!"#$%&#'()*+,$-)#.$%/0*1$234$5/67("*$8/7*"$9:;;1<$

=/#:>*)6$?:>@*"$AB33CC$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$D'&;6*"$4.$8&E*$J.

F*G.$H

position. For example, hot wire GTAW would be suitable for welding high-

quality stainless steel tanks and vessels that are rotated during welding.

While it would be tempting to apply hot wire technology to true out-of-posi-

tion orbital welding, the significant increase in deposition that can be

achieved in downhand hot wire welding will not be seen in orbital applica-

tions. However, some benefit may be achieved in orbital applications at the

expense of greater complexity.

The GTAW process is metallurgically “simple” in

that the electrode is not consumed and filler

metals added to the weld may be precisely

designed to achieve a particular metallurgical

result. Thus, the hot wire GTAW process is

particularly applicable to 300 series stainless

steel as well as to engineered materials such as

duplex stainless steels, or high-nickel alloys,

where the metallurgical properties of the base

metal may be adversely affected by welding

unless high-quality welding procedures are

employed. The proper use of the GTAW process

with the addition of hot wire can optimize the

corrosion resistance and/or mechanical proper-

ties of the weldment and have a beneficial effect

on the material performance in service.

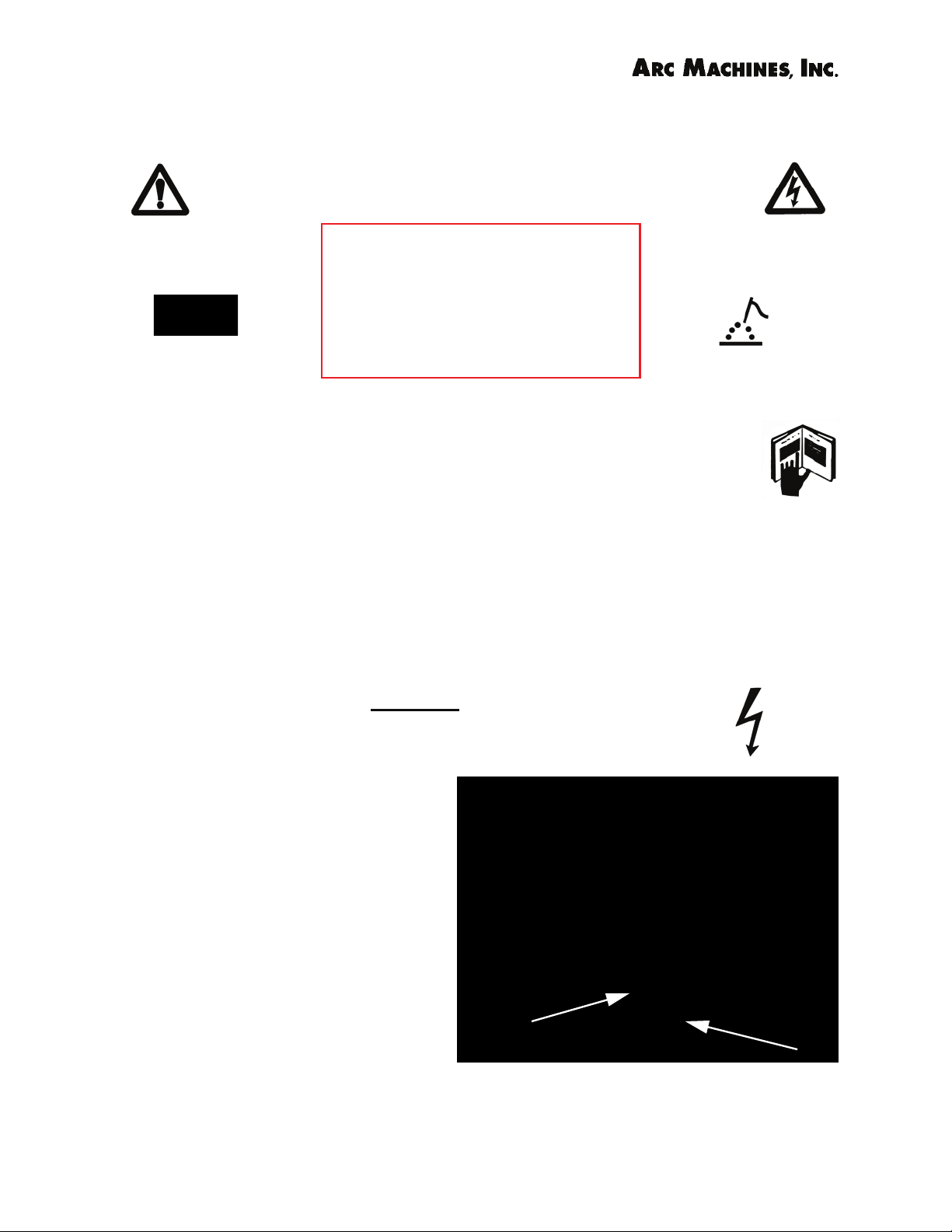

The Model 501 Hot Wire Power Supply can be used in combination with AMI’s Model 2 and

Model 415 Power Supply for fast, high-quality, heavy-duty applications such as turbines. The

photos show a demonstration of cladding at a trade show with the Model 2 with a hot wire

torch. Photo on the right is a close up of the torch.

Arc Machines Model 415 Windows!-

based Power Supply/Controller