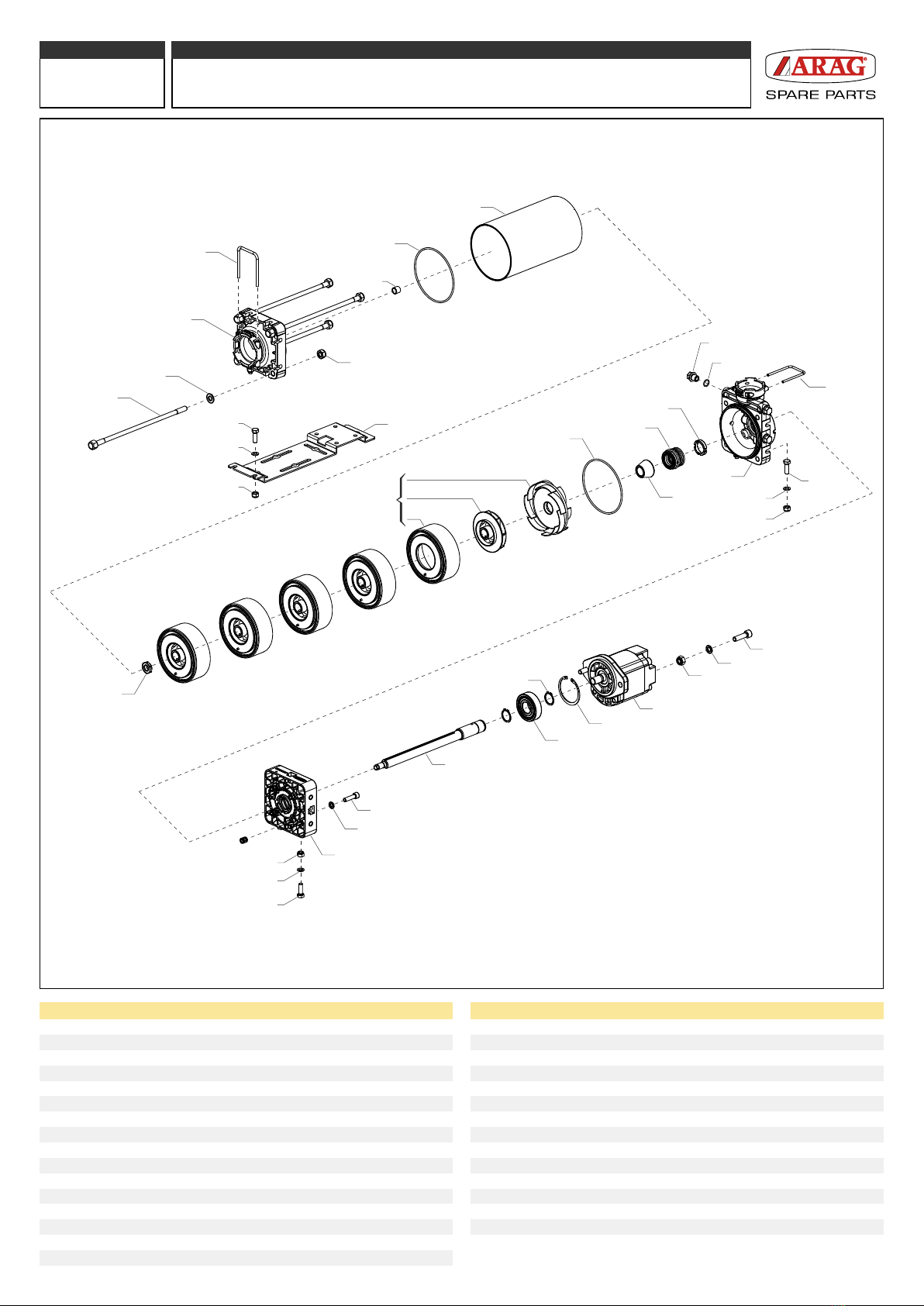

LEGEND OF SYMBOLS

=Generic danger

=Warning

CONTENTS

Legend of symbols ................................................................................................................................................................................. 2

1 Product description ................................................................................................................................................................................ 3

2 Intended use............................................................................................................................................................................................ 3

3 Package content...................................................................................................................................................................................... 3

4 Versions, codes and operating curves ................................................................................................................................................. 3

4.1 Versions and codes ........................................................................................................................................................................ 3

4.2 Operating curves ............................................................................................................................................................................ 4

4.2.1 How to read the diagrams: ............................................................................................................................................................. 4

4.2.2 Curves ............................................................................................................................................................................................ 4

5 Installation............................................................................................................................................................................................... 6

5.1 Example of a typical system composition ....................................................................................................................................... 6

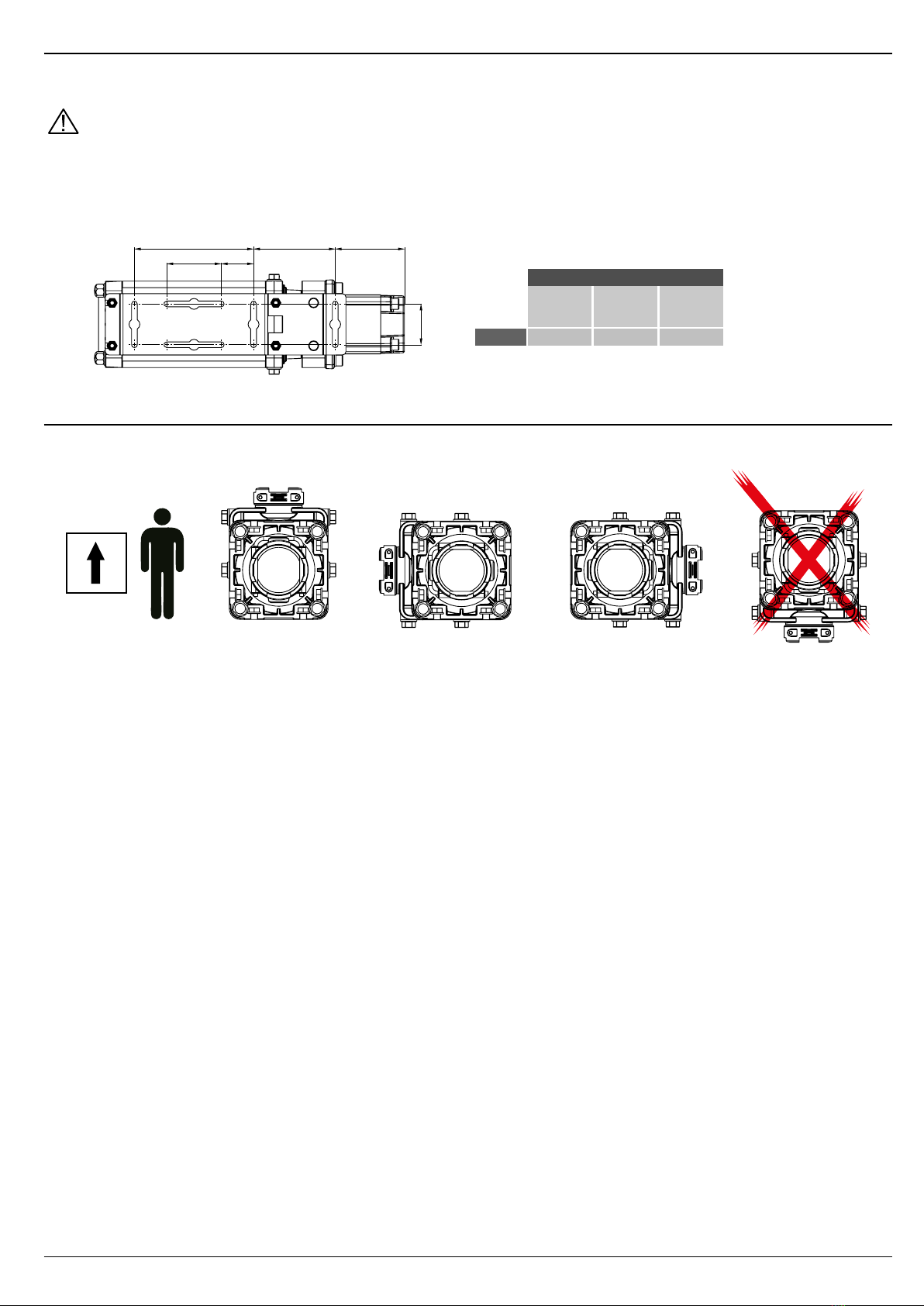

5.2 Dimensions (mm)............................................................................................................................................................................ 6

5.3 Attachment...................................................................................................................................................................................... 7

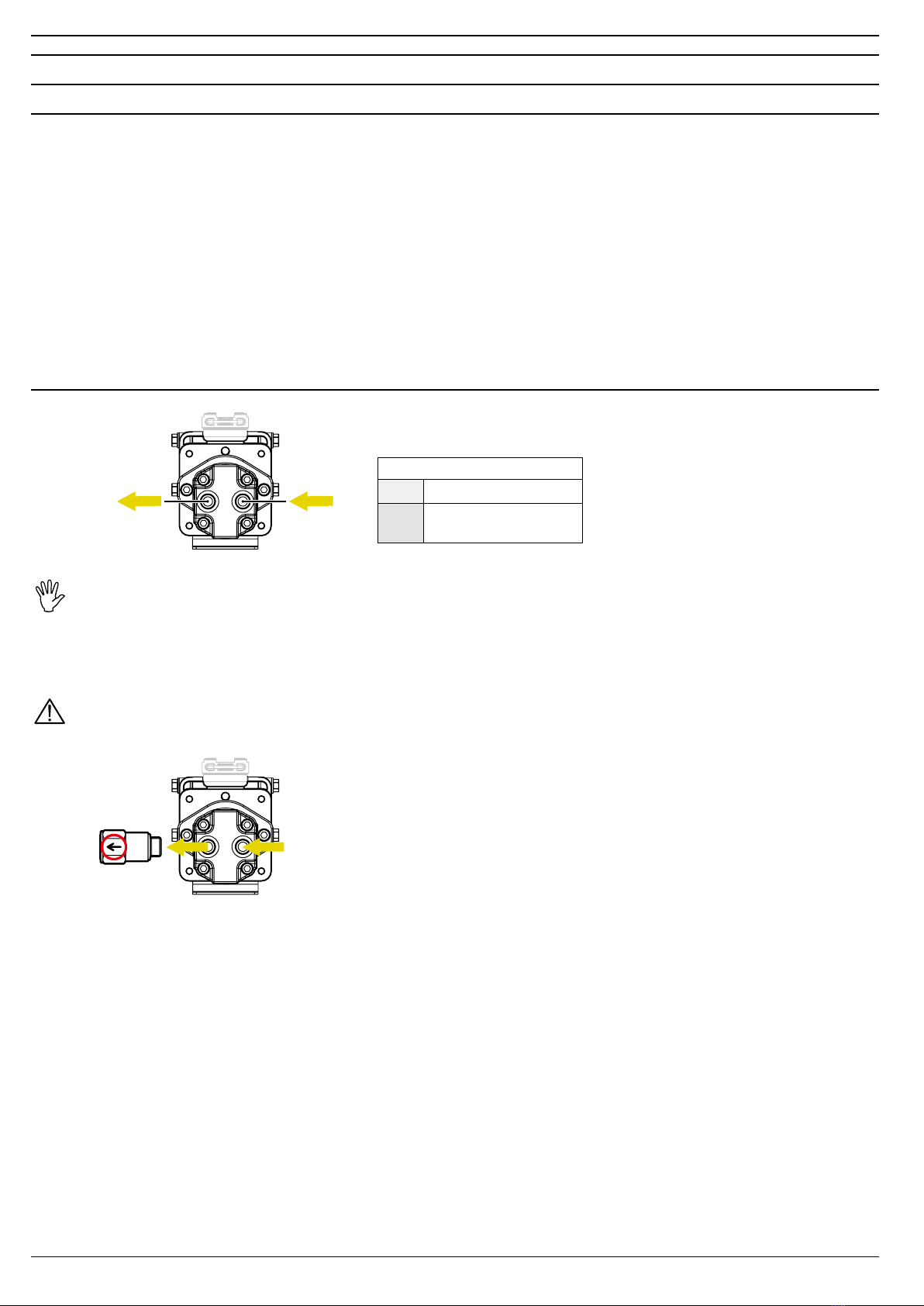

5.4 Pump assembly direction................................................................................................................................................................ 7

6 Connections ............................................................................................................................................................................................ 8

6.1 Hydraulic motor (OIL) connections ................................................................................................................................................. 8

6.1.1 Safety guidelines............................................................................................................................................................................ 8

6.1.2 Hydraulic motor oil line connection ................................................................................................................................................ 8

6.2 Water connection............................................................................................................................................................................ 9

6.2.1 Safety guidelines ............................................................................................................................................................................ 9

6.2.2 Water/air bleed ............................................................................................................................................................................... 9

7 Starting the pump ................................................................................................................................................................................. 10

8 Maintenance / Diagnostics / Repairs................................................................................................................................................... 10

8.1 Troubleshooting ............................................................................................................................................................................ 10

8.2 Technical data............................................................................................................................................................................... 10

9 End-of-life disposal............................................................................................................................................................................... 10

10 Guarantee terms.....................................................................................................................................................................................11

This manual is an integral part of the equipment to which it refers and must accompany the equipment in case of sale

or change of ownership. Keep it for any future reference; ARAG reserves the right to modify product specications and

instructions at any moment and without notice.