protected

from overcurrent charge/discharge with appropriately rated overcurrent protection devices. If

grounding is required, see Section 6.5.3.

M-Line Battery Module

Each battery module includes twelve 1,000 V, 20 A fuses, one for each component battery stack.

The fuses do not come pre-installed (see Section 5.5 for fuse installation instructions). The

combined maximum fuse rating of 240 A is greater than the maximum rated current of the

module, 204 A, to allow for internal energy redistribution.

3.3 Chemical Hazards

AHI battery materials are non-toxic and present no chemical hazards. The AHI electrolyte is sodium-

sulfate-based saltwater with a neutral pH. In the unlikely event that the electrolyte comes in contact

with eyes or skin, thoroughly wash it out with water. Electrolyte residue on the battery terminal can be

wiped away with a cloth. A collection pan under the battery stack or module is not needed as the

electrolyte will not leak during normal operation, and any leaked electrolyte will not damage battery

surfaces or equipment. Refer to the SDS for additional information.

3.4 Gas Emissions

The battery may emit trace amounts of gas H2, O2, CO2, and CO during normal operation. These gases

do not accumulate in hazardous quantities in typical installations when the batteries are installed and

4 AQ-OP-00016_C

operated in accordance with the guidelines of this document. The battery has fully passed UL 1973

overcharge testing, an abuse test that includes monitoring for combustible vapor concentrations.

Overcharging the battery (outside of specified guidelines) will result in venting of some incremental

amounts of the gases listed above through the pressure relief valve.

3.5 Weight Hazards

S-Line Battery Stack

The battery stack weighs 118 kg (260 lbs) and must be transported and handled with appropriate

precautions. See Section 5.3 for moving and tilting restrictions.

M-Line Battery Module

The battery module weighs 1,504 kg (3,315 lbs) and must be transported and handled with

appropriate precautions. The use of forklift trucks and pallet jacks is recommended to move and

position battery modules.

3.6 Ingress Protection

The International Electrotechnical Commission publishes the International Protection (IP) Code, which

classifies the degrees of protection provided by electrical equipment enclosures against ingress of

solid particles and liquid.

Product

Solid Particle Protection Level 2

a

Liquid Ingress Protection Level 2

b

IP code

Battery stack

Confirmed

Confirmed

IP22

Battery module

Confirmed

Not tested

IP2X

a

protected from ingress of objects greater than 12.5 mm, such as fingers or similar objects (IP

#

#)

b

protected against harmful effects of ingress of dripping water when tilted up to 15 degrees, for a duration of 10 minutes or less (IP#

#

)

3.7 Decommissioning Hazards

AHI batteries are non-toxic and non-corrosive. Do not dump into any sewers, on the ground, or into

any body of water where water runs off into open bodies of water. Dispose of according to all federal,

state, and local regulations.

5 AQ-OP-00016_C

4Transportation and Receipt of Product

4.1 Shipping

4.1.1 Shipping Hazards

The shipping configurations for battery stacks have undergone a modified International Safe Transit

Association (ISTA) 3H shipping test. Modified ISTA 3H testing is pending for the battery module.

Aquion battery stacks and modules are shipped at a very low state of charge and voltage. See

Section 7.1 for initial charging instructions.

4.1.2 Shipping Requirements

S-Line and M-Line batteries should be shipped in an upright position and should not be tipped for an

extended period of time during shipping. Ensure that this restriction is communicated to the shipper

prior to transport. The affixed Tip-N-Tell indicators trip if the package experiences extreme tilt. See

Section 5.3 for moving and tilting restrictions.

4.2 Disassembly Hazards

WARNING: Do NOT attempt to disassemble battery stacks. Do NOT remove the nut on the

compression fixture on top of the stack. Battery stacks have been compressed to optimize

battery performance. Releasing this load could result in poor battery performance, permanent

damage to stack components, and/or injury.

4.3 Packaging

S-Line Battery Stack

Battery stacks arrive 12 or fewer to a pallet. They may be wrapped (U.S. shipments) or crated

(shipments outside the United States). On crated shipments, a Tip-N-Tell indicator and a Drop-

N-Tell indicator are affixed on the outside of the crate. On wrapped shipments, these indicators

are affixed on the outside of the wrapping.

M-Line Battery Module

Battery modules arrive wrapped and on a pallet. The Tip-N-Tell and Drop-N-Tell indicators are

affixed to the outside of the wrapping.

4.4 Delivery Inspection

Immediately upon delivery, inspect all hard goods for signs of damage or tipping during transit before

signing for the delivery. Any of the following MAY indicate damage during transport:

+Damaged or torn packaging

+Tripped Drop-N-Tell indicator

+Scraped or punctured product components

+Leaking electrolyte (clear liquid)

+Tripped Tip-N-Tell indicator

6 AQ-OP-00016_C

If you find damage, document any signs of damage on the bill of lading before accepting the shipment.

Separately document and photograph all damage, and make a claim with the carrier as soon as

possible. Contact your distributor immediately.

Slight bulges or depressions in the battery stack cases are normal. The battery stack cases are

intentionally flexible to accommodate compression of the electrode stack and normal variations in

internal pressure during operation. A slight concave deformation, or depression, in the sidewall of the

battery stack case is not unusual, especially in new batteries, and does not present an unsafe

condition. A convex deformation, or bulge, projecting no more than 10 mm from the sidewall of the

battery is also not unusual and does not present an unsafe condition. If a bulge projects more than

10 mm, do not place the battery in service, or remove it from service if already commissioned, and

contact Aquion Technical Support (see Section 10).

7 AQ-OP-00016_C

5Installation

ATTENTION:

BATTERIES SHIP AT LESS THAN 2% STATE OF CHARGE AND LESS THAN 45 V. See

Section 7.1.

MODULE FUSES ARE INSTALLED BUT NOT CONNECTED. MODULE WILL NOT

FUNCTION UNTIL FUSES ARE CONNECTED. See Section 5.5.

SENSED BATTERY MODULES AND STACKS MUST BE SET UP WITH THE AQUION

BATTERY MONITORING SYSTEM BEFORE OPERATION. See Section 5.4.

5.1 Unpacking

Unpack all items carefully and note quantities received. Battery stacks are shipped on pallets. Any

accessories may have been shipped separately. Battery modules are permanently fastened to pallets.

Contact your authorized Aquion distributor if any items are missing or damaged.

5.2 Site Requirements

5.2.1 Exposure and Enclosure

Battery stacks and modules should beinstalled indoors or enclosed fromthe elements. A fully sealed

enclosure is not necessary.

Install and operate battery stacks and modules out of direct exposure tosunlight. Prolonged exposure

to ultraviolet light may damage the polypropylene casing and reduce product lifetime.

5.2.2 Size and Weight

The battery stack weighs 118 kg(260 lbs), and the battery module weighs 1,504 kg (3,315 lbs).

Position battery stacks and modules only on surfaces appropriately rated for the product’s weight.

Ensure that the installation location is large enough to contain the battery product.

5.2.3 Ventilation

In typical residential installations, it is likely that existing household ventilation is adequate for Aquion

batteries. If existing ventilation is unknown, or for applications where the batteries are installed into

smaller or more sealed spaces (enclosures, shipping containers, etc.), Aquion recommends installing

ventilation per regional guidelines for battery rooms. For example, in North America, IBC and/or

NFPA 1 guidelines recommend that all battery installations in enclosed spaces include ventilation

equal to either six (6) air changes per hour or ventilation at 1 cubic foot per minute (CFM) per square

foot of room size. In Europe and other locations, EN 50272 guidelines recommend that batteries be

installed in well-ventilated rooms where ventilation corresponds to battery capacity and the exhaust

air is discharged outside the building.

!

8 AQ-OP-00016_C

5.2.4 Humidity

Install batteries in clean, ordinary conditions protected fromwater exposure.Direct exposure of

battery stacks or modules to water may cause shorting. The units may be installed in humid or coastal

regions with atmospheric salt.

5.2.5 Ambient Temperature

Battery stacks and modules must be operated intemperatures between -5°C and 40°C ona24-hour

average. Operation above or below these limits will cause advanced degradation of the battery

chemistry. Battery stacks and modules must be stored in temperatures between -10°C and 40°C.

Storage above or below these limits may permanently damage the batteries.

5.3 Moving

S-Line Battery Stack

Use proper lifting procedures and personal protective equipment when moving the S-Line

product. The S-Line product has been designed to be moved using the lifting eye and metal tie-

rod that runs vertically through the center of the stack. Each pallet of S-Line stacks includes one

lifting eye. The lifting eye screws onto the tie rod and can be used to move one stack at a time. No

other component of the S-Line product is designed to support the weight of the stack. Use a

crane, hoist, or similar device of appropriate load-bearing capacity to lift the S-Line product

vertically by the lifting eye threaded onto the tie-rod.

NEVER LIFT S-LINE PRODUCTS BY THE TERMINALS OR ANY PART OTHER THAN THE

SUPPLIED LIFTING EYE THREADED ONTO THE TIE-ROD AS THIS WILL VOID THE WARRANTY

AND MAY CAUSE DAMAGE TO THE PRODUCT AND/OR

SIGNIFICANT INJURY.

Alternatively, use an appropriately sized hand truck to move S-Line

batteries. Position the battery on the hand truck so that the wiring faces

out, away from the upright frame of the hand truck. During movement

to the installation site and during installation, batteries may be tilted up

to forty-five (45) degrees for up to one hour. Before moving any S-Line

batteries, ensure that the travel path will not require tipping the battery

more than forty-five (45) degrees and that the installation location is

level.

M-Line Battery Module

The battery module must be transported and handled with appropriate precaution. The use of

forklift trucks and pallet jacks is recommended to move and position battery modules. Before

moving any battery module, ensure that the travel path will not require tipping the battery more

than fifteen (15) degrees and that the installation location is level.

9 AQ-OP-00016_C

5.4 Placement

S-Line battery stacks and M-Line battery modules do not need any particular amount of clearance

between other stacks, modules, or other architectural features. Always follow local codes for aisle and

access requirements. Do not stack battery stacks or battery modules on top of each other. Do not

place other items on top of the battery stacks or battery modules. The battery stacks and modules

are designed to be installed in an upright position (less than fifteen (15) degrees of tilt).

5.5 Battery Module Fuse Connection

Each battery module ships with 12 installed but disconnected 20-A fuses, one for each component

battery stack, located beneath the module’s top cover. All 12 fuses must be connected for the module

to operate. Connect the fuses before connecting the module to your system.

1. Remove the module top cover.

a. Remove the four bolts from the front and

back of the module top cover.

b. Lift off the cover by raising the back end

first, sliding the cover slightly forward to

clear the terminal posts, and lifting the

entire cover clear.

ATTENTION:

Before restricting physical access to battery systems, such as in racking or

shipping containers,

1. Connect module fuses.

This requires removing and replacing the module

cover. See Section 5.5.

2. Set upsensed battery modules or stacks with the Aquion Battery Monitoring

System (BMS-200).

This requires physical connection of power and

communication cables. See the BMS-200 Manual for instructions.

!

10 AQ-OP-00016_C

2. Connect the two fuse bundle connectors.

a. Inside the top tray, locate the fuse board

and the two loose fuse bundle connectors.

b. Insert the connectors into the

corresponding receptacles on the fuse

board until you hear a click. Check that the

connectors are tightly secured.

3. Replace the top cover.

a. Lower the front end over the terminal

posts, then lower the back end.

4. Replace the four bolts on the front and back of

the top cover. For each bolt:

a. If the clip beneath the edge of the cover has

tilted, realign the clip vertically so that its

hole aligns with the hole in the cover.

b. Screw in the bolt through the hole in the top

cover and the hole in the clip.

11 AQ-OP-00016_C

6Electrical Integration

6.1 Electrical Interfaces and Connections

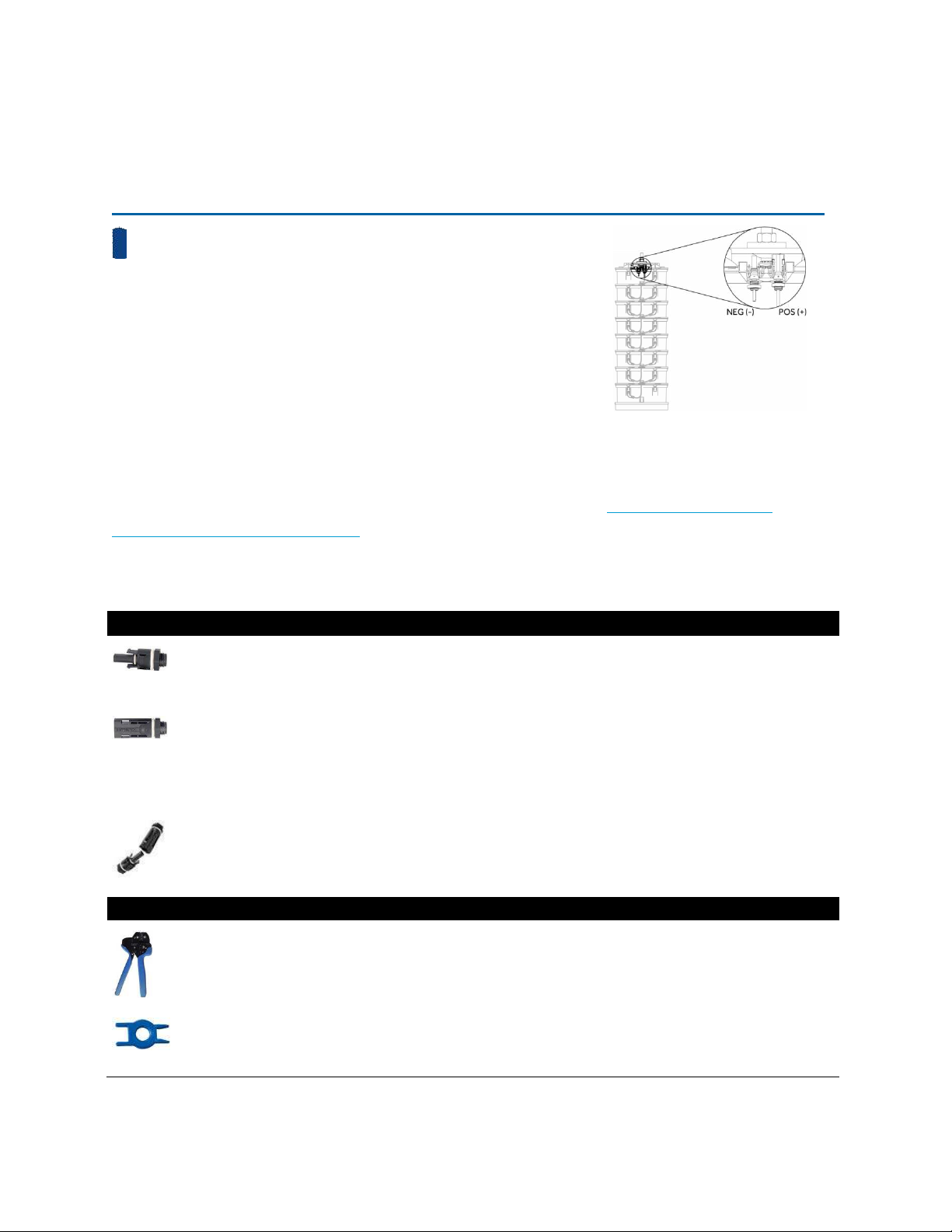

S-Line Battery Stack

6.1.1 Stack Connectors

The connectors, found at the top of the battery stack, are as follows:

−Negative (Black): Female Amphenol Helios H4 Connector

(H4CFC4DI)

+Positive (Red): Male Amphenol Helios H4 Connector (H4CMC4DI)

6.1.2 Stack Accessories

The following standard solar connectors and tools are required to make connections to the S30-0080

battery stack. Aquion Energy does not supply these parts. They can be purchased through Amphenol

distributors worldwide. Find your nearest authorized distributor here: http://www.amphenol-

sine.com/Distributors_c_108.html.

Image Part Name

Optional,

Recommended,

Required Purpose Part Number Manufacturer

Quantity per

Battery Stack

Connectors

H4 PV Panel

Connector,

Male

Required Connection to

positive battery

stack terminal

H4CMC4DI Amphenol

SineCo

1

H4 PV Panel

Connector,

Female

Required Connection to

negative battery

stack terminal

H4CFC4DI Amphenol

SineCo

1

-------------------------------------------------------- OR -------------------------------------------------------

H4 PV Panel

Connector,

Mated Pair

Optional Connection to

negative and

positive battery

stack terminals

H4CPC4DI Amphenol

SineCo

1

Tools

Helios H4

Panel

Connector

crimpers

Required Attach H4 Panel

Connectors to

cable

H4TC0001 Amphenol

Industrial

NA

H4 Universal

Unlocking

Tool

Recommended Releases H4 Panel

Connectors from

cable

H4TU0000 Amphenol

Industrial

NA

12 AQ-OP-00016_C

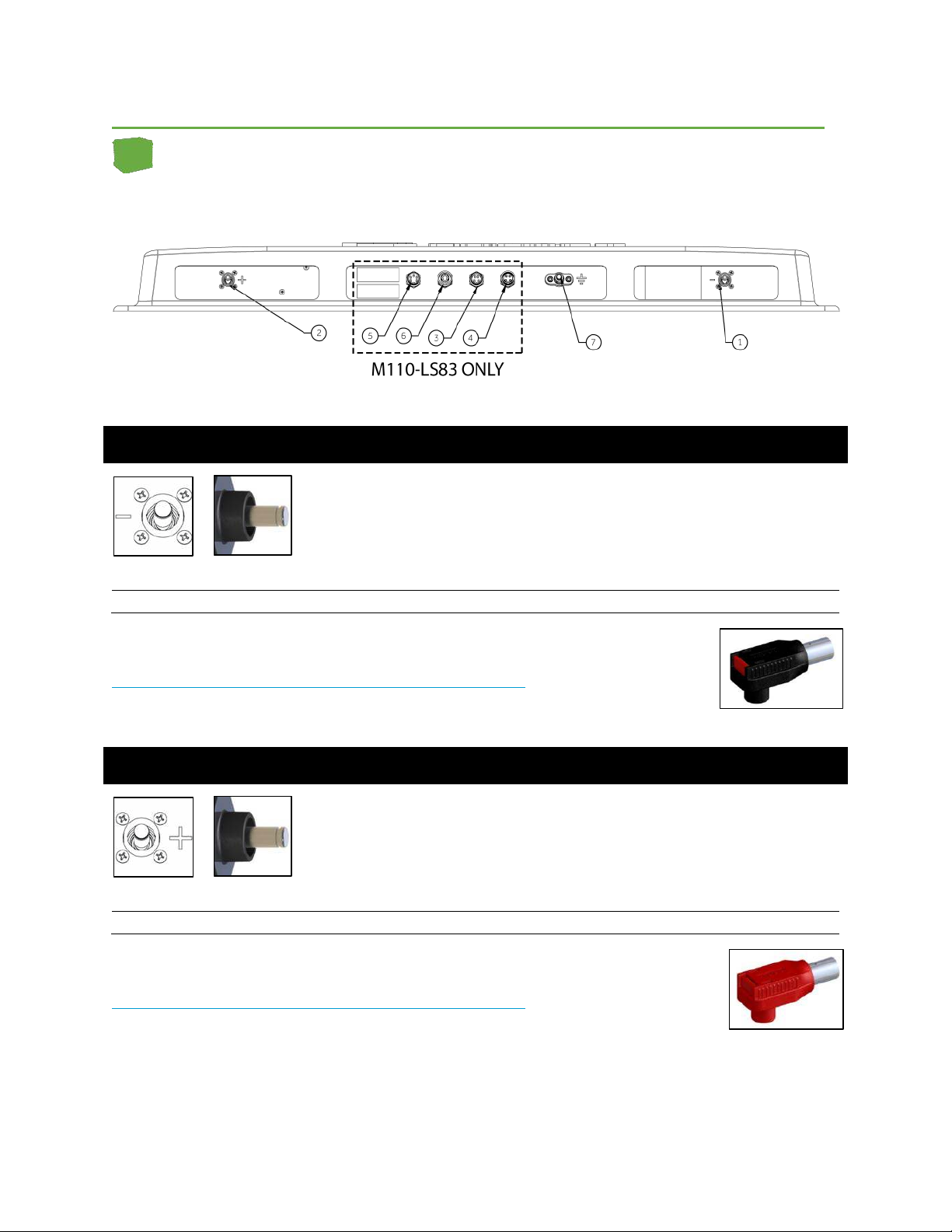

M-Line Battery Module

6.1.3 Module Connectors

①Module Negative (-) Battery Terminal

Function:

Negative termination of battery module

Part:

Amphenol RADLOK RL9-100-101 Black

Pin # Name Wire Color Description

1 BATT- Black Module Battery Negative Terminal

Mating connector:

Amphenol RADLOK Tubular Connector Black RL0-100-1-xxBK

Part not supplied by Aquion. Find your nearest authorized Amphenol distributor at

http://www.amphenol-sine.com/Distributors_c_108.html. In the part number, xx

refers to cable size, which is determined by your installation.

②Module Positive (+) Battery Terminal

Function:

Positive termination of battery module

Part:

Amphenol RADLOK RL9-100-101 Red

Pin # Name Wire Color Description

1 BATT+ Red Module Battery Positive Terminal

Mating connector:

Amphenol RADLOK Tubular Connector Red RL0-100-1-xxRE

Part not supplied by Aquion. Find your nearest authorized Amphenol distributor at

http://www.amphenol-sine.com/Distributors_c_108.html. In the part number, xx

refers to c1able size, which is determined by your installation.

13 AQ-OP-00016_C

③24V I/O IN

Function: Power input for contactor control

Part:

Amphenol SineCo MN41PW02Mxxx 4-pin miniBOSS, Male

Receptacle, External Threads

Pin # Name Wire Color Description

1 24V_IO_NEG Black 24 V I/O Negative

2 24V_IO_POS White 24 V I/O Positive (for driving contactors)

3 INTLK_RLY_IN Red Interlock Relay In (normally open)

4 RLY_RTN_IN Green Interlock Relay Return In

Mating connector:

Amphenol SineCo MN47B4BC01Mxxx 4-pin miniBOSS Cordset

Part not supplied by Aquion. Find your nearest authorized Amphenol distributor at

http://www.amphenol-sine.com/Distributors_c_108.html. In the part number, xxx

refers to cable length, which is determined by your installation.

④24V I/O OUT

Function: Power output for contactor control

Part:

Amphenol SineCo MN44PW02Mxxx 4-pin miniBOSS, Female

Receptacle, Internal Threads

Pin # Name Wire Color Description

1 24V_IO_NEG Black 24 V I/O Negative

2 24V_IO_POS White 24 V I/O Positive (for driving contactors)

3 INTLK_RLY_IN Red Interlock Relay In (normally open)

4 RLY_RTN_IN Green Interlock Relay Return In

Mating connector:

Amphenol SineCo MN47B4BC01Mxxx 4-pin miniBOSS Cordset

Part not supplied by Aquion. Find your nearest authorized Amphenol distributor at

http://www.amphenol-sine.com/Distributors_c_108.html. In the part number, xxx

refers to cable length, which is determined by your installation.

14 AQ-OP-00016_C

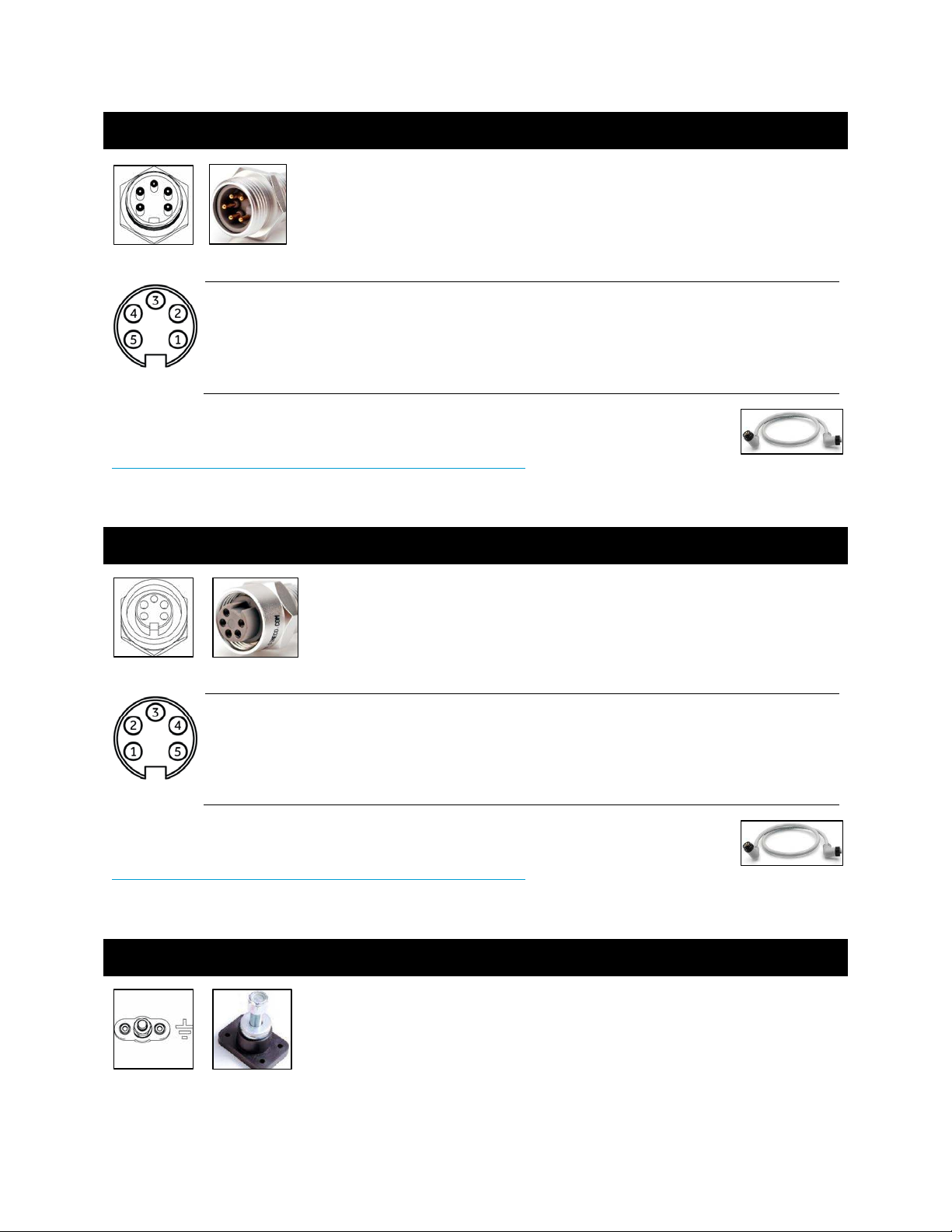

⑤CAN IN

Function: Input for sensing board power and CANbus communication

Part:

Amphenol SineCo DeviceNet MN51PD01M005 Male Receptacle,

External Threads

Pin # Name Wire Color Description

1 CAN_GND Bare Isolated CAN Ground

2 24V_LOGIC_POS Red 24 V Logic Positive

3 24V_LOGIC_NEG Black 24 V Logic Negative

4 CAN_H White CAN High Signal

5 CAN_L Blue CAN Low Signal

Mating connector:

Amphenol SineCo DeviceNet Thick MN57B4BD01Mxxx Patch Cable

Part not supplied by Aquion. Find your nearest authorized Amphenol distributor at

http://www.amphenol-sine.com/Distributors_c_108.html. In the part number, xxx

refers to cable length, which is determined by your installation.

⑥CAN OUT

Function:

Output for sensing board power and CANbus communication

Part:

Amphenol SineCo DeviceNet MN54PD01M005 Female Receptacle,

Internal Threads

Pin # Name Wire Color Description

1 CAN_GND Bare Isolated CAN Ground

2 24V_LOGIC_POS Red 24 V Logic Positive

3 24V_LOGIC_NEG Black 24 V Logic Negative

4 CAN_H White CAN High Signal

5 CAN_L Blue CAN Low Signal

Mating connector:

Amphenol SineCo DeviceNet Thick MN57B4BD01Mxxx Patch Cable

Part not supplied by Aquion. Find your nearest authorized Amphenol distributor at

http://www.amphenol-sine.com/Distributors_c_108.html. In the part number, xxx

refers to cable length, which is determined by your installation.

⑦EARTH GROUND LUG

Function:

Battery module grounding

Part:

Cooper Bussmann C1938

Mating connector:

Ground wire with 3/8" ring terminal

Parts not supplied by Aquion.

15 AQ-OP-00016_C

6.1.4 Module Accessories

The following power and communication cables are required to make connections to the M110-LS83

and M100-L083 battery modules. Aquion Energy does not supply these parts. They can be purchased

through Amphenol distributors worldwide. Find your nearest authorized distributor here:

http://www.amphenol-sine.com/Distributors_c_108.html.

Image Part Name

Optional,

Recommended,

Required Purpose Part Number Manufacturer

Quantity

per Module

4-pin

miniBOSS

Cordset

Required for

M100-LS83

Provides 24 V to power

the coil in the safety

contactor

MN47B4BC01Mxxx Amphenol

SineCo

1

DeviceNet

Thick Patch

Cable

Required for

M100-LS83

CANbus connection

between sensed modules

and BMS-200

MN57B4BD01Mxxx Amphenol

SineCo

1

6.1.5 Module Contactor Control

A DC contactor is installed on the positive (+) lead of each battery module. The DC contactor

must be powered by an external 24 V power supply. Aquion does not provide this power supply.

Each DC contactor power supply must be capable of supplying 100 mA times the number of

modules in the system, plus up to 1 A of surge current. The DC contactor operation can be easily

integrated into a system-level emergency stop (ESTOP) system to break down the series voltage

to <57.6 Vdc.

For systems equipped with an Aquion Battery Monitoring System (BMS), the DC contactor can be

commanded open by the BMS if certain alarm limits are exceeded. However, there will be a

1-second (adjustable) warning signal sent by both hardware and software before the module

contactor is opened. The hardware signal is a dry contact signal on the module 4-pin 24 V

connector that can be sensed by the site controller. The software signal is a Modbus command

sent from the BMS to the site controller.

6.2 Product Wiring Diagrams

S-Line Battery Stack

16 AQ-OP-00016_C

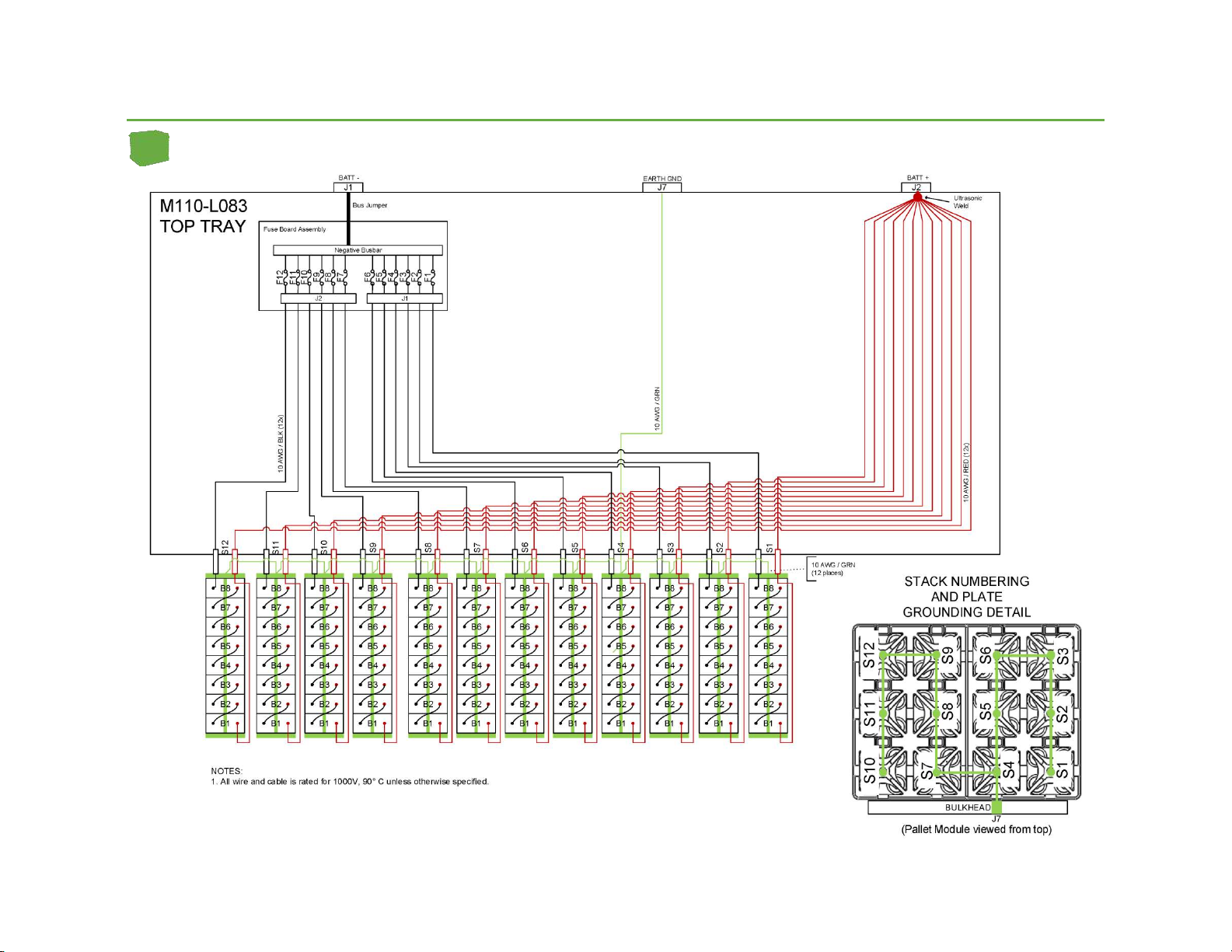

M-Line Battery Module

This manual suits for next models

4

Table of contents

Other Aquion Energy Camera Accessories manuals