by pressing this button:

1indicator is on under lift TIG argon arc welding;

2“SYN”indicator is on under electrode diameter selection

mode;

3indicator is on under MMA mode.

12 ,Electrode Selection: When“SYN” indicator is on,

electrode diameter can be selected by pressing this button.

13 ,Function Mode: It is MMA functions selecting button.

When indicator is on, MMA functions can be set:

①,Function Mode button is pressed once to adjust welding

current by rotating current knob with indicator“A” blinking.

Welding current setting is finished with “A”off after 3S.

②,Function Mode button is pressed twice to adjust arc-force

current by rotating current knob with indicator blinking.

Arc-force current setting is finished with arc-force indicator off

after 3S.

③,Function Mode button is pressed three times to adjust hot

start current by rotating current knob with indicator

blinking. Hot start current setting is finished with hot start

indicator off after 3S.

14. +output terminal: Connected to electrode holder.

15. -output terminal: Connected to earth clamp.

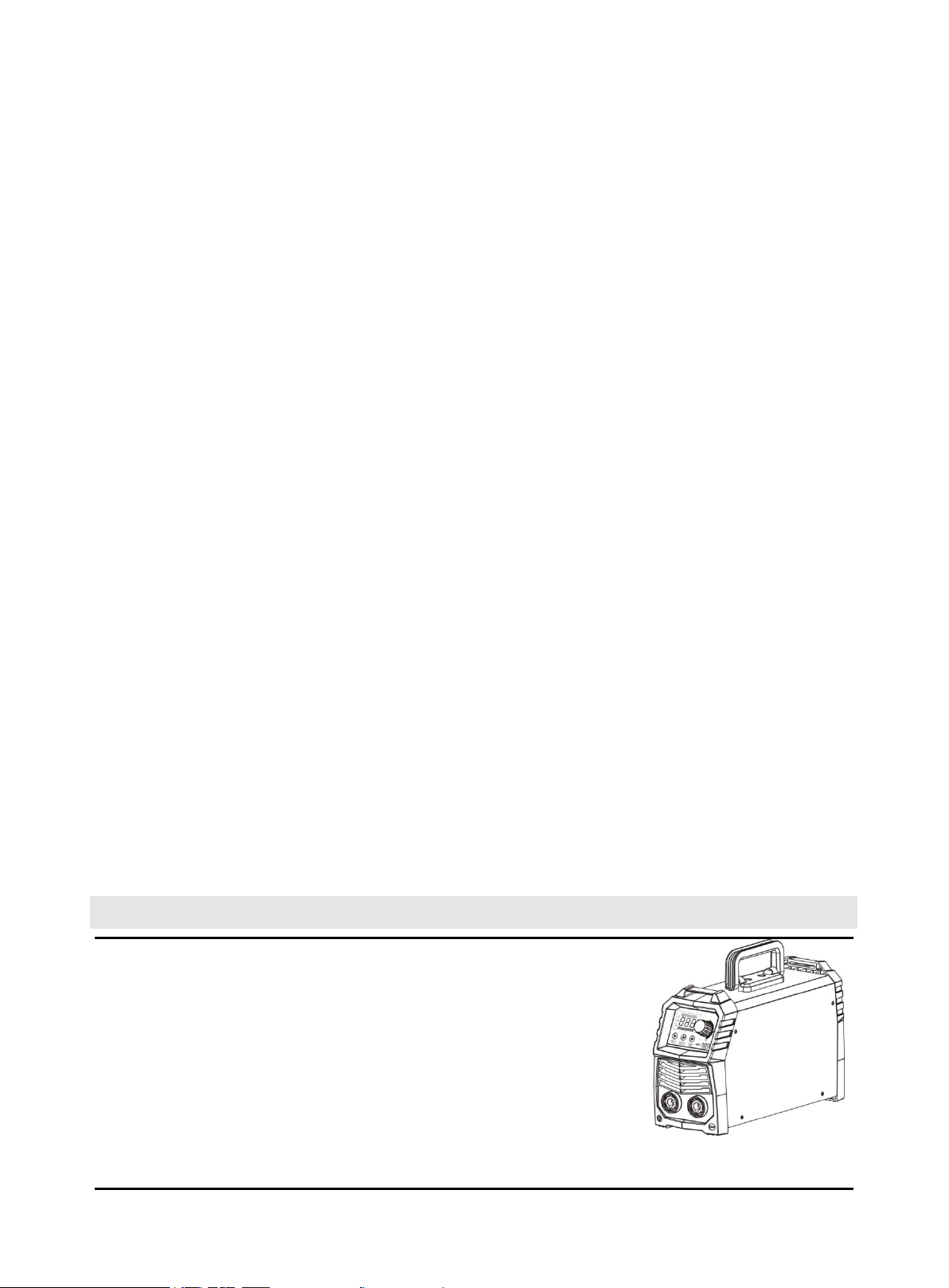

16. Power cord

17. Power switch: Control power.

18.Cooling fan

19.Handle

Combination key for switching VRD on and off:

Welding Mode and Electrode Selection buttons are pressed

simultaneously to switch on or off MMA VRD. Under MMA,

VRD is not available by default, but it is available when

welding Mode and Electrode Selection buttons are pressed

simultaneously for 3S with -1 display. And VRD is

unavailable if press them for 3S again with -0 display.

Combination key for switching anti-stick on and off:

Electrode Selection and Function Mode are pressed

simultaneously to switch on or off MMA anti-stick. Under

MMA, anti-stick function is available by default, but it is

unavailable when Electrode Selection and Function Mode

buttons are pressed simultaneously for 3S with -0display.

And anti-stick function is available if press them for 3S again

with -1display.