Infranor XtrapulsCD1-pm User manual

1

PROFIBUS

POSITIONER

XtrapulsCD1-pm

Installation manual

2

XtrapulsCD1-pm –Installation manual

WARNING

This is a general manual describing a series of servo drives having output capability suitable for driving AC

brushless sinusoidal servo motors.

Instructions for storage, use after storage, commissioning as well as all technical details require the

MANDATORY reading of the manual before getting the drives operational.

Please see Xtrapuls CD1-pm User Guide for the operation of the drive (commissioning, configuration…).

For the PROFIBUS communication, see manual Xtrapuls CD1-pm –PROFIBUS Communication Profile.

Maintenance procedures should be attempted only by highly skilled technicians having good knowledge

of electronics and servo systems with variable speed (EN 60204-1 standard) and using proper test

equipment.

The conformity with the standards and the "CE" approval is only valid if the items are installed according to the

recommendations of the drive manuals. Connections are the user's responsibility if recommendations and

drawings requirements are not met.

All electrical industrial automatisms which lifetime is coming to its end are Waste Electronic and Electrical

Equipment (WEEE) according to article R543-172 of the French Environmental Code.

WEEE classification of the INFRANORproducts

Categorie 9: Monitoring and control instruments

In accordance with the Decree nr. 2012-617 of May 2nd, 2012 which specifies the provisions related to

the professional EEE manufacturers' obligations, INFRANOR France is a member of RECYLUM : eco-

organization ecosystem certified for the collection, treatment and recycling of WEEE.

In France, RECYLUM allows all professionals benefiting from a free collection and recycling solution, in

observance of the regulation, the environment and health.

Information and sorting instructions regarding INFRANORproducts

!

Any contact with electrical parts, even after power down, may involve physical damage.

Wait for at least 5 minutes after power down before handling the drives (a residual voltage of several

hundreds of volts may remain during a few minutes).

ESD INFORMATION (Electro Static Discharge)

INFRANOR drives are conceived to be best protected against electrostatic discharges. However,

some components are particularly sensitive and may be damaged if the drives are not properly stored

and handled.

STORAGE

- The drives must be stored in their original package.

- When taken out of their package, they must be stored positioned on one of their flat metal

surfaces and on a dissipating or electrostatically neutral support.

- Avoid any contact between the drive connectors and material with electrostatic potential

(plastic film, polyester, carpet…).

HANDLING

- If no protection equipment is available (dissipating shoes or bracelets), the drives must be

handled via their metal housing.

- Never get in contact with the connectors.

DISPOSAL

This symbol indicates that INFRANOR devices must be eliminated by selective disposal and not

with household waste.

CD1-pm 3

XtrapulsCD1-pm –Installation manual

Type of waste

Waste category

Waste management

Packaging

Cardboard

Recyclable waste

Waste disposal centre / collection

point of recyclable waste

Documents

Paper

Recyclable waste

Waste disposal centre / collection

point of recyclable waste

Mechanics

Metal

Recyclable waste

Waste disposal centre / metal

collection point

Heatsinks

Metal

Recyclable waste

Waste disposal centre / metal

collection point

Electronical

boards and

components

WEEE (Waste Electronic and

Electrical Equipment)

Dangerous industrial

waste

France:

http://www.ecosystem.eco/fr/sous-

rubrique/solutions

Abroad:

Country-specific regulation

Sorting instructions may vary according to regions / countries.

INFRANOR does not assume any responsibility for any physical or material damage due to improper handling or

wrong descriptions of the ordered items.

Any intervention on the items, which is not specified in the manual, will immediately cancel the warranty.

Infranor reserves the right to change any information contained in this manual without notice.

© INFRANOR, September 2020. All rights reserved.

Issue: 8.15

4

Contents

XtrapulsCD1-pm –Installation manual

Content

PAGE

CONTENT ................................................................................................................................................4

CHAPTER 1 –GENERAL DESCRIPTION..............................................................................................6

1- INTRODUCTION...............................................................................................................................6

2–DESCRIPTION /COMPLIANCE WITH THE STANDARDS............................................................6

2.1 - GENERAL DESCRIPTION........................................................................................................6

2.2 - REFERENCE TO THE STANDARDS: "CE" CERTIFICATION.................................................7

2.3 - REFERENCE TO THE STANDARDS: "UL" LISTING...............................................................7

3-OTHER DOCUMENTS REQUIRED FOR THE COMMISSIONING .................................................7

CHAPTER 2 –SPECIFICATIONS...........................................................................................................8

1-MAIN TECHNICAL DATA.................................................................................................................8

1.1 –XTRAPULS CD1-pm-230-/I POSITIONER...............................................................................8

1.2 –XTRAPULS CD1-pm-400/I POSITIONER................................................................................8

1.3 - COMMON SPECIFICATIONS TO BOTH POSITIONER VERSIONS XTRAPULS CD1-pm-

230/I AND XTRAPULS CD1-pm-400/I...............................................................................................9

2-DIMENSIONS................................................................................................................................ 12

2.1 - XTRAPULS CD1-pm-230/I POSITIONER.............................................................................. 12

2.2 - XTRAPULS CD1-pm-400/1.8 TO 7.2 A POSITIONER.......................................................... 12

2.3 - XTRAPULS CD1-pm-400/14 A POSITIONER ....................................................................... 12

2.4 - XTRAPULS CD1-pm-400/30/45/70 AND 90 A POSITIONER ............................................... 12

2.5 - BRAKING RESISTOR dp 100/100, dp 200/100, dp 50/200, dp 33/280 and dp 16.5/560 ..... 13

3-FASTENING.................................................................................................................................. 14

3.1 - XTRAPULS CD1-pm-230/I POSITIONER.............................................................................. 14

3.2 - XTRAPULS CD1-pm-400/1.8 TO 7.2 A POSITIONER.......................................................... 14

3.3 - XTRAPULS CD1-pm-400/14 A POSITIONER ....................................................................... 14

3.4 - XTRAPULS CD1-pm-400/30/45/70 AND 90 A POSITIONER ............................................... 14

4–MULTIAXES CABINET MOUNTING ............................................................................................ 15

4.1 - XTRAPULS CD1-pm-230/I POSITIONER.............................................................................. 15

4.2 - XTRAPULS CD1-pm-400/1.8 TO 7.2 A POSITIONER.......................................................... 15

4.3 - XTRAPULS CD1-pm-400/14 A POSITIONER ....................................................................... 15

4.4 - XTRAPULS CD1-pm-400/30/45/70 AND 90 A POSITIONER ............................................... 15

CHAPTER 3 - INPUTS - OUTPUTS..................................................................................................... 16

1-CONNECTOR LOCATION............................................................................................................ 16

2-LEDS.............................................................................................................................................. 17

2.1 –DRIVE FAULT LEDs.............................................................................................................. 17

3-X1: RESOLVER CONNECTOR .................................................................................................... 17

4–X2: DIGITAL I/OS CONNECTOR.................................................................................................. 18

5–X3: ENCODER CONNECTOR ..................................................................................................... 20

5.1 - X3 CONNECTOR FOR TTL INCREMENTAL ENCODER & HES INPUT (Sub D 25 pins

female)............................................................................................................................................ 20

5.2 - X3 CONNECTOR FOR SinCos INCREMENTAL ENCODER & HES INPUT (Sub D 25 pins

female)............................................................................................................................................ 21

5.3 - X3 CONNECTOR FOR ABSOLUTE SINGLE TURN SIN/COS ENCODER (Sub D 25 pins

female)............................................................................................................................................ 22

5.4 - X3 CONNECTOR FOR ENCODER OUTPUT (Sub D 25 pins female) ................................. 23

6-X4: COMMAND CONNECTOR..................................................................................................... 24

6.1 - SPECIFICATIONS OF THE LOGIC INPUTS: FC+, FC-, INDEX, ENABLE, RESET ............ 24

6.2 - SPECIFICATION OF THE "AOK" LOGIC RELAY OUTPUT.................................................. 25

7-X5: RS-232 CONNECTOR........................................................................................................... 25

8-X6: PROFIBUS.............................................................................................................................. 25

9-X8: AUXILIARY SUPPLY AND BRAKE CONNECTOR................................................................. 25

10 -X9: POWER CONNECTOR: MAINS, MOTOR, BRAKING RESISTOR (CD1-PM-230 V&400 V)26

5

XtrapulsCD1-pm –Installation manual

CHAPTER 4 - CONNECTIONS............................................................................................................ 27

1-CONNECTION DIAGRAMS.......................................................................................................... 27

1.1 –XTRAPULS CD1-pm-230/I POSITIONER............................................................................. 27

1.2 –XTRAPULS CD1-pm-400/I POSITIONER............................................................................. 28

1.3 –SERIAL LINK CONNECTION................................................................................................ 28

1.4 –CONNECTION OF A BACKUP BATTERY FOR THE 24 VDC AUXILIARY SUPPLY.......... 29

1.5 –CONNECTION EXAMPLE FOR A MULTIAXIS APPLICATION .......................................... 29

2-WIRING RECOMMENDATIONS................................................................................................... 30

2.1 –GROUND CONNECTIONS AND LEAKAGE CURRENT...................................................... 30

2.2 –CONNECTORS SHIELD CONNECTION.............................................................................. 31

2.3 –CONNECTION VIEW OF XTRAPULS CD1-pm-400/30/45/70 and 90 A.............................. 32

2.4 - MOTOR, RESOLVER AND ENCODER CABLES.................................................................. 32

2.5 - SERIAL LINK CABLES........................................................................................................... 33

2.6 –CONNECTION CABLES OF THE BRAKING RESISTOR .................................................... 33

3-REQUIREMENTS OF COMPLIANCE WITH THE UL STANDARDS............................................ 34

3.1 –CONNECTION BY MEANS OF FASTON SOCKET ............................................................. 34

3.2 –24 V SUPPLY ........................................................................................................................ 34

3.3 –POWER SUPPLY AND UL FUSE RATING .......................................................................... 34

3.4 –XTRAPULS CD1-pm-230/I DRIVE: CONNECTION DIAGRAM WITH PROTECTIONS BY

"UL" FUSES.................................................................................................................................... 35

3.5 –XTRAPULS CD1-pm-400/I DRIVE: CONNECTION DIAGRAM WITH PROTECTIONS BY

"UL" FUSES.................................................................................................................................... 36

3.6 –CONNECTION EXAMPLE FOR A UL COMPLIANT MULTIAXIS APPLICATION................ 37

4–FIRST POWERING OF THE XTRAPULS CD1-PM POSITIONER................................................ 37

4.1 - VERY IMPORTANT................................................................................................................ 37

4.2 -SWITCH ON THE 24 VDC SUPPLY..................................................................................... 37

4.3 –SWITCH ON THE 230 VAC OR 400 VAC SUPPLY (according to the positioner type)........ 37

4.4 –FURTHER COMMISSIONING PROCEDURE ..................................................................... 37

CHAPTER 5 –APPENDIX.................................................................................................................... 38

1-HARDWARE ADJUSTMENTS OF THE LOGIC BOARD .............................................................. 38

2–ADJUSTMENT TO VARIOUS RESOLVER TYPES ..................................................................... 39

3-USE OF THE "AOK" OUTPUT....................................................................................................... 39

4-ENERGY RECUPERATION VIA ABRAKING RESISTOR ........................................................... 40

5-ORDERING CODE........................................................................................................................ 40

6

Chapter 1 - General description

XtrapulsCD1-pm –Installation manual

Chapter 1 –General description

1- INTRODUCTION

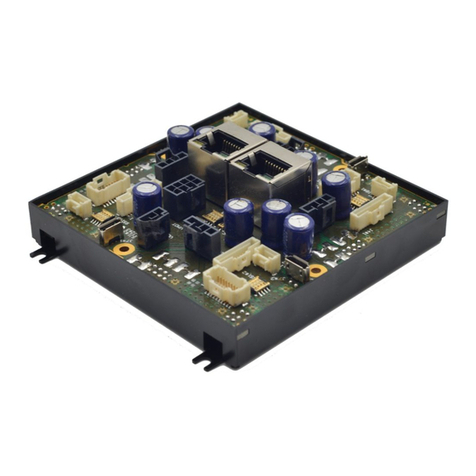

Series XtrapulsCD1-pm Profibus positioners are PWM servo drives for the control of AC sinusoidal motors

(brushless) equipped with a position sensor.

The XtrapulsCD1-pm servo drive is available as a stand-alone single-axis block that includes all supplies and

mains filter. It is available in both mains operated versions 230 VAC and 400/480 VAC.

The XtrapulsCD1-pm positioner works with a PROFIBUS DP interface or in stand-alone by using only digital I/Os.

It generates itself the positioning trajectory that allows the programming of 128 positioning sequences.

2 –DESCRIPTION / COMPLIANCE WITH THE STANDARDS

2.1 - GENERAL DESCRIPTION

The XtrapulsCD1-pm drive directly controls the motor torque and speed by means of the information provided by

a high resolution position sensor (resolver or encoder). The sinusoidal current commutation based on this high

resolution position sensor provides very smooth motor torque/force control.

The XtrapulsCD1-pm drive can be configured for the feedback of various position sensor types. The appropriate

position sensor configuration is selectable by software and saved in the drive.

- With a resolver sensor feedback, the motor absolute position value over one revolution is available and the

servo motor can immediately be enabled after the drive power up.

- With a "SinCos tracks" sensor which provides two analog Sin and Cos signals electrically compliant with the

SinCos encoder signals and which period is equal to the motor pole pitch, the servo-motor can be immediately

enabled after the powering of the drive.

- With an absolute single-turn SinCos encoder feedback (Heidenhain ERN 1085 or compliant), the servo

motor can also immediately be enabled after the drive power up.

- With an incremental encoder only, a motor phasing procedure (Phasing) must be executed at each drive

power up before the motor enabling.

- With an incremental encoder + Hall Effect Sensors (HES) feedback, the motor phasing procedure is no more

necessary and the servo motor can immediately be enabled after the drive power up.

- With an absolute single-turn, multi-turn or linear encoder using the ENDAT® or HIPERFACE® communication

protocols and fitted with incremental SinCos outputs, the servo-motor can also be immediately enabled after the

powering of the drive.

Series XtrapulsCD1-pm positioners have their own DC/DC converter to provide appropriate logic voltage to the

modules. An auxiliary 24 VDC +/- 15 % supply is generally available on all machines and supplies a DC/DC

converter with all logic supplies required by the positioner. The auxiliary supply allows to keep the logic board on,

after the power supply has been switched off, in order to keep all parameters in the memory and to avoid

initializing the machine all over again. A 24 VDC battery supply with specific wiring allows to keep the position

even after switching off the auxiliary 24 VDC supply. This wiring can be used for "absolute" operation with the

XtrapulsCD1-pm positioner (see chapter 4: Connections).

The power supply is depending on the positioner type:

•XtrapulsCD1-pm-230/I: 230 VAC single-phase mains operation power supply with limitation of the

operation power (see chapter 2, section 1.1) or three-phase via a transformer or an autotransformer (or

direct three-phase mains operation if there are three-phase mains available in 200 to 230 VAC).

•XtrapulsCD1-pm-400/I: 400 to 480 VAC three-phase mains operated power supply.

A soft start system of the power supply allows to limit the inrush current at power on.

7

XtrapulsCD1-pm –Installation manual

Chapter 1 - General description

The very small dimensions of the XtrapulsCD1-pm positioner allow an optimum integration in 300 mm deep

cabinets (connectors included). The XtrapulsCD1-pm positioner operates with a PROFIBUS DP interface or in

stand-alone by using only digital I/Os. The selection of the various operation modes (PROFIBUS or stand-alone)

is made by means of micro-switches accessible by the operator.

2.2 - REFERENCE TO THE STANDARDS: "CE" CERTIFICATION

Series XtrapulsCD1-pm positioners have been approved with regard to their conformity with the Electromagnetic

Compatibility standards concerning the power servos referenced in the EN 61800-3 standard "Electrical variable

speed power servo systems":

- EN 55011, group 1, C3 category, regarding radiated radioelectric disturbances,

- EN 61000.4-2-3-4-5 regarding immunity.

Standard to be applied to the electrical equipment of industrial machines: EN 60204-1.

2.3 - REFERENCE TO THE STANDARDS: "UL" LISTING

Xtrapuls CD1-pm series have been “CULUS” listed according to UL508C, and UL840 regarding the insulator.

This product was evaluated to:

- the Third Edition of UL508C, the UL Standard for Power Conversion Equipment, for the UL Listing (USL),

- the CSA Standard for Industrial Control Equipment, C22.2 N° 14-10, for the Canadian UL Listing (CNL).

Providing that the manual is specifying that the end user has to provide an isolated power supply, for 24 VDC

auxiliary input protected by a 4 A UL Listed fuse, the power board is considered within a limited voltage/current

circuit per section 31.4 of UL508C. Therefore, spacings on the power board are not required to be evaluated per

section 31.2 of UL508C and were evaluated according to UL 840.

Per UL 840 requirements, spacings are limited to 2.5 mm assuming pollution degree 2 environment.

Ground connection is fixed in the frame of the device by a rivet, Avibulb masse, BN10-5168. The connector

complies with standard dimensions given in table 6.2 of UL 310, the standard for Electrical Quick connect

terminals.

3 - OTHER DOCUMENTS REQUIRED FOR THE COMMISSIONING

" XtrapulsCD1-pm Profibus positioner User Manual".

" XtrapulsCD1-pm Profibus Communication Profile".

"CD1-pm SinCos track feedback" application note regarding the use of motors equipped with "SinCos tracks"

position sensors.

"CD1-pm absolute encoders feedback" application note regarding the use of absolute single-turn, multi-turn

or linear encoders using the ENDAT or HIPERFACE Communication protocols.

8

Chapter 2 –Specifications

XtrapulsCD1-pm –Installation manual

Chapter 2 –Specifications

1 - MAIN TECHNICAL DATA

1.1 –XTRAPULS CD1-pm-230-/I POSITIONER

Mains operated power supply voltage 230 VAC + 10 %/- 15 % 1~ or 3~, 50 - 60 Hz

Isolated auxiliary galvanic and motor brake 24 VDC +/- 15 % - 320 mA without brake

supply voltage

Motor phase-phase output voltage 200 Vrms

Integrated braking system External 100 Ohm/100 W braking resistor (dp 100/100)

Min. resistance: 50 Ohm (dp 50/200)

Minimum inductance between phases 1 mH

OUTPUT CURRENT RATINGS (at a maximum room temperature of 40°C)

Drive type

Max. output

current (Arms)

for 1 sec.

+/- 5 %

(230 VAC)

Rated

output

current

(Arms)

(230 VAC)

Power

losses

(W)

Rated input

current (Arms)

(230 VAC,

60 Hz)

Max. protection

fuses for line

circuit

RK5 listed

(Bussman /

Littelfuse)

Short-

circuit

power of

the mains

UL

listed

CD1-pm-230/2.25

2.25

1.1

25

1.1

6 A

5 kA

yes

CD1-pm-230/4.5

4.5

2.25

30

2.25

6 A

5 kA

yes

CD1-pm-230/7.5

7.5

3.75

44

3.75

6 A

5 kA

yes

CD1-pm-230/10.5

10.5

5.25

55

5.25

6 A

5 kA

yes

CD1-pm-230/16.5

16.5

8.25

66

8.25

9 A

5 kA

yes

1.2 –XTRAPULS CD1-pm-400/I POSITIONER

Mains operating power supply voltage

400 to 480 VAC + 10 %/- 15 % 3~, TN or TT system with

grounded neutral point 50 to 60 Hz (phase-ground voltage

must be balanced)

Isolated auxiliary and motor brake supply voltage

24 VDC +/- 15 % - 320 mA without brake

Motor phase-phase output voltage

380 to 460 Vrms depending on the mains

Integrated braking system

Xtrapuls CD1-pm-400/1.8 to 7.2 A:

External 200 Ohms/100 W resistor (dp 200/100)

Minimum resistor value: 150 Ohms/100 W

Xtrapuls CD1-pm-400/14:

External 50 Ohms/200 W resistor (dp 50/200)

Xtrapuls CD1-pm-400/30/45:

External resistor 33Ω/280 W (dp 33/280)

Xtrapls CD1-pm-400/70/90:

External resistor 16.5Ω/560 W (dp 16.5/560)

Minimum inductance between phases

2 mH

OPERATION POWER RESTRICTION IN SINGLE-PHASE OPERATION

Continuous RMS power ensuring a capacitor lifetime of 20 000 hours:

- 650 W for Xtrapuls CD1-pm-230/2.25 to 10.5

- 1000 W for Xtrapuls CD1-pm-230/16.5.

!

9

XtrapulsCD1-pm –Installation manual

Chapter 2 - Specifications

OUTPUT CURRENT RATINGS (at a maximum room temperature of 40°C)

Output voltage range for 400-480 VAC (rms) three-phase mains

Output current range: 1.8 A, 2.7 A, 5.1 A, 7.2 A, 14 A, 30 A, 45 A, 70 A, 90 A (rms)

Drive type

Max. output

current

(Arms) for

1 sec.

+/- 5 %

(480 VAC)

Rated

output

current

(Arms)

(480 VAC)

Power

losses

(W)

Rated input

current

(Arms)

(480 VAC,

60 Hz)

Max. protection

fuses for line

circuit

RK5 listed or

A60Q40 for

400/70 and

400/90 listed

Short-circuit

power of the

mains

UL listed

CD1-pm-400/1.8

1.8

0.9

35

0.9

2 A

5 kA

yes

CD1-pm-400/2.7

2.7

1.35

43

1.35

2 A

5 kA

yes

CD1-pm-400/5.1

5.1

2.55

71

2.55

4 A

5 kA

yes

CD1-pm-400/7.2

7.2

3.6

93

3.6

4 A

5 kA

yes

CD1-pm-400/14

14

7

200

7

8 A

5 kA

yes

CD1-pm-400/30

30

15

400

15

20 A

5 kA

yes

CD1-pm-400/45

45

20

560

20

20 A

5 kA

yes

CD1-pm-400/70

70

35

650

35

40 A

5 kA

yes

CD1-pm-400/90

90

35

650

35

40 A

5 KA

yes

1.3 - COMMON SPECIFICATIONS TO BOTH POSITIONER VERSIONS XTRAPULS CD1-pm-230/I AND

XTRAPULS CD1-pm-400/I

Regulation loops: current, speed and position

Digital

Mains filter on power supply

Integrated in the positioner

CD1-400/90 exception:

- EMC capacitors integrated

- Common mode choke not integrated

- Recommended filter: F-400-70-90

Common mode filter on auxiliary supply

Integrated in the positioner

Common mode filter on motor brake supply

Integrated in the positioner

Power stage protections

- power supply overvoltage

- internal switch protection

- short-circuit between motor phases or between motor

phase and ground

- drive overtemperature (on XtrapulsCD1-pm-400/I only)

- fan system error

- PWM control error

- power stage supply error

- braking system error

Motor brake control

Max. 1.5 A with 24 VDC

PWM switching frequency

8 kHz

Minimum inductance between phases

1 mH for 230 V / 2 mH for 400 V

Digital current regulator (PI)

Adjusted to the motor

Current loop bandwidth

Cut-off frequency for 45° phase shift : 1000 Hz

Internal current limitation

Imax: 20 % to 100 % and Irated: 20 % to 50 %

Imax duration = 1 second

Digital speed and position regulators

Sampling period = 0,5 ms

Anti-wind-up system of the integrator

Adjustable digital gains

Speed loop bandwidth

Selectable cut-off frequency for 45° phase shift: 50 Hz,

75 Hz or 100 Hz

10

Chapter 2 –Specifications

XtrapulsCD1-pm –Installation manual

Max. motor speed

Adjustable from 100 rpm to 25.000 rpm

Resolver input

Position conversion: 65536 ppr (16 bit)

Excitation frequency: 8 kHz

Transformation ratio: 0.3 to 0.5

(other available values are factory set)

Encoder input

Selectable by software:

Quadrature signals A & B with Z marker pulse

RS 422 line receiver

Maximum pulse frequency: 1 MHz

Resolution: 500 to 106ppr

Incremental Sin/Cos encoder

Heidenhain 1Vcc Sin/Cos type or compliant

Maximum signal frequency: 200 kHz

Resolution: 500 to 106ppr

Interpolation factor: 1024

Absolute single-turn Sin/Cos encoder

Heidenhain ERN 1085 or compliant

Maximum signal frequency: 200 kHz

Resolution: 2048 or 512 ppr

Interpolation factor: 1024

Hall sensors input

Selectable by software: 120° or 60° HES type

5 V or 12 V supply voltage

HES sequence error detection

Encoder position output

A and B channels in quadrature

Z marker pulse: 1 per motor revolution

RS-422 line driver

Programmable resolution from 64 ppr to 16384 ppr

Arc minute accuracy = (8 + 5400/Resolution)

Logic inputs

- Enable / Disable: ENABLE

- Limit switch +: FC+

- Limit switch -: FC-

- Homing input: INDEX

- Reset of a stored fault: RESET

- Sequence start: START

- Sequence stop: STOP

- Programmable inputs : IN1 to IN6

Logic outputs

- Sequence in progress: SEQ

- Position reached: POS

- Speed reached :SPEED

- Programmable outputs : OUT1 to OUT4

Analog input

+/-10 V resolution 14 bit (1 reconfigurable logic output)

On-the-fly speed limitation

Polarity selectable by software:

- no limitation for 0 Volt

- no limitation for 10 Volt

Analog output

+/-10 V resolution 8 bit (1 reconfigurable logic output)

Load: 10 mA, linearity: 2 %, low pass filter: 170 Hz

Programmable output signal: Channel 1 of the digital

oscilloscope (current, speed or position) or Phasing OK

output (from 0 V to 10 V when the motor phasing is OK

for an incremental encoder without HES)

Relay outputs

Relay contact: Umax = 50 V

Imax = 100 mA, Pmax = 10 W

"Amp ready": Closed if drive OK, open if fault

11

XtrapulsCD1-pm –Installation manual

Chapter 2 - Specifications

Open collector output protected against load

short-circuit

Motor brake coil with 24 VDC/1.5 A

PROFIBUS link

PPO-1 or PPO-2 or PPO-3 or PPO-4.

Fault display

LEDs on front panel and diagnostic by serial link RS232 +

diagnostic by PROFIBUS.

Motor and application parameter setting

Serial link RS232 or Profibus DP link

Automatic functions

Drive adjustment to the motor (AUTO-PHASING)

Automatic regulator tuning (AUTO-TUNING)

Compliance with the standards: CE certification.

360° shield connection, equipotentiality according

to the wiring rules.

Xtrapuls CD1-pm-400/70 and 90 A with mains

filter F-400-70/90

EMC standards:

- immunity: EN 61000.4-2-3-4-5

- conducted and radiated disturbances: EN 55011, Group

1, C3 category

Electrical standards for industrial machines:

- EN 60204-1 : insulator 1500 Vac / 1 mn

leakage current > 30 mA (EMI filters).

Compliance with the standards: UL listing

"360°" shield; equipotentiality according to the

wiring rules.

XtrapulsCD1-pm series have been “CULUS” listed according

to UL508C, and UL840 regarding the insulator.

This product was evaluated to:

- the Third Edition of UL508C, the UL Standard for Power

Conversion Equipment, for the UL Listing (USL),

- the CSA Standard for Industrial Control Equipment,

C22.2 N° 14-10, for the Canadian UL Listing (CNL).

Temperature

- storage -20° C à +70° C

- operation +5° C à +40° C

From 40° C, the rated currents must be reduced of

3 % per additional Celsius degree

Max. temperature: 50° C

Altitude

1000 m

Moisture

< 50% at 40° C and < 90% at 20° C: EN 60204-1 standard

Condensation prohibited (storage and operation)

Cooling

Forced air (fan integrated in the XtrapulsCD1-pm

positioner)

Check for free ventilation and no upper or lower obstruction

of the air admissions

Mounting position

Vertical

Environment

Open chassis to be mounted in a housing protecting the

drive from conducting dust and condensation (pollution

degree 2 environment)

Mounting location

Closed cabinet without any conducting and/or corroding

agents and according to the environment conditions

requirements.

Condensation prohibited

Weight

XtrapulsCD1-pm-230/I: approx. 1.5 kg

XtrapulsCD1-pm-400/1.8 to 7.2: approx. 2 kg

XtrapulsCD1-pm-400/14: approx. 3 kg

XtrapulsCD1-pm-400/30 and 45: about 5 kg

XtrapulsCD1-pm-400/70 and 90: about 6 kg

12

Chapter 2 –Specifications

XtrapulsCD1-pm –Installation manual

2 - DIMENSIONS

2.1 - XTRAPULS CD1-pm-230/I POSITIONER

2.2 - XTRAPULS CD1-pm-400/1.8 TO 7.2 A

POSITIONER

2.3 - XTRAPULS CD1-pm-400/14 A

POSITIONER

2.4 - XTRAPULS CD1-pm-400/30/45/70 AND 90 A

POSITIONER

13

XtrapulsCD1-pm –Installation manual

Chapter 2 - Specifications

2.5 - BRAKING RESISTOR dp 100/100, dp 200/100, dp 50/200, dp 33/280 and dp 16.5/560

dp 16.5/560

Connection of the braking resistor EF 400, 16.5 /560 W on pins 1 and 3 of the braking resistor connector.

Dimensions

dp 50/200, dp 100/100 and dp

200/100

dp 33/280

dp 16.5/560

A

157 mm

290 mm

290 mm

B

145 mm

278 mm

278 mm

C

83 mm

83 mm

57 mm

D

52 mm

57 mm

145 mm

14

Chapter 2 –Specifications

XtrapulsCD1-pm –Installation manual

3 - FASTENING

VERTICAL MOUNTING IS MANDATORY!

3.1 - XTRAPULS CD1-pm-230/I POSITIONER

3.2 - XTRAPULS CD1-pm-400/1.8 TO 7.2 A

POSITIONER

3.3 - XTRAPULS CD1-pm-400/14 A

POSITIONER

3.4 - XTRAPULS CD1-pm-400/30/45/70 AND 90 A

POSITIONER

15

XtrapulsCD1-pm –Installation manual

Chapter 2 - Specifications

4 –MULTIAXIS CABINET MOUNTING

4.1 - XTRAPULS CD1-pm-230/I POSITIONER

4.2 - XTRAPULS CD1-pm-400/1.8 TO 7.2 A

POSITIONER

4.3 - XTRAPULS CD1-pm-400/14 A

POSITIONER

4.4 - XTRAPULS CD1-pm-400/30/45/70 AND 90 A

POSITIONER

16

Chapter 3 - Inputs-Outputs

XtrapulsCD1-pm –Installation manual

Chapter 3 - Inputs - Outputs

1 - CONNECTOR LOCATION

17

XtrapulsCD1-pm –Installation manual

Chapter 3 - Inputs - Outputs

2 - LEDs

2.1 –DRIVE ERROR LEDs

Location: below the X4 command connector

ON: power supply

SYS: system fault

ERROR: Faults grouped on "ERROR" Led: These faults are coded and can be displayed by means of the

VDSetup software via the serial RS232 link or the Profibus. The "ERROR" Led groups the following faults:

SA: Power supply overvoltage

CL: Out of 24 VDC supply range (between 18 and 29 V)

FT: Phase/ground short-circuit

FD/R: Braking system short-circuited or overheated

FV: Fan

FO: Short-circuit, temperature, power stage supply, PWM error

I2t: I2t protection error

RDC: Digital resolver converter tracking error

CNT: Encoder counting error

POS: Position following error

E2P: EEPROM error

BUS: PROFIBUS communication error (or Positioner initialization/configuration error)

BUSY: Procedure execution error

TMOT: Motor temperature

RES: Resolver cable interruption

COD: Encoder cable interruption

HALL : Hall Effect Sensors error

BUS: PROFIBUS communication OK.

BUSY: Procedure in progress (blinking).

AP: No power supply. The AOK output does not take into account the display of AP.

All faults (except for the "Undervolt." fault) involve:

- the positioner disabling

- the motor brake control.

- the opening of the AOK relay contact. This relay must be wired as described in section 5.3 for switching off the

power supply in order to keep a zero type standstill.

The AP fault involves:

- the positioner disabling

- the motor brake control.

3 - X1: RESOLVER CONNECTOR

Sub D 9 pins female (same for all drive types 230 V and 400 V)

PIN

FUNCTION

REMARKS

1

TC (thermal sensor)

If thermal switch connected to X1

6

Shield connection

The shield must have a 360° connection on the

connector metal cover. This connection can be

completed by connecting the wires to pin 1.

2

TC (thermal sensor)

If thermal switch connected to X1

7

S1 (cosine-)

Resolver connector

3

S3 (cosine+)

Resolver connector

8

S4 (sine-)

Resolver connector

4

S2 (sine+)

Resolver connector

9

R2 (reference-)

Resolver connector

5

R1 (reference+)

Resolver connector

For other resolver connections, see chapter 5 (Appendix), section 2.

ON (green)

SYS (yellow)

ERROR (red)

BUSY (yellow)

BUS (green)

AP (red)

18

Chapter 3 - Inputs-Outputs

XtrapulsCD1-pm –Installation manual

4 - X2: DIGITAL I/Os CONNECTOR

Sub D 25 pins male (same connector for all drive types in 230 V and 400 V)

Pins

I/O

Description

1

I

Optocoupled input "START"

2

I

Optocoupled input "STOP"

3

I

Optocoupled input IN1

4

O

Z/

5

O

Z

6

O

A/

7

O

A

8

O

B/

9

O

B

10

I

Optocoupled input IN2

11

I

Optocoupled input IN3

12

I

0 V external

13

I

Optocoupled input IN4

14

I

Optocoupled input IN5

15

I

Optocoupled input IN6

16

O

Isolated output SEQ

17

O

Isolated output POS

18

O

Isolated output SPEED

19

O

Isolated output OUT1

20

O

Isolated output OUT2

21

O

Isolated output OUT3 (**)

Configurable analog input by jumpers

22

O

Isolated output OUT4 (**)

Configurable analog output by jumpers

23

O

0 V internal

24

I

External supply +24 V (*)

25

I

0 V external

(*) +24 V input only required when the outputs SEQ, POS, SPEED, OUT1, OUT2, OUT3, OUT4 are used.

(**) The analog input and the analog output are configured by the 3 jumpers located on the drive connector board

as described below.

Logic outputs selection

CD1-pm

Connector board

Analog I/Os selection

CD1-pm

Connector board

19

XtrapulsCD1-pm –Installation manual

Chapter 3 - Inputs - Outputs

SPECIFICATIONS OF THE LOGIC INPUTS : IN1 to IN6

These inputs are optocoupled and work in positive logic.

SPECIFICATIONS OF THE LOGIC OUTPUTS: SEQ, POS, SPEED, OUT1 to OUT4

❖External supply +24 V (18 V < U < 30 V)

❖Maximum voltage drop = 2 V

❖Protection against overloads

❖Output current available per output (mA)

Number of activated outputs / Cyclic rate (%)

100 %

70 %

50 %

30 %

2

200 mA

200 mA

200 mA

200 mA

4

100 mA

150 mA

200 mA

200 mA

7

60 mA

80 mA

120 mA

200 mA

SPECIFICATIONS OF THE ENCODER OUTPUTS

Recommended receiver: 26LS32.

The input voltage corresponding to level 1

is between 18 V and 30 V

100 kΩ

Logic input

0 V

CD1-pm

5 V

8.2 k

100 nF

+5 V

26LS31

driver

A

/A

B

/B

Z

/Z

0 V

CD1-pm

CD1-pm

330 Ohm

+24 V external

+24 V external

10 k

Driver

0 V external

0 V

20

Chapter 3 - Inputs-Outputs

XtrapulsCD1-pm –Installation manual

SPECIFICATIONS OF THE ANALOG INPUT

SPECIFICATIONS OF THE ANALOG OUTPUT

5 –X3: ENCODER CONNECTOR

Sub D 25 pins female (same connector for all drive types in 230 V and 400 V)

5.1 - X3 CONNECTOR FOR TTL INCREMENTAL ENCODER & HES INPUT (Sub D 25 pins female)

The “TTL incremental encoder & HES” configuration is selectable by software and stored in the drive EEPROM.

The corresponding X3 connector pin function is described below.

PIN

FUNCTION

REMARKS

18

Marker Z/

Differential input of the encoder marker pulse Z/

5

Marker Z

Differential input of the encoder marker pulse Z

19

Channel A/

Differential input of the encoder channel A/

6

Channel A

Differential input of the encoder channel A

20

Channel B/

Differential input of the encoder channel B/

7

Channel B

Differential input of the encoder channel B

8

+5 V

Encoder supply voltage (300 mA max. current)

21

GND

Encoder supply GND

11

HALL U

Hall sensor input signal phase U

24

HALL V

Hall sensor input signal phase V

12

HALL W

Hall sensor input signal phase W

10

+12 V

Hall sensors supply voltage: output impedance = 9 Ω, max 150 mA available

23

AGND

Hall sensors supply GND

9

TC+

Motor thermal sensor input

22

TC-

Motor thermal sensor input

others

reserved

200 K

X2-22

CD1-pm

X2-23

33 K

4.7 nF

20 K

CD1-pm

X2-21

100 K

X2-23

100 K

1 nF

16 K

Other manuals for XtrapulsCD1-pm

1

This manual suits for next models

16

Table of contents

Other Infranor Servo Drive manuals