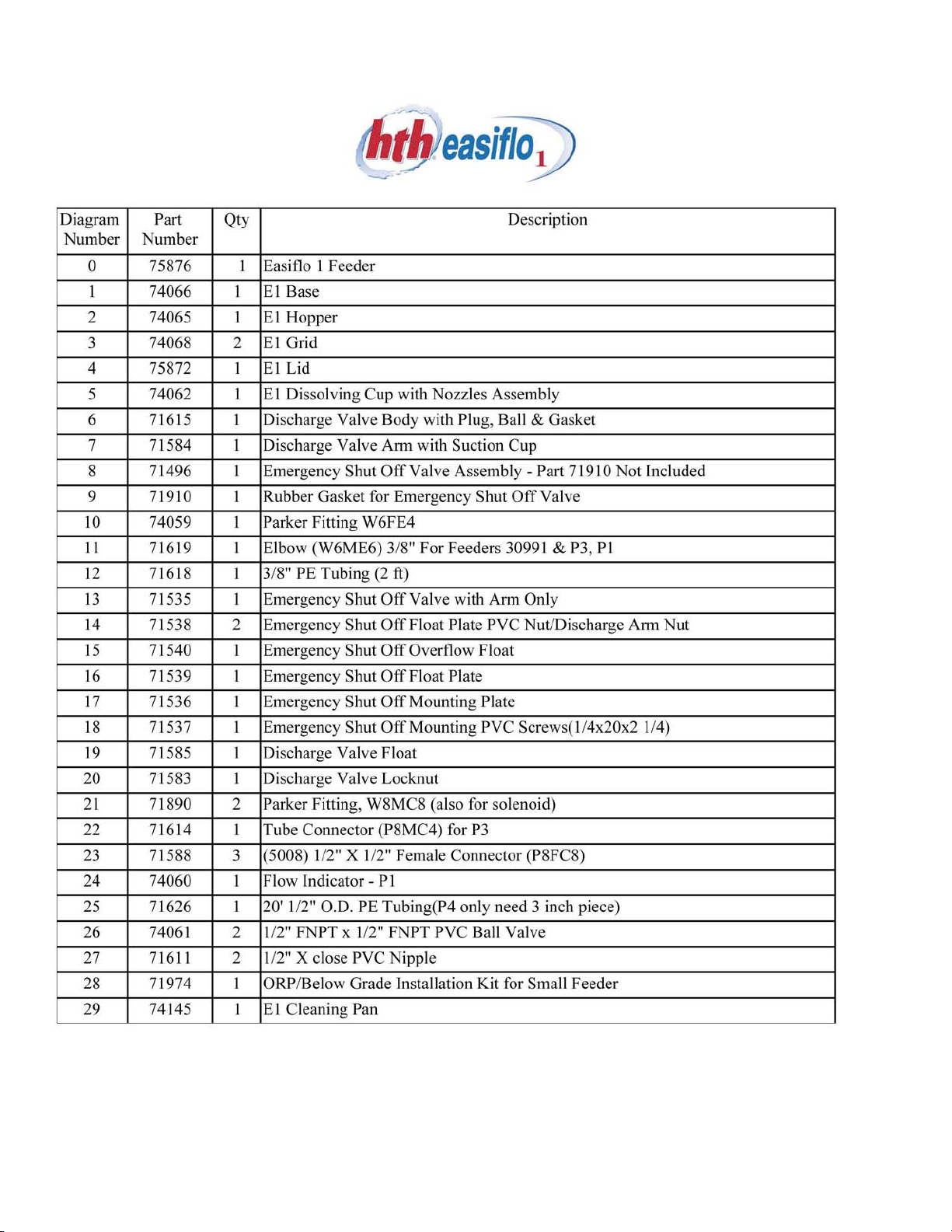

START-UP PROCEDURES

After completing the PRE-START-UP CHECKLIST, and

establishing that all components of the chlorinator are

operating properly, your Easiflo® 1 Chlorinator is ready

for start-up.

Routine maintenance of the Easiflo®1 Chlorinator is

minimized when proper pool water balance is

maintained. Maintain pool water chemistry as follows:

Total Alkalinity 60-80ppm

Calcium Hardness 200-1800ppm

PH 7.2-7.6

Adherence to these recommendations at all times will

ensure the most effective and economical performance

from the Easiflo®1 Chlorinator.

NOTE: The use of CO2 to lower pH will raise Total

Alkalinity. High total alkalinity (over 80 ppm) will

increase scale and solids buildup in chlorinator.

WARNING

Use ONLY Easiflo®Briquettes in the Chlorinator. The

use of any other treatment chemicals will void the

warranty. DANGER: Under no circumstances mix

calcium hypochlorite with other forms of concentrated

chlorine or other chemicals. Fire and/or explosion may

result. Caution must be used when refilling dispenser.

KEEP OUT OF REACH OF CHILDREN

Output Rate and Start-up Settings for

Commercial Pools and Spas Vs. Inlet

Flow Rates

1. Fill the Briquette Hopper with Easiflo®Briquettes.

The Briquette Hopper holds 12.7kg of briquettes.

2. Open all valves to the pool and the outlet ball valve

of the chlorinator.

3. Check the chart below to determine an

approximate start-up Inlet Flow setting for your

pool (or be certain that the Auto Controller is

calibrated and the set-points are correct). Set the

Flow Indicator at the recommended setting using

the inlet ball valve. Note: For best chlorinator

performance with an ORP controller, set the flow

indicator for a pool 30% larger than the one at your

facility. This will assist in maintaining desired Free

Available chlorine level in pool without

overshooting ORP set point.

4. Monitor the water flow to the chlorinator daily to

ensure that a proper flow is being maintained.

5. During the first few days of operation, check

chlorine level in the pool frequently to establish the

best Inlet Flow setting (or Auto Controller setting)

for your pool. Adjust the chlorine output either up

or down according to the table, or adjust the

chlorine setpoint.