2/4

LS1532

GETTINGSTARTED

Open the shipping carton and verify that all

equipment necessary to operate the system has

arrivedintact.Refer to thefollowingpacking list for

information on what items are included with your

model. If any equipment is missing or damaged,

contactyourArenaLucidealerimmediately.

n°1LEDstripreelLS1532

n°5pluginpoweradapter

Before beginning initial setup of your projector,

makesurethatthereisnoevidentdamagecaused

bytransportation.Intheeventthattheunit’shousing

or cable is damaged, do not plug it in and do not

attempt to use it until after contacting yourArena

Lucidealerforassistance.

INSTALLINGTHEDEVICE

TheLEDstripissuppliedwoundin5mreel;onthe

backsidethereisalayerofdoublesidedadhesive

tapewhichfacilitatesassembly,protectedbyafilm.

Youcanunrollthereelonaflatsurfacetoprepareit

forinstallation.Arrangethestripsothatthewiresfor

theelectricalconnectionarenearthepoweroutput

terminals. During the unrolling operation absolutely

avoidbendsandtwistsofthestripbecausethiscan

damage the conductive tracks and welding of smd

LEDs on the strip, thus compromising the good

electricalcontactbetweenLEDsandtracks.

Planyourinstallationbeforeremovingtheprotective

tapefromtheadhesiveatthebackofthestrip.Once

theadhesivehasbeenfixed,removingthestripwill

result in a significant loss of adhesive strength. To

ensure excellent adhesion, make sure that the

mounting surface is smooth, nonporous, flat, dry

andclean,freefromoilorsiliconecoatingsordust.

The fixing surface must be intact. We recommend

usingdegreasingproductsbeforemountingtogeta

better result. A clean surface also guarantees a

good thermal dissipation of the strip that will be

applied.

It is advisable to always apply the LED strip on

aluminumprofilesofadequatedissipatingpower,so

as to effectively remove the heat produced by the

stripandensurealonglifeoftheLEDs.

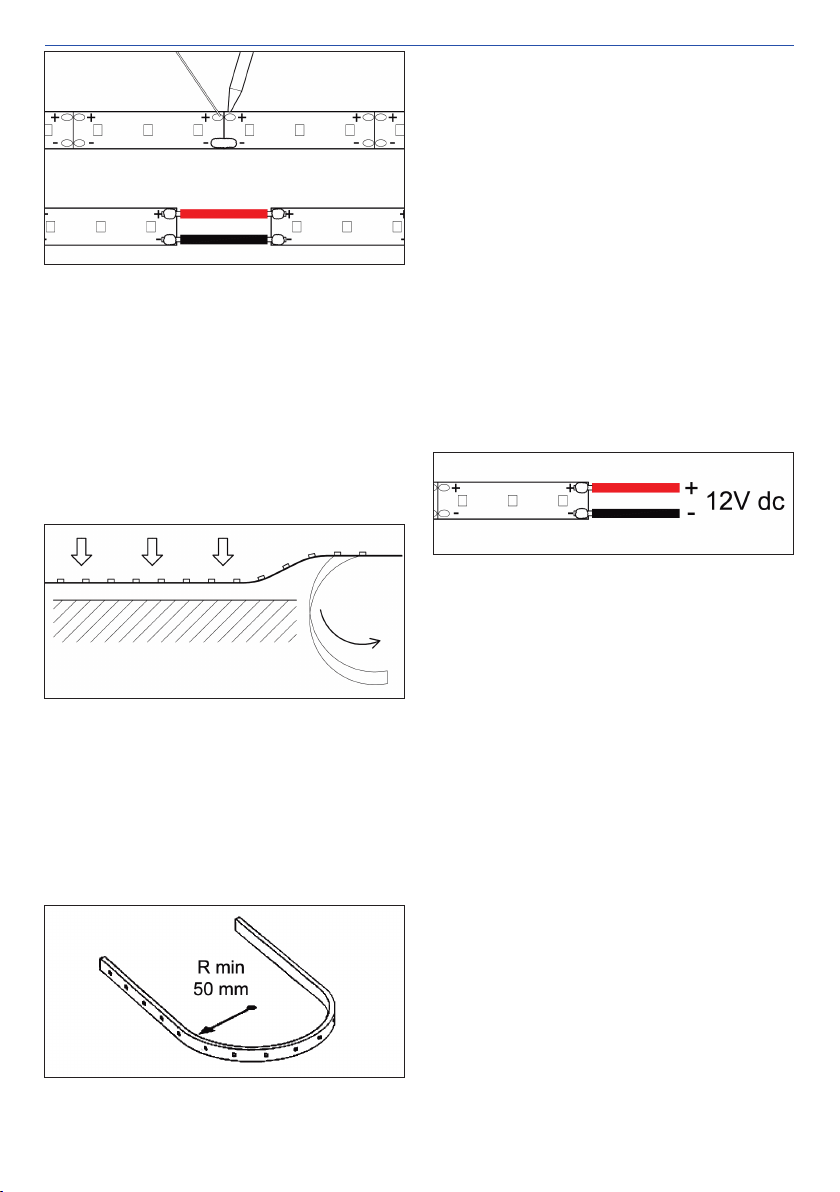

Whenthestripiscutorwhentwopiecesarewelded

togetherorwhenthesupplywiresareweldedtothe

strip,itisnecessarytocheckduringinstallationthat

there are no copper smears or welding points that

touch the metal surfaces: parasitic short circuits

betweenthecopperpadsandthemetalsurfacecan

turnoffsomesegments of LEDs,causinga device

malfunction,or theycan havedamaging effects on

thepowersupplies.

Tomeetdifferentinstallationrequirements,theLED

strip can be sectioned with standard scissors at

regularintervalssoastobeabletorealizesegments

ofvariablelengths.Theexactsectioningpointisthat

correspondingtothecopperpadsthatreplicatethe

+/LEDsupplylabels:cutaccuratelyalongtheblack

dividinglinedrawnbetweenthetwopairsoffacing

pads. For construction requirements, the minimum

croppingunitisa25mmlongsegment).

A cut in any other position of the strip irreparably

damages the segment enclosed between the pad

series,whichthereforecannolongerbeswitchedon.

For each new piece made it is necessary to apply

the supply wires, plugging the power adaptors

includedovertheedgeofthestrip.Payattentionto

the polarity +/ printed on the edge and the colors

red/blackoftheadaptors.

Otherwiseyoucanweldgenericpowersupplywires

usingasolderingiron.Duringweldingdonotexceed

the maximum time of 10 seconds of application of

the welder and keep the maximum welding

temperature lower than 260°C. The colors of the

wiresmustbeeasilyunderstood,soasnottomake

mistakes in the subsequent installation phases. If

possible use the same colors as the wires on the

head of the original reel and apply labels with the

polarityindicated.

In the same way, shorter lengths can be welded

togethertoobtain asegmentof thedesiredlength.

Neverexceedthemaximumtotallengthof5meters.

The welding can be carried out using the copper

padsdirectly,surmountingthetwosectionsontheir

end part, or by means of electric wires if it is