8

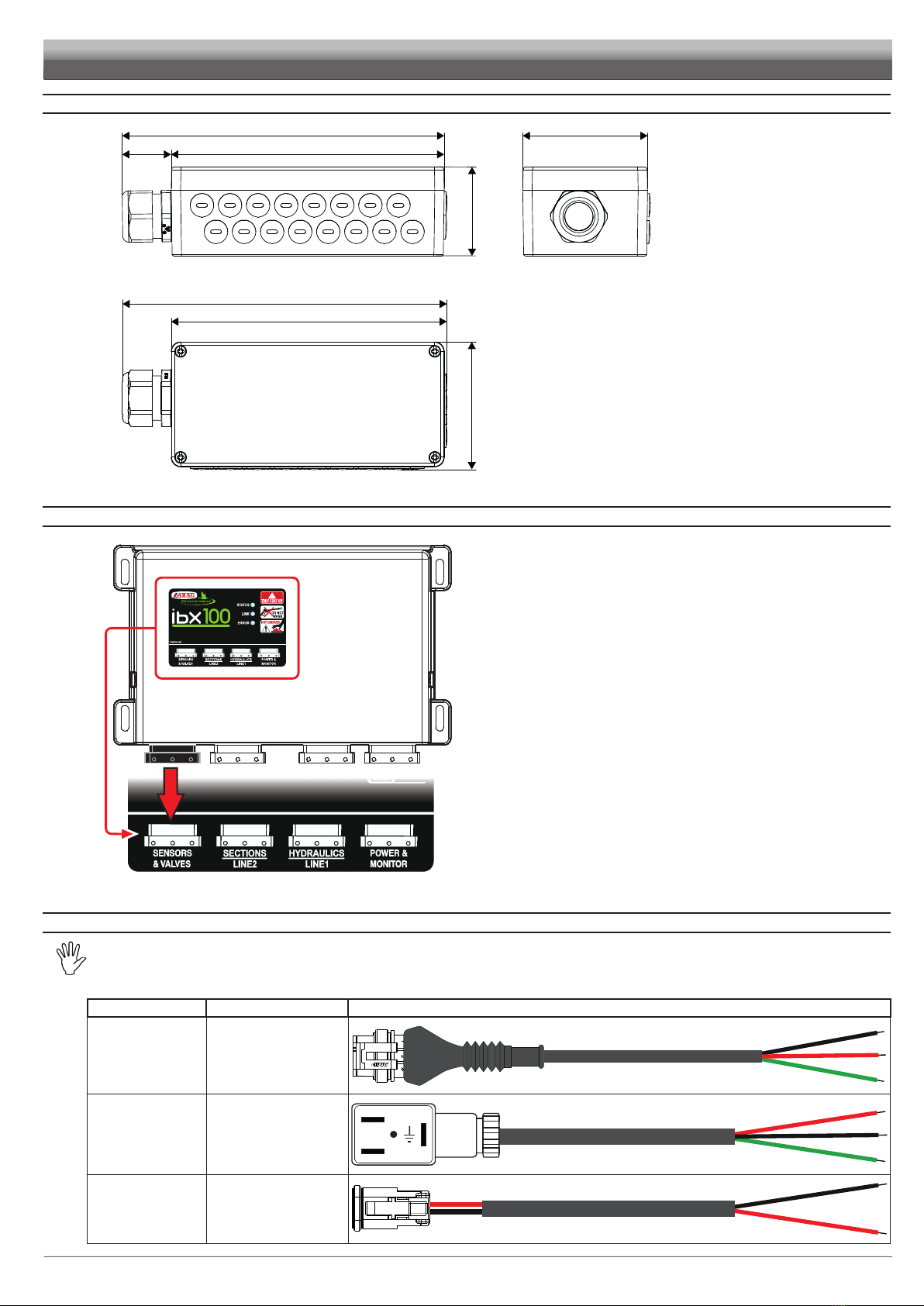

CONFIGURATION - AIR SEEDER

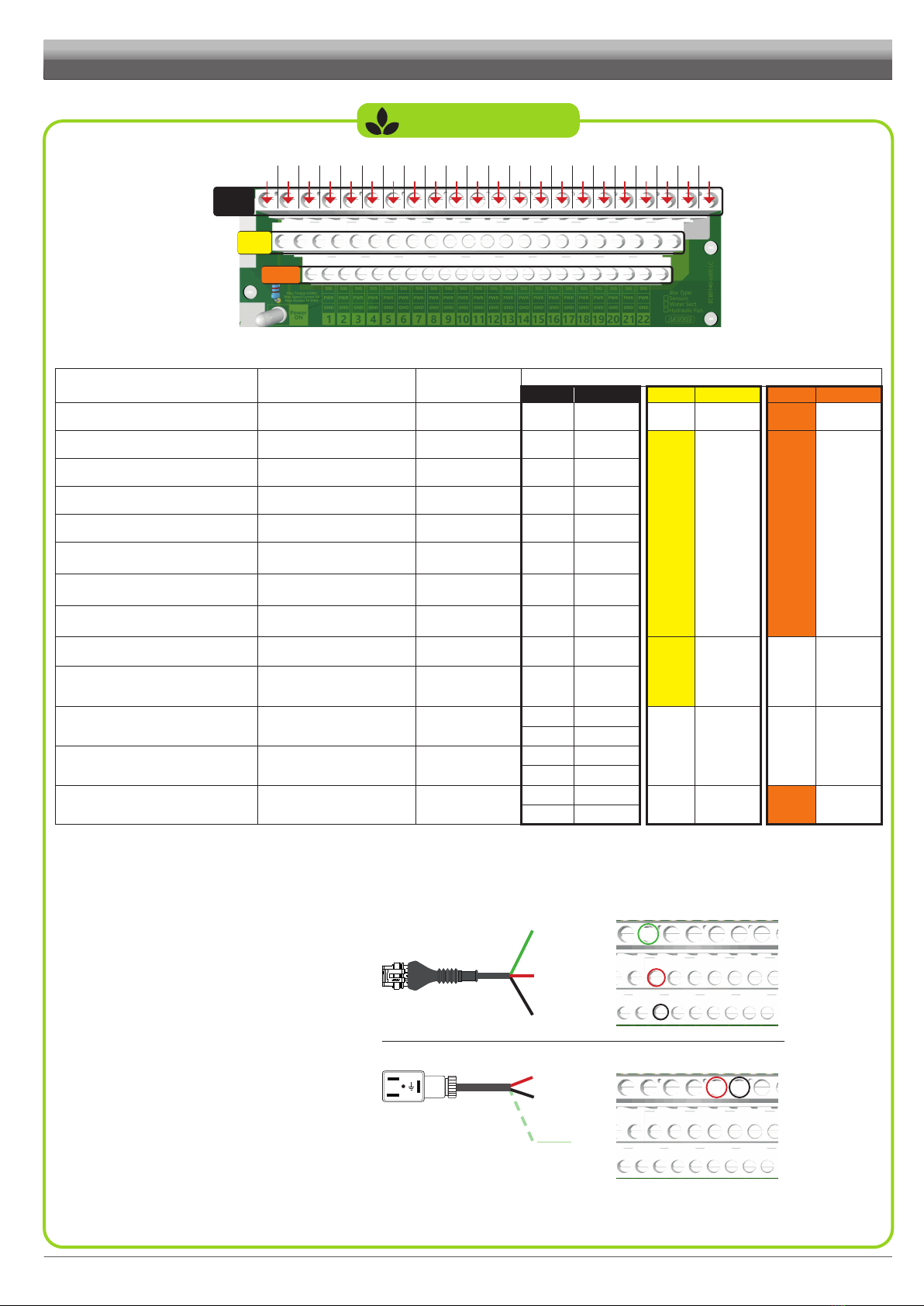

n.c.: not connected

#SIG

PWR

GND

1 9 175 13 213 11 197 152 10 186 14 224 12 208 16

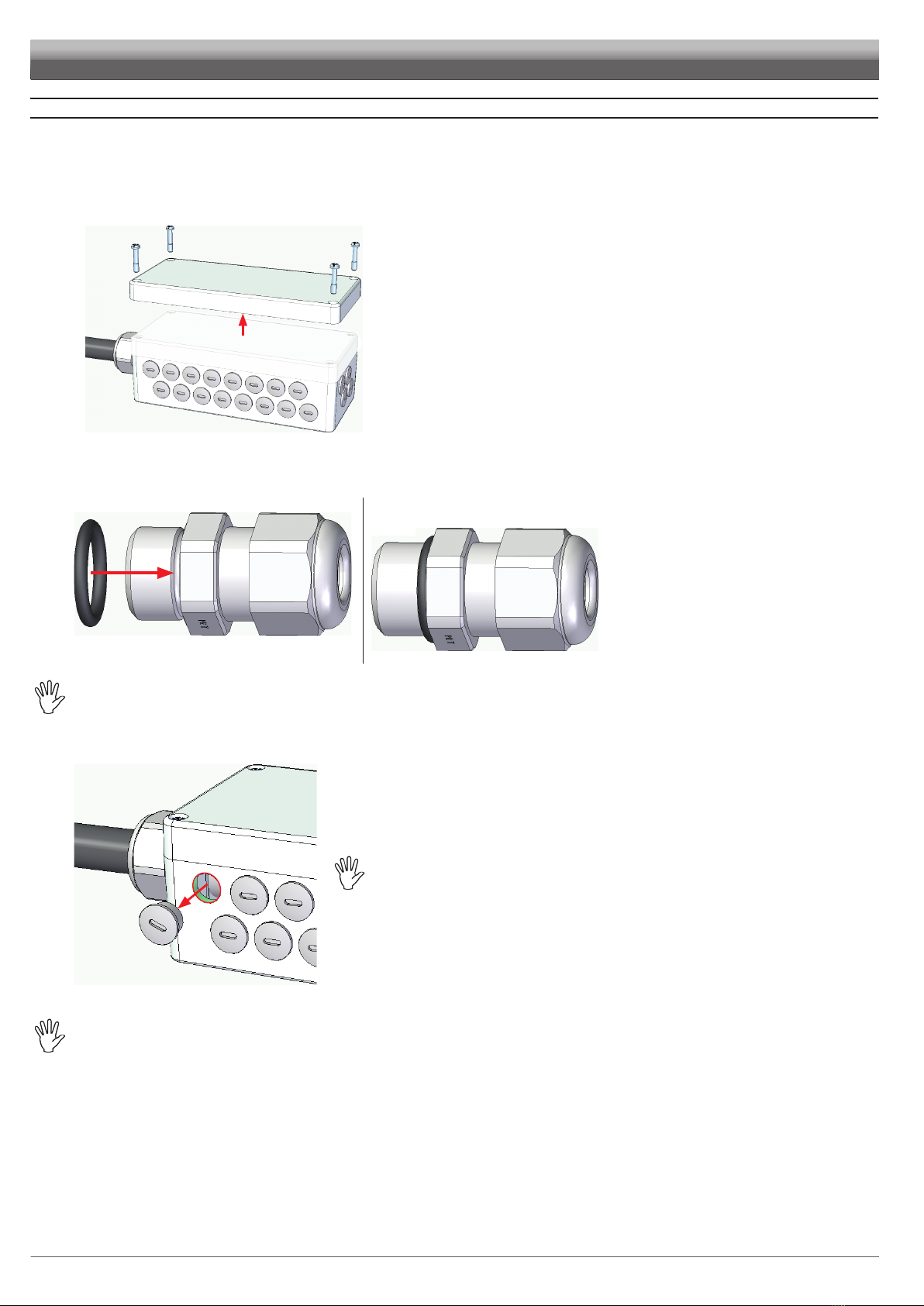

E.g.: CABLE CODE 4621AA10000.100 with speed signal

#SIG

PWR

GNDPIN 1

PIN 2

PIN 3 11

E.g.: CABLE CODE 8650900.140 for proportional valve control

#SIG

PIN 2

PIN 3

PIN 1 1817

SIGNAL TYPE OF SENSOR

[ARAG CODE]

CABLE

ADAPTER

CONNECTION OF CABLES SENSOR / VALVES (Pin)

Clamp Wire Clamp Wire Clamp Wire

PRESSURE

Analogue sensor

4621AA10000.100 #SIG 1GREEN PWR RED n.c. BLACK

MACHINE STATUS Digital sensor

4621AA10000.100 #SIG 7GREEN

PWR RED GND BLACK

TANK 1 LEVEL Capacitive sensor

4621AA10000.100 #SIG 15 GREEN

TANK 2 LEVEL Capacitive sensor

4621AA10000.100 #SIG 16 GREEN

TANK 3 LEVEL Capacitive sensor

4621AA10000.100 #SIG 8GREEN

TANK 4 LEVEL Capacitive sensor

4621AA10000.100 #SIG 10 GREEN

SPEED Digital sensor

4621AA10000.100 #SIG 11 GREEN

RPM 1 Digital sensor

4621AA10000.100 #SIG 14

(**) GREEN

FLOWRATE Digital sensor

4621AA10000.100 #SIG 12

(**) GREEN

FAN ROTATION Digital sensor

4621AA10000.100 #SIG 13 GREEN

TANK 1 LEVEL - ADDITIONAL Capacitive sensor

4621AA10000.100 #SIG 12

(**) GREEN

TANK 2 LEVEL - ADDITIONAL Capacitive sensor

4621AA10000.100 #SIG 14

(**) GREEN

CALIBRATION BUTTON Button

-#SIG 9contact 2 n.c. n.c. GND contact 1

CAN BUS-MOTOR COMMUNICATION - [not supplied] #SIG 21 can_L n.c. n.c. GND gnd

#SIG 22 can_H

PROPORTIONAL VALVE CONTROL

Motorized proportional valve

[ARAG SERIES 863T - 873T

8650900.140

#SIG 17 RED

n.c. n.c. n.c. n.c.

#SIG 18 BLACK

MAIN VALVE CONTROL Motorized ON-OFF valve

8650900.140 #SIG 19 RED

#SIG 20 BLACK

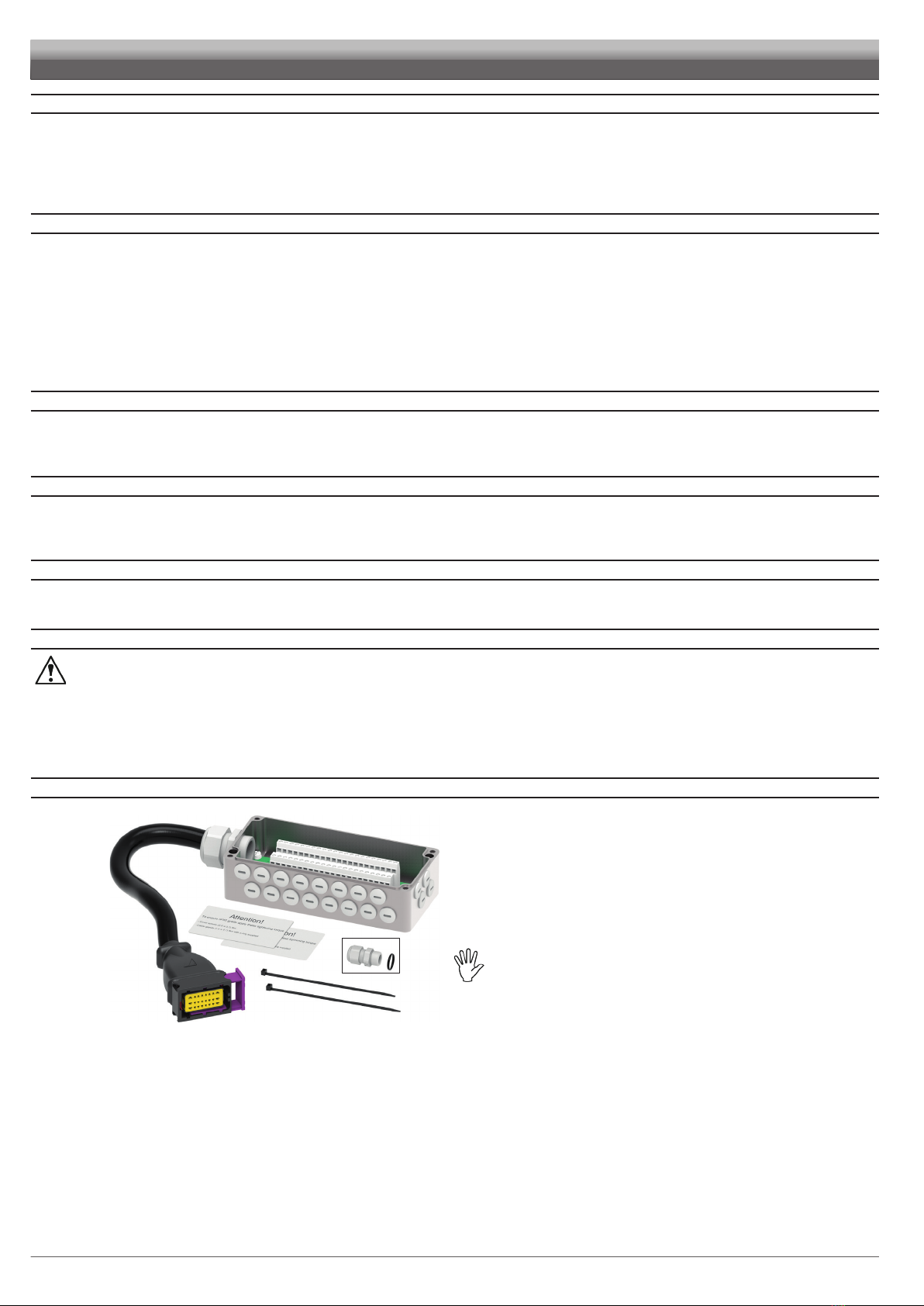

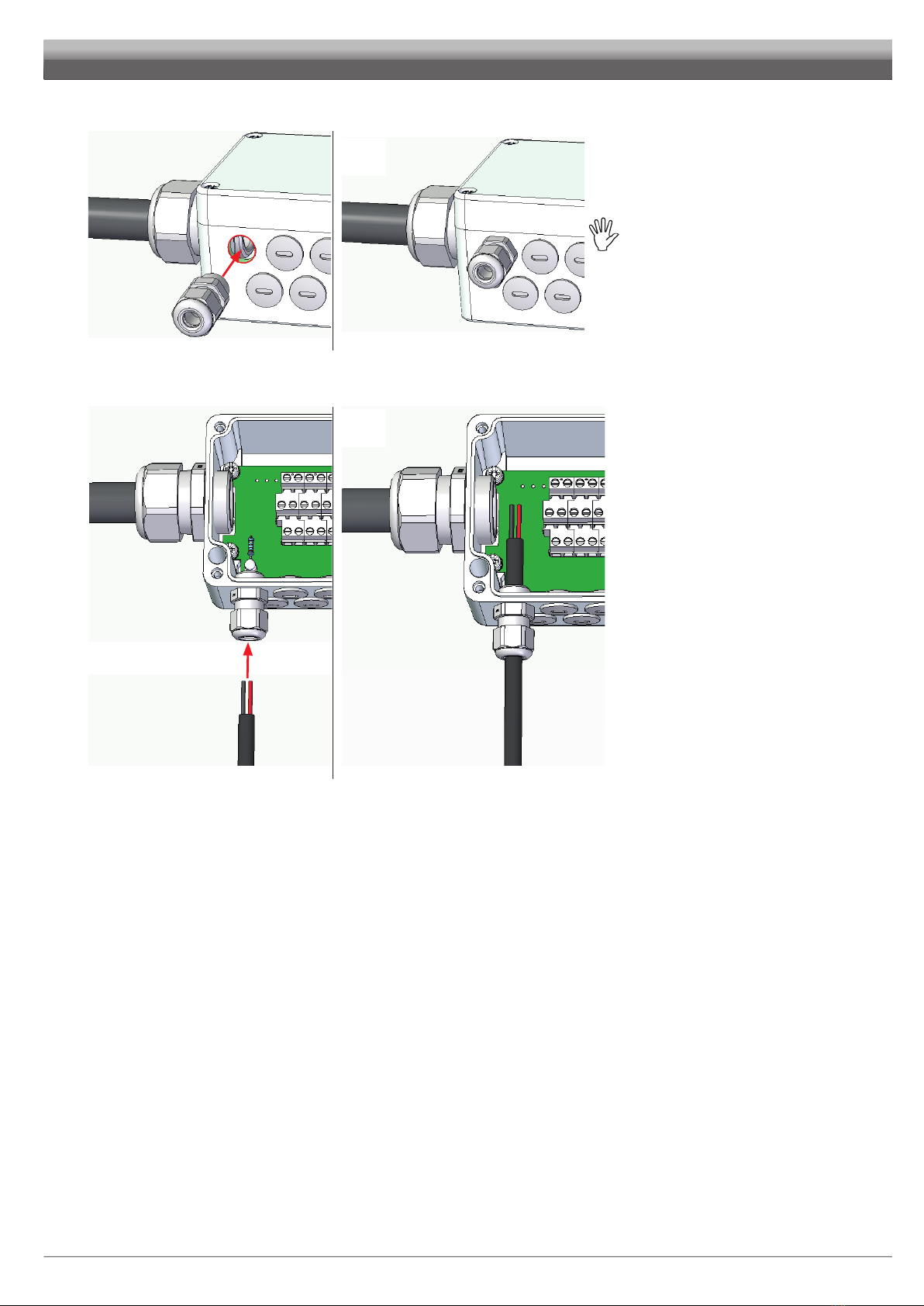

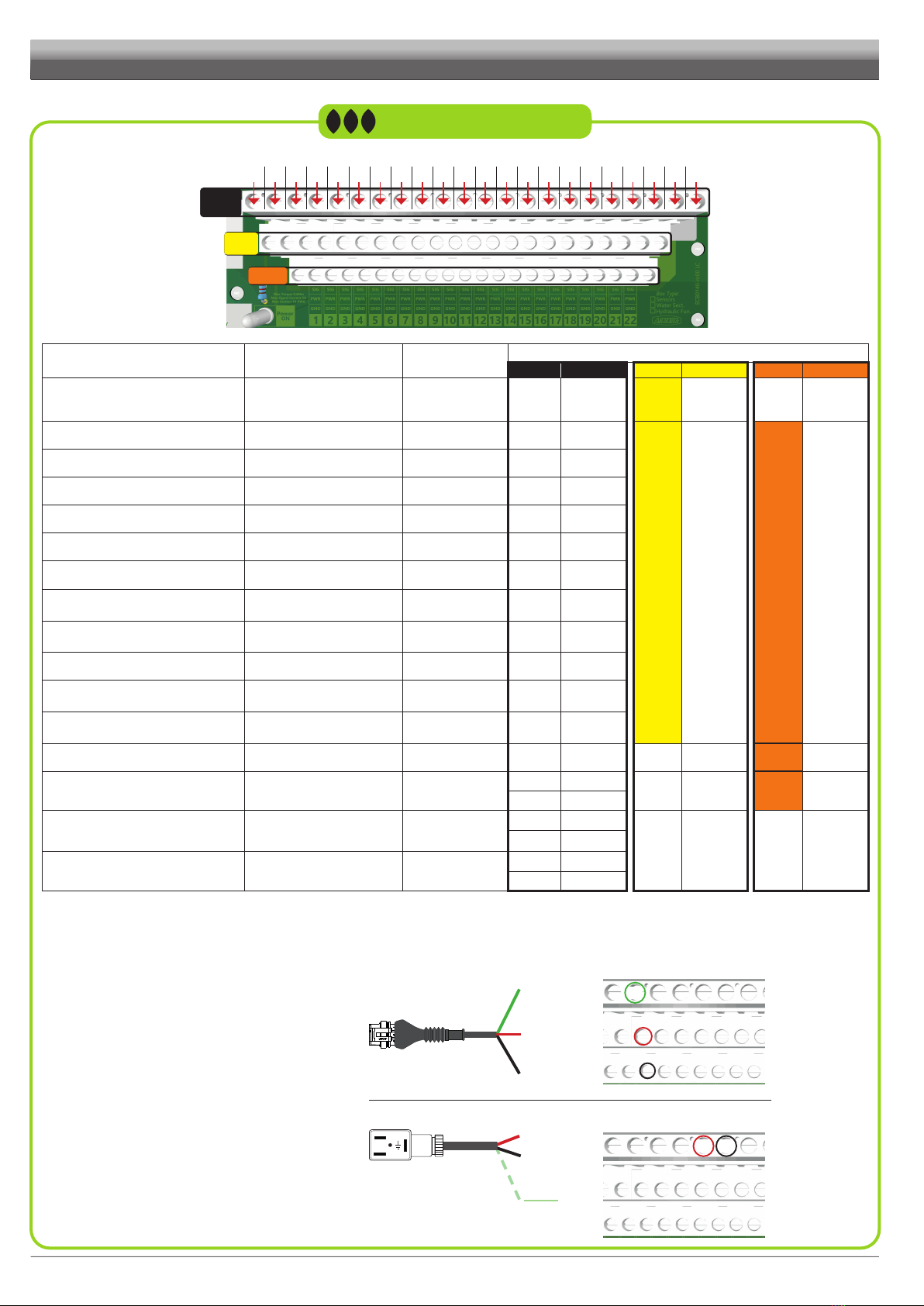

Below are some examples of

connection of the adapter cable wires

to the terminal board of the printed

circuit board: