TITAN-SVX Operation Manual page 3 Rev 4.05

Table of Contents

1. INTRODUCTION ........................................................................................................................................ 5

1.1. TECHNICAL FEATURES ....................................................................................................................................6

2. GENERAL OPERATION OVERVIEW ........................................................................................................ 7

2.1. PULSE MODE.....................................................................................................................................................7

2.2. CONTROL MODE...............................................................................................................................................8

2.2.1. Position Value .............................................................................................................................................. 8

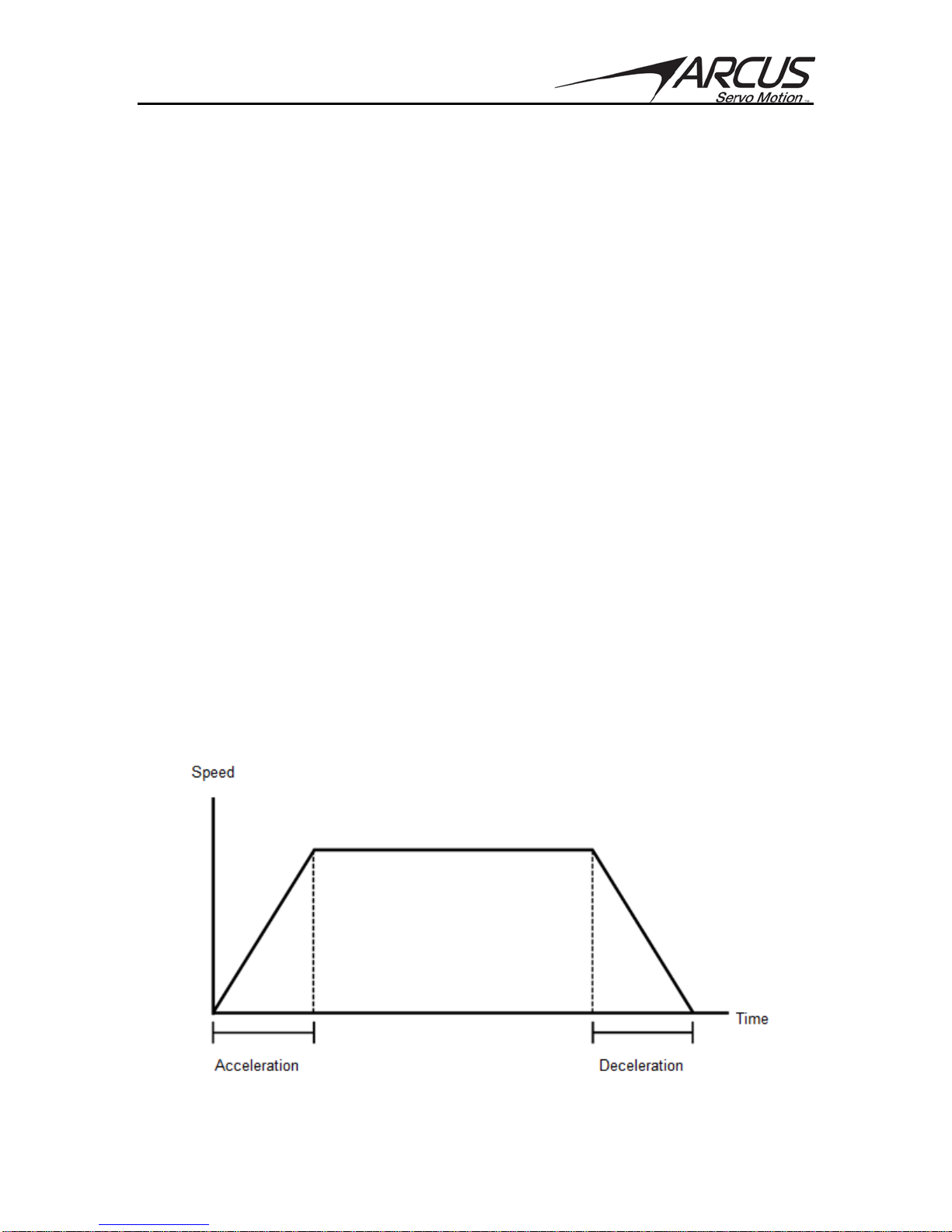

2.2.2. Motion Profile .............................................................................................................................................. 8

2.2.3. Homing............................................................................................................................................................ 9

2.2.4. Limits .............................................................................................................................................................11

2.3. MOTOR POWER .............................................................................................................................................11

2.4. JOG MOVE .......................................................................................................................................................11

2.5. STOPPING ....................................................................................................................................................... 12

2.6. POSITIONAL MOVES......................................................................................................................................12

2.7. MOTOR STATUS............................................................................................................................................. 12

2.8. FAULT STATUS............................................................................................................................................... 12

2.9. DIGITAL INPUTS /OUTPUTS .......................................................................................................................13

2.10. ANALOG INPUTS ......................................................................................................................................... 14

2.11. JOYSTICK CONTROL .................................................................................................................................... 14

2.12. CLOSED LOOP CONTROL GAINS ............................................................................................................... 15

2.12.1. P-Gain..........................................................................................................................................................15

2.12.2. V-Gain..........................................................................................................................................................15

2.12.3. I-Gain...........................................................................................................................................................15

2.12.4. C-Gain..........................................................................................................................................................15

2.13. DYNAMIC GAINS ......................................................................................................................................... 15

2.14. FORCE CONTROL ........................................................................................................................................ 16

2.15. STANDALONE PROGRAM SPECIFICATION ............................................................................................... 18

2.15.1. Standalone Program Specification ...............................................................................................19

2.15.2. Multi-thread / multi-tasking............................................................................................................19

2.15.3. Standalone Subroutines .....................................................................................................................19

2.15.4. Standalone Variables...........................................................................................................................19

2.15.5. Math Operations....................................................................................................................................20

2.15.6. Standalone Run On Boot-Up.............................................................................................................20

2.15.7. Storing Standalone Program to Flash.........................................................................................20

2.15.8. Standalone Command Set..................................................................................................................21

2.15.9. Conditional Statements ......................................................................................................................24

2.15.10. Example Standalone Programs....................................................................................................25

3. SERIAL COMMUNICATING COMMANDS................................................................................................29

3.1. STATUS COMMANDS ..................................................................................................................................... 29

3.2. LED COMMANDS........................................................................................................................................... 29

3.3. MOTION COMMANDS.................................................................................................................................... 30

3.4. GAIN COMMANDS.......................................................................................................................................... 30

3.5. STANDALONE PROGRAM COMMANDS ....................................................................................................... 31

3.6. LIMIT COMMANDS......................................................................................................................................... 31

3.7. DIGITAL IO COMMANDS............................................................................................................................... 32

3.8. VARIABLE COMMANDS................................................................................................................................. 32

3.9. COMMUNICATION COMMANDS ................................................................................................................... 32