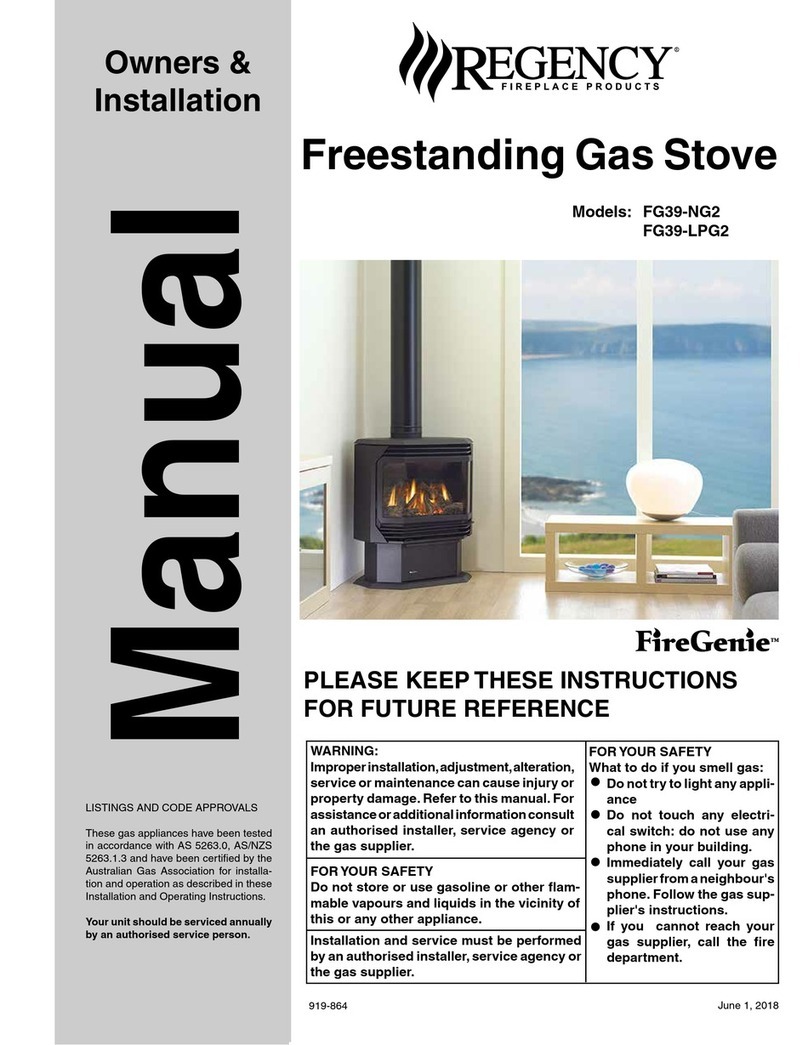

Arada Stoves Farringdon 16 User manual

11785 SE Highway 212 –Suite 305

Clackamas, OR 97015-9050

(503) 650-0088

Arada Stoves LTD

Project # 035-S-075-1

Model: Farringdon 16

Type: Free Standing Residential

Catalytic Wood Fired Heater

February 24, 2017 (Dirigo)

Revised: July 11, 2022, August 30,

2022

EPA Test Method 28R for

Certification and Auditing of

Wood Heaters

Contact:

Mr. Jon Butterworth

The Fire Works

Weycroft Avenue

Axminster, Devon

United Kingdom EX13 5HU

JButterworth@aradastoves.com

+44 1297 35700

Project # 035-S-075-1 Model: Farringdon 16

Page | 1

Revision:

July 11, 2022

•Changed CO from g/hr to g/min

•Updated Summary Table for clarity.

•Added 1st hour emissions in g/hr for all runs.

•Added train precision criteria table.

•Added fuel load density to summary table.

•Added firebox volume drawing to main body of report.

•Added statement that no negative catch weights recorded.

August 30, 2022

•Added additional description of dilution tunnel per EPA request dated August 24, 2022 .

See Notes page and Page 28.

•Updated conditioning data to state that it was operated at a medium burn rate.

•All fuel used for conditioning was between 18% and 25% wet basis per ASTM E2780-10.

Because Conditioning data is not part of the overall results of the unit as tested,

Individual piece moisture was checked but not recorded.-Please note that the items that

are required to be recorded for conditioning purposes are:

oTime and Weight for all fuel (ASTM E2780-10 section 9.1.4)

oFlue gas temperature a minimum of once per hour (ASTM E2780-10 Section

9.1.5)

•Added comment to notes section that no written instructions were provided to the lab

from the manufacturer regarding the operation of the catalyst bypass. Operation of the

bypass was consistent with those in the Users Manual provided.

Project # 035-S-075-1 Model: Farringdon 16

Page | 2

Table of Contents

Revision:........................................................................................................................1

Affidavit:.........................................................................................................................4

Introduction:..................................................................................................................5

Notes:.............................................................................................................................5

Wood Heater Identification and Testing:.....................................................................6

Test Procedures and Equipment:..........................................................................................................7

Results:..........................................................................................................................8

Efficiency:............................................................................................................................................10

Summary Table: ....................................................................................................................................12

Run 2:..................................................................................................................................................12

Run 3:..................................................................................................................................................13

Run 4:..................................................................................................................................................13

Run 5:..................................................................................................................................................13

Precision:.....................................................................................................................14

Filter Catch:................................................................................................................. 15

Run 1:.....................................................................................................................................................15

Run 3:.....................................................................................................................................................16

Run 4:.....................................................................................................................................................16

Run 5:.....................................................................................................................................................17

Test Condition Summary:........................................................................................... 18

Heater Specifications:.................................................................................................18

Heater Dimensions................................................................................................................................18

Useable Firebox Volume:.....................................................................................................................19

Air Flow Schematic...............................................................................................................................20

Process Operations and Description:.................................................................................................25

Settings & Run Notes ...........................................................................................................................25

Test Fuel Properties: ............................................................................................................................27

Pre-burn Configuration: .......................................................................................................................27

Sampling Locations and Descriptions: ..............................................................................................28

Sample Points .......................................................................................................................................28

Sampling Methods:.....................................................................................................29

Analytical Methods Description:................................................................................ 29

Project # 035-S-075-1 Model: Farringdon 16

Page | 3

Calibration, Quality Control and Assurances:.......................................................... 29

Appliance Sealing and Storage: ................................................................................29

Sealing Label.........................................................................................................................................29

Sealed Unit.............................................................................................................................................30

Sampling and Analytical Procedures........................................................................32

Participants.................................................................................................................. 32

Analysis and Report Writing ......................................................................................32

Observers:...................................................................................................................32

Appliance Updates......................................................................................................32

Accreditations:............................................................................................................33

List of Appendices:.....................................................................................................37

Project # 035-S-075-1 Model: Farringdon 16

Page | 4

Affidavit:

Dirigo Laboratories, Inc. was contracted by Arada Stoves Ltd. to provide testing

services for the Farringdon 16 catalytic wood fired heater per EPA Method 28R for

Certification and Auditing of Wood Heaters. All testing and associated procedures were

conducted at Dirigo Laboratories, Inc. beginning on 2/14/2017 and ending on 2/17/2017.

Dirigo Laboratories is located at 11785 SE Highway 212 –Suite 305, Clackamas,

Oregon 97015. Testing procedures followed EPA Method 28R and ASTM E2780-10.

Particulate sampling was performed per ASTM E2515-11 Standard Test Method for

Determination of Particulate Matter Emissions Collected by a Dilution Tunnel.

Dirigo Laboratories is accredited by the U.S. Environmental Protection Agency for the

certification and auditing of wood heaters pursuant to subpart AAA of 40 CFR Part 60,

New Source Performance Standards for Residential Wood Heaters and subpart QQQQ

of 40 CFR Part 60, Standards of Performance for New Hydronic Heaters and Forced Air

Furnaces, Methods 28R, 28WHH, 28 WHH-PTS, and all methods listed in Sections

60.534 and 60.5476. Dirigo holds EPA Accreditation Certificate Numbers 4 and 4M

(mobile). Dirigo Laboratories, Inc. is accredited by A2LA to ISO 17020:2012 “Criteria for

Bodies Performing Inspections, ISO 17025:2005 “Requirements for Testing

Laboratories”, and ISO 17065:2012 “Requirements for Bodies Operating Product

Certification Systems”. Dirigo holds A2LA Certificate Numbers 3726.01, 3726.02, and

3726.03. See Appendix E for Accreditations.

The following people were associated with the testing, analysis and report writing

associated with this project.

John Steinert, President

Ben Nelke, Test Technician

Doug Towne, QA Manager

Project # 035-S-075-1 Model: Farringdon 16

Page | 5

Introduction:

Arada Stoves Ltd. of Axminster, United Kingdom, contracted with Dirigo Laboratories,

Inc. to perform EPA certification testing for their Model Farringdon 16 catalytic wood

heater. All testing was performed at Dirigo Laboratories, Inc. Testing was performed by

Mr. Ben Nelke.

Notes:

•A 50 hour break-in was performed on the appliance at Dirigo Laboratories, Inc.

from 12/02/16 through 12/14/16.

•Prior to testing, the dilution tunnel was cleaned with a steel brush.

•The heater has no blower so no fan confirmation test was performed.

•Front filters were changed on sample train A at one hour for all runs.

•There were no negative filter or probe weights for any of the test runs. All runs

were appropriate and valid.

•Leak checks were performed for all test runs and were verified in the run data.

•Sample ports are located 16.5 feet downstream from any disturbances and 1 foot

upstream from any disturbances. Flow rate traverse data was collected 12 feet

downstream from any disturbances and 5.5 feet upstream from any disturbances.

(See page 28)

•There were no written instructions provided by the manufacturer to the

Laboratory. The catalyst bypass was operated per the Owners Manual.

Project # 035-S-075-1 Model: Farringdon 16

Page | 6

Wood Heater Identification and Testing:

•Appliance Tested: Farringdon 16 Free Standing

•Serial Number: DEV6764B

•Manufacturer: Arada Stoves Ltd.

•Catalyst: Yes

•Heat exchange blower: None

•Type: Wood Stove

•Style: Free Standing

•Date Received: Tuesday, November 29, 2016

•Wood Heater Aging: December 2 - December 14, 2016

•Testing Period –Start: Tuesday, February 14, 2017 Finish: Friday, February

17, 2017

•Test Location: Dirigo Laboratories, Inc. 11785 SE HWY 212 - Suite 305,

Clackamas, OR 97015

•Elevation: ≈131 Feet above sea level

•Test Technician(s): Ben Nelke

•Observers: None

Project # 035-S-075-1 Model: Farringdon 16

Page | 7

Test Procedures and Equipment:

All Sampling and analytical procedures were performed by Ben Nelke. All procedures

used are directly from EPA Method 28R, ASTM E2780-10 and ASTM E2515-11.See

the list below for equipment used. See Appendix D for calibration data.

Equipment List:

1. Analyzer -California Analytical ZRE CO2/CO/O2 IR ANALYZER

2. Delmhorst J-2000 Wood Moisture Meter

3. Dayton 4c121 Blower for dilution tunnel -Emissions Booth #1

4. ScienTech Balance Scale

5. 10 lb Calibration Weight

6. DigiWeigh Bench Shipping Scale

7. APEX XC-60 Digital Emissions Sampling Box A

8. APEX XC-60 Digital Emissions Sampling Box B

9. APEX Ambient sampling box

10.Gast MOA-P122-AA Vacuum Pump

11.Rice Lake 3'x3' floor scale w/digital weight indicator

Project # 035-S-075-1 Model: Farringdon 16

Page | 8

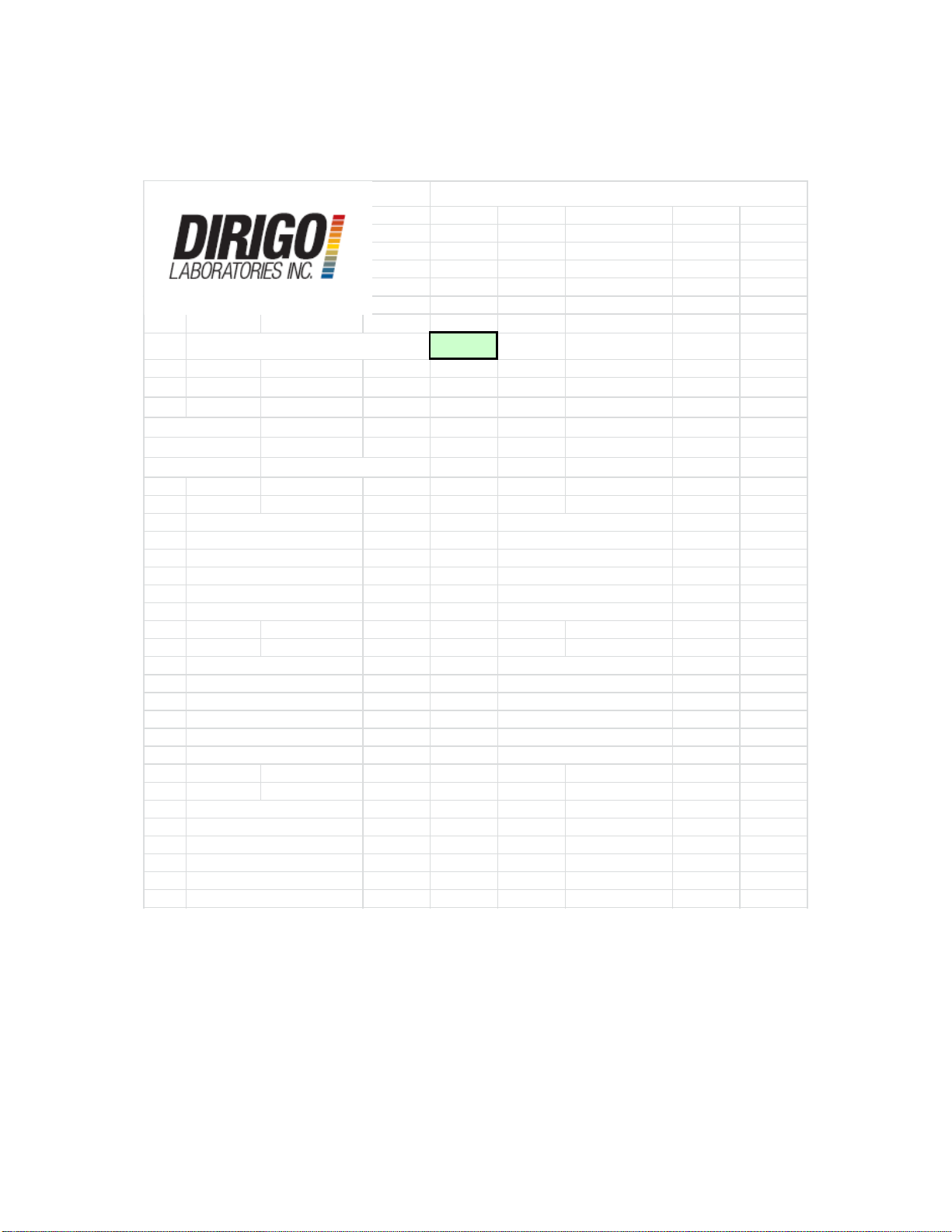

Results:

For the Farringdon 16 wood heater, the weighted average emission rate is 1.5 g/hr with

a weighted average efficiency of 77.2% and a weighted average CO of 0.91 g/min. The

Arada Stoves Ltd. Model Farringdon 16 catalytic free standing wood heater meets the

2020 PM emission standard of ≤2.0 g/hr per CFR 40 part 60, §60.532 (b).

Detailed individual run data can be found in separate digital folders supplied with this

report.

Emissions:

EPA Method 28 - Weighted Average

Weighted Average: 1.5 (g/hr)

Client: Arada

Model: Farringdon 16

Tracking No.: 75

Project No.: 035-S-075-1

Test Dates: 2/14/17 - 2/17/17

Burn Rate Category 1 Burn Rate Category 1

Burn Rate (kg/hr-dry) 0.59 Burn Rate (kg/hr-dry) 0.77

Emissions Rate (g/hr) 0.9 Emissions Rate (g/hr) 1.1

Emissions Rate Cap (g/hr) 15 Emissions Rate Cap (g/hr) 15

Weighting Factor 10.96% Weighting Factor 14.42%

Run Number 1 Run Number 2

Burn Rate Category 2 Burn Rate Category 3

Burn Rate (kg/hr-dry) 0.98 Burn Rate (kg/hr-dry) 1.29

Emissions Rate (g/hr) 2.0 Emissions Rate (g/hr) 1.5

Emissions Rate Cap (g/hr) 15 Emissions Rate Cap (g/hr) 15

Weighting Factor 22.65% Weighting Factor 30.52%

Run Number 3 Run Number 4

Burn Rate Category 4

Burn Rate (kg/hr-dry) 2.01

Emissions Rate (g/hr) 1.7

Emissions Rate Cap (g/hr) 18

Weighting Factor 21.45%

Run Number 5

Project # 035-S-075-1 Model: Farringdon 16

Page | 9

EPA Method 28 - Weighted Average

Client: Arada

Model: Farringdon 16

Tracking No.: 75

Project No.: 035-S-075-1

Test Dates: 2/14/17 - 2/17/17

0.0

0.5

1.0

1.5

2.0

2.5

0.59 0.77 0.98 1.29 2.01

Emissions Rate (g/hr)

BurnRate (kg/hr)

EPAMethod28 - WeightedAverage

Project # 035-S-075-1 Model: Farringdon 16

Page | 10

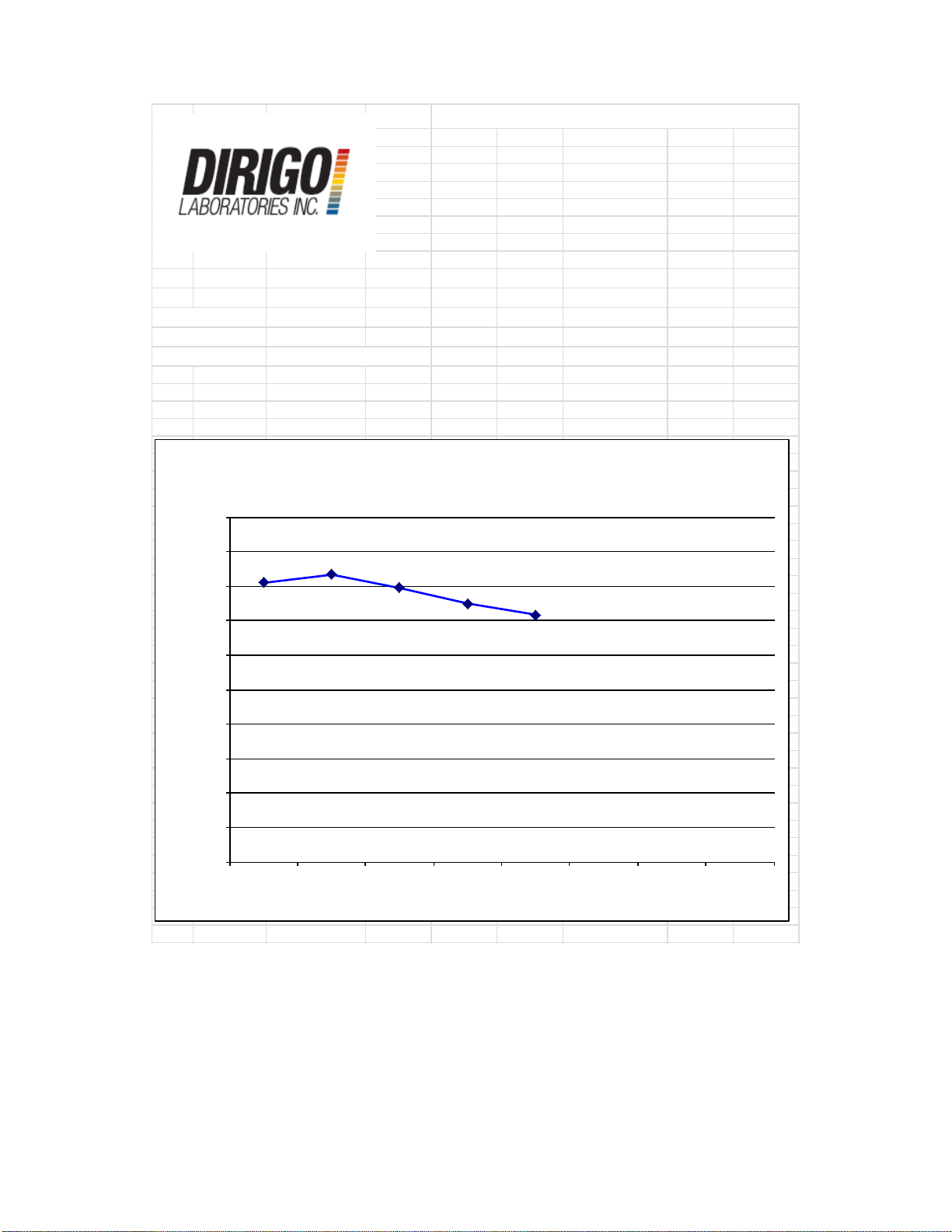

Efficiency:

All efficiency values use the HHV.

CSA B415.1-10 Weighted Average

Weighted Average: 77.2 %

Client: Arada

Model: Farringdon 16

Tracking No.: 75

Project No.: 035-S-075-1

Test Dates: 2/14/17 - 2/17/17

Burn Rate Category 1 Burn Rate Category 1

Burn Rate (kg/hr-dry) 0.59 Burn Rate (kg/hr-dry) 0.77

OA Efficiency % 81.1 OA Efficiency % 83.4

Emissions Rate Cap (g/hr) 15 Emissions Rate Cap (g/hr) 15

Weighting Factor 10.96% Weighting Factor 14.42%

Run Number 1 Run Number 2

Burn Rate Category 2 Burn Rate Category 3

Burn Rate (kg/hr-dry) 0.98 Burn Rate (kg/hr-dry) 1.29

OA Efficiency % 79.5 OA Efficiency % 75.0

Emissions Rate Cap (g/hr) 15 Emissions Rate Cap (g/hr) 15

Weighting Factor 22.65% Weighting Factor 30.52%

Run Number 3 Run Number 4

Burn Rate Category 4

Burn Rate (kg/hr-dry) 2.01

Emissions Rate (g/hr) 71.7

Emissions Rate Cap (g/hr) 18

Weighting Factor 21.45%

Run Number 5

Project # 035-S-075-1 Model: Farringdon 16

Page | 11

CSA B415.1-10 - Weighted Average

Client: Arada

Model: Farringdon 16

Tracking No.: 75

Project No.: 035-S-075-1

Test Dates: 2/14/17 - 2/17/17

0.0

10.0

20.0

30.0

40.0

50.0

60.0

70.0

80.0

90.0

100.0

0.59 0.77 0.98 1.29 2.01

OverallEfficiency%

BurnRate (kg/hr)

CSAB415.1-10-WeightedAverage

Project # 035-S-075-1 Model: Farringdon 16

Page | 12

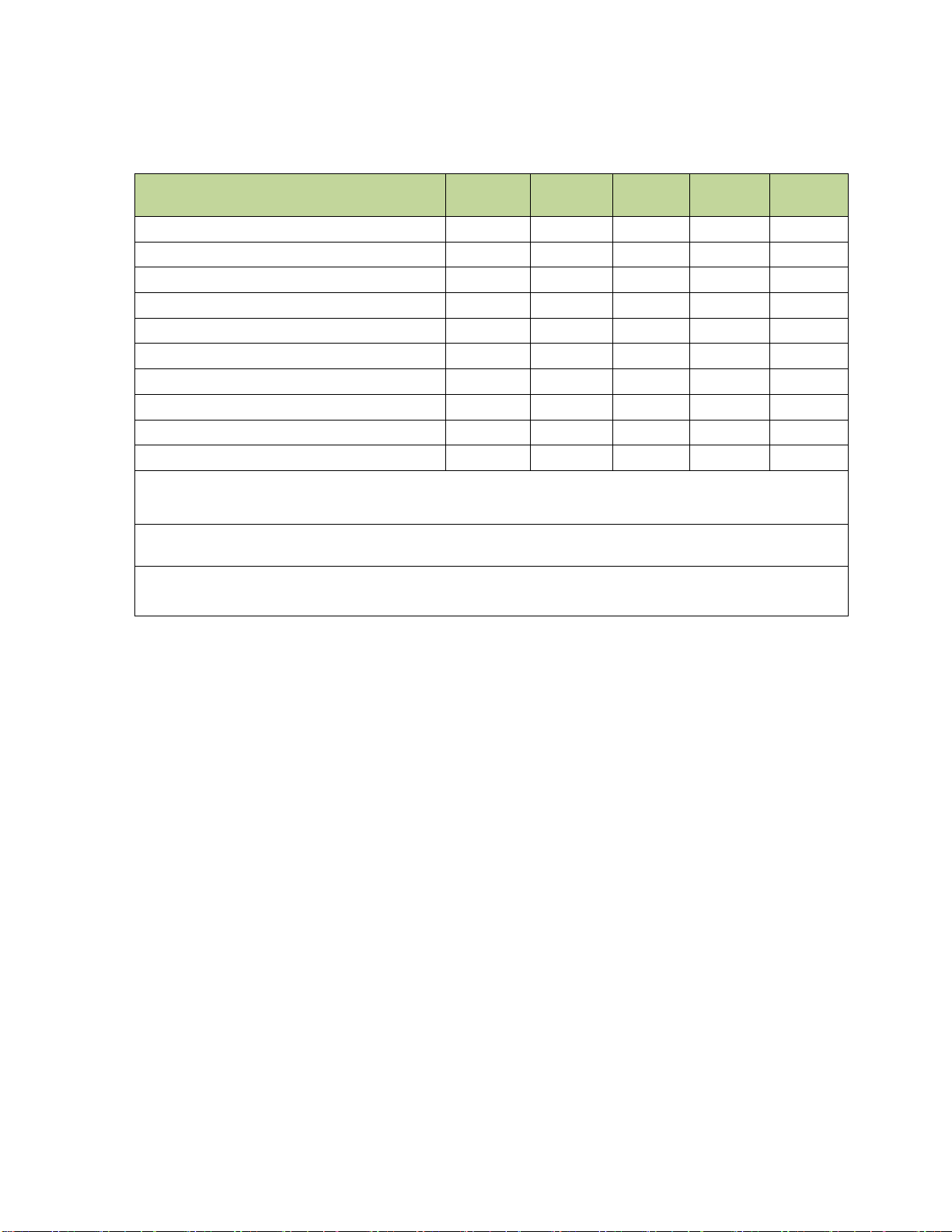

Summary Table:

Run 1

Run 2

Run 3

Run 4

Run 5

Date

2/14/17

2/15/17

2/16/17

2/17/17

2/17/17

Run Number

1

2

3

4

5

Emission Rate (g/hr)

0.91

1.06

1.99

1.53

1.68

Burn Rate (kg/hr)

0.59

0.77

0.98

1.29

2.01

Heat Output (Btu/hr)

8,298

12,124

14,589

18,210

27,025

Overall Efficiency (% HHV)

81.1

83.4

49.5

75.0

71.7

CO Emissions (g/MJ Output)

4.33

0.74

3.61

4.03

3.21

CO Emissions (g/kg Dry Fuel)

69.62

12.27

56.79

59.79

45.64

CO Emissions (g/min)

0.68

0.16

0.92

1.29

1.53

Emissions Rate –First Hour (g/hr)

3.23

3.48

5.85

4.54

3.18

Particulate emission average of 5 test runs: 1.5 grams per hour.

Weighted average HHV efficiency of 5 test runs: 77.2%.

Average CO emissions of 4 test runs: 0.91 g/min.

Run 1:

An attempt at a category I burn rate was performed on 2/14/17, resulting in a 0.59 kg/hr

category I burn rate. The test duration was 7 hours. The fuel weight was 10.9 lbs.

There was an average particulate emissions rate of 0.91 g/hr. The run had an overall

efficiency of 81.1%. The A filter was changed at 1 hr. The 1-hour filter catch was 3.23

g/hr. All test results were appropriate and valid. The burn rate category was achieved.

There were no anomalies and all criteria were met.

Run 2:

An attempt at a category II burn rate was performed on 2/15/17. However, 25 minutes

into the test run, the 4 x 4 on the front stack of the fuel load fell forward against the

glass slowing the burn witch resulted in an additional category I burn rate of 0.77 kg/hr.

The test duration was 5 hours 10 minutes. The fuel weight was 10.6 lbs. There was an

average particulate emissions rate of 1.06 g/hr. The run had an overall efficiency of

83.4%. The A filter was changed at 1 hr. The 1-hour filter catch was 3.48 g/hr. All test

results were appropriate and valid. The attempted burn rate category was missed.

There were no anomalies and all criteria were met.

Project # 035-S-075-1 Model: Farringdon 16

Page | 13

Run 3:

Run 3 was an attempt at a category II burn rate performed on 2/16/17, resulting in a

0.98 kg/hr burn rate. The test duration was 4 hours 10 minutes. The fuel weight was

10.7 lbs. There was an average particulate emissions rate of 1.99 g/hr. The run had an

overall efficiency of 79.5%. The A filter was changed at 1 hr. The 1-hour filter catch

was 5.85 g/hr. All test results were appropriate and valid. The burn rate category was

achieved. There were no anomalies and all criteria were met.

Run 4:

Run 4 was an attempt at a category III burn rate performed on 2/17/17, resulting in a

1.29 kg/hr burn rate. The test duration was 3 hours 10 minutes. The fuel weight was

10.8 lbs. There was an average particulate emissions rate of 1.53 g/hr. The run had an

overall efficiency of 75.0%. The A filter was changed at 1 hr. The 1-hour filter catch

was 4.54 g/hr. All test results were appropriate and valid. The burn rate category was

achieved. There were no anomalies and all criteria were met.

Run 5:

Run 5 was a high burn performed on 2/17/17 resulting in a 2.01 kg/hr burn rate. The

test duration was 2 hours. The fuel weight was 10.6 lbs. There was an average

particulate emissions rate of 1.68 g/hr. The run had an overall efficiency of 71.7%. The

A filter was changed at 1 hr. The 1-hour filter catch was 3.18g/hr. All test results were

appropriate and valid. The burn rate category was achieved. There were no anomalies

and all criteria were met.

Project # 035-S-075-1 Model: Farringdon 16

Page | 14

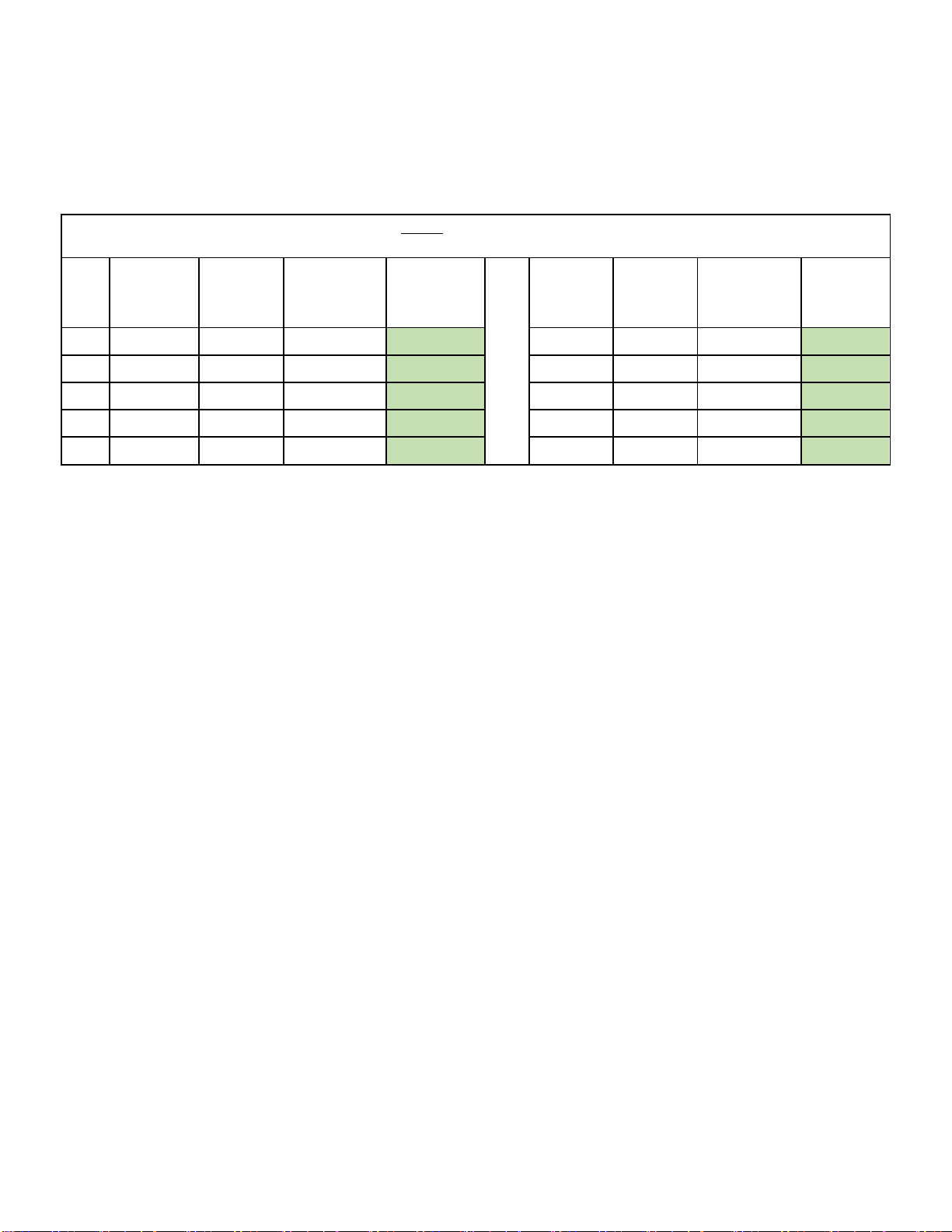

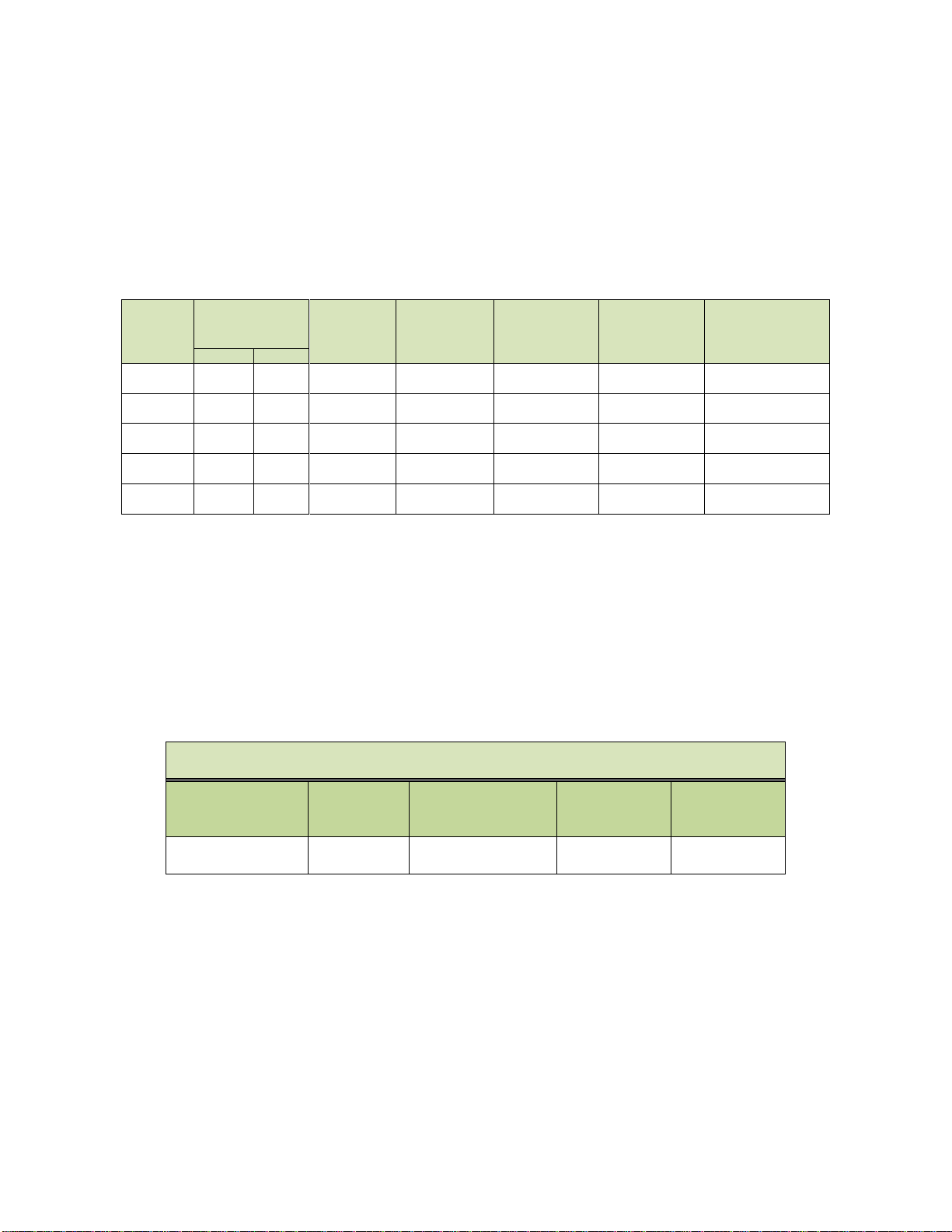

Precision:

Dual Train Comparison (ASTM E2515 11.7 - If either criterion (7.5% of average or 0.5 g/kg difference) is met, the

run is valid.

Run

#

Train A %

of avg.

Train B %

of avg.

Max

difference

(%)

<7.5% of

average?

Or

Train A

g/kg

Train B

g/kg

Difference

<0.5 g/kg

from each

other?

1

105.7

94.3

5.7

✓

1.638

1.463

0.175

✓

2

100.9

99.1

0.9

✓

1.387

1.362

0.025

✓

3

98.9

101.1

1.1

✓

2.021

2.064

0.043

✓

4

96.8

103.2

3.2

✓

1.144

1.221

0.077

✓

5

97.4

102.6

2.6

✓

0.817

0.859

0.042

✓

Project # 035-S-075-1 Model: Farringdon 16

Page | 15

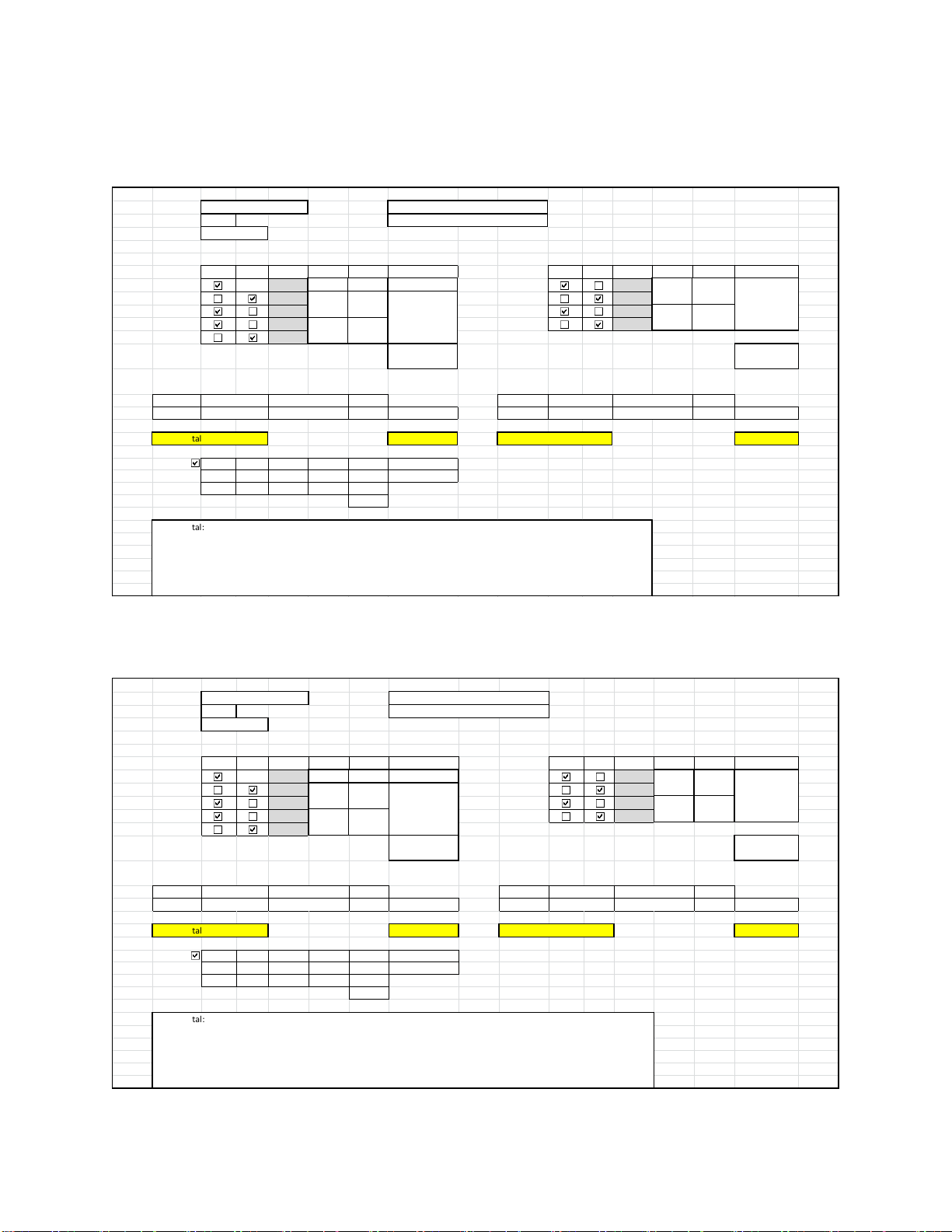

Filter Catch:

Run 1:

Run 2:

Project # MFG

Run # 1 Model

Date

Train A Front Rear Filter # Tare Final Net Train B Front Rear Filter # Tare Final Net

First Hour 3028 0.1175 0.1206 0.0031 3030

3029 3031

3033 O ring

O Ring O ring

O Ring

6.3 mg 5.7 mg

Nozzle Nozzle

# Net # Net

1A 0.0003 0.3 1B 0.0001 0.1

6.6 mg 5.8 mg

Ambient Filter # Tare Final Net Vol (liter)

3032 0.1169 0.1170 0.0001 2305.638

O ring 1.6727 1.6730 0.0003

Total 0.4 mg

Notes:

035-S-075-1

2/21/17

Arada

Farringdon 16

TARE

FINAL

0.2348

Train A Total: 6.6mg Train B Total: 5.8mg Ambient Total: 0.4mg 1 Hour Catch: 3.1mg

0.2372

115.6254

115.6257

TARE

FINAL

115.9004

115.9005

Train A Total Catch

Train B Total Catch

3.5909

3.5917

0.0057

0.0032

3.5446

0.2341

0.2392

3.5452

Project # MFG

Run # 2 Model

Date

Train A Front Rear Filter # Tare Final Net Train B Front Rear Filter # Tare Final Net

First Hour 3034 0.1179 0.1212 0.0033 3036

3035 3037

3039 O ring

O Ring O ring

O Ring

4.9 mg 4.9 mg

Nozzle Nozzle

# Net # Net

6A 0.0004 0.4 6B 0.0002 0.2

5.3 mg 5.1 mg

Ambient Filter # Tare Final Net Vol (liter)

3038 0.1174 0.1174 0.0000 1736.481

O ring 1.6482 1.6484 0.0002

Total 0.2 mg

Notes:

0.0049

0.0016

3.5554

0.2354

0.2395

3.5562

Train A Total: 5.3mg Train B Total: 5.1mg Ambient Total: 0.2mg 1 Hour Catch: 3.3mg

0.2366

116.5641

116.5645

TARE

FINAL

116.1165

116.1167

Train A Total Catch

Train B Total Catch

3.5158

3.5168

035-S-075-1

2/21/17

Arada

Farringdon 16

TARE

FINAL

0.2360

Project # 035-S-075-1 Model: Farringdon 16

Page | 16

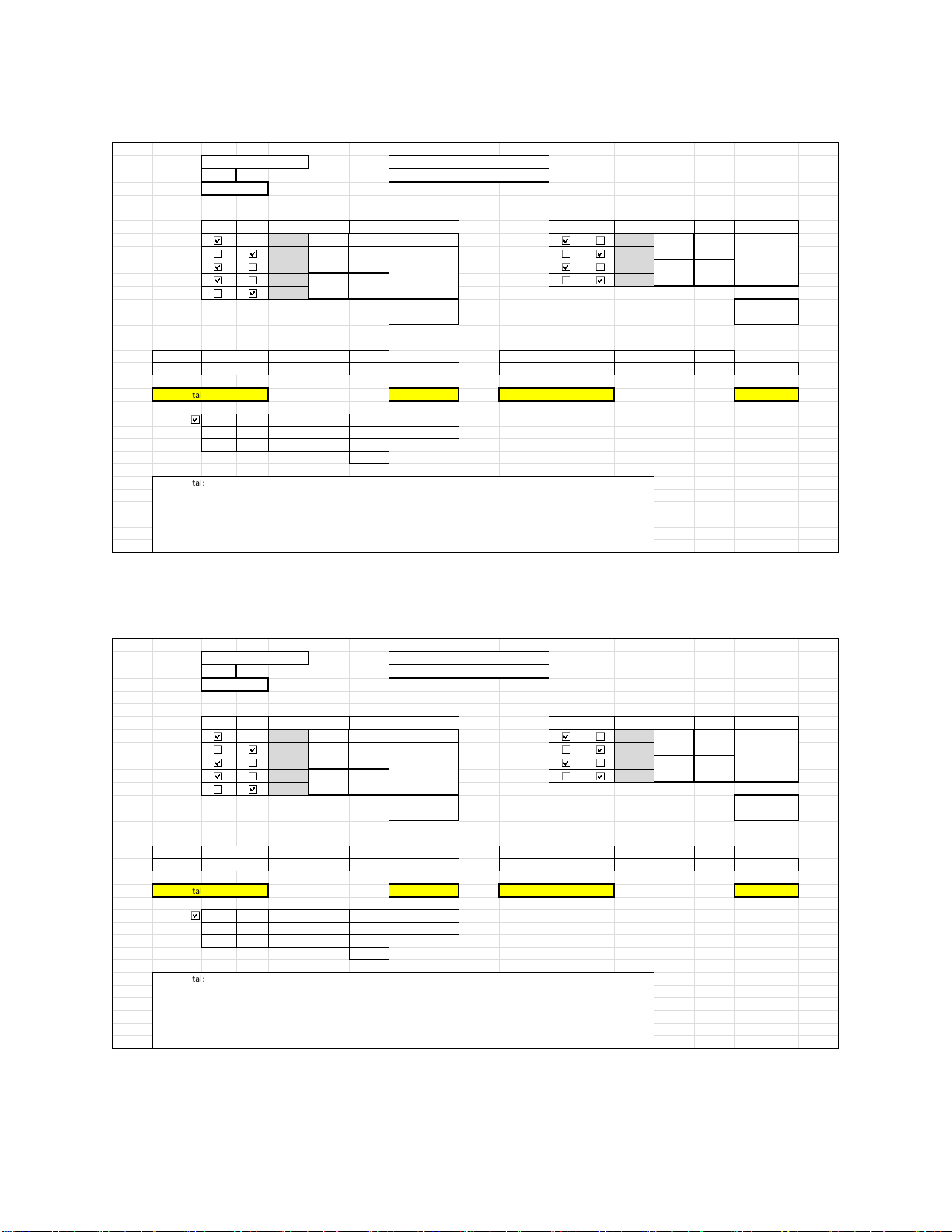

Run 3:

Run 4:

Project # MFG

Run # 3 Model

Date

Train A Front Rear Filter # Tare Final Net Train B Front Rear Filter # Tare Final Net

First Hour 3040 0.1181 0.1234 0.0053 3042

3041 3043

3045 O ring

O Ring O ring

O Ring

7.5 mg 7.4 mg

Nozzle Nozzle

# Net # Net

10A 0.0000 0.0 10B 0.0001 0.1

7.5 mg 7.5 mg

Ambient Filter # Tare Final Net Vol (liter)

3044 0.1177 0.1179 0.0002 1403.742

O ring 1.6416 1.6416 0.0000

Total 0.0002 mg

Notes:

035-S-075-1

2/21/17

Arada

Farringdon 16

TARE

FINAL

0.2358

Train A Total: 7.5mg Train B Tota: 7.5mg Ambient Total: 0.2mg 1Hour Catch: 5.3mg

0.2380

116.8265

116.8265

TARE

FINAL

117.1676

117.1677

Train A Total Catch

Train B Total Catch

3.5420

3.5420

0.0074

0.0022

3.5593

0.2361

0.2435

3.5593

Project # MFG

Run # 4 Model

Date

Train A Front Rear Filter # Tare Final Net Train B Front Rear Filter # Tare Final Net

First Hour 3046 0.1174 0.1216 0.0042 3048

3047 3049

3051 O ring

O Ring O ring

O Ring

0.1 mg 4.5 mg

Nozzle Nozzle

# Net # Net

12A 0.0000 0.0 12B 0.0000 0.0

0.1 mg 4.5 mg

Ambient Filter # Tare Final Net Vol (liter)

3050 0.1175 0.1175 0.0000 1003.027

O ring 1.6823 1.6823 0.0000

Total 0.0 mg

Notes:

035-S-075-1

2-21-2-17

Arada

Farringdon 16

TARE

FINAL

0.2346

Train A Total: 4.3mg Train B Total: 4.5mg Ambient Total: 0.0mg 1 Hour Catch: 4.2mg

0.2347

116.8890

116.8890

TARE

FINAL

117.0523

117.0523

Train A Total Catch

Train B Total Catch

3.5734

3.5734

0.0045

0.0001

3.5379

0.2357

0.2402

3.5379

Project # 035-S-075-1 Model: Farringdon 16

Page | 17

Run 5:

Project # MFG

Run # 5 Model

Date

Train A Front Rear Filter # Tare Final Net Train B Front Rear Filter # Tare Final Net

First Hour 3052 0.1172 0.1202 0.0030 3054

3053 3055

3057 O ring

O Ring O ring

O Ring

3.1 mg 3.1 mg

Nozzle Nozzle

# Net # Net

13A 0.0000 0.0 13B 0.0001 0.1

3.1 mg 3.2 mg

Ambient Filter # Tare Final Net Vol (liter)

3056 0.1180 0.1180 0.0000 633.178

O ring 1.6545 1.6546 0.0001

Total 0.1 mg

Notes:

0.0031

0.0001

3.5135

0.2354

0.2385

3.5135

Train A Total: 3.1mg Train B Total: 3.2mg Ambient Total: 0.1mg 1 Hour Catch: 3.0mg

0.2346

117.4532

117.4532

TARE

FINAL

117.0625

117.0626

Train A Total Catch

Train B Total Catch

3.5771

3.5771

035-S-075-1

2/21/17

Arada

Farringdon 16

TARE

FINAL

0.2345

Project # 035-S-075-1 Model: Farringdon 16

Page | 18

Test Condition Summary:

All testing conditions for all runs fell within allowable specifications of EPA Method 28R,

ASTM E2780-10 and ASTM E2515-11. A summary of facility conditions, temperature

averages, fuel burned and run times is listed below.

Runs

Ambient (Deg.

F)

Barometric

Pressure

(In. Hg.)

Test Fuel

Burned (Lbs.)

Fuel Loading

Density

(lbs/ft3)

Test Fuel

Moisture (Dry

Basis)

Run Time (Min.)

Pre

Post

1

69

69

30.06

10.9

6.94

20.6

420

2

70

70

29.72

10.6

6.75

20.3

310

3

72

70

29.56

10.7

6.82

19.3

250

4

67

69

29.60

10.8

6.88

19.7

190

5

70

73

29.60

10.6

6.75

19.9

120

Heater Specifications:

Dimensions, firebox configuration, air supply locations, air introduction locations, and

baffle locations of the wood heater are referenced below and on the following page.

Heater Dimensions

Heater Dimensions

Height

Width

Depth

Firebox

Volume

Weight

13.5”

21.250”

11.75”

1.57 ft3

340.7 lbs

Project # 035-S-075-1 Model: Farringdon 16

Page | 19

Useable Firebox Volume:

Table of contents

Popular Stove manuals by other brands

VARDE OVNE

VARDE OVNE Aura 1 Installation and user guide

TEK Biomasse

TEK Biomasse AVALON instruction manual

BFM Europe

BFM Europe portway Installation and operating instructions

United States Stove

United States Stove US3200E Owner’s Instruction and Operation Manual

Henley Stoves

Henley Stoves ECO C550 Installation & operating instructions

Dimplex

Dimplex DMCS13R owner's manual