job better and be safer at the rate for

which it was designed.

(3). USE RIGHT TOOL. Don’t force tool

or attachment to do a job for which it was

not designed.

(4). SECURE WORK. Use clamps or a

vise to hold work when practical. It’s safer

than using your hand frees both hands to

operate tool.

(5). MAINTAIN TOOLS IN TOP

CONDITION. Keep tools sharp and clean

for best and safest performance. Follow

instructions for lubricating and changing

accessories.

(6). USE RECOMMENDED

ACCESSORIES. Consult the owner’s

manual for recommended accessories.

The use of improper accessories may

cause hazards.

(7). AVOID ACCIDENTAL STARTING.

Make sure switch is in “OFF” position

before plugging in power cord.

(8). DIRECTIONOF FEED. Feed work

into a blade or cutter against the direction

of rotation of the blade or cutter only.

(9). ADJUST AND POSITION the blade

guide arm before starting the cut.

(10). KEEP BLADE GUIDE ARM TIGHT,

A loose blade guide arm aill affect sawing

accuracy .

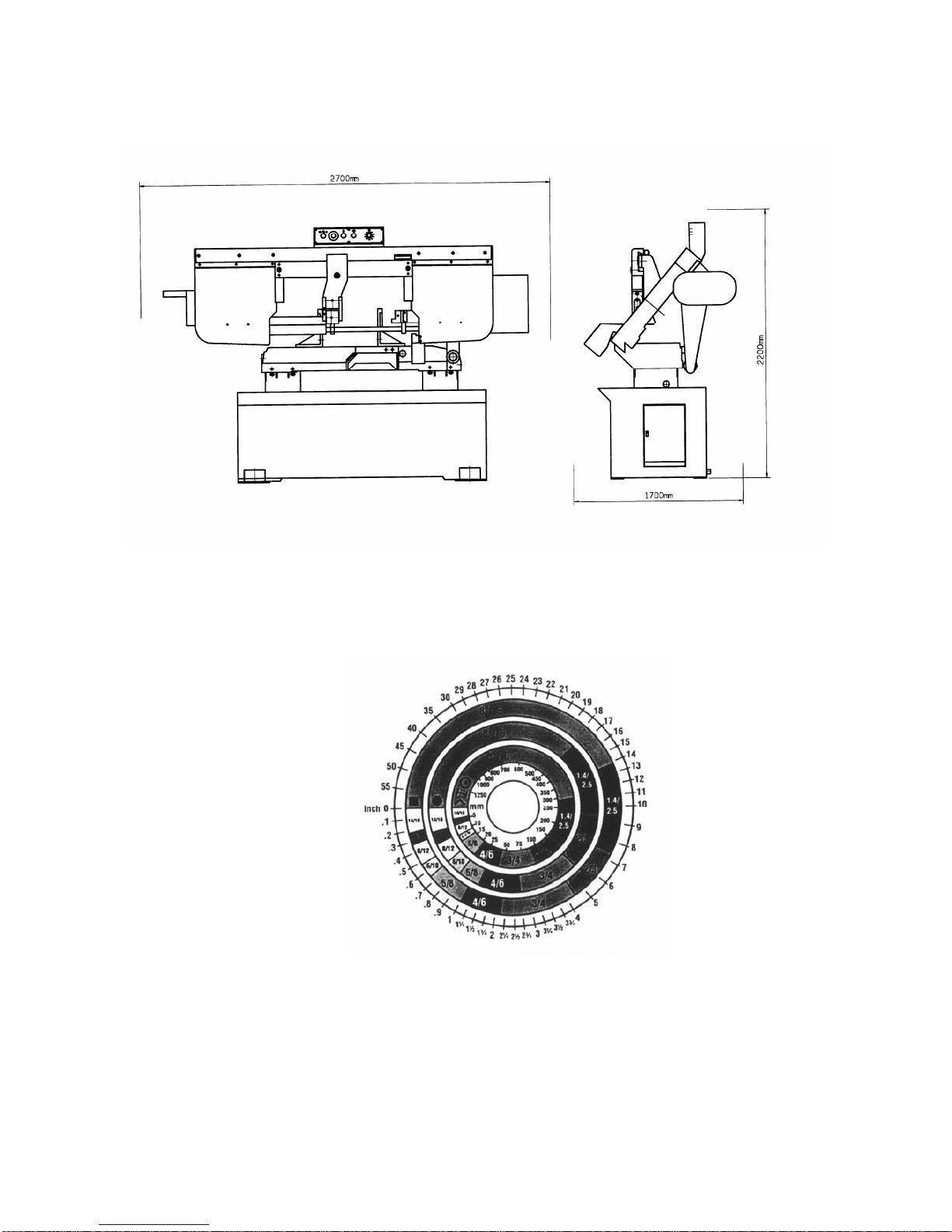

(11). MAKE SURE blade speed is set

correctly for material being cut.

(12). CHECK for proper blade size and

type.

(13). STOP the machine before putting

material in the vise.

(14). ALWAYS have stock firmly clamped

in vise before starting cut.

(15). GROUNDALL TOOLS. If tool is

equipped with three-prong plug, it should

be plugged into a three-hole electrical

receptacle. If an adapter is used to

accommodate atwoprong receptacle, the

adapter lug must be attached to a known

ground. Never removed the third prong.

C. ADJUSTMENT :

MAKE all adjustments with the power off.

In order to obtain the machine. Precision

and correct ways of adjustment while

assembling, the user should read the

detailed instruction in this manual.

D. WORKING ENVIRONMENT:

(1). KEEP WORK AREA CLEAN.

Cluttered areas and benches invite

accidents.

(2). DON’T USE IN DANGEROUS

ENVIRONMENT. Don’t use power tools in

damp or wet locations, or expose them to

rain. Keep work area well-lighted.

(3). KEEP CHILEREN AND VISITIORS

AWAY. All children and visitors should be

kept a safe distance from work area.

(4). DON’T install & use this machine in

explosive, dangerous environment.

E. MAINTENANCE:

(1). DISCONNECT machine from power

source when making repairs.

(2). CHECK DAMAGED PARTS. Before

further use of the tool, a guard or other

part that is damaged should be carefully

checked to ensure that it will operate

properly and perform its intended function

- -

4