1.8

Start - Up: Turn on Servos

Pressthe blue “Servos On” pushbutton. It should illuminate and you shouldhearaslighthumastheaxes

motors engage. This part of the screen is the prompt area, and different information will be presented here

according to the current mode or page.

After the programs have been backed up you will be prompted to turn the servos on.

The prompt area requests "Servos on."

Jog Automatic Single Block Manual Data Input

PLEASE TURN SERVOS ON

POSITION

COMMAND

: X +0.00000 Z +0.00000 FEED 10.0 IPM

PERCENT FEED: 100

Jog mode allows manual motion, tool offsets, and zero

Single Block and Automatic allow execution of stored programs,

and also give access to tool offsets and the Editor

Manual Data Input allows immediate execution of program

statements, as well as tool offset and editing functions

Jog Automatic Single Block Manual Data Input

PLEASE TURN SERVOS ON

POSITION

COMMAND

: X +0.00000 Z +0.00000 FEED 10.0 IPM

PERCENT FEED: 100

Jog mode allows manual motion, tool offsets, and zero

Single Block and Automatic allow execution of stored programs,

and also give access to tool offsets and the Editor

Manual Data Input allows immediate execution of program

statements, as well as tool offset and editing functions

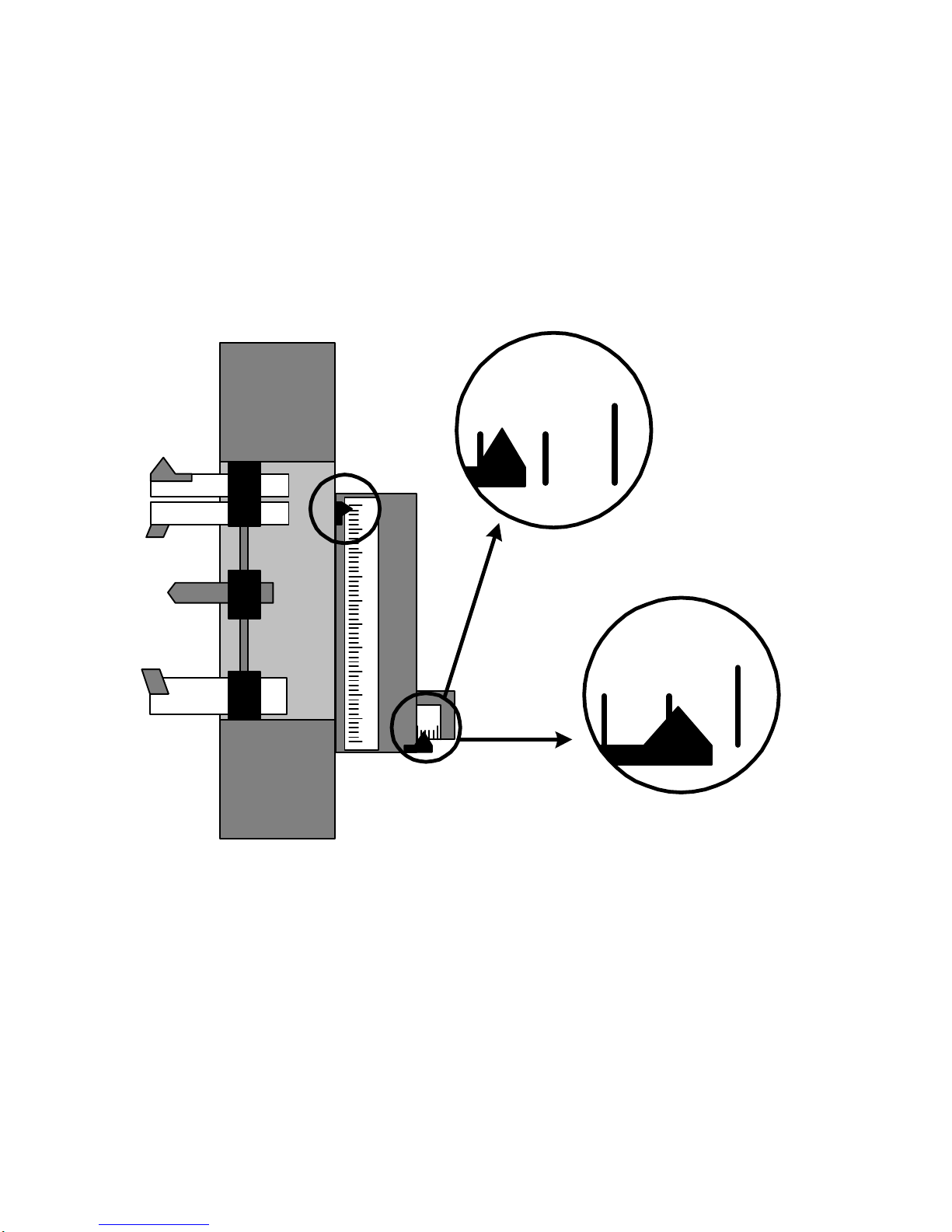

Turn servos ON with Blue button

Omni

Turn

EMERGENCY

STOP

SERVOS

ON

CONTROL

ON

CYCLE

START MOTION

STOP

SPINDLE

OVERRIDE

1000

SPINDLE

OFFAUTO

JOG JOG

X -

Z +Z -

X +

OmniTurn front panel Keyboard

Spindle

100%

Coolant

Parts

Catcher

Spindle

Spindle

~

`

Ctrl Fn Alt

Alt Ins Del

ZEnd

?

/

>

.

MNBVCX

Shift DelIns Shift

<

,

A

Caps

Lock

"

'

:

;

L

KJ

H

GFDSEnter

PgUp

End

QW{

[

OIUYTRE|

\

P}

]

!

1@

2#

3*

8

&

7

^

6

%

5

$

4(

9)

0+

=

_

-

Backspace

Home PgUp

Esc F1 F10F9F8F7F6F5F4F3F2 F11 F12

Num

Lock PrtSc

SysRq Scroll

Lock Pause

Break

Num

Lock Caps

Lock Scroll

Lock