Con

en

1

1.1

1.2

1.3

1.4

2

3

4

4.1

4.2

4.3

5

6

7

7.1

7.2

8

9

9.1

9.2

10

10.1

10.2

10.3

10.4

10.5

10.6

10.7

10.8

10.9

10.10

10.11

10.12

10.13

10.14

10.15

11

11.1

11.2

11.3

11.4

12

13

CONTENT

Safety precaution ......................................................................................................................1

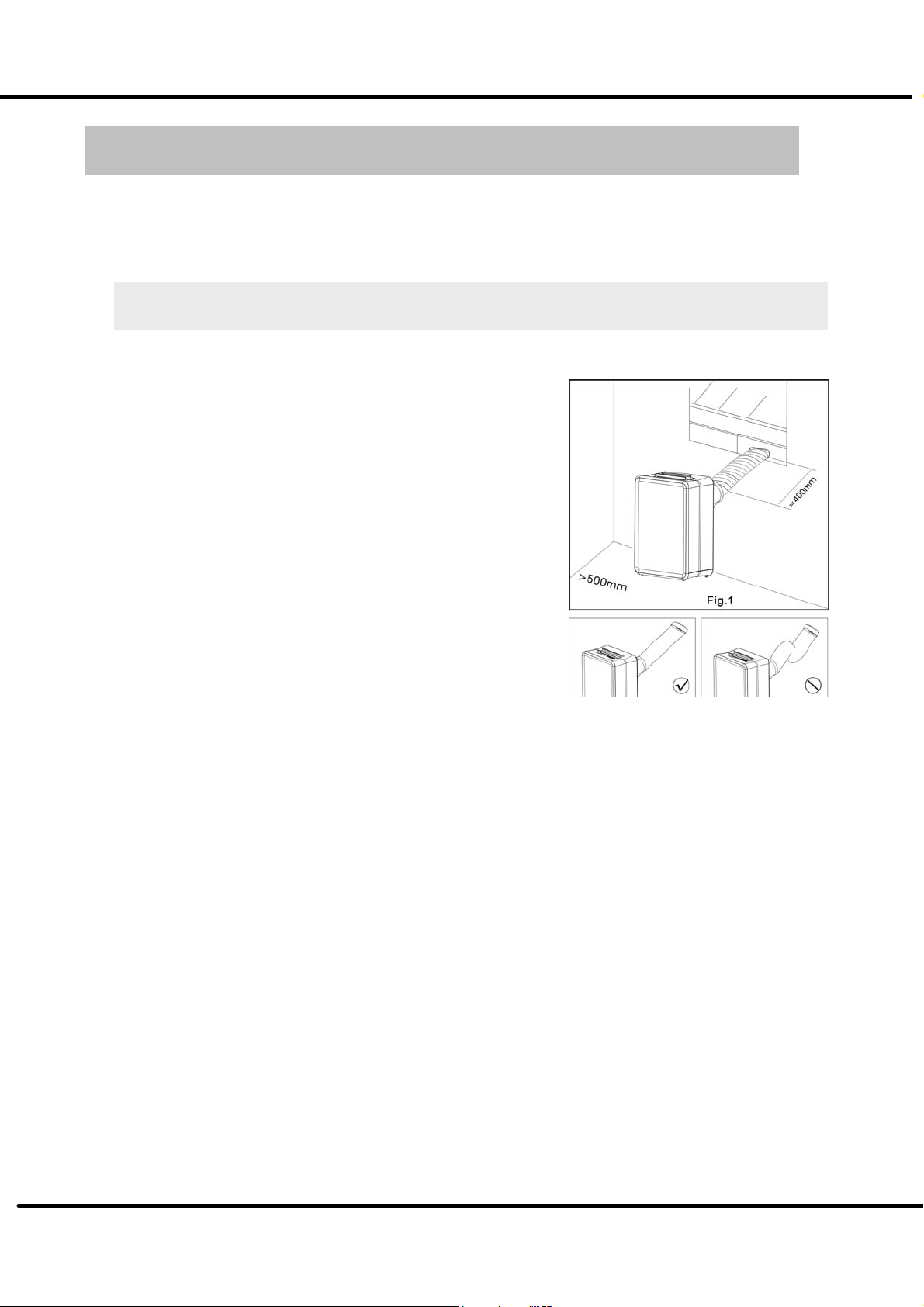

Installation

............................................................................................................................................

1

Caution

..................................................................................................................................................

1

Operational ...........................................................................................................................................

1

Attention …………………………………………………………………………………………...…2

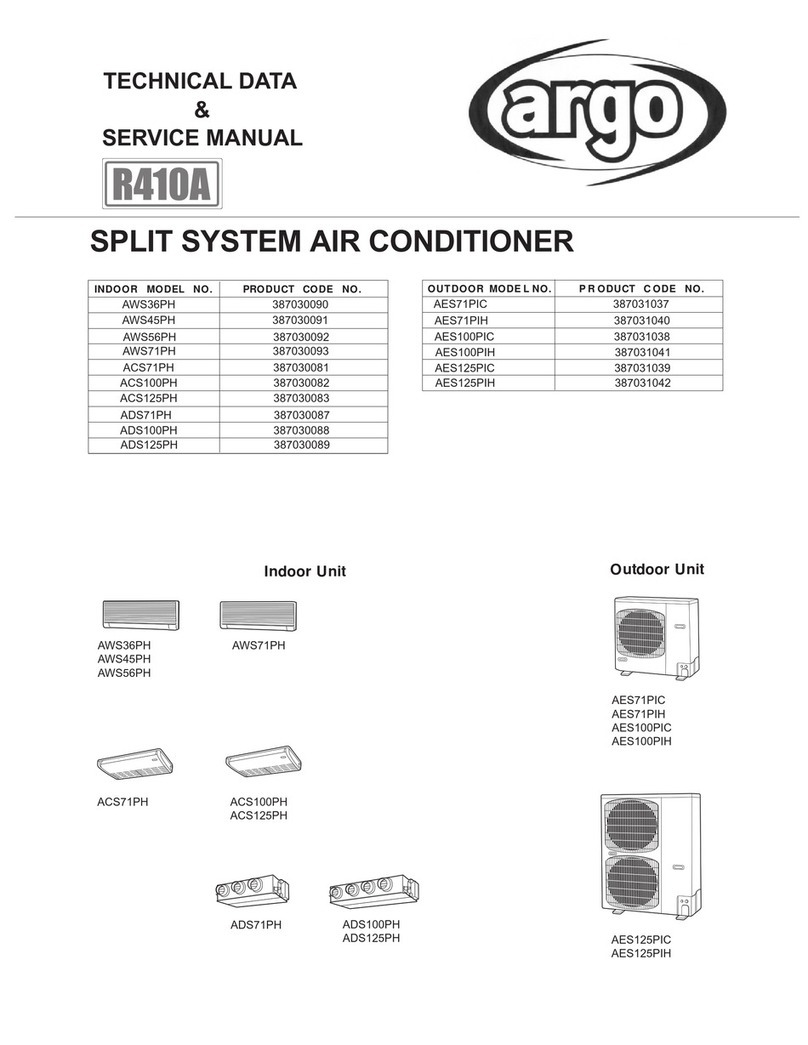

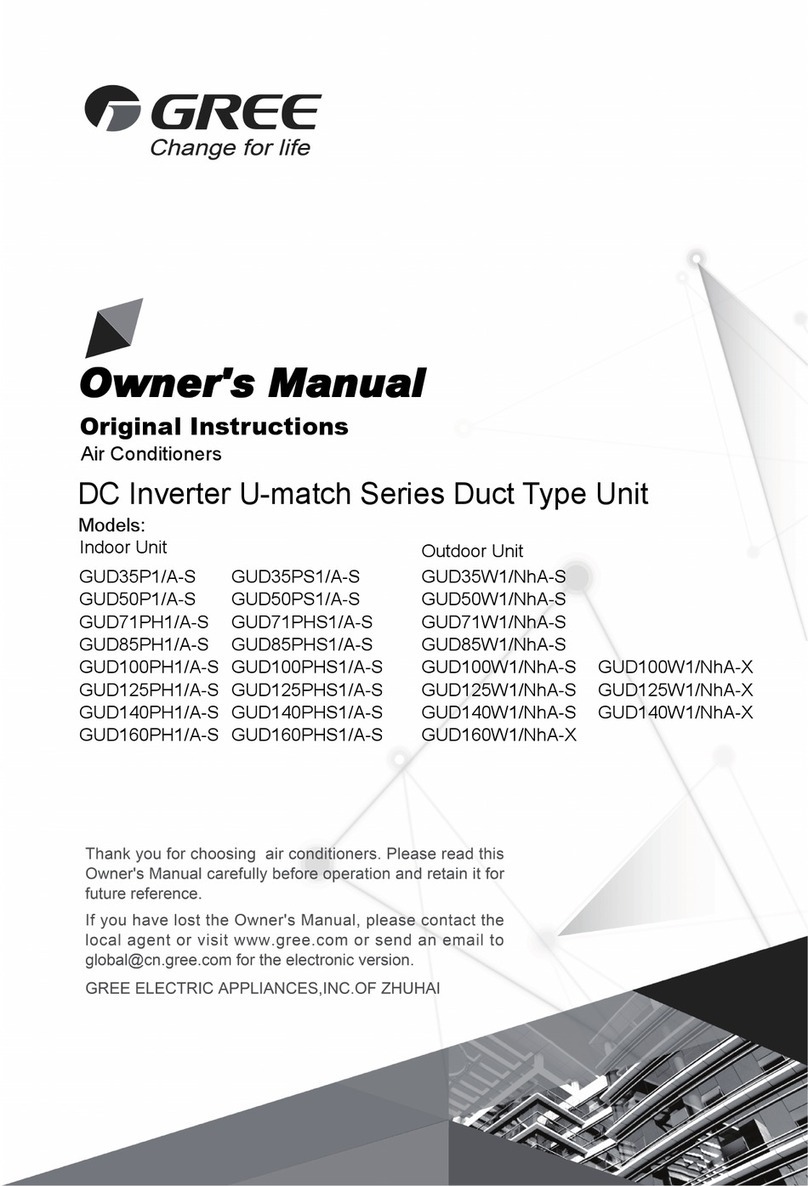

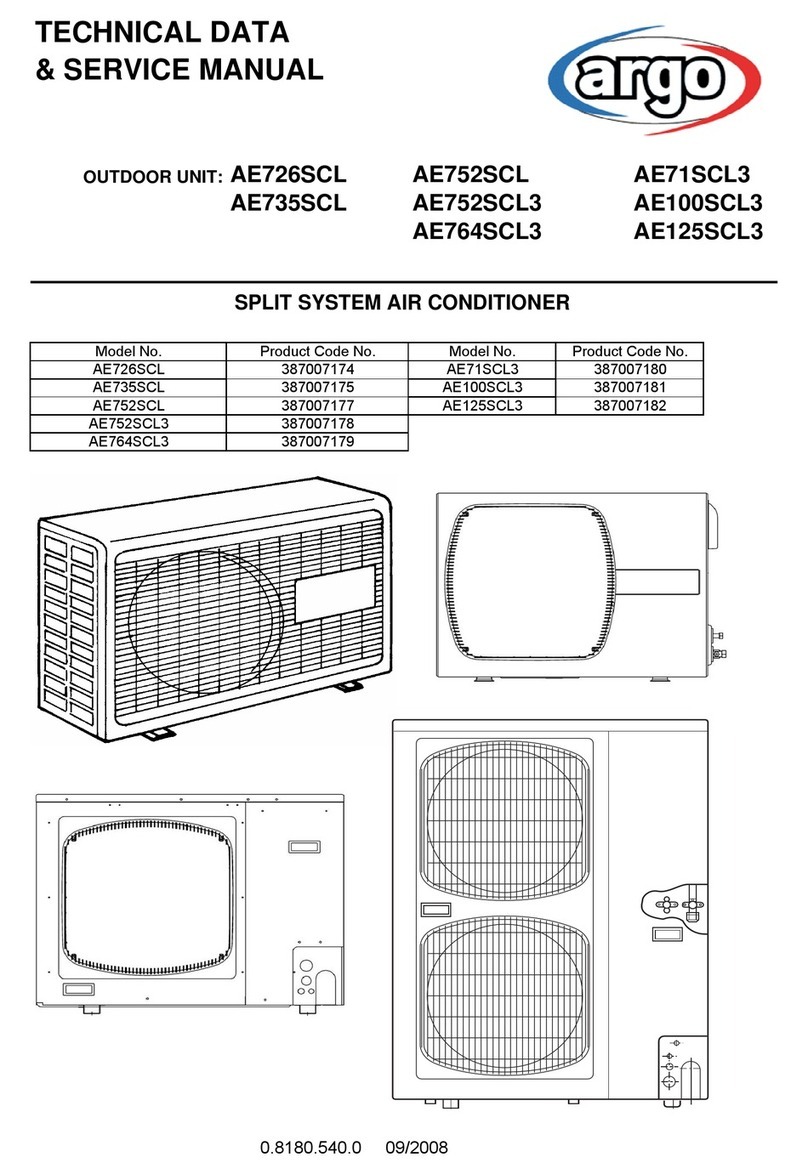

Specification ..............................................................................................................................3

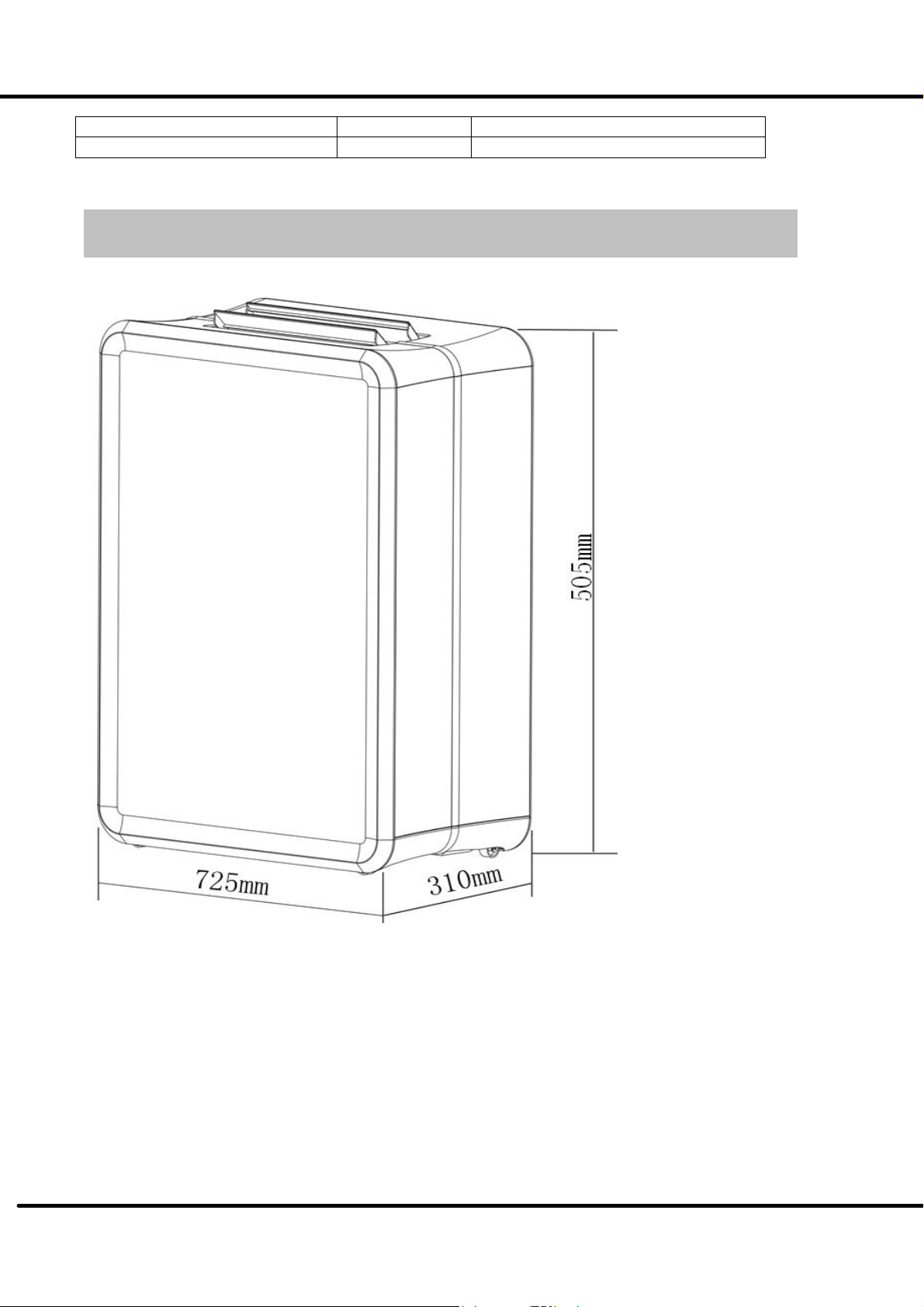

Out dimension ...........................................................................................................................5

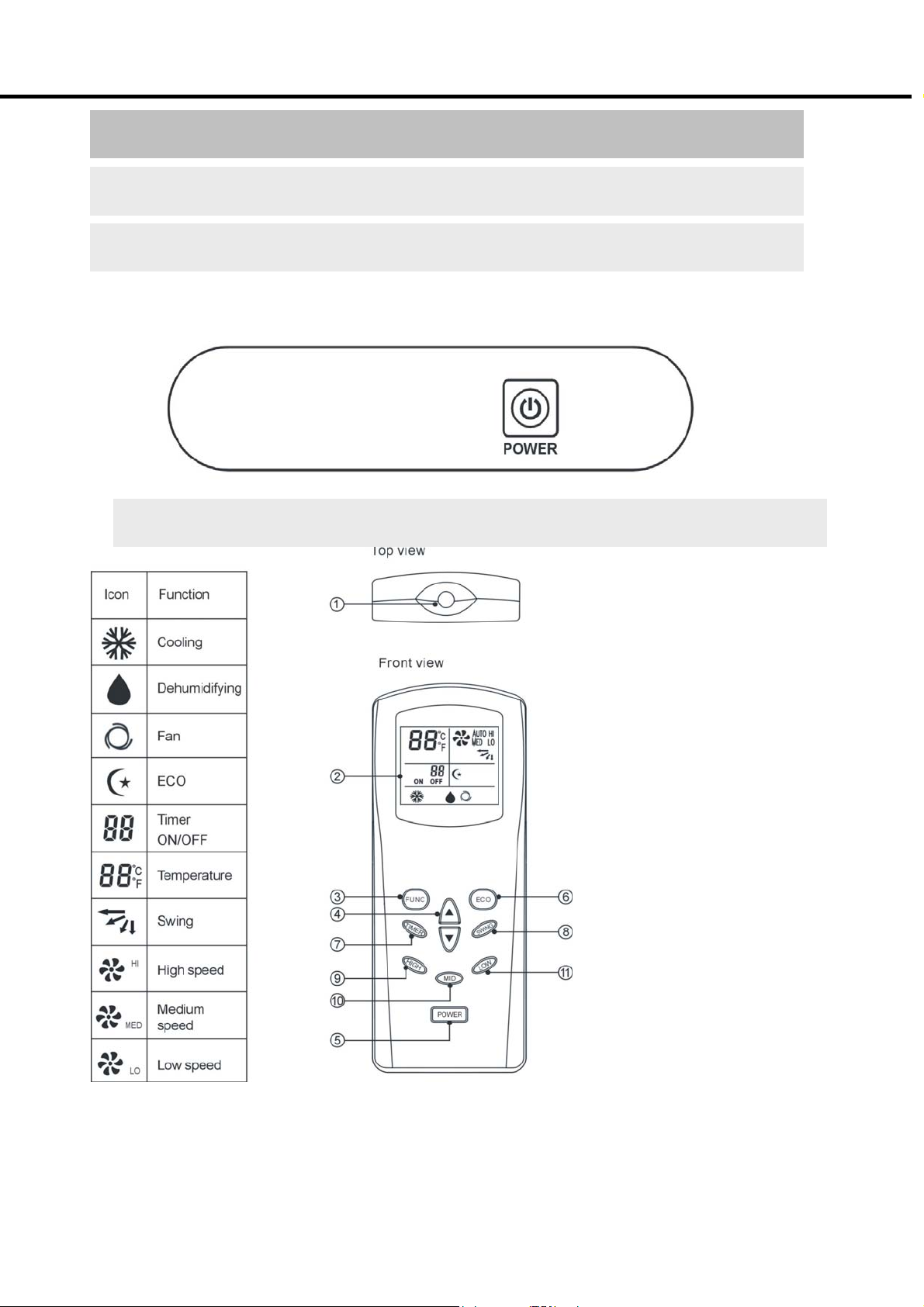

Control panel & Description of function ……………………………………………………6

LED

display...........................................................................................................................................

6

Power key …………………………………………………………………………………………….6

Remote control function refrigerant cycle ……………………………………………………………8

Refrigerant cycle diagram ……………………………………………………………………9

PCB drawing & wiring diagram ……………………………………………………………10

Unit Disassembly sequence .....................................................................................................12

Step1 Casing Disassembly

.............................................................................................................

12

Step2 Internal Parts Disassembly

..................................................................................................

14

Exploded ..................................................................................................................................15

Feature ………………………………………………………………………………………..18

Parts of the Air Conditioner

................................................................................................................

18

Accessories

........................................................................................................................................

18

Electronic function .................................................................................................................20

Function

..............................................................................................................................................

20

Controller Specifications

.......................................................................................................................

20

Controller Structure

...............................................................................................................................

20

Sensor Definitions

................................................................................................................................

20

Mode

...................................................................................................................................................

20

Sleep …………………………………………………………………………………………………...

21

Timer setting .......................................................................................................................................

21

Other controls

…………...…………………………………………………………………………….

22

Timer Setting ..

……………………………………………………………………………………….

22

Compressor delay protection Protection …...................................................................................................22

Sensor errors ……………………………………………………………………………………...22

Step Motor ………………………………………………………………………...…………………..22

Running signal indicator ………………………… …………………….……………………………..22

Power Button …………………………………………………………………………………………..23

Auto-restarting function ………………………………………………………………………………...23

Basic test procedure ................................................................................................................24

Defective compressor

........................................................................................................................

25

Sealed refrigeration system

r

e

pairs

....................................................................................................

25

Fan

motor............................................................................................................................................

27

Capacitor

.............................................................................................................................................

28

Characteristic of temperature sensor ....................................................................................29

Trouble shooting ......................................................................................................................30