Fastech Ezi-SERVO MINI User manual

Operating Manual

www.fastech-motions.com

www.fastech.co.kr - 2

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

3

6

9

9

10

10

11

11

11

12

12

13

14

15

15

16

17

18

18

18

19

19

19

20

20

20

20

20

21

21

22

23

24

25

Table of Contents

1. Precautions

2. Main Characteristics

3. Ezi-SERVO MINI Part Numbering

4. Standard Combination

5. Combination with Brake

6. Combination with Gearbox

7. Drive Specification and Dimension

7.1 Specifications of Drive

7.2 Dimensions of Drive [mm]

8. Specifications of Motor

9. Torque Characteristics of Motor

10. Dimensions of Motor [mm]

11. Notes on Installation

12. Specifications of Motor with Brake

13. Dimensions of Motor with Brake [mm]

14. Specifications of Motor with Gearbox

15. Dimensions of Motor with Gearbox [mm]

16. Settings and Operation

16.1 Drive Status LED

16.2 Pulse Input Setting Switch(SW2.6)

16.3 Rotational Direction Setting Switch(SW2.5)

16.4 Resolution Setting Switch(SW1.5~1.8)

16.5 Position Controller Gain Settingn Switch(SW2.1~2.4)

16.6 In-Position Value Setting Switch(SW1.1~1.4)

16.7 Input/Output Signal Connector(CN1)

16.8 Encoder Connector(CN2)

16.9 Motor Connector(CN3)

16.10 Power Connector(CN4)

17. System Configuration

17.1 Options

17.2 Connector Specifications

18. External Wiring Diagram

19. Control Signal Input/Output Description

Appendix

www.fastech.co.kr - 3

※ Before operation ※

·Thank you for your purchasing Ezi-SERVO MINI.

·For high-speed and high-precision drive of a stepping motor, Ezi-SERVO MINI is an unique drive that

adopts a new control scheme owing to an on-board high-performance 32bit digital signal processor.

·This manual describes handling, maintenance, repair, diagnosis and troubleshooting of Ezi-SERVO MINI.

·Before operating Ezi-SERVO MINI, thoroughly read this manual.

·After reading the manual, keep the manual near the Ezi-SERVO MINI so that any user can read the

manual whenever needed.

1. Precautions

◆ General Precautions

·Contents of this manual are subject to change without prior notice for functional improvement, change of

specifications or

user's better understanding. Thoroughly read the manual provided with the purchased

Ezi-SERVO MINI.

·When the manual is damaged or lost, please go to the homepage(www.fastech-motions.com) and downloaded

the manual.

·Our company is not responsible for a product breakdown due to user's dismantling for the product, and such

a breakdown is not guaranteed by the warranty.

◆ Put the Safety First

·Before installation, operation and repairing the Ezi-SERVO MINI, thoroughly read the manual and fully understand

the contents. Before operating the Ezi-SERVO MINI please, understand the mechanical characteristics of the Ezi-

SERVO MINI and related safety information and precautions.

·This manual divides safety precautions into Attention and Warning.

·Although precaution is only a Attention, a serious result could be caused depending on the situation.

Follow safety precautions.

Attention : If user does not properly handle the product, the user may seriously or slightly injured

and damages may occur in the machine.

Warning : If user does not properly handle the product, a dangerous situation (such as an electric

shock) may occur resulting in deaths or serious injuries.

www.fastech.co.kr - 4

◆ Check the Product

Check the Product is damaged or parts are missing.

Otherwise, the machine may get damaged or the user may get injured.

Attention

◆ Installation

Carefully move the Ezi-SERVO MINI.

Otherwise the Product may get damaged or User's foot may get injured by dropping the

product.

Use non-flammable materials such as metal in the place where the Ezi-SERVO MINI is to

be installed.

Otherwise, a fire may occur.

When installing several Ezi-SERVO MINI in a sealed place, install a cooling fan to keep

the ambient temperature of the Ezi-SERVO MINI as 50℃ or lower.

Otherwise, a fire or other kinds of accidents may occur due to overheating.

The process of Installation, Connection, Operation, Checking and Repairing should be

done with qualified person.

Otherwise, a fire or other kinds of accidents may occur.

Attention

Warning

◆ Connect Cables

Keep the rated range of lnput Voltage for Ezi-SERVO MINI.

Otherwise, a fire or other kinds of accidents may occur.

Cable connection should follow the wiring diagram.

Otherwise, a fire or other kinds of accidents may occur.

Before connecting cables, check if input power is off.

Otherwise, an electric shock or a fire may occur.

The case of the Ezi-SERVO MINI is insulated from the ground of the internal circuit by

the condenser. Ground the Ezi-SERVO MINI.

Otherwise, an electric shock or a fire may occur.

Attention

Warning

www.fastech.co.kr - 5

◆ Operation

◆ Check and Repair

If a protection function(alarm) occurs, firstly remove its cause and then release(alarm reset)

the protection function.

If you operate continuously without removing its cause, the machine may get damaged or

the user may get injured.

Do not make Motor Free and make input signal to ON during operation.

Motor will stop and stop current will become zero. The machine may get damaged or the

user may get injured.

Make all input signals to OFF before supply input voltage to Ezi-SERVO MINI.

The machine may get damaged or the user may get injured by motor operation.

All parameter values are set by default factory setting value. Change this value after

reading this manual throughly.

Otherwise, the machine may get damaged or other kinds of accidents may occur.

Stop to supply power to the main circuit and wait for a while before checking or

repairing the Ezi-SERVO MINI.

Electricity remaining in the capacitor may cause danger.

Do not change cabling while power is being supplied.

Otherwise, the user may get injured or the product may get damaged.

Do not reconstruct the Ezi-SERVO MINI.

Otherwise, an electric shock may occur or the reconstructed product can not get

After-Service.

Attention

Attention

www.fastech.co.kr - 6

2. Main Characteristics

Ezi-SERVO automatically controls motor current according

to load. Ezi-SERVO reduces motor current when motor

load is low and increases motor current when load is

high. By optimizing the motor current, motor heat can

be minimized and energy can be saved.

3

Heat Reduction / Energy Saving

(Motor Current Control according to load)

1

Ezi-SERVO is an innovative Closed Loop System that

utilizes a high-resolution motor mounted encoder

constantly to monitor the current position. The encoder

feedback allows the Ezi-SERVO to update the current

position every 25 μs e c . It allows the Ezi-SERVO drive to

compensate for the loss of position, ensuring accurate

positioning. For example, due to a sudden load change,

a conventional stepper motor and drive could lose a

step but Ezi-SERVO automatically correct the position

by encoder feedback.

Closed Loop System

To ensure machine performance, smoothness, positional

error and low servo noise, conventional servo systems

require the adjustment of its servo’s gains as an initial

crucial step. Even systems that employ auto-tuning

require manual tuning after the system is installed,

especially if more that one axis are interdependent.

Ezi-SERVO employs the best characteristics of stepper,

closed loop motion controls and algorithms to eliminate

the need of tedious gain tuning required for conventional

closed loop servo systems. This means that Ezi-SERVO

is optimized for the application and ready to work right

out of the box. The Ezi-SERVO system employs the

unique characteristics of the closed loop stepping motor

control, eliminating these cumbersome steps and giving

the engineer a high performance servo system without

wasting setup time. Ezi-SERVO is especially well suited

for low stiffness loads (for example, a belt and pulley

system) that sometime require conventional

servo systems to inertia match

with the additional expensive

and bulky gearbox.

Ezi-SERVO also performs

exceptionally, even under

heavy loads and high

speeds.

2

No Gain Tuning

www.fastech.co.kr - 7

Compared with common step motors and drives, Ezi-

SERVO motion control systems can maintain a high torque

state over relatively long period of time. This means

that Ezi-SERVO continuously operates without loss of

position under 100% of the load. Unlike conventional

Microstep drives, Ezi-SERVO exploits continuous high

torque operation during high speed motion due to its

innovative optimum current phase control.

High Torque

8

Ezi-SERVO is a high-precision servo drive, using a

high-resolution encoder with 32,000 pulses/revolution.

Unlike a conventional Microstep drive, the on-board

high performance MCU (Micro Controller Unit) performs

vector control and filtering, producing a smooth rotational

control with minimum ripples.

Smooth and Accurate

5

Similar to conventional stepping motors, Ezi-SERVO

instantly synchronizes with command pulses providing

fast positional response. Ezi-SERVO is the optimum

choice when zero-speed stability and rapid motions

within a short distance are required. Traditional servo

motor systems have a natural delay called settling time

between the command input signals and the resultant

motion because of the constant monitoring of the current

position.

Fast Response

6

Traditional servo motor drives overshoot their position

and try to correct overshooting by moving the opposite

direction, especially in high gain applications. This is

called null hunt and is especially prevalent in systems

that the break away or static friction is significantly

higher than the running friction. The cure is lowering

the gain, which affects accuracy or using Ezi-SERVO

Motion Control System. Ezi-SERVO utilizes the unique

characteristics of stepping motors and locks itself

into the desired target position, eliminating Null Hunt.

This feature is especially useful in applications such

as nanotech manufacturing, semiconductor fabrication,

vision systems and ink jet printing in which system

oscillation and vibration could be a problem.

No Hunting

4

The unit of the position command can be divided

precisely. (Max. 32,000 pulses/revolution)

High Resolution

7

www.fastech.co.kr - 8

1. Reliable positioning without loss of synchronism.

2. Holding stable position and automatically recovering to the original position even after experiencing positioning error

due to external forces, such as mechanical vibration or vertical positional holding.

3. Ezi-SERVO utilizes 100% of the full range of rated motor torque, contrary to a conventional open-loop stepping driver

that can use up to 50% of the rated motor torque due to the loss of synchronism.

4. Capability to operate at high speed due to load-dependent current control, open-loop stepping drivers use

a constant current control at all speed ranges without considering load variations.

1. No gain tuning. (Automatic gain adjustment in response to a load change)

2. Maintains the stable holding position without oscillation after completion of positioning.

3. Fast positioning due to the independent control by on-board MCU.

4. Continuous operation during rapid short-stroke movement due to instantaneous positioning.

The Ezi-SERVO operates well at high speed without the

loss of synchronism or positioning error. Ezi-SERVO’s

ability of continuous current position monitoring of

enables the stepping motor to generate high torque,

even under a 100% load condition.

High Speed

9

● Advantages over Open-Loop Control Stepping Drive

● Advantages over Servo Motor Controller

www.fastech.co.kr - 9

3. Ezi-SERVO MINI Part Numbering 4. Standard Combination

Product Name

MI : Mini Type

Drive Series Type

Brake

User Code

Reduction Gear Ratio

20

:

20mm

28

:

28mm

35 :

35mm

42

:

42mm

S

: Small

M

: Medium

L

: Large

XL

:

Extra Large

A :

10,000[ppr]

B : 20,000[ppr]

C :

32,000[ppr]

D :

16,000[ppr]

F :

4,000[ppr]

Motor Flange Size

Motor Length

Encoder Resolution

Blank : Without Brake

BK : Brake

Blank - Without Gear

PN03

- 1:3

PN05

- 1:5

PN08 - 1:8

PN10

- 1:10

PN15

- 1:15

PN25

- 1:25

PN40

- 1:40

PN50

- 1:50

Ezi-SERVO-MI-42M-A-BK-PN05-□

* When places an order for Stopper type 28mm, 35mm motor, please

write “M” additionally after motor length of Unit Part Number.

(Ex : Ezi-SERVO-MI-28LM-D, Ezi-SERVO-MI-35LM-D)

Unit Part

Number Motor Model

Number Drive Model

Number

Ezi-SERVO-MI-20M-F EzM-20M-F EzS-PD-MI-20M-F

Ezi-SERVO-MI-20L-F EzM-20L-F EzS-PD-MI-20L-F

Ezi-SERVO-MI-28S-D EzM-28S-D EzS-PD-MI-28S-D

Ezi-SERVO-MI-28SM-D EzM-28SM-D EzS-PD-MI-28S-D

Ezi-SERVO-MI-28M-D EzM-28M-D EzS-PD-MI-28M-D

Ezi-SERVO-MI-28MM-D EzM-28MM-D EzS-PD-MI-28M-D

Ezi-SERVO-MI-28L-D EzM-28L-D EzS-PD-MI-28L-D

Ezi-SERVO-MI-28LM-D EzM-28LM-D EzS-PD-MI-28L-D

Ezi-SERVO-MI-35M-D EzM-35M-D EzS-PD-MI-35M-D

Ezi-SERVO-MI-35MM-D EzM-35MM-D EzS-PD-MI-35M-D

Ezi-SERVO-MI-35L-D EzM-35L-D EzS-PD-MI-35L-D

Ezi-SERVO-MI-35LM-D EzM-35LM-D EzS-PD-MI-35L-D

Ezi-SERVO-MI-42S-A EzM-42S-A EzS-PD-MI-42S-A

Ezi-SERVO-MI-42S-B EzM-42S-B EzS-PD-MI-42S-B

Ezi-SERVO-MI-42S-C EzM-42S-C EzS-PD-MI-42S-C

Ezi-SERVO-MI-42M-A EzM-42M-A EzS-PD-MI-42M-A

Ezi-SERVO-MI-42M-B EzM-42M-B EzS-PD-MI-42M-B

Ezi-SERVO-MI-42M-C EzM-42M-C EzS-PD-MI-42M-C

Ezi-SERVO-MI-42L-A EzM-42L-A EzS-PD-MI-42L-A

Ezi-SERVO-MI-42L-B EzM-42L-B EzS-PD-MI-42L-B

Ezi-SERVO-MI-42L-C EzM-42L-C EzS-PD-MI-42L-C

Ezi-SERVO-MI-42XL-A EzM-42XL-A EzS-PD-MI-42XL-A

Ezi-SERVO-MI-42XL-B EzM-42XL-B EzS-PD-MI-42XL-B

Ezi-SERVO-MI-42XL-C EzM-42XL-C EzS-PD-MI-42XL-C

www.fastech.co.kr - 10

5. Combination with Brake 6. Combination with Gearbox

Unit Part

Number Motor Model

Number Drive Model

Number

Ezi-SERVO-MI-42S-A-BK EzM-42S-A-BK EzS-PD-MI-42S-A

Ezi-SERVO-MI-42S-B-BK EzM-42S-B-BK EzS-PD-MI-42S-B

Ezi-SERVO-MI-42M-A-BK EzM-42M-A-BK EzS-PD-MI-42M-A

Ezi-SERVO-MI-42M-B-BK EzM-42M-B-BK EzS-PD-MI-42M-B

Ezi-SERVO-MI-42L-A-BK EzM-42L-A-BK EzS-PD-MI-42L-A

Ezi-SERVO-MI-42L-B-BK EzM-42L-B-BK EzS-PD-MI-42L-B

Ezi-SERVO-MI-42XL-A-BK EzM-42XL-A-BK EzS-PD-MI-42XL-A

Ezi-SERVO-MI-42XL-B-BK EzM-42XL-B-BK EzS-PD-MI-42XL-B

Unit Part

Number Motor Model

Number Drive Model

Number Reduction

gear ratio

Ezi-SERVO-MI-42S-A-PN3 EzM-42S-A-PN3 EzS-PD-MI-42S-A 1:3

Ezi-SERVO-MI-42S-B-PN3 EzM-42S-B-PN3 EzS-PD-MI-42S-B

Ezi-SERVO-MI-42S-A-PN5 EzM-42S-A-PN5 EzS-PD-MI-42S-A 1:5

Ezi-SERVO-MI-42S-B-PN5 EzM-42S-B-PN5 EzS-PD-MI-42S-B

Ezi-SERVO-MI-42S-A-PN8 EzM-42S-A-PN8 EzS-PD-MI-42S-A 1:8

Ezi-SERVO-MI-42S-B-PN8 EzM-42S-B-PN8 EzS-PD-MI-42S-B

Ezi-SERVO-MI-42S-A-PN10 EzM-42S-A-PN10 EzS-PD-MI-42S-A 1:10

Ezi-SERVO-MI-42S-B-PN10 EzM-42S-B-PN10 EzS-PD-MI-42S-B

Ezi-SERVO-MI-42S-A-PN15 EzM-42S-A-PN15 EzS-PD-MI-42S-A 1:15

Ezi-SERVO-MI-42S-B-PN15 EzM-42S-B-PN15 EzS-PD-MI-42S-B

Ezi-SERVO-MI-42S-A-PN25 EzM-42S-A-PN25 EzS-PD-MI-42S-A 1:25

Ezi-SERVO-MI-42S-B-PN25 EzM-42S-B-PN25 EzS-PD-MI-42S-B

Ezi-SERVO-MI-42S-A-PN40 EzM-42S-A-PN40 EzS-PD-MI-42S-A 1:40

Ezi-SERVO-MI-42S-B-PN40 EzM-42S-B-PN40 EzS-PD-MI-42S-B

Ezi-SERVO-MI-42S-A-PN50 EzM-42S-A-PN50 EzS-PD-MI-42S-A 1:50

Ezi-SERVO-MI-42S-B-PN50 EzM-42S-B-PN50 EzS-PD-MI-42S-B

Ezi-SERVO-MI-42M-A-PN3 EzM-42M-A-PN3 EzS-PD-MI-42M-A 1:3

Ezi-SERVO-MI-42M-B-PN3 EzM-42M-B-PN3 EzS-PD-MI-42M-B

Ezi-SERVO-MI-42M-A-PN5 EzM-42M-A-PN5 EzS-PD-MI-42M-A 1:5

Ezi-SERVO-MI-42M-B-PN5 EzM-42M-B-PN5 EzS-PD-MI-42M-B

Ezi-SERVO-MI-42M-A-PN8 EzM-42M-A-PN8 EzS-PD-MI-42M-A 1:8

Ezi-SERVO-MI-42M-B-PN8 EzM-42M-B-PN8 EzS-PD-MI-42M-B

Ezi-SERVO-MI-42M-A-PN10 EzM-42M-A-PN10 EzS-PD-MI-42M-A 1:10

Ezi-SERVO-MI-42M-B-PN10 EzM-42M-B-PN10 EzS-PD-MI-42M-B

Ezi-SERVO-MI-42M-A-PN15 EzM-42M-A-PN15 EzS-PD-MI-42M-A 1:15

Ezi-SERVO-MI-42M-B-PN15 EzM-42M-B-PN15 EzS-PD-MI-42M-B

Ezi-SERVO-MI-42M-A-PN25 EzM-42M-A-PN25 EzS-PD-MI-42M-A 1:25

Ezi-SERVO-MI-42M-B-PN25 EzM-42M-B-PN25 EzS-PD-MI-42M-B

Ezi-SERVO-MI-42M-A-PN40 EzM-42M-A-PN40 EzS-PD-MI-42M-A 1:40

Ezi-SERVO-MI-42M-B-PN40 EzM-42M-B-PN40 EzS-PD-MI-42M-B

Ezi-SERVO-MI-42M-A-PN50 EzM-42M-A-PN50 EzS-PD-MI-42M-A 1:50

Ezi-SERVO-MI-42M-B-PN50 EzM-42M-B-PN50 EzS-PD-MI-42M-B

Ezi-SERVO-MI-42L-A-PN3 EzM-42L-A-PN3 EzS-PD-MI-42L-A 1:3

Ezi-SERVO-MI-42L-B-PN3 EzM-42L-B-PN3 EzS-PD-MI-42L-B

Ezi-SERVO-MI-42L-A-PN5 EzM-42L-A-PN5 EzS-PD-MI-42L-A 1:5

Ezi-SERVO-MI-42L-B-PN5 EzM-42L-B-PN5 EzS-PD-MI-42L-B

Ezi-SERVO-MI-42L-A-PN8 EzM-42L-A-PN8 EzS-PD-MI-42L-A 1:8

Ezi-SERVO-MI-42L-B-PN8 EzM-42L-B-PN8 EzS-PD-MI-42L-B

Ezi-SERVO-MI-42L-A-PN10 EzM-42L-A-PN10 EzS-PD-MI-42L-A 1:10

Ezi-SERVO-MI-42L-B-PN10 EzM-42L-B-PN10 EzS-PD-MI-42L-B

Ezi-SERVO-MI-42L-A-PN15 EzM-42L-A-PN15 EzS-PD-MI-42L-A 1:15

Ezi-SERVO-MI-42L-B-PN15 EzM-42L-B-PN15 EzS-PD-MI-42L-B

Ezi-SERVO-MI-42L-A-PN25 EzM-42L-A-PN25 EzS-PD-MI-42L-A 1:25

Ezi-SERVO-MI-42L-B-PN25 EzM-42L-B-PN25 EzS-PD-MI-42L-B

Ezi-SERVO-MI-42L-A-PN40 EzM-42L-A-PN40 EzS-PD-MI-42L-A 1:40

Ezi-SERVO-MI-42L-B-PN40 EzM-42L-B-PN40 EzS-PD-MI-42L-B

Ezi-SERVO-MI-42L-A-PN50 EzM-42L-A-PN50 EzS-PD-MI-42L-A 1:50

Ezi-SERVO-MI-42L-B-PN50 EzM-42L-B-PN50 EzS-PD-MI-42L-B

Ezi-SERVO-MI-42XL-A-PN3 EzM-42XL-A-PN3 EzS-PD-MI-42XL-A 1:3

Ezi-SERVO-MI-42XL-B-PN3 EzM-42XL-B-PN3 EzS-PD-MI-42XL-B

Ezi-SERVO-MI-42XL-A-PN5 EzM-42XL-A-PN5 EzS-PD-MI-42XL-A 1:5

Ezi-SERVO-MI-42XL-B-PN5 EzM-42XL-B-PN5 EzS-PD-MI-42XL-B

Ezi-SERVO-MI-42XL-A-PN8 EzM-42XL-A-PN8 EzS-PD-MI-42XL-A 1:8

Ezi-SERVO-MI-42XL-B-PN8 EzM-42XL-B-PN8 EzS-PD-MI-42XL-B

Ezi-SERVO-MI-42XL-A-PN10 EzM-42XL-A-PN10 EzS-PD-MI-42XL-A 1:10

Ezi-SERVO-MI-42XL-B-PN10 EzM-42XL-B-PN10 EzS-PD-MI-42XL-B

Ezi-SERVO-MI-42XL-A-PN15 EzM-42XL-A-PN15 EzS-PD-MI-42XL-A 1:15

Ezi-SERVO-MI-42XL-B-PN15 EzM-42XL-B-PN15 EzS-PD-MI-42XL-B

Ezi-SERVO-MI-42XL-A-PN25 EzM-42XL-A-PN25 EzS-PD-MI-42XL-A 1:25

Ezi-SERVO-MI-42XL-B-PN25 EzM-42XL-B-PN25 EzS-PD-MI-42XL-B

Ezi-SERVO-MI-42XL-A-PN40 EzM-42XL-A-PN40 EzS-PD-MI-42XL-A 1:40

Ezi-SERVO-MI-42XL-B-PN40 EzM-42XL-B-PN40 EzS-PD-MI-42XL-B

Ezi-SERVO-MI-42XL-A-PN50 EzM-42XL-A-PN50 EzS-PD-MI-42XL-A 1:50

Ezi-SERVO-MI-42XL-B-PN50 EzM-42XL-B-PN50 EzS-PD-MI-42XL-B

www.fastech.co.kr - 11

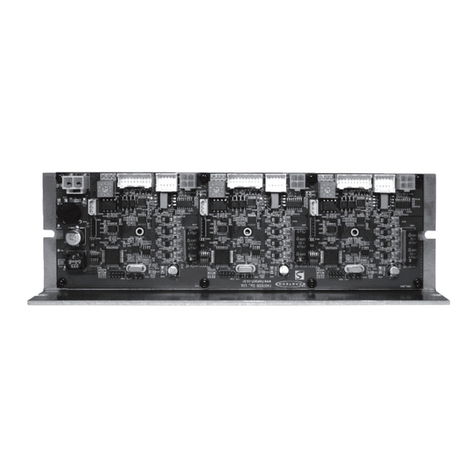

7. Drive Specification and Dimension

7.1 Specifications of Drive

7.2 Dimensions of Drive [mm]

Motor Model EzM-20

series EzM-28

series EzM-35

series EzM-42

series

Driver Model EzS-PD-MI-20

series EzS-PD-MI-28

series EzS-PD-MI-35

series EzS-PD-MI-42

series

Input Voltage 24VDC ±10%

Control Method Closed loop control with 32bit MCU

Current Consumption Max 500mA (Except motor current)

Operating

Condition

Ambient

Temperature

·In Use: 0~50℃

·In Storage: -20~70℃

Humidity ·In Use: 35~85% RH (Non-Condensing)

·In Storage: 10~90% RH (Non-Condensing)

Vib. Resist. 0.5g

Function

Rotation Speed 0~3,000 [rpm] *1

Resolution [ppr]

4,000/Rev. Encoder model: 500 1,000 1,600 2,000 3,600 5,000 6,400 7,200 10,000

4,000

10,000/Rev. Encoder model: 500 1,000 1

,600 2,000 3,600 5,000 6,400 7,200 10,000

16,000/Rev. Encoder model: 500 1,000 1

,600 2,000 3,600 5,000 6,400 7,200 10,000

16,000

20,000/Rev. Encoder model: 500 1,000 1,600 2,000 3,600 5,000 6,400 7,200 10,000 20,000

32,000/Rev. Encoder model: 500 1,000 1,600 2,000 3,600 5,000 6,400 7,200 10,000

32,000

(Selectable with DIP switch) *2

Max. Input Pulse

Frequency 500kHz (Duty 50%)

Protection Functions

Over Current Error, Over Speed Error, Position Tracking Error, Over Load Error, Over Temperature Error,

Over Regenerated Voltage Error, Motor Connect Error, Encoder Connect Error, In-Position Error,

System Error, ROM Error, Position Overflow Error

LED Display Power status, In-Position status, Servo On status, Alarm status

In-Position Selection 0~F (Selectable with DIP switch)

Position Gain Selection 0~F (Selectable with DIP switch)

Pulse Input Method 1-Pulse / 2-Pulse (Selectable with DIP switch)

Rotational Direction CW/CCW (Selectable with DIP switch)

Speed/Position

Control Command Pulse Train Input

I/O

Signal

Input Signals Position Command Pulse, Servo On/Off, Alarm Reset (Photocoupler Input)

Output Signals In-Position, Alarm (Photocoupler Output)

Encoder Signal (A+, A-, B+, B-, Z+, Z-, 26C31 of Equivalent) (Line Driver Output), Brake

*1 : Up to the resolution of 10,000[ppr], maximum speed can be reached by 3,000[rpm] and with the resolution more than 10,000[ppr], maximum speed

shall be reduced accordingly.

*2 : When selected resolution is more than encoder resolution, motor shall be operated by microstep between pulses.

PWR MOTOR ENCODER IN/OUT PWR ALM

INP SON

mini

77

82.8

9

9

21.5

3.5

3.5

2.9

21.5 53.9

(55)

69.8

www.fastech.co.kr - 12

8. Specifications of Motor

9. Torque Characteristics of Motor

Ezi-SERVO-MI-20 series Ezi-SERVO-MI-28 series

Torque[N.m]

Speed[rpm]

0.012

0.010

0.008

0.006

0.004

0.002

0

10 500 1,000 1,500 2,000 2,500 3,000

20M

20L

24V

Motor Voltage :

Torque[N.m]

Speed[rpm]

0.12

0.10

0.08

0.06

0.04

0.02

0

10 500 1,000 1,500 2,000 2,500 3,000

28S

28M

28L

24V

Motor Voltage :

Ezi-SERVO-MI-35 series Ezi-SERVO-MI-42 series

Motor Voltage :

Torque[N.m]

Speed[rpm]

0.18

0.15

0.12

0.09

0.06

0.03

0

10 500 1,000 1,500 2,000 2,500 3,000

35M

35L

24V

0.6

0.5

0.4

0.3

0.2

0.1

0

10 500 1,000 1,500 2,000 2,500 3,000

24V

42S

42M

42L

42XL

Motor Voltage :

Torque[N.m]

Speed[rpm]

MODEL

EzM-20

series EzM-28

series EzM-35

series EzM-42

series

UNIT 20M 20L 28S 28M 28L 35M 35L 42S 42M 42L 42XL

DRIVE METHOD -BI-POLAR

NUMBER OF PHASES -2 2 2 2 2 2 2 2 2 2 2

CURRENT per PHASE A0.5 0.5 0.95 0.95 0.95 1.5 1.5 1.2 1.2 1.2 1.2

HOLDING TORQUE N·m 0.016 0.025 0.069 0.098 0.118 0.13 0.23 0.32 0.44 0.5 0.65

ROTOR INERTIA g·c m

2

2.5 3.3 9.0 13 18 15 20 35 54 77 114

WEIGHTS g79 104 147 204 232 194 226 299 364 433 567

LENGTH(L) mm 28 38 32 45 50 32 36 34 40 48 60

PERMISSIBLE

OVERHUNG LOAD

(DISTANCE FROM

END OF SHAFT)

3mm

N

18 18 30 30 30 22 22 22 22 22 22

8mm 30 30 38 38 38 26 26 26 26 26 26

13mm - - 53 53 53 33 33 3 3 33 33 33

18mm - - - - - 46 46 46 46 46 46

PERMISSIBLE THRUST LOAD NLower than motor weight

INSULATION RESISTANCE Mohm 100 MIN.(at 500VDC)

INSULATION CLASS -CLASS B(130℃)

OPERATING TEMPERATURE ℃0 to 55

www.fastech.co.kr - 13

10. Dimensions of Motor [mm]

20mm

Model name Length(L)

EzM-20M 28

EzM-20L 38

28mm

Model name Length(L)

EzM-28S 32

EzM-28M 45

EzM-28L 50

28mm

(Stopper type)

Model name Length(L)

EzM-28SM 32

EzM-28MM 45

EzM-28LM 50

35mm

Model name Length(L)

EzM-35M 32

EzM-35L 36

※ When ordering 28mm Stopper type of motor, please add“M”after standard motor model number.

Ø16 -0.05

0

□20±0.5

4-16±0.1

4-M2 DP2.5

L±1

L+15±1

4 -0.012

0

3.5±0.1

10±0.5

7±0.2

1.5±0.2

20.6

27.6

A

0.075 A

Ø 0.075 A

0.025

Ø

15±0.5

L±1

L+13.6±1

10±0.2

2±0.2

Ø5 -0.012

0

4.5±0.1

Ø22 -0.05

0

□28±0.5

4-23±0.15

4-M2.5 DP2.5

31

28

0.075 A

Ø 0.075 A

A0.025

15±0.5

L±1

L+13.6±1

10±0.2

2±0.2

Ø5 -0.012

0

4.5±0.1

Ø22 -0.05

0

□28±0.5

4-23±0.1528.3

4-M2.5 DP2.5

47.2

A

0.075 A

Ø 0.075 A

0.025

□35

4-29±0.2

20±0.5

L MAX

Ø5 -0.013

0

Ø22 -0.05

0

L+14±1

2

41.5

35

0.1 A

Ø 0.075 A

A

0.025

4-M3 DP3 MIN

www.fastech.co.kr - 14

10. Dimensions of Motor [mm]

□35

4-29±0.2

20±0.5

L MAX

Ø5 -0.013

0

Ø22 -0.05

0

L+14

2

52

35

0.1 A

Ø 0.075 A

A0.025

4-M3 DP3 MIN ±1

42mm

Model name Length(L)

EzM-42S 34

EzM-42M 40

EzM-42L 48

EzM-42XL 60

4-M3 DP4.5

L±1

L+24±1

22 -0.05

0

Ø5 -0.011

0

4.5±0.1

24±0.5

1.8±0.2

20±0.2

42

54

□42 0

+1

4-31±0.2

0.1 A

Ø 0.075 A

A0.025

Ø

35mm

Model name Length(L)

EzM-35MM 32

EzM-35LM 36

(Stopper type)

※ When ordering 35mm Stopper type of motor, please add“M”after standard motor model number.

11. Notes on Installation

1) Ezi-SERVO MINI is designed for indoor use only.

2) The ambient temperature of the room should be 0℃~50℃.

3) If the temperature of the product case is higher than 50℃, radiate heat of the outside to

cool down.

4) Do not install Ezi-SERVO MINI under direct rays, near magnetic or radioactive objects.

5) If you set more than 2 drives, you must set over 20mm vertically and over 50mm horizontally

as shown below.

PWR MOTOR ENCODER IN/OUT PWR ALM

INP SON

PWR MOTOR ENCODER IN/OUT PWR ALM

INP SON

PWR MOTOR ENCODER IN/OUT PWR ALM

INP SON

PWR MOTOR ENCODER IN/OUT PWR ALM

INP SON

More than 50mm

More than

20mm

www.fastech.co.kr - 15

* Brake Operation Timing Chart

Ezi-SERVO MINI controls Brake by Drive automatically.

Please refer to below Timing Chart when Brake is controlled

by the upper controller other than using Ezi-SERVO MINI Brake control.

Otherwise, Drive malfunctioning and loads can be fall down.

Also, please do not operate Brake while motor operation to prevent damage.

Drive Enable

ON

OFF

ON

OFF

Brake power

0.5second ~ 1second

Unit Part

Number

Motor Model

Number

Electronic Brake Motor

Unit

Weight

[g]

Permitted Overhung

Load [N] Permitted

Thrust

Load

[N]

Type

Voltage

Input

[V]

Rated

Current

[A]

Power

Consumption

[W]

Statical

Friction

Torque

[ N·m ]

Length from Motor

Point [mm]

3 8 13 18

Ezi-SERVO-MI-42S-■-BK

EzM-42S-■-BK Non-

exci-

tation

run

Type

24VDC

±10% 0.2 50.2

510

22 26 33 46

Must be

Lower

than

Unit’s

Weight

Ezi-SERVO-MI-42M-■-BK

EzM-42M-■-BK 570

Ezi-SERVO-MI-42L-■-BK

EzM-42L-■-BK 640

Ezi-SERVO-MI-42XL-■-BK

EzM-42XL-■-BK 770

* The code of encoder resolution will be marked in“■”

* Electronic Brake cannot be used for braking. Position hold purpose only when power OFF.

* The weight means Motor Unit Weight including Motor and Electronic Brake.

* Motor Model Number is combined model name of Motor and Brake.

* Motor specification and torque characteristic are same as Standard Motor.

42mm

Model Name Length(L) Weight(kg)

EzM-42S 34 0.51

EzM-42M 40 0.57

EzM-42L 48 0.64

EzM-42XL 60 0.77

4-M3 THRU

SMR-04V-N(JST) Lead wire UL 3398 AWG26

Length : 400mm

P.C.D 43.8

0.075 A

15

8

19 44

2

L

±1

63

±0.5 L+24±1

54

42

L+87(±1.5)

□

42

Ø

22

-0.02

0

Ø

5

-0.015

4.5

0

0.025

0.1 A

A

12. Specifications of Motor with Brake

13. Dimensions of Motor with Brake [mm]

www.fastech.co.kr - 16

42mm

Unit Part Number

Maximum

Holding

Torque

[ N·m ]

Rotor

Inertia

Moment

[ k g·m

2

]

Back-

lash

[min]

Angle

Trans-

mission

Error

[min]

Re-

duction

Gear

Ratio

Resolution

(10,000

[ppr]

Standard)

Permitted

Torque

[ N·m ]

Maximum

Torque

[ N·m ]

Permitted

Speed

Range

[rpm]

Unit

Weight

[kg]

Permitted

Overhung

Load [N] Permitted

Thrust

Load

[N]

Axis

Center

Standard

Ezi-SERVO-MI-42S-■-PN3 0.55

35x10

-7

3 5

30.012 ° 612 0~1000

0.89

240 270

Ezi-SERVO-MI-42S-■-PN5 0.92 50.0072 ° 918 0~600 290 330

Ezi-SERVO-MI-42S-■-PN8 1.47 80.0045 ° 918 0~375 340 410

Ezi-SERVO-MI-42S-■-PN10 1.84 10 0.0036 ° 612 0~300 360 450

Ezi-SERVO-MI-42S-■-PN15 2.67

5 7

15 0.0024 ° 612 0~200

0.99

410 540

Ezi-SERVO-MI-42S-■-PN25 4.46 25 0.00144 ° 918 0~120 490 640

Ezi-SERVO-MI-42S-■-PN40 7.13 40 0.0009 ° 918 0~75 570 640

Ezi-SERVO-MI-42S-■-PN50 9.00 50 0.00072 ° 918 0~60 620 640

Ezi-SERVO-MI-42M-■-PN3 0.85

54x10

-7

3 5

30.012 ° 612 0~1000

0.96

240 270

Ezi-SERVO-MI-42M-■-PN5 1.42 50.0072 ° 918 0~600 290 330

Ezi-SERVO-MI-42M-■-PN8 2.28 80.0045 ° 918 0~375 340 410

Ezi-SERVO-MI-42M-■-PN10 2.85 10 0.0036 ° 612 0~300 360 450

Ezi-SERVO-MI-42M-■-PN15 4.14

5 7

15 0.0024 ° 612 0~200

1.06

410 540

Ezi-SERVO-MI-42M-■-PN25 6.90 25 0.00144 ° 918 0~120 490 640

Ezi-SERVO-MI-42M-■-PN40 9.00 40 0.0009 ° 918 0~75 570 640

Ezi-SERVO-MI-42M-■-PN50 9.00 50 0.00072 ° 918 0~60 620 640

Ezi-SERVO-MI-42L-■-PN3 0.93

77x10

-7

3 5

30.012 ° 612 0~1000

1.02

240 270

Ezi-SERVO-MI-42L-■-PN5 1.55 50.0072 ° 918 0~600 290 330

Ezi-SERVO-MI-42L-■-PN8 2.48 80.0045 ° 918 0~375 340 410

Ezi-SERVO-MI-42L-■-PN10 3.10 10 0.0036 ° 612 0~300 360 450

Ezi-SERVO-MI-42L-■-PN15 4.51

5 7

15 0.0024 ° 612 0~200

1.12

410 540

Ezi-SERVO-MI-42L-■-PN25 7.52 25 0.00144 ° 918 0~120 490 640

Ezi-SERVO-MI-42L-■-PN40 9.00 40 0.0009 ° 918 0~75 570 640

Ezi-SERVO-MI-42L-■-PN50 9.00 50 0.00072 ° 918 0~60 620 640

Ezi-SERVO-MI-42XL-■-PN3 1.42

114x10

-7

3 5

30.012 ° 612 0~1000

1.15

240 270

Ezi-SERVO-MI-42XL-■-PN5 2.38 50.0072 ° 918 0~600 290 330

Ezi-SERVO-MI-42XL-■-PN8 3.80 80.0045 ° 918 0~375 340 410

Ezi-SERVO-MI-42XL-■-PN10 4.76 10 0.0036 ° 612 0~300 360 450

Ezi-SERVO-MI-42XL-■-PN15 6.00

5 7

15 0.0024 ° 612 0~200

1.25

410 540

Ezi-SERVO-MI-42XL-■-PN25 9.00 25 0.00144 ° 918 0~120 490 640

Ezi-SERVO-MI-42XL-■-PN40 9.00 40 0.0009 ° 918 0~75 570 640

Ezi-SERVO-MI-42XL-■-PN50 9.00 50 0.00072 ° 918 0~60 620 640

* The code of encoder resolution will be marked in“■”

14. Specifications of Motor with Gearbox

www.fastech.co.kr - 17

42mm

Unit Part Number Motor Stage □Reduction Gear Ratio L Length [mm]

Ezi-SERVO-MI-42S-■-PN□EzM-42S-■-PN□

Single

Stage

3, 5, 8, 10 34

Ezi-SERVO-MI-42M-■-PN□EzM-42M-■-PN□3, 5, 8, 10 40

Ezi-SERVO-MI-42L-■-PN□EzM-42L-■-PN□3, 5, 8, 10 48

Ezi-SERVO-MI-42XL-■-PN□EzM-42XL-■-PN□3, 5, 8, 10 60

Unit Part Number Motor Stage □Reduction Gear Ratio L Length [mm]

Ezi-SERVO-MI-42S-■-PN□EzM-42S-■-PN□

Double

Stage

15, 25, 40, 50 34

Ezi-SERVO-MI-42M-■-PN□EzM-42M-■-PN□15, 25, 40, 50 40

Ezi-SERVO-MI-42L-■-PN□EzM-42L-■-PN□15, 25, 40, 50 48

Ezi-SERVO-MI-42XL-■-PN□EzM-42XL-■-PN□15, 25, 40, 50 60

4-ø3.4 THRU

P.C.D 50

2

54

□

42

M4 DP10

5

26

R 0.4

19.5

162

88.5

L+112.5±1

L+24±1

62.5

4 42

5.5

L

±1

ø35

-0.025

(g6)

-0.009

ø13

-0.003

(j6)

+0.008

0.025

0.1 A

0.5 A

A

4-ø3.4 THRU

P.C.D 50

54

□

42 42

26

R 0.4

19.5

162

105

L+129±1

L+24±1

79

4

5.5

L

±1

ø35

-0.025(g6)

-0.009

ø13

-0.003(j6)

+0.008

0.025

0.1 A

0.05 A

A

A

2

M4 DP10

5

* The code of encoder resolution will be marked in“■”

* The code of encoder resolution will be marked in“■”

15. Dimensions of Motor with Gearbox [mm]

www.fastech.co.kr - 18

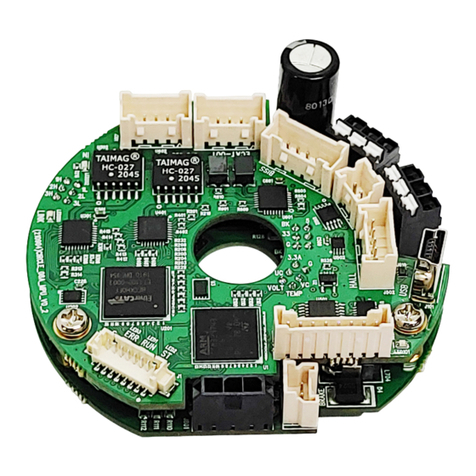

16. Settings and Operation

Drive status LED

Encoder connection(CN2)

Motor connection(CN3)

Power connection(CN4)

Input/Output signal

connection(CN1)

In-Position value setting switch

(SW1.1~1.4)

Pulse input setting switch(SW2.6)

Resolution setting switch(SW1.5~1.8)

Direction setting switch(SW2.5)

Position controller gain setting

switch(SW2.1~2.4)

16.1 Drive Status LED

16.2 Pulse Input Setting Switch(SW2.6)

Indication Color Function ON/OFF Condition

PWR Green Power input indication LED is turned ON when power is applied

INP Yellow Complete Positioning Motion Lights On when Positioning error reaches within

the preset pulse selected by dip switch

SON Orange Servo On/Off Indication Servo On: Lights On, Servo Off: Lights Off

ALM Red Alarm indication

Flash when protection function is activated

(Identifiable which protection mode is activated

by counting the blinking times)

Indication Switch Name Functions

PSelecting pulse

input mode

Selectable 1-Pulse input mode or 2-Pulse input mode as Pulse input signal.

ON: 1-Pulse mode OFF: 2-Pulse mode ※ Default: 2-Pulse mode

CW(Pulse) Pin

CCW(Dir) Pin

Rotational Direction CW CWCCW CCW

2-Pulse Mode 1-Pulse Mode

◆ Protection functions and LED flash times

Times Protection Conditions

1Over Current Error

The current through power devices in inverter exceeds 4.8A

2Over Speed Error Motor speed exceeds 3,000 [rpm]

3Position Tracking Error Position error value is higher than 180˚ in motor run state

4Over Load Error The motor is continuously operated more than 5 seconds under

a load exceeding the max. torque

5Over Temperature Error Inside temperature of drive exceeds 85℃

6Over Regeneratived

Voltage Error Back-EMF is higher than 48V

7Motor Connect Error The power is ON without connection of the motor cable to drive

8

Encoder Connect

Error Cable connection error in Encoder connection of drive

10 In-Position Error After operation is finished, position error more than 1 pulse is

continued for more than 3 seconds

11 System Error Error occurs in drive system

12 ROM Error Error occurs in parameter storage device(ROM)

15 Position Overflow Error Position error value is higher than 1 8 0˚ in motor stop state

Alarm LED flash

(Ex, Position tracking error)

www.fastech.co.kr - 19

16.3 Rotational Direction Setting Switch(SW2.5)

Indication Switch Name Functions

DSwitching Rotational

Direction

Based on CW(+Dir signal) input to driver.

ON: CCW(-Direction) OFF: CW(+Direction) ※ Default: CW mode

Direction setting

switch: ON

Direction setting

switch: OFF

Position Pulse/

Revolution

Position Pulse/

Revolution

8 7 6 5 8 7 6 5

ON ON ON ON 500*1 OFF ON ON ON 7,200

ON ON ON OFF 500 OFF ON ON OFF 10,000

ON ON OFF ON 1,000 OFF ON OFF ON NC

ON ON OFF OFF 1,600 OFF ON OFF OFF NC

ON OFF ON ON 2,000 OFF OFF ON ON NC

ON OFF ON OFF 3,600 OFF OFF ON OFF NC

ON OFF OFF ON 5,000 OFF OFF OFF ON NC

ON OFF OFF OFF 6,400 OFF OFF OFF OFF NC

16.4 Resolution Setting Switch(SW1.5~1.8)

*1 : Will be different according to the resolution of encoder adopted to the product.

But in case of the encoder with 10,000[ppr] resolution, it will be set as 500.

※ When selected resolution is more than encoder resolution, motor shall be operated by microstep between pulse.

16.5 Position Controller Gain Settingn Switch(SW2.1~2.4)

The Position Controller Gain Switch allows for the correction of the motor position deviation after stopping caused by load and friction.

Depending on the motor load, the user may have to select a different gain position to stabilize and to correct positional error quickly.

To tune the controller

1. Set the switch to “ON” position.

2. Start to rotate the switch until system becomes stable.

3. Rotate the switch 1~2 position to reach better performance.

*1 : Value in the columns are in relative units. They only show the parameter changes depending on the switch’s position.

*2 : Default = ON ON OFF OFF

The Number of pulse per revolution.

Position Time Constant of the

Integral part Proportional Gain*1

4 3 2 1

ON ON ON ON 1 1

ON ON ON OFF 1 2

ON ON OFF ON 1 3

ON ON OFF OFF 1 4

*2

ON OFF ON ON 1 5

ON OFF ON OFF 2 1

ON OFF OFF ON 2 2

ON OFF OFF OFF 2 3

OFF ON ON ON 2 4

OFF ON ON OFF 2 5

OFF ON OFF ON 3 1

OFF ON OFF OFF 3 2

OFF OFF ON ON 3 3

OFF OFF ON OFF 3 4

OFF OFF OFF ON 3 5

OFF OFF OFF OFF 3 6

www.fastech.co.kr - 20

Position

In-Position Value[Pulse]

Fast Response

Position

In-Position Value[Pulse]

Accurate Response

4 3 2 1 4 3 2 1

ON ON ON ON 0

*1

OFF ON ON ON 0

ON ON ON OFF 1OFF ON ON OFF 1

ON ON OFF ON 2OFF ON OFF ON 2

ON ON OFF OFF 3OFF ON OFF OFF 3

ON OFF ON ON 4OFF OFF ON ON 4

ON OFF ON OFF 5OFF OFF ON OFF 5

ON OFF OFF ON 6OFF OFF OFF ON 6

ON OFF OFF OFF 7OFF OFF OFF OFF 7

16.6 In-Position Value Setting Switch(SW1.1~1.4)

To select the output condition of In-Position signal. In-Position output signal is generated when the pulse number of positional error is

lower than selected In-Position value set by this switch after positioning command is executed.

*1 : Default = 0

1 19

2 20

16.7 Input/Output Signal Connector(CN1) 16.8 Encoder Connector(CN2)

NO. Function I/O

1A+ Input

2A- Input

3B+ Input

4B- Input

5Z+ Input

6Z- Input

75VDC Output

8GND Output

9F.GND ----

10 F.GND ----

14

16.9 Motor Connector(CN3)

NO. Function I/O

1B Phase Output

2/B Phase Output

3/A Phase Output

4A Phase Output

16.10 Power Connector(CN4)

NO. Function I/O

124VDC Input

2GND Input 1 2

NO. Function I/O

1CW+(Pulse+) Input

2CW-(Pulse-) Input

3CCW+(Dir+) Input

4CCW-(Dir-) Input

5A+ Output

6A- Output

7B+ Output

8B- Output

9Z+ Output

10 Z- Output

11 Alarm Output

12 In-Position Output

13 Servo On/Off Input

14 Alarm Reset Input

15 NC ----

16 BRAKE+ Output

17 BRAKE- Output

18 S-GND Output

19 EXT_GND Input

20 EXT_24VDC Input

1 9

2 10

Setting method of Fast Response and Accurate Response

In-Position

(Fast Response)

Position

In-Position

(Accurate Response)

Target Position

In-Position

Time

Time

This manual suits for next models

23

Table of contents

Other Fastech Servo Drive manuals

Popular Servo Drive manuals by other brands

Mitsubishi Electric

Mitsubishi Electric Melservo-H Series Specifications and Instruction Guide

IMI TA

IMI TA MC15/24 Mounting instructions

Higen

Higen FDA5000 Series Operation manual

Welcon

Welcon WEC-D048/08-FS0025-E Hardware manual

Lenze

Lenze L-force EWS0006 Mounting instructions

Rockwell Automation

Rockwell Automation Allen-Bradley Kinetix 5500 user manual