2

Good ventilation

This cutting machine can create powerful cutting current and has strict cooling

requirements that cannot be met with natural ventilation. Therefore the built-in fan is

very important in enabling the machine to work stable with effective cooling. The

operator should make sure that the louvers be uncovered and unblocked. The

minimum distance between the machine and nearby objects should be 30cm.

Overvoltage is forbidden.

This machine is of automatic mains voltage compensation, which ensures that the

cutting current varies within the given range. In case that the input mains voltage

exceeds the tolerance value, it would possibly damage the machine. The operator

should understand this circumstance fully and adopt relevant precautions.

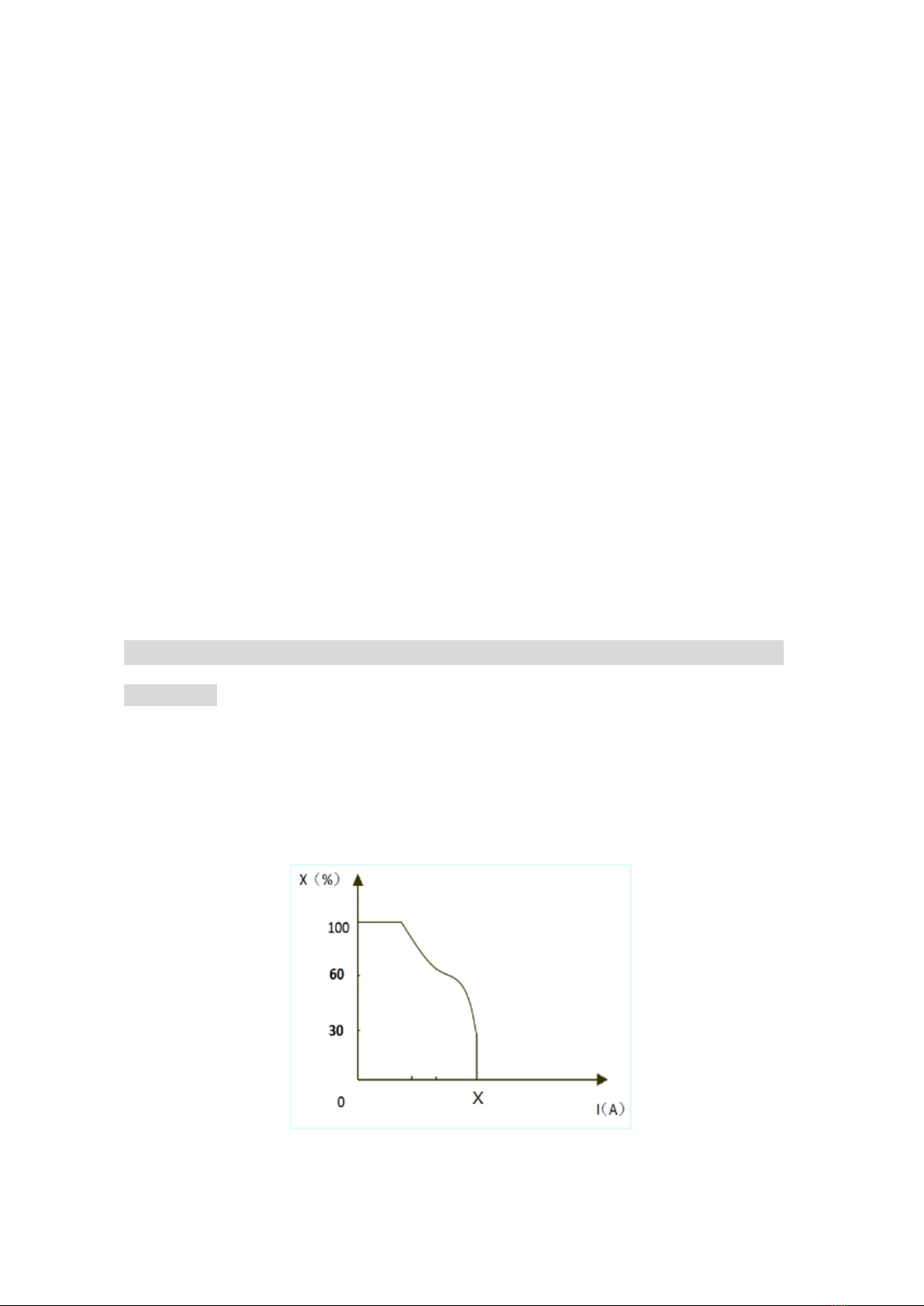

Overload is forbidden.

Remember to observe the max load current at any moment (refer to the

corresponding duty cycle). Make sure that the cutting current should not exceed the

maximum load current. Overload could obviously shorten the machine's lifespan, or

even damage the machine.

Suddenly the “E61” code may appear on the digital screen while the machine is of

over-load status. Under this circumstance, it is unnecessary to restart the machine.

Keep the built-in fan working to lower the temperature inside the machine. Cutting can

be continued after the inner temperature falls into the standard range and the yellow

LED is off.

Replacing the components can be dangerous.

Only professionals can replace the components of the machine.

Make sure there are no foreign bodies such as wire leads, screws, gaskets and metal

bars falling into the machine inside when replacing the components.

Make sure the connecting wires inside the machine are correctly connected after

replacing the PCBs, and then the machine can be run. Otherwise, there is a risk of

damage to property

1.2 Precautions for operation

Smoke-may be harmful to your health!

Keep your head away from the smoke to avoid inhalation of

waste gas in cutting.

Keep the working environment well ventilated with exhaust or

ventilation equipment when cutting.

Arc radiation-may hurt your eyes and burn your skin!

Use proper mask and wear protective clothing to protect your

eyes and body.

Use proper mask or curtain to protect onlooker from being

injured.

Digital Welder Expert, Know You More

https://www.arccaptain.com