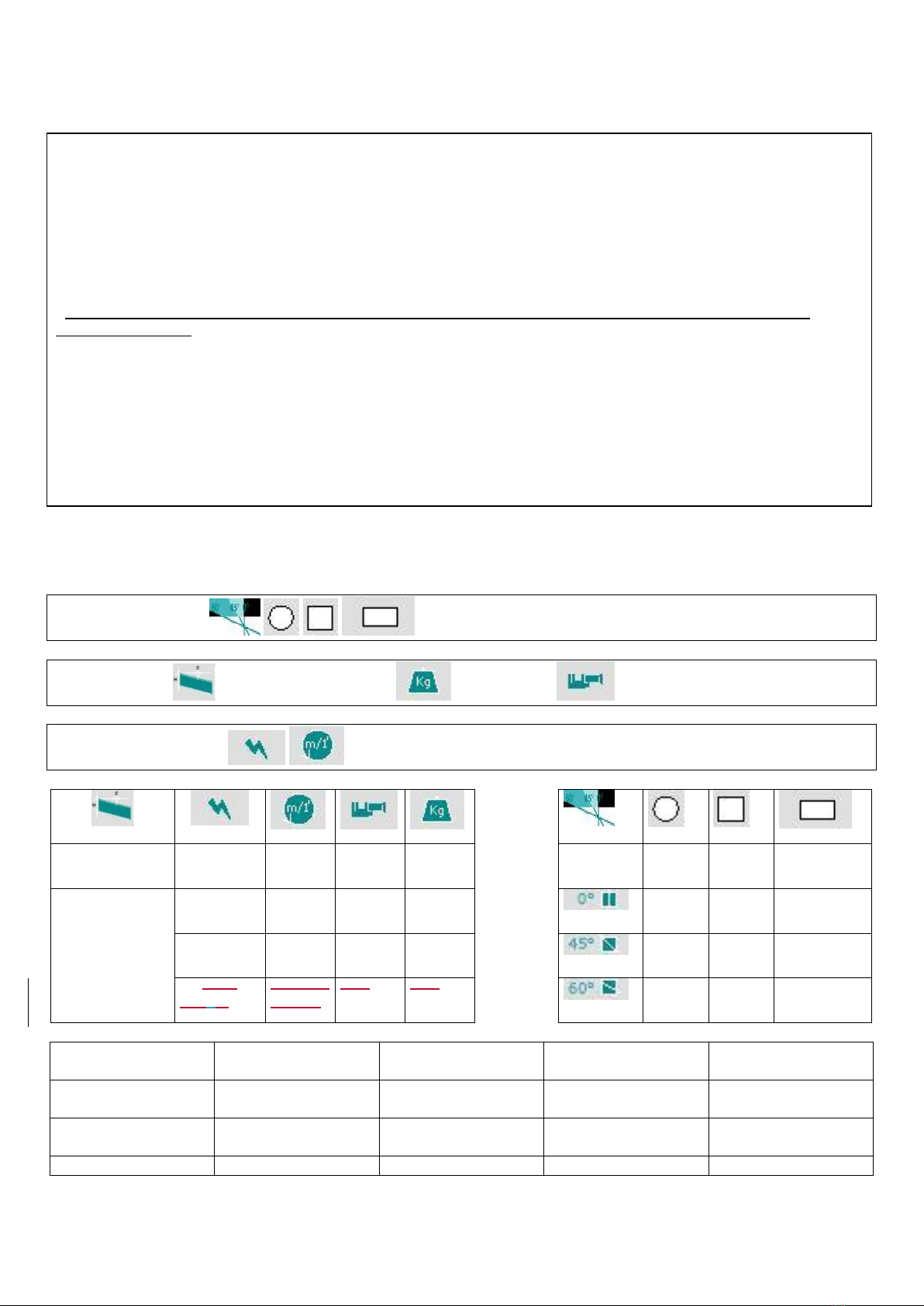

8 –TRANSPORT & LIFTING

For the transport of the machine only the methods indicated below are possible. However, be sure that the means of

transport snd lifting are able to stand the machine's weight and its packing (about 400 Kg):

WARNING

The personnel in charge of loading, unloading and moving the machines should use protective gloves.

WARNING

When lifting or moving the machine, or a part of it, take care of clearing the operations area of the people, considering

also an appropriate safety area around it, so as to avoid any risks of injuring people or damaging things located nearly.

Special packings –wooden crate , wooden case –may be predisposed on request, by charge.

ALL THE OPERATIONS THAT INVOLVE MOVING THE MACHINE MUST BE CONDUCTED WHILE RESPECTING

THE FOLLOWING BASIC RULES:

+ When moving the machine, an appropriate means has to be used, with a loading capacity higher than the weight

to lift, which is indicated on the machine.

+ When choosing and then using equipment such as ropes, chains or lifting belts, be careful about their geometry

during the lifting and about the consequent actual loading capacity.

+ The machine is structured so as to offer lifting points, which are appropriately indicated and will have to be used

for lifting it.

+ In case the lifting belts touch parts of the machine, nylon belts are required; ropes or chains wrapped with jute or

clean covering can also be used. A great care is necessary while slinging and moving the machine in order to

hinder damages.

+ All operations have to be conducted with graduality, so as to avoid jolts and dangerous situations.

+ The person in charge of the operations has to make sure that all the national, local and company norms in

reference to injury prevention and work safety are respected.

+ Onr or more areas for material storage have to be identified.

The packing of the machine guarantees protection even during shipments with normal means of transport. Special

packing can be supplied in case of particular requests by the user.

These models are supplied with a carton packing which allows to store them one above the other (1+1 max.) and to

move them for a short way.

After unpacking, remove the locks between base and floor stand, assemble them and place the unit the working area.

The floor stand is not assembled when delivered, it must be fixed to the machine by means of screws on the four

corners. The rear side is punched. Use two lifting belts, placed below the front and back side of the base and put the

machine on the floor stand. The weight is shown on the packing and also written in the technical data of the manual.

Make sure that the lifting tools are suited to the weight and that the operation is correctly made without unbalancing the

machine.

In case the bandsaw has to be moved again, fix always the saw frame to the floor stand

Warning: if machine is delivered by open trucks, please cover it !

Transport with wooden crate or wooden case. ( BY REQUEST , ON CHARGE )

The machine is wrapped with thermoplastic material in order to assure a suited protection of all its parts; then it is

packed into a wooden crate or cage to protect it from collisions, inclement weather and so on.

To lift it, use a forklift from front side of machine, with forks length 1.5 m or more (see picture ).

You need to follow the indications you find on the packing before proceeding to moving or opening it.

WARNING

The machine is fixed to the packing by means of screws, so as to hinder that it can move during the transport