www.aquorwatersystems.com

1-800-458-1749

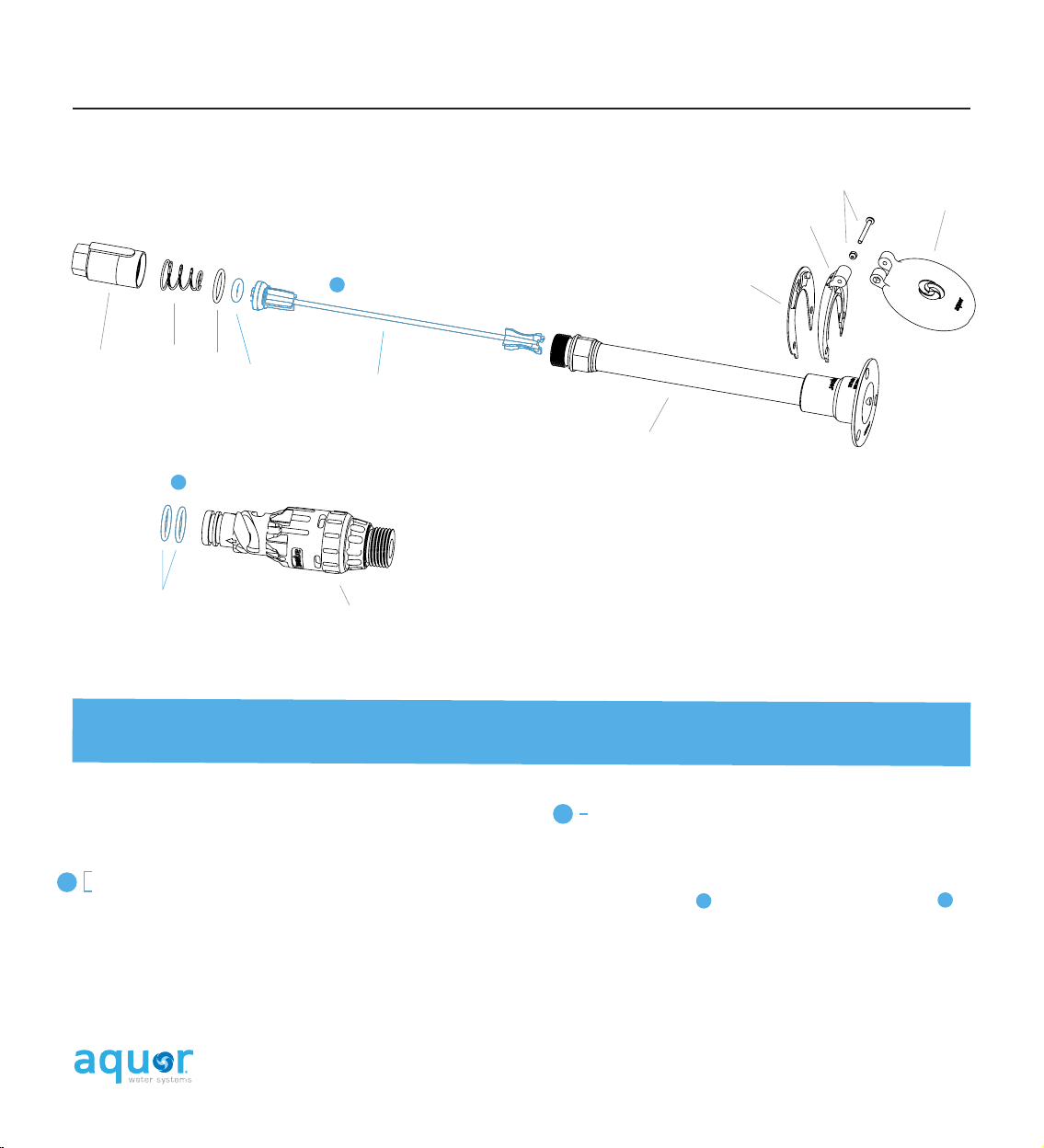

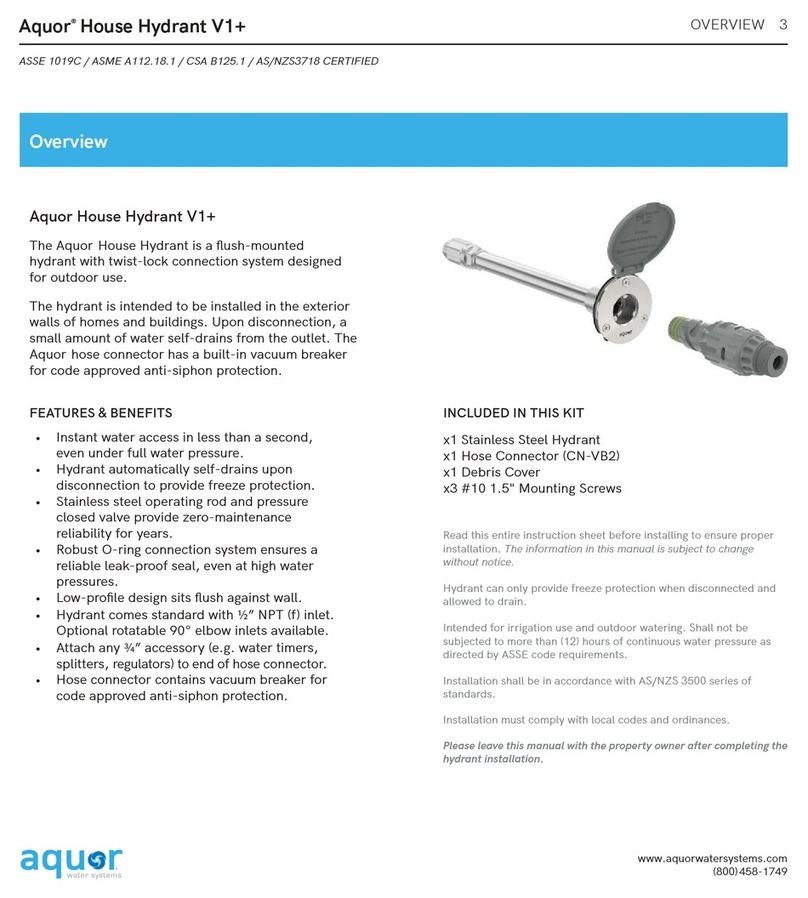

Aquor®Wall Hydrant V1+

ASSE 1019C / ASME A112.18.1 / CSA B125.1 APPROVED

13

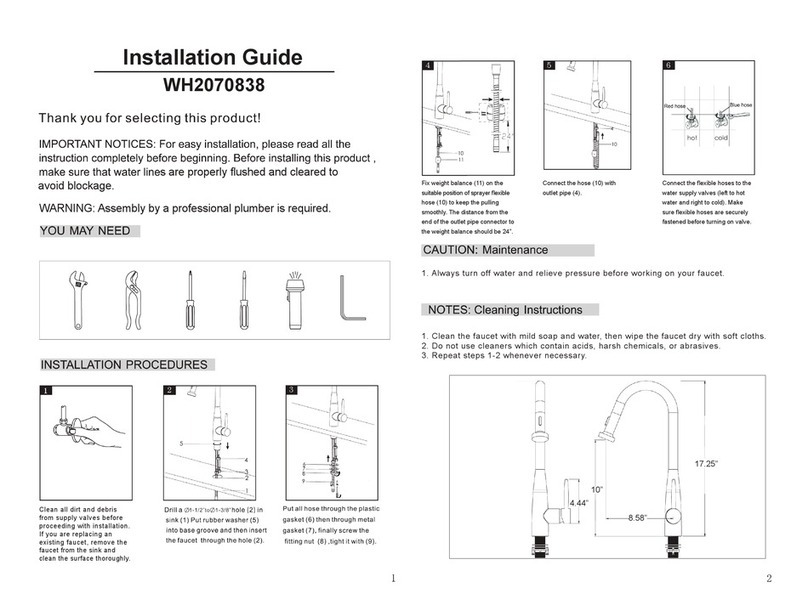

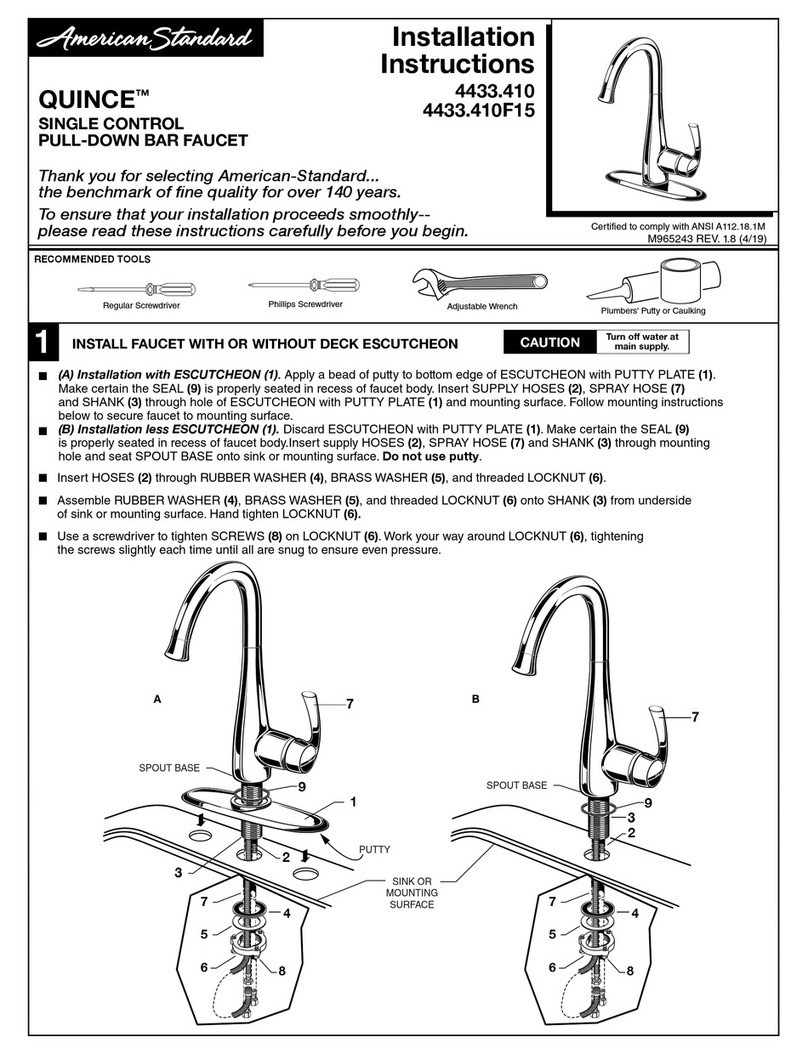

Depending on the type of plumbing, it will vary how

the hydrant connects. Common ways of connecting

to copper plumbing include soldering and push-fit

adapters.

Tip: With PEX tubing, we recommend adding an

expansion loop inside the wall if possible. This

allows the entire hydrant and fitting assembly to

be inspected and serviced from the exterior of the

building, if ever needed.

INSTALLATION & OPERATION

Operating Aquor® wall hydrants is a simple

process. Water starts flowing through the hydrant

when the hose connector is plugged in. Turn o the

hydrant by unplugging the hose connector.

Attach the Aquor®hose connector to any garden

hose. It can stay attached; there is no need to

remove it every use. Before storage, de-pressurize

your hose by squeezing the nozzle on the other end.

Always remove hose during freezing

temperatures.

Operation

Use any accessory as you would with a traditional

bib. Inline ball valves, timers, splitters, vacuum

breakers, and etc. can be attached to the connector.

Common ways of connecting to PEX include crimp

rings, expansion tools, and push-fit adapters.

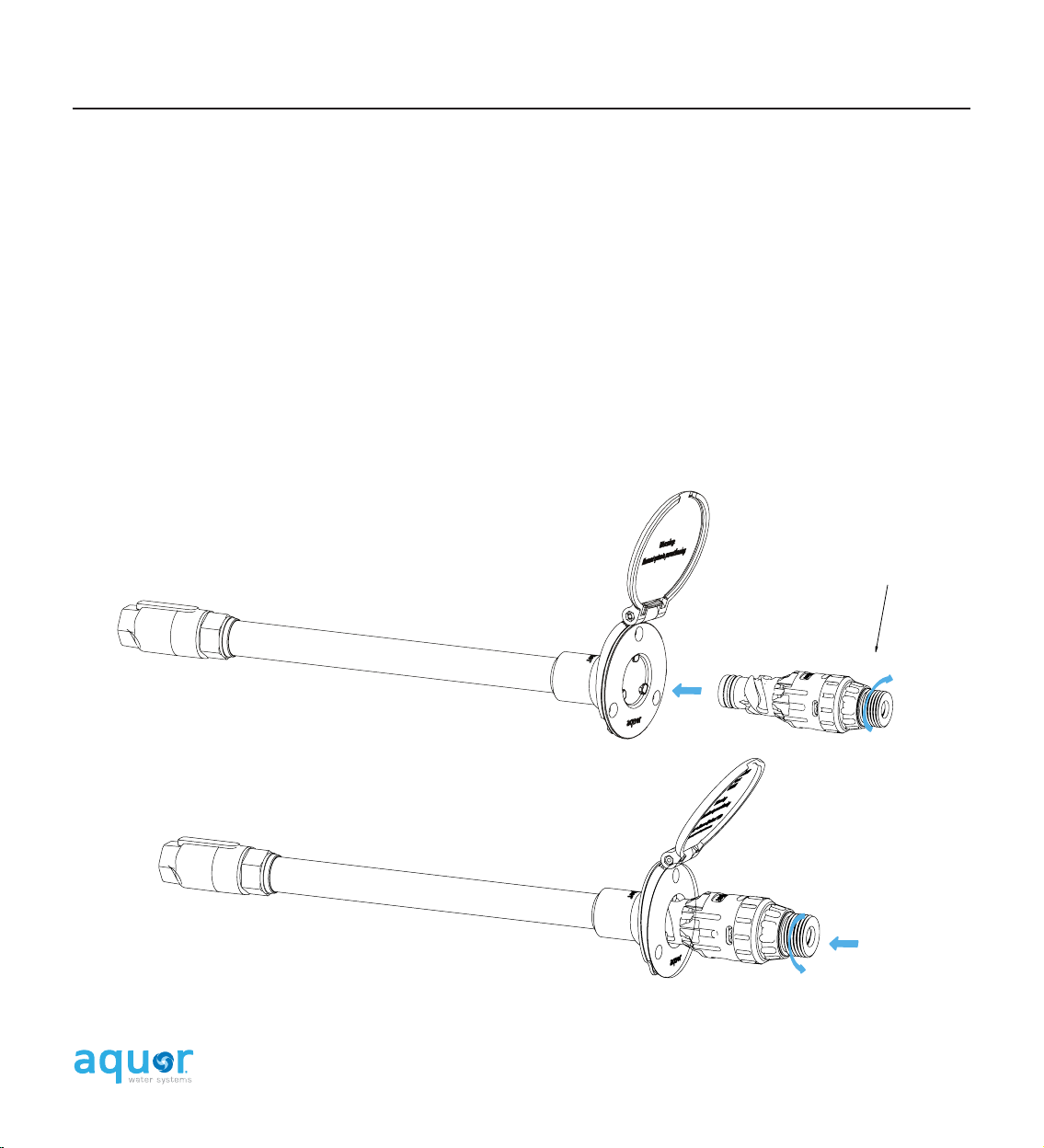

Before plugging in, attach a garden hose to

the Aquor®hose connector.

Complete the installation by turning on the water

supply.

Aquor®Hose Connector

Ball Valve (optional)

Garden Hose

Some Aquor®hose connectors have a

one-way check valve to prevent water

from spraying when you disconnect.

Tip: With copper plumbing, consider securing the

hydrant's inlet against a stud. This way the hydrant

can be removed from the building's exterior if ever

needed. The hydrant faceplate and body can be

rotated out and re-attached to the inlet.

Use a closed-end, such as a nozzle, on the hose

to create backpressure. Connect to the hydrant

and water should pressurize the hose immediately.

Disconnect and ensure the hydrant drains, then

remains leak-free.

Inspect the hydrant and plumbing connections for

any leaks.