4

2.2.3 Performance Features

Advanced IGBT inverter technology

The inverter frequency is 43KHz, which significantly reduces the loss of copper and iron, improves the

efficiency of the whole machine, and saves energy.

The main power electronics use spike withstanding IGBT, smaller volume and high reliability.

Leading digital control method

Adopt the internationally-leading MCU intelligent digital control technology, welding functions,

performance and welding procedure requirements all have been greatly improved.

New software controlled, easy to upgrade and maintain.

Excellent welding ability in TIG&MMA

Achievable high-quality MMA welding: easier arc ignition, stable welding current, little spatter, and

well-formed weld, support acid/alkaline electrodes.

The unique “Dash-Arc” technology patent improve arc striking speed from 200ms to 40ms, 99.99% arc

striking success rate. Digital constant current regulation technology ensures low noise and high stable arc

quality in the full specification.

TIG weld supports three typical TIG operation methods: two-step, four-step and spot welding, providing a

good way for users to meet special process requirements.

AC TIG can be widely used in welding of various aluminum alloys, magnesium alloys and other

non-ferrous metals, and has various waveform options.

DC TIG welding can be used for welding of various stainless steels and carbon steels.

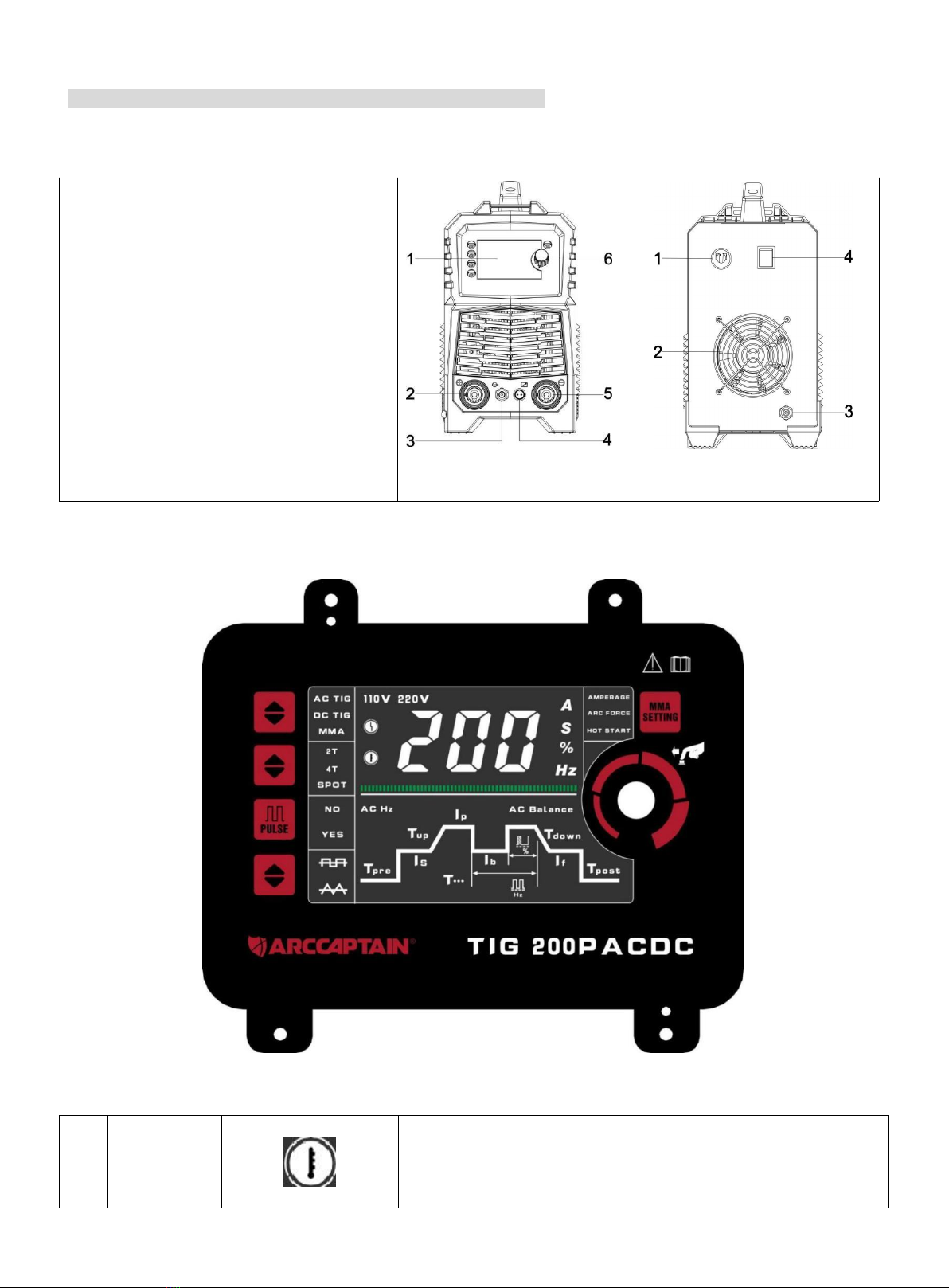

Friendly human-computer interface and beautiful structure design

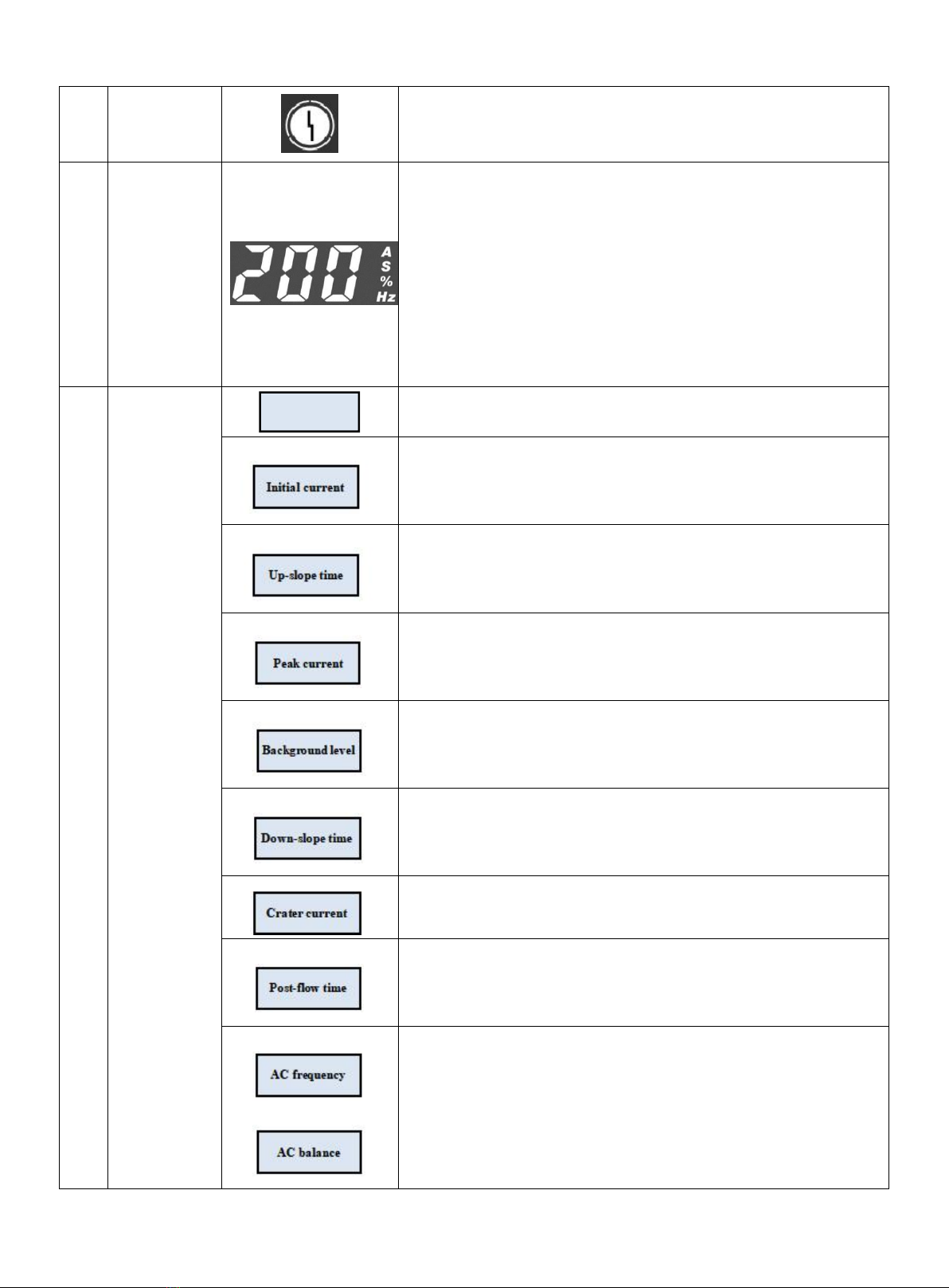

Big size LED display provide a simple, intuitive and understandable human-computer interface. The layout

of the operation panel is convenient to operation.

TIG200PACDC’s front and back panels are made of high-strength engineering plastics, to ensure the

machine works efficiently under harsh conditions such as high impact and drop.

Enjoy excellent insulation performance.

Adopt moisture-proof, dust-proof, and anti-static design and have good corrosion resistance.

Perfect automatic protection function

The machine has a perfect protection function which provides a corresponding code prompt when

providing protection.

When the ambient temperature is too high or the machine is used overloaded, the overheat protection can

prevent the high temperature from damaging the welder.

Support remote control

The machine provides gun control and foot switch options for users to select as required.

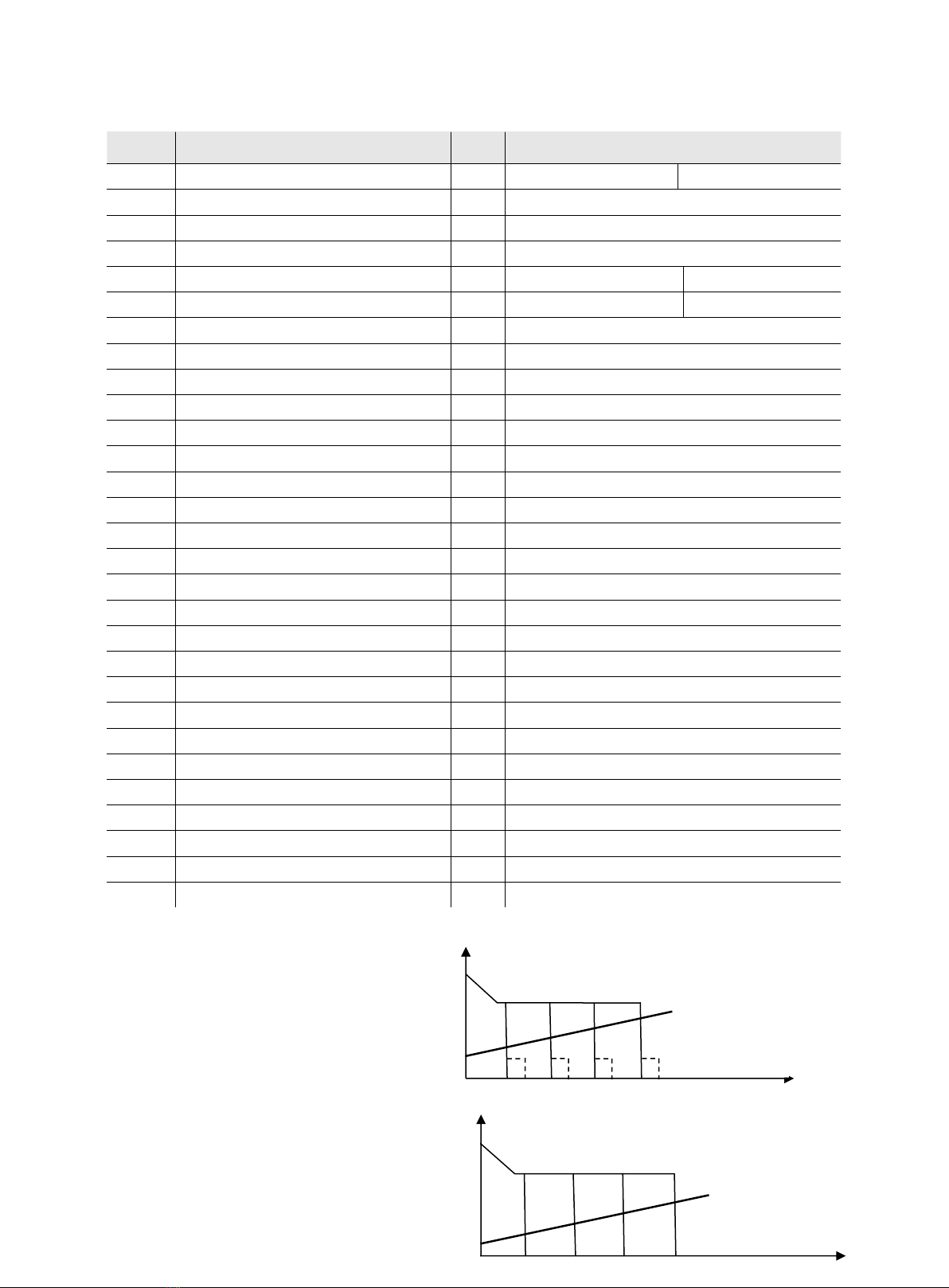

3. Technical Parameters

Digital Welding Expert, Know You More

https://www.arccaptain.com