ILD 6 User manual

1

ILD 6 Insert: EN13229 - NS3058

Manual version No. 12-1b B 25-02-2013

Model 6 insert

2

CONTENT

First use .................................................................................................................................................................. 3

Technical data sheet ............................................................................................................................................. 4

Before installation ................................................................................................................................................. 5

Packing ................................................................................................................................................................... 5

Installation ............................................................................................................................................................. 6

entilation example ............................................................................................................................................ 11

Distance to combustible wall protected by brick or Jøtul Firewall ................................................................ 12

Closed combustion system ................................................................................................................................. 14

Chimney & flue collar .......................................................................................................................................... 14

The chimney effect ............................................................................................................................................. 15

Measurements ..................................................................................................................................................... 17

Setup Examples ................................................................................................................................................... 18

Refuelling on to a low fire bed .......................................................................................................................... 19

Fuel overloading .................................................................................................................................................. 19

Environmental use .............................................................................................................................................. 19

Smoke Control Areas ........................................................................................................................................... 20

Primary air control ............................................................................................................................................... 21

Secondary air control .......................................................................................................................................... 22

Ash drawer and bottom grate ............................................................................................................................ 23

Dampers left open ............................................................................................................................................... 23

Fuel........................................................................................................................................................................ 24

Lighting the stove ............................................................................................................................................... 25

Cleaning maintenance ......................................................................................................................................... 26

Trouble shooting .................................................................................................................................................. 27

3

Thank you for having confidence in us

Thank you for having confidence in usThank you for having confidence in us

Thank you for having confidence in us

Ild is a range of safe, environmentally friendly and efficient high-quality stoves, which meet all

requirements for a modern heating source. In order to get the best out of your stove, we

recommend that you read this booklet and our homepage www.ildstoves.com carefully.

First use

First useFirst use

First use

Before the stove is fired up for the first time, we advise you to open all windows and doors in

the room to ensure optimum ventilation. When the stove is at operating temperature, the

surface paint will harden and emit a strong odour for a short time. As the stove heats up and

cools down there may be expansion and contraction noises from the metal. This is normal.

4

Technical data sheet

Technical data sheetTechnical data sheet

Technical data sheet

Model 6 Wood Units

CO-Emission at 13% O2 : 0,097 %

NOx @ 13% O2 71 mg/Nm

3

Efficiency 83 %

Nominal performance 4,5 Kw.

Chimney temperature EN13229 204 C

o

Recommended under pressure in flue connection piece 16 Pa.

Flue pipe under pressure EN 13229 12 Pa.

Combustion air requirements 12 m3/h

Fuel consumption 1,32 Kg/h

Refuelling amount. 1,05 Kg.

Refuelling frequency for nominal output 47 Min.

Weight 54 Kg.

Flue connection piece internal diameter 126 mm.

Flue connection piece external diameter 130 mm.

Max. Fuelsize diameter 80 mm.

Max. Fuel length 155 mm.

Heat output range 4,3 – 4,9 Kw.

Type of verification EN 13229NS3058-Din+

5

Before

BeforeBefore

Before

installation

installationinstallation

installation

Ensure that your Local registered installer can recommend wood stove installation

Ensure that updated European, national and local standards can be fulfilled

Ensure that the area can support the stove and installation weight

Ensure that there will be sufficient space and access to service

Ensure that the Chimney has a minimum draft of 12 Pa.

Ensure that the heat output of the stove is suitable for the room

Ensure that combustible materials are at least 125 mm + thickness of insulation, from the rear

part of the stove.

Warning! It is not allowed to make any unauthorised changes to the stove

Packing

Packing Packing

Packing

The stove comes packaged in the cardboard box on wooden pallet nailed down on vertical

boards at the corners. In cardboard box stove is fixed with EPS styrofoam elements.

Consult local regulations on the disposal of these materials; the wood has been treated to

repel vermin and may not be burnt in stove.

6

Installation

Installation Installation

Installation

Prepare a non-combustible base with spare space (+) for the convection box which is: W 390

(+) H 550 (+) Depth 350 (+)

Hearth must be minimum 350 mm. Higher than floor and 150 mm wider at both sides than

outer frame in front it must reach out 450 mm from frame .

In the United Kingdom, Hearth depth must meet local standards. This is 300mm in front of the

stove and 150mm each side of the stove.

After unpacking the stove, the first thing which needs to be done is remove the baffle plate

from the firebox. In order to remove the baffle plate you need to remove two pins (Picture 1)

and after that draw baffle plate out from the firebox (Picture 2).

Picture

1

Picture

2

After removing the baffle plate you need to unscrew 4 bolts which hold connecting piece for

close combustion (Picture 3).

Picture 3

7

The firebox should be removed from the convector box before installation. This is done in a

few steps.

1. The frame is secured by 2 bolts top and 4 bolts bottom. Using a 3mm Allen key, remove

these and keep frame and bolts safe and protected. (fig 5).

2. Using a 5mm Allen key, unscrew the 1 bolt that secures the firebox to the convector

box (fig 4)

Picture 4 Picture 5

3. Remove the 4 bolts holding the flue spigot to the convector box (fig 7).

4. Lift the firebox a little and drag it forwards slightly (fig 6).

Picture 6 Picture 7

8

5. From inside the convector box remove the 4 nuts holding the connector plate in place.

(fig 8)

6. Make the flue pipe connection to the spigot and secure with the 2 Allen bolts. This is

done above the convector box (fig 9).

Picture

8

Picture

9

7. Now the convector box can be positioned. Once in place, the flue spigot and flue pipe

can be fed through the aperture at the top of the convector box (fig 10)

Picture 1

0

9

8. Reconnect the connector plate with the 4 nuts to hold the flue spigot loosely in place

(fig 11).

9. Level the convector box using the 4 leveling screws in the base of the convector box.

(fig 12).

Picture 11 Picture 12

10. There are 4 pre drilled holes in both the base and the side of the convector box for

securing it to the hearth. Ensure appropriate fixings are used. NO PLASTIC PLU S etc.

(fig 13 & 14).

Picture 13 Picture 14

10

11. Once the convector box is secured, the firebox can be re-inserted and the flue spigot re-

attached using the 4 bolts removed earlier. (Fig 15 & 16)

12. Re-connect the firebox using the 1 bolt that was removed earlier. (fig 17).

Picture 15 Picture 16

13. Replace baffle plate and pins. (fig. 18)

Picture 17 Picture 18

11

75

100

Min. 540

Ventilation example:

Ventilation example:Ventilation example:

Ventilation example:

All measurements are minimum. Make sure grates are placed where blocking wont’ happen

Effective open area

Min. 350 mm² for combustible setup

Min. 200 mm² for non-combustible

setup

Effective open area

Min. 500 mm² for combustible setup

Min. 200 mm² for non-combustible

setup

Minimum

distance to

furniture 900

mm.

125

12

125

istance to

istance toistance to

istance to

combustible wall

combustible wallcombustible wall

combustible wall

protected by

protected byprotected by

protected by

brick or

brick orbrick or

brick or

Jøtul

JøtulJøtul

Jøtul

Firewall

FirewallFirewall

Firewall

*

**

*

istance to brick requires that the flue pipe is insulated all the way down to the stove with

minimum 30mm isolation.

Be aware that the temperature can rice up to 200º 300mm over the stove by strong firing.

Flammable materials

Brick or Jøtul Firewall

*

75

200

13

Floor plate

If you are setting up the stove on a flammable floor, observe national and local regulations on

the size of the non-flammable underlay that covers the floor around the stove.

Your local ILD dealer can advise you on regulations concerning flammable materials in the

vicinity of your stove.

The idea behind the floor plate is that it protects the floor and flammable material against

sparks.

The floor plate can be made of steel or glass, and the stove can be set up on brick, natural

stone or similar materials.

The cavity may not be

filled with insulating

material

Upper convection opening 500 mm

2

Lower convection opening 350 mm

2

14

Closed combustion system

Closed combustion systemClosed combustion system

Closed combustion system

When installed in highly insulated houses, in case or exhaust ventilation, an active cooker

hood or similar, it is recommended that the combustion air is supplied through the bottom or

rear of the stove, from outside which is connected to a minimum Ø 80 mm. ventilation pipe.

The installation must have maximum length of 6 M. and consist of a maximum of 3 bends as

well as a single inlet grille, make sure to place inlet grille where blocking of these will be

avoided.

The total counter pressure must not exceed 2 Pa. At a minimum chimney draught of 18 Pa.

this measured at the stove's flue collar.

Special weather and geographical conditions, mean that the installation, must always be

carried out and approved by approved installer of ventilation.

It is recommended to make installation, with valves, making it possible to close ventilation

systems, if stove are not in use for longer periods, then these can be activated to prevent

draft.

Chimney

ChimneyChimney

Chimney

& flue co

& flue co& flue co

& flue collar

llarllar

llar

Chimney must have a minimum draught of 12 Pa this measured at the stove’s connection

piece. If you are not sure of the stove’s draught, a chimney sweep can measure it.

The installer will also ensure that the chimney is airtight, safe and has access for sweeping.

If there are any other connections to the chimney, the chimney sweep should also be asked

for advice before installation.

The local building and housing authorities must always approve the installation.

The connecting pipe must be manufactured in accordance with EN 1856-2.

If a rear connection is required, rotate flue collar base and collar will point 45 degrees

backwards.

Remember to always ensure that the seal between the stove and flue connection piece is

intact and airtight.

Avoid weight higher than 30 kg. to rest in top of stove / flue collar, this can damage stove.

15

The chimney effect

The chimney effectThe chimney effect

The chimney effect

The following chapter has source from SOLIFTEC, and is authorized information regarding the

chimney and its effect.

If the chimney is not suitable, it will not generate enough upward draught, not enough air will

be sucked in towards the fuel for it to burn adequately, and smoke will not be properly

evacuated. Most closed stoves need an upward draught of about 16 Pascals.

Although a chimney appears to ‘suck’ and smoke appears to naturally rise, it is more accurate

to think of the weight of dense outside air pushing down to force air into the building, into the

fire and so push the hotter, lighter, waste gases out up the stack, somewhat like an air bubble

rises in water. This ‘Chimney Effect’ generates the ‘draught’ (or draft), the very tiny difference

in pressure inside and outside the flue.

How strong the draught is depends on four things:

HEAT

inside the chimney.

The gases inside the chimney must stay VERY hot, or they will not

rise. Although a small length (up to about 1m) of uninsulated flue pipe may be acceptable

directly from a stove, the entire length of the chimney above must be insulated, typically by

thick masonry around an insulated ceramic liner or using prefabricated insulated components.

Large voids inside the flue mean a large area of masonry to cool down the gases, especially if

their outer surface is outside the building and exposed to the cold. Efficient modern stoves

release less heat into the flue and need especially strict attention to the chimney.

HEI HT

of the chimney – the higher it is, the more draught will be generated. There is a

procedure for calculating chimney height in BS EN13384-1:2002 but it is extremely complex.

For typical domestic chimneys and appliances in Britain and Ireland both the British Standard

(BS 8303-1:1994) and Document J suggest a height of about 4.7 metres of straight, smooth,

insulated chimney above the appliance. Less than perfectly sound chimneys will need to be

taller to compensate. Special rules apply to Open Fires.

Path

The entire path from fire to chimney terminal needs to be smooth, straight and vertical

wherever possible. Where bends absolutely cannot be avoided, they should be very gentle

(say a maximum of 2x 45º) and the chimney height increased by at least a metre to

compensate. The flue needs to be absolutely sealed, without the slightest tiny crack at any

point which might let cool air in. The flue needs to be big enough for the appliance being used

– BS 8303 suggests a minimum of 125mm diameter for closed appliance up to 20 kW rated

output (150 mm if burning smoky fuels) – but not so big that its large surface area will cool the

smoke (say, bigger than about 375mm square). Special rules apply to open fires.

16

AIR SUPPLY –

There needs to a route by which outside air can enter to replace the volume

being lost up the chimney. While this can sometimes be provided by air leaking in through

doors, windows etc., it is often necessary to fit a purpose-made air vent. An extractor fan, or

another fuel-using appliance, even in a different room, can remove this air.

Chimney fire. It is important to avoid soot in the chimney to avoid a fire (See trouble shooting)

If a fire occurs close primary and secondary air completely, call fire rescue and calmly go

through their questioner.

17

Measurements

MeasurementsMeasurements

Measurements

18

Setup Examples

Setup ExamplesSetup Examples

Setup Examples

Insert in fire mantle be aware that heat must be able to leave the build-in surround, if not you

will not benefit from heat and your building material could be damaged from the high heat.

Stoking overloading

The stove is approved as an intermittent heater which means that you must load the stove

with a suitable amount of fuel (see data) which then burns down into embers before you

refuel it the next time. Be careful of over firing, this causes great wear and tear to the stove

and may, in serious cases, destroy the stove. Refuelling frequency with the recommended fuel

is approximately 45 Min.

75

19

Refuelling on to a low fire bed

Refuelling on to a low fire bedRefuelling on to a low fire bed

Refuelling on to a low fire bed

If there is insufficient burning material in the firebed to ignite a new fuel charge, excessive

smoke emission can occur. Refuelling must be carried out onto a sufficient quantity of glowing

embers and ash that the new fuel charge will ignite within a reasonable period. If there are

too few embers in the fire bed, add suitable kindling to prevent excessive smoke.

Fuel overloading

Fuel overloadingFuel overloading

Fuel overloading

The maximum amount of fuel specified in this manual should not be exceeded, overloading

can cause excess smoke. Any part of the fuel cannot be placed in higher level than the lower

part of the metal piece in the backside of the burn chamber.

Environmental

Environmental Environmental

Environmental use

useuse

use

It is important to us, that our environment is considered in best possible way, it is an

advantage to all, and as a bonus, fuel is used, much better.

Air supply for the combustion is added through 2 valves which are controlled through 2

controls. The lower control handle is primary air, which is used for lighting a cold stove and

when firing dense wood, maximum air is added, when the control is in furthest right position,

when fire is established, gently close the primary control by sliding it towards left.

Ongoing control of the fire is done by the upper air control. It is more open when pushed to

the right, and restricted when pushed to the left. The fire should be run efficiently, and the

best indication of this is the color of the firebricks inside the firebox. If they are soothed up,

then the fire is burning too cold, and this should be addressed..

Also notice that fuels must be less than 20 cm. long and no more than 10 cm in diameter the

percentage of moisture must be lower than 18%.

20

The Clean Air Act 1993 and

The Clean Air Act 1993 and The Clean Air Act 1993 and

The Clean Air Act 1993 and Smoke Control Areas

Smoke Control AreasSmoke Control Areas

Smoke Control Areas

Under the Clean Air Act local authorities may declare the whole or part of the district of the

authority to be a smoke control area. It is an offence to emit smoke from a chimney of a

building, from a furnace or from any fixed boiler if located in a designated smoke control area.

It is also an offence to acquire an “unauthorised fuel” for use within a smoke control area

unless it is used in an “exempt” appliance (“exempted” from the controls which generally apply

in the smoke control area).

The Secretary of State for Environment, Food and Rural Affairs has powers under the Act to

authorise smokeless fuels or exempt appliances for use in smoke control areas in England. In

Scotland and Wales this power rests with Ministers in the devolved administrations for those

countries. Separate legislation, the Clean Air (Northern Ireland) Order 1981, applies in

Northern Ireland. Therefore it is a requirement that fuels burnt or obtained for use in smoke

control areas have been “authorised” in Regulations and that appliances used to burn solid

fuel in those areas (other than “unauthorised” fuels) have been exempted by an Order made

and signed by the Secretary of State or Minister in the devolved administrations.

Further information on the requirements of the Clean Air Act can be found here :

http://smokecontrol.defra.gov.uk/

Your local authority is responsible for implementing the Clean Air Act 1993 including

designation and supervision of smoke control areas and you can contact them for details of

Clean Air Act requirements”

The ILD 6 insert has been recommended as suitable for use in smoke control areas when

burning wood logsand when fitted with a permanent stop to prevent closure of the secondary

air control beyond 18% open.

Table of contents

Other ILD Stove manuals

Popular Stove manuals by other brands

Defy

Defy DGS 126 owner's manual

Palazzetti

Palazzetti ARIA NT DX GENERAL INFORMATION - WARNINGS - INSTALLATION - MAINTENANCE

Koper

Koper Bear IT 10+5 kW User and service manual

Mazona Stoves

Mazona Stoves Glencara Operation and installation manual

wiking

wiking Miro 1 Installation

hergom

hergom E-20 NS Installation, use and maintenance instructions

Westfire

Westfire WF36 Installation manual and operating instructions

Beldray

Beldray BODEN instruction manual

Contura

Contura C620T Style quick start guide

Hi-Flame

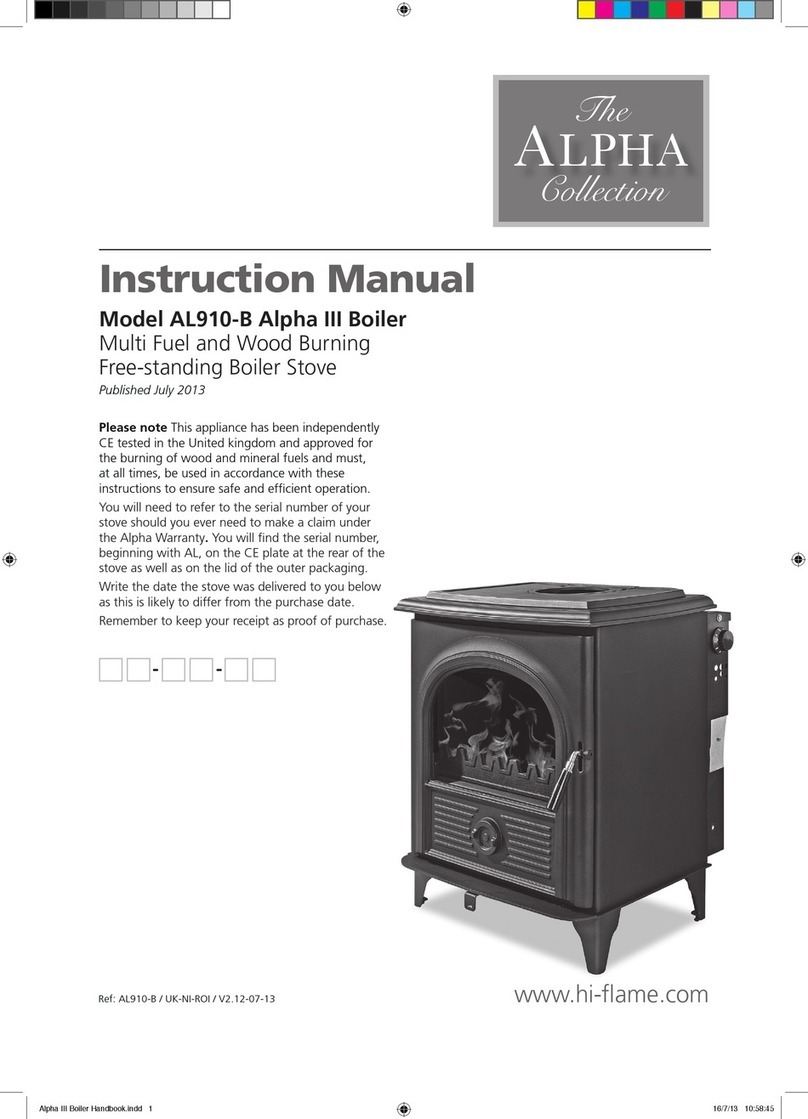

Hi-Flame AL910-B Alpha III instruction manual

Rayburn

Rayburn Heatranger 440 Servicing instructions

Extraflame

Extraflame Vicenza V3.4 Installation and operating instructions