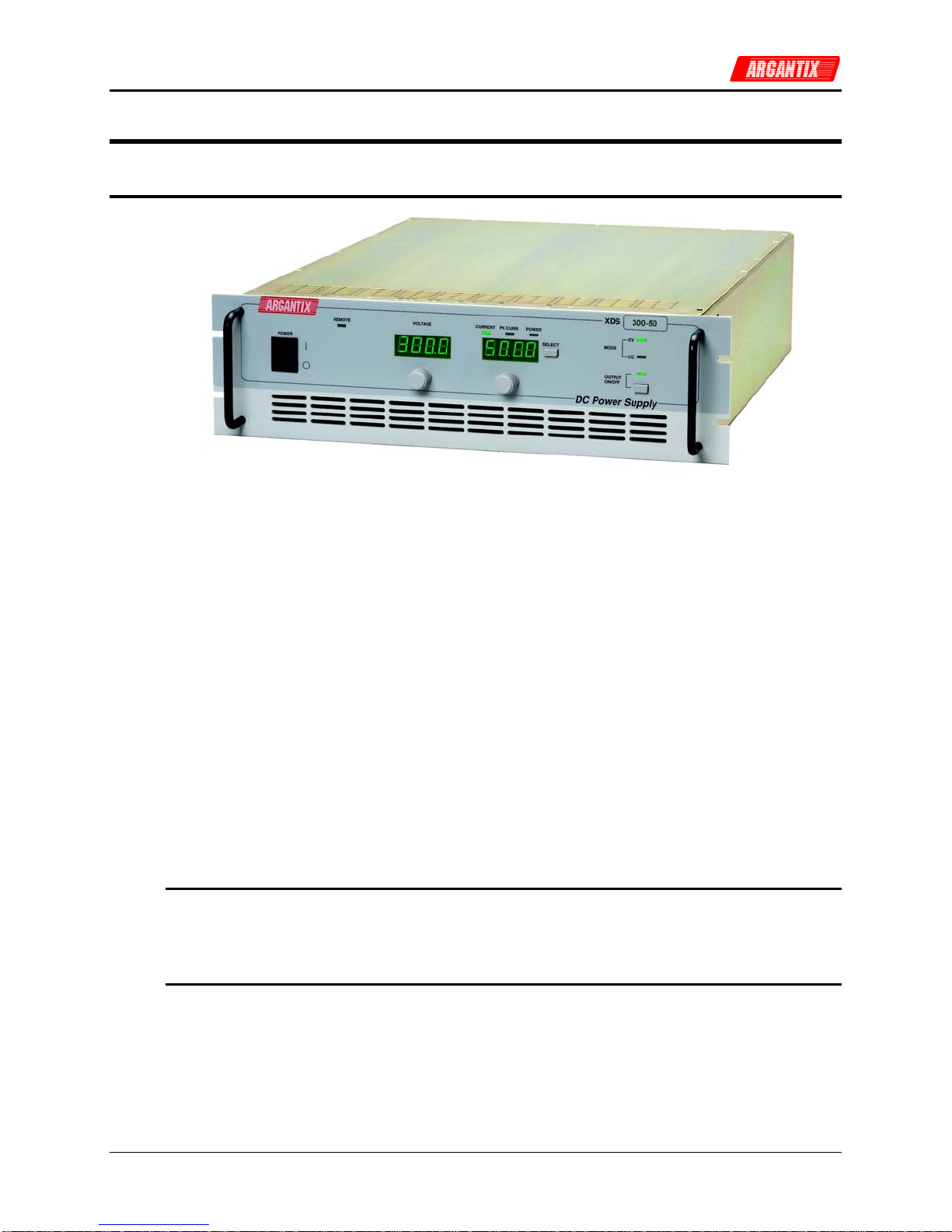

User and Programming Manual

6 XDS Series

Table of Contents

1

Introduction.................................................................................................................................. 10

1.1

General Description............................................................................................................................. 10

1.2

Bench Top use.................................................................................................................................... 11

1.3

Equipment Rack use........................................................................................................................... 11

2

Specifications............................................................................................................................... 12

2.1

Electrical.............................................................................................................................................. 12

2.2

Measurements .................................................................................................................................... 15

2.3

Environmental ..................................................................................................................................... 17

2.4

Mechanical.......................................................................................................................................... 17

2.5

Agency Approvals ............................................................................................................................... 18

2.6

Remote Control Interfaces .................................................................................................................. 18

2.7

Protection............................................................................................................................................ 19

2.8

Controls and Indicators ....................................................................................................................... 19

2.9

Parallel Operation................................................................................................................................ 19

2.10

Factory Configuration Options......................................................................................................... 20

2.11

-LC Option....................................................................................................................................... 20

3

Installation and Functional Test................................................................................................... 21

3.1

Inspection............................................................................................................................................ 21

3.2

Location and Mounting........................................................................................................................ 21

3.3

Input / Output Connectors................................................................................................................... 22

3.4

Wire Sizing and Lug Size.................................................................................................................... 25

3.5

AC Input Wiring................................................................................................................................... 26

4

Front Panel Operation ................................................................................................................. 28

4.1

Functional Controls ............................................................................................................................. 28

4.2

How to examples................................................................................................................................. 31

4.3

Setting the Power on Initialization Values............................................................................................ 33

4.4

Operating Modes................................................................................................................................. 34

4.5

Special Features ................................................................................................................................. 35

5

Model Configurations................................................................................................................... 37

5.1

Available Configurations...................................................................................................................... 37

5.2

Changing Configurations..................................................................................................................... 38

5.3

Stand Alone Configuration .................................................................................................................. 40

5.4

Parallel Mode ...................................................................................................................................... 40

5.5

RPV Mode........................................................................................................................................... 43

5.6

RPC Mode........................................................................................................................................... 43

6

Principle of Operation.................................................................................................................. 44

6.1

General ............................................................................................................................................... 44

6.2

Overall Description.............................................................................................................................. 44

6.3

Bias Power Supply (A7)....................................................................................................................... 47

6.4

Power Module (A9 through A11)......................................................................................................... 48

6.5

Controller Module (A3)........................................................................................................................ 50

7

Calibration.................................................................................................................................... 52

7.1

Calibration Equipment......................................................................................................................... 52

7.2

Routine Calibration.............................................................................................................................. 53

7.3

Non-Routine Calibration...................................................................................................................... 56