AQUOR House Hydrant V2+ User manual

Aquor®House Hydrant V2+

ASSE 1019A CERTIFIED / meets IAPMO/cUPC

3

www.aquorwatersystems.com

(800) 458-1749

Overview

OVERVIEW

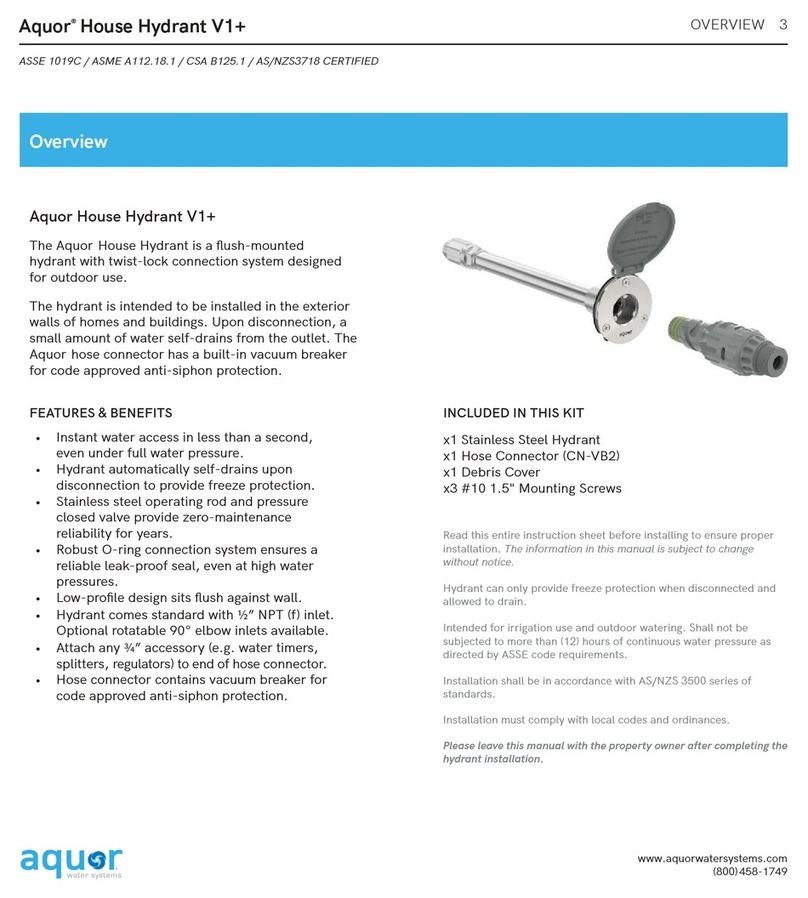

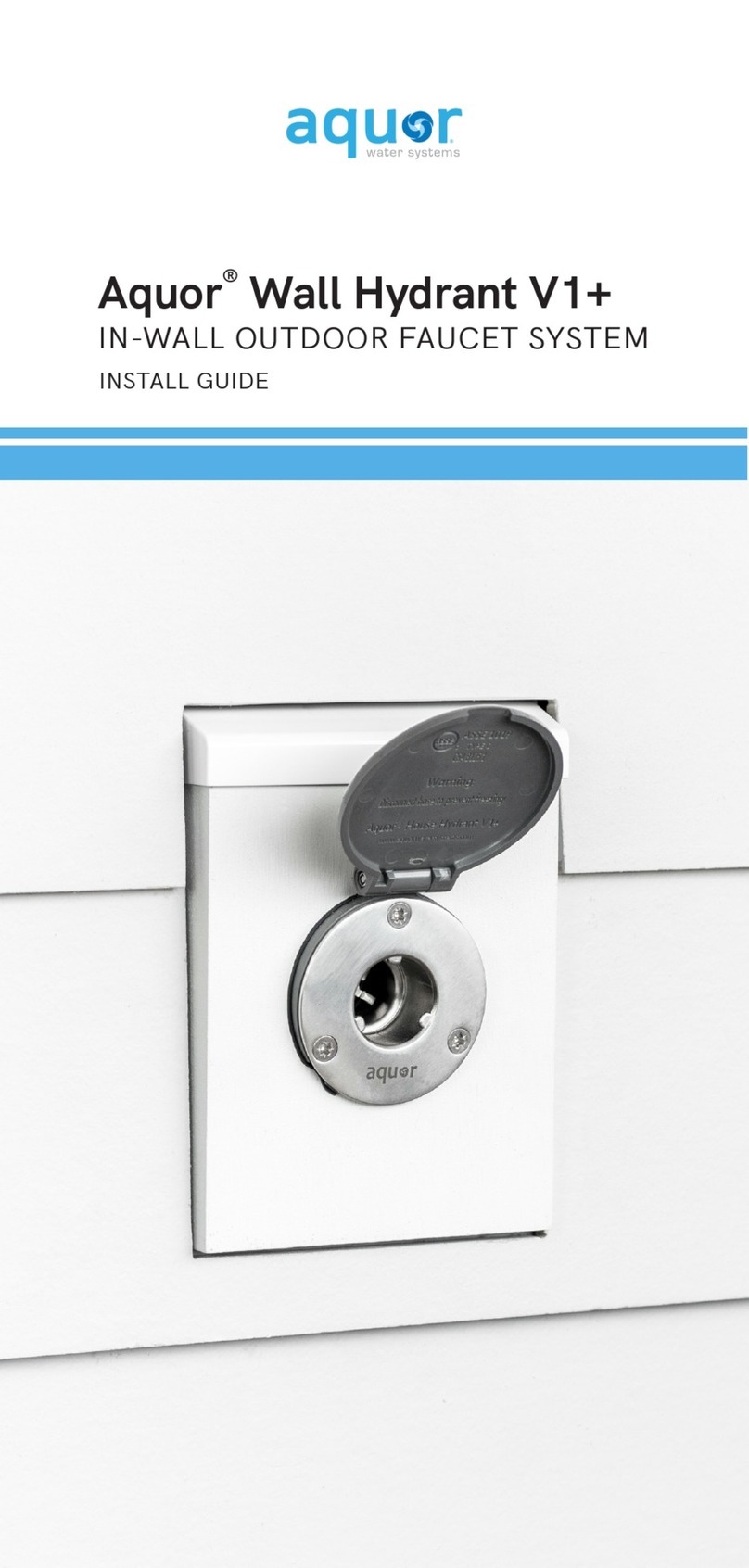

Aquor House Hydrant V2+

The Aquor®House Hydrant is a flush-mounted

hydrant with twist-lock connection system designed

for outdoor use.

The house hydrant is intended to be installed in

the exterior walls of homes and buildings. Upon

disconnection, a small amount of water self-drains

from the outlet. The Aquor® hose connector has a

built-in vacuum breaker for code approved

anti-siphon protection.

INCLUDED IN THIS KIT

x1 Stainless Steel Hydrant

x1 Hose Connector (CN-S1)

x1 Debris Cover

x4 #10 1.5” Mounting Screws

Read this entire instruction sheet before installing to ensure proper

installation. The information in this manual is subject to change

without notice.

Hydrant can only provide freeze protection when disconnected and

allowed to drain.

Intended for irrigation use and outdoor watering. Shall not be

subjected to more than (12) hours of continuous water pressure as

directed by ASSE code requirements.

Installation must comply with local codes and ordinances.

Please leave this manual with the property owner after completing the

hydrant installation.

FEATURES & BENEFITS

• Allows user to access water instantly by

connecting under full water pressure.

• Integral vacuum breaker in faceplate provides

anti-siphon protection.

• Robust O-ring connection system ensures a

reliable leak-proof seal, even at high water

pressures.

• Stainless steel operating rod and pressure-closed

valve provide zero-maintenance reliability for

years.

• Hydrant automatically self-drains upon

disconnection to provide freeze protection.

• Hydrant comes standard with ” female NPT

inlet. Rotatable 90° elbow and other optional

inlets available.

• Any ” accessory (e.g. water timers, splitters,

regulators) can be attached to end of hose

connector.

• Aquor®hose connector contains integral check

valve for additional backflow protection.

Aquor®House Hydrant V2+

ASSE 1019A CERTIFIED / meets IAPMO/cUPC

5

www.aquorwatersystems.com

(800) 458-1749

. PREPARE WALL

Determine the location for the hydrant. The

hydrant’s inlet must be installed into a heated area

of the structure that will not drop below freezing.

Before installation, make sure there is adequate work

room for securing the hydrant to the supply line.

Prepare the mounting surface and entry hole.

Aquor®House Hydrants require a vertical and

smooth mounting surface to ensure proper

installation and draining. Depending on the exterior

wall surface, a mounting block may be required

to provide a vertical and smooth mounting spot.

Mounting blocks can be commonly

found in hardware stores,

or can be made on-site

with materials such as

wood, fiber-cement, or

PVC trim board. Aquor®

mounting blocks can

be found on our website.

Installation

INSTALLATION

. SECURE HYDRANT TO WALL

Pre-pilot the mounting holes. Make sure to insert the

debris cover wedge behind the hydrant faceplate for

accurate markings.

Using a 1 /” hole saw, bore the entry hole through

the wall (and mounting block if using one) in the

desired location. Ensure the entry hole is vertically

level.

Tip: If enlarging an existing hole, try

cutting a dowel of the appropriate size

to use as a guide for the hole saw.

Tip: Use a low speed setting or a hand screwdriver

to avoid stripping the fasteners.

If drilling through a deep wall, you may

need to accommodate for the hydrant’s

downward angle.

A. Drill one 1 /”

(39 mm) hole.

B. Drill another

1 /” (39 mm)

hole below it,

1 /” (39 mm)

vertically on center.

C. Remove the

remaining material

to get the right

size for the hydrant.

1/”

(39 mm)

Aquor®House Hydrant V2+

ASSE 1019A CERTIFIED / meets IAPMO/cUPC

7

www.aquorwatersystems.com

(800) 458-1749

With the cover wedge behind the faceplate flange

secure the hydrant to the wall. x4 #10 1.5” stainless

steel screws are provided.

Cover wedge

behind faceplate

With the appropriate fitting installed, re-attach the

inlet to the hydrant body.

INSTALLATION

Tip: Drilling into brick or stone? Consider using

specialized fasteners and/or anchors. We also

manufacture optional stainless steel mounting plates

to space the mounting holes out further if needed.

After securing, test the cover to make sure it opens

and closes properly.

Tip: The inlet is on an O-ring seal. It’s designed to

rotate up to one turn while still keeping a watertight

seal. This is useful for alignment, especially for the

optional 90° elbow inlets. Tighten the inlet until it

stops, then rotate back to the desired spot. This seal

is rated to 250 PSI.

. CONNECT TO PLUMBING

With the appropriate fitting threaded in, connect the

hydrant to your plumbing system.

Hand-tight is fine; do not over-torque the

hydrant’s body connection. Do NOT apply

teflon tape or any kind of sealant to the

hydrant’s body threads.

. ATTACH FITTING

Proceed to the interior of the wall. Before attaching

a fitting, unscrew the hydrant’s rear inlet from the

main hydrant body.

The hydrant’s default inlet is ” NPT (f). Other

optional inlet styles are available.

Thread in the appropriate ” NPT fitting for your

plumbing type, wrapped in teflon tape then pipe-

joint compound. Firmly tighten with a wrench.

Aquor®House Hydrant V2+

ASSE 1019A CERTIFIED / meets IAPMO/cUPC

9

www.aquorwatersystems.com

(800) 458-1749

Tip: With copper plumbing and a V2+ series hydrant,

we recommend adding a shut-o valve and service

panel for maintenance access.

Common ways of connecting to PEX include crimp

rings, expansion tools, and push-fit adapters.

Complete the installation by turning on the water

supply.

Tip: With PEX tubing, we recommend adding an

expansion loop inside the wall if possible. This

allows the entire hydrant and fitting assembly to

be inspected and serviced from the exterior of the

building, if ever needed.

Depending on the type of plumbing, it will vary how

the hydrant connects. Common ways of connecting

to copper plumbing include soldering and push-fit

adapters.

Before plugging in, attach a garden hose to

the Aquor®hose connector.

Use a closed-end, such as a nozzle, on the hose

to create back pressure. Connect to the hydrant

and water should pressurize the hose immediately.

Disconnect and ensure the hydrant drains, then

remains leak-free.

Inspect the hydrant and plumbing connections for

any leaks.

INSTALLATION & OPERATION

Operation

Operating Aquor® House Hydrants is a simple

process. Water starts flowing through the hydrant

when the hose connector is plugged in. Turn o the

hydrant by unplugging the hose connector.

Attach the Aquor®hose connector to any garden

hose. It can stay attached; there is no need to

remove it every use. Before storage, depressurize

your hose by squeezing the nozzle on the other end.

Always remove hose during freezing

temperatures.

Use any accessory as you would with a traditional

bib. Inline ball valves, timers, splitters, vacuum

breakers, and etc. can be attached to the connector.

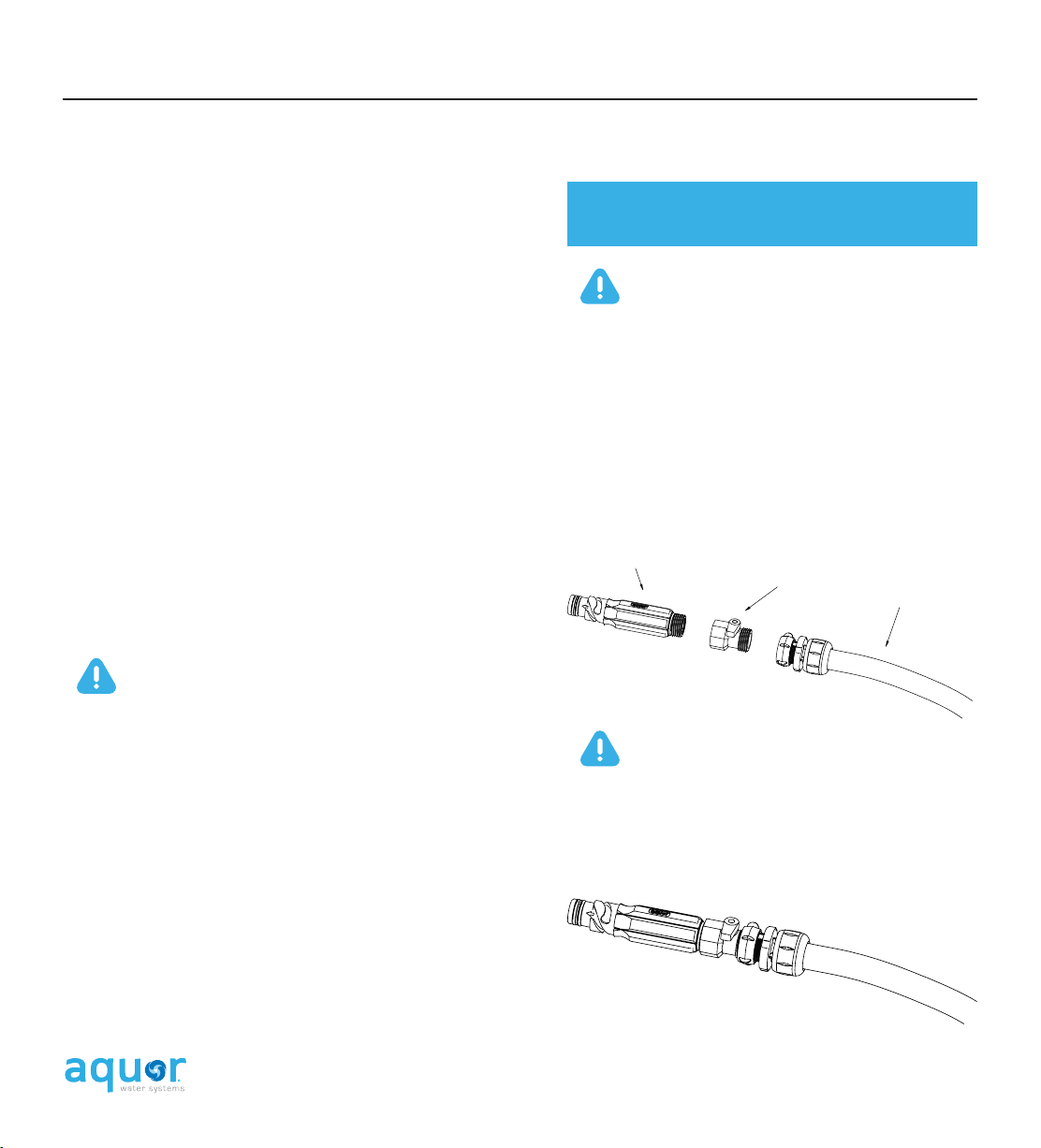

Some Aquor®hose connectors have a

one-way check valve to prevent water

from spraying when you disconnect.

Aquor®Hose Connector

Ball Valve (optional)

Any Garden Hose

Aquor®House Hydrant V2+

ASSE 1019A CERTIFIED / meets IAPMO/cUPC

11

www.aquorwatersystems.com

(800) 458-1749

Nibs on hydrant faceplate

To connect: Line up the three helical grooves on

the hose connector with the three nibs on the

hydrant faceplate. Simultaneously push and twist

the connector clockwise in a smooth motion. Make

sure to align the grooves fully and push in before

twisting. Water flow will start instantly when the

connector is engaged.

To disconnect: Push the connector in slightly,

then untwist counter-clockwise. The hydrant will

self-drain any remaining water left in the body.

The water will drain for the few moments, this is

perfectly normal.

Remember to depressurize your hose before

storage. It’s best to disconnect the hydrant when

not in use. For the longest lifespan, store your

Aquor® hose connectors out of the elements.

Connect hose to hose

connector before

connecting to hydrant.

Grooves on hose connector

OPERATION

Bayonet locking design keeps

connector secure when engaged

Tip: If you leave the Aquor®connector attached to

your garden hose, make sure to depressurize the

hose after use. Temperature changes can cause

water inside to expand, causing excessive pressure

on the connector’s internal check valve (and your

nozzle or accessories) over time.

For installation or other technical questions, please

call our customer service team at 1-800-458-1749.

Aquor®House Hydrant V2+

ASSE 1019A CERTIFIED / meets IAPMO/cUPC

13

www.aquorwatersystems.com

(800) 458-1749

Aquor®hydrants leave the factory fully tested

and operational. They are treated with an FDA

approved lubricant where needed. The hydrant

requires no scheduled maintenance to provide a

long operational life. If a problem does arise, all the

serviceable components are oered in repair kits

(see page 15).

It’s best to disconnect the hydrant when not in use.

The hydrant can only oer freeze protection when

disconnected. We recommend unplugging after

each use.

For freeze protection, the hydrant does not need

to be covered any further. As long as it has been

disconnected, allowed to drain, and the ambient

temperature inside the wall remains above freezing,

the hydrant and the plumbing will be protected.

Storing your hose connectors out of the elements

can prolong their lifespan. You can drain your

hose and bring it inside - the internal check valve

prevents any unwanted draining afterwards, so your

floor stays dry.

Protect the hose connector’s O-rings. They are

designed for extremely long lifespans if used

properly. Use care not to snag the connector

O-rings on the hydrant nibs. When connecting, line

up the grooves before attempting to push or twist.

Maintenance

MAINTENANCE

Routine cleaning with soap and water is usually

sucient to maintain the corrosion resistance and

appearance of the marine-grade stainless steel. Use

a soft brush to remove any accumulated dirt, then

rinse with clean water. Use stainless steel polish as

needed.

If you have hard water buildup, the hydrant can be

completely disassembled for service or cleaning

if needed. The inner valve and stem are accessed

through the rear.

We recommend replacing the internal valve once

every 20 years, or as needed. You may periodically

clean and lubricate the O-ring if there is mineral

buildup.

Aquor®House Hydrant V2+

ASSE 1019A CERTIFIED / meets IAPMO/cUPC

15

www.aquorwatersystems.com

(800) 458-1749

Hydrant

1. Rear Valve Housing (Inlet)

2. Valve Spring

3. Hydrant Body O-Ring

4. Inner Valve O-Ring

5. Operating Rod

6. Hydrant Body

Parts Description

7. Vacuum Breaker Washer

8. Vacuum Breaker Valve

9. Vacuum Breaker Seal

10. Vacuum Breaker Retainer

11. Vacuum Breaker Spring

12. Vacuum Breaker Cover

A

B

1

17

18 19 20

2345

A

C

Debris Cover

13. Debris Cover Gasket

14. Debris Cover Wedge

15. Debris Cover Nut & Bolt

16. Debris Cover

PARTS DESCRIPTION

Hose Connector

17. Connector O-Rings

18. Connector Body

19. Check Valve O-Ring

20. Check Valve

21. Check Valve Spring

22. Check Valve Retainer

Need Parts? Stem Replacement Kits available in 2”, 4”, 6”,

8”, 10”, and 12” , Vacuum Breaker Replacement

Kits , and Hose Connector O-Ring Kits are available.

For help, email us at contact@aquorwatersystems.com

or call us at 1-800-458-1749.

A

B

C

C

22

21

6

13 14

15

16

7 8 9 10 11 12

B

Aquor®House Hydrant V2+

ASSE 1019A CERTIFIED / meets IAPMO/cUPC

17

www.aquorwatersystems.com

(800) 458-1749

Technical Specs

TECHNICAL SPECS

In the Box

Backflow Protection

Inlet x Outlet

Operating Temperature

Operating Water Pressure

Flow Rate

Plumbing Compatibility

Hydrant Material

Connector Material

O-Ring Material

Cover Material

Certifications

Warranty

SKU

SKU

VBHP002

VBHP004

VBHP006

VBHP008

VBHP010

VBHP012

Stem Length (A)

2” Hydrant

4” Hydrant

6” Hydrant

8” Hydrant

10” Hydrant

12” Hydrant

Overall Length (B)

4 /” (114 mm)

5 /” (141 mm)

7 /” (192 mm)

9 /” (241 mm)

11 /” (292 mm)

13 /” (343 mm)

Optional 90° elbow inlets reduce overall length by 1/2”(13 mm).

Hydrant, Debris Cover, Hose

Connector, x4 #10 1.5” Mount-

ing Screws, Install Instructions

Yes, built-in vacuum breaker

1/2 “ NPT (f) x 3/4” GHT (m)

33 -140 °F

25-125 PSI

6.8 GPM @ 52 PSI

All (PEX recommended)

316L Stainless Steel

Acetal Resin Polymer

Fluorocarbon Rubber

ASA Thermoplastic

ASSE 1019A, meets IAMP/cUPC

10 Years stainless steel,

5 Years polymer

VBHP002, VBHP004,

VBHP006, VBHP008,

VBHP010, VBHP012

Aquor®House Hydrant V2+

ASSE 1019A CERTIFIED / meets IAPMO/cUPC

19

www.aquorwatersystems.com

(800) 458-1749

TECHNICAL SPECS

VBHP

STEM LENGTH: "

OVERALL LENGTH: - /"

Close-Couple House Hydrant V2+

VBHP

STEM LENGTH: "

OVERALL LENGTH: - /"

4" House Hydrant V2+

Aquor®House Hydrant V2+

ASSE 1019A CERTIFIED / meets IAPMO/cUPC

21

www.aquorwatersystems.com

(800) 458-1749

TECHNICAL SPECS

VBHP

STEM LENGTH: "

OVERALL LENGTH: - /"

6" House Hydrant V2+

VBHP

STEM LENGTH: "

OVERALL LENGTH: - /"

8" House Hydrant V2+

Aquor®House Hydrant V2+

ASSE 1019A CERTIFIED / meets IAPMO/cUPC

23

www.aquorwatersystems.com

(800) 458-1749

TECHNICAL SPECS

VBHP

STEM LENGTH: "

OVERALL LENGTH: - /"

10" House Hydrant V2+

VBHP

STEM LENGTH: "

OVERALL LENGTH: - /”

12" House Hydrant V2+

Aquor®House Hydrant V2+

ASSE 1019A CERTIFIED / meets IAPMO/cUPC

25

www.aquorwatersystems.com

(800) 458-1749

No water flow when connected.

Water leaking from plumbing connection.

Water leaking from hydrant body-to-inlet connection.

Troubleshooting

PROBLEM

TROUBLESHOOTING

First you’ll want to identify whether the issue is in the

hydrant, or the hose connector.

Make sure water supply is live to the hydrant. Try

depressing the hydrant valve with your thumb to test for

pressure. If the water pressure is live, the issue is likely

the hose connector.

Inspect the hose connector to see if the internal check-

valve is stuck. In variable weather conditions, if left

pressurized outside, water expansion may cause the

check valve to seize.

If the hose connector has a ball-valve, make sure it is on.

For threaded fittings, re-wrap with 4-5 wraps of teflon

tape, followed by a layer of pipe-joint compound. Firmly

tighten with wrenches.

For PEX specific fittings, ensure a compatible PEX tubing

type and installation tool are being used. Check fitting

dimensions for spec.

Inspect the O-ring between the rear valve housing (inlet)

and hydrant body. The inlet can be backed o up to

on full rotation without losing a watertight seal. Ensure

no teflon tape or sealant is applied. Inlet should thread

smoothly.

SOLUTION

Aquor®House Hydrant V2+

ASSE 1019A CERTIFIED / meets IAPMO/cUPC

27

www.aquorwatersystems.com

(800) 458-1749

Correct order of vacuum breaker assembly

Water leaking from the hydrant main outlet when

disconnected.

Water leaking from

vacuum breaker

when connected.

Water sprays from the vacuum breaker when

connecting.

Hose connector won’t stay plugged in.

Water leaking from the hydrant main outlet (front) when

connected.

PROBLEM

TROUBLESHOOTING

A slow leak may indicate a stuck or bent internal rod, or

damaged O-ring.

First, try to reset the valve from the front. Shut-o water

supply and use needlenose pliers to press in and rotate

the internal operating rod. Resistance could indicate a

piece of debris behind the valve.

If leak persists, remove the internal operating rod from

the hydrant by unscrewing the rear inlet from the body.

Inspect the O-ring and stem for any damage, remove

debris or replace assembly if needed.

First, ensure water pressure is between 25-125 PSI.

Pressure that is too high or too low can cause issues with

backflow preventers.

Next, test with a second hose connector. If the issue

persists, replace the faulty hose connector.

A small burst of water when connecting or disconnecting

is normal due to pressure.

If the spray or leak persists, inspect the vacuum breaker

washer and replace if needed.

Ensure water pressure is not too low. The hydrant uses

water pressure to seal, and is designed for pressures of

25-125 PSI. If you are installing the hydrant on a well

or low-pressure system, contact us for a higher weight

hydrant valve spring, or add a pressure booster.

First, make sure the vacuum- breaker is not leaking.

Inspect hose connector O-rings for damage, replace or

lubricate if needed.

SOLUTION

Aquor®House Hydrant V2+

ASSE 1019A CERTIFIED / meets IAPMO/cUPC

29

www.aquorwatersystems.com

(800) 458-1749

Hose connector is dicult to connect or disconnect.

Warranty

PROBLEM

TROUBLESHOOTING, WARRANTY, & CONTACT

For any questions, please get in touch with our customer

service team at contact@aquorwatersystems.com or call

us at 1-800-458-1749 Mon-Fri 9AM-4PM.

Contact Us

Try squeezing your hose nozzle while simultaneously

disconnecting.

If left outdoors in variable weather, water expansion

may have caused the connector’s internal check-valve

to seize. Try disassembling or removing the connector’s

check valve. Test with a dierent hose connector.

There may be a piece of debris stuck in the hydrant’s

main valve. Shut o the water supply, then test the

valve’s forward/back operation with your thumb or a

tool. It should operate smoothly. If needed, remove

hydrant’s operating rod by unscrewing the rear inlet.

If the issue occurs gradually over time, try cleaning the

hydrant’s outlet and lubricating the connector O-rings.

SOLUTION

We stand behind every product we make. Aquor

oers a 10 year warranty on all stainless steel

components and 5 years on all polymer components.

Our mission is to manufacture the highest quality

water connectors possible, engineered to last

decades of frequent use.

Visit our website to activate

your product warranty.

www.aquorwatersystems.com

/pages/warranty-registration

This manual suits for next models

8

Table of contents

Other AQUOR Plumbing Product manuals

Popular Plumbing Product manuals by other brands

Bradley

Bradley S19-210FW Installation

Axor

Axor Citterio 39037003 Instructions for use/assembly instructions

Tylo

Tylo Sauna i1515 Corner manual

Signature Hardware

Signature Hardware BEASLEY 948676 manual

DURAVIT

DURAVIT Inipi 7509 Series Mounting instruction

Symmons

Symmons Canterbury 4-163 Operation & maintenance manual